08 DDEC VI-12 - ddcsn

08 DDEC VI-12 - ddcsn

08 DDEC VI-12 - ddcsn

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

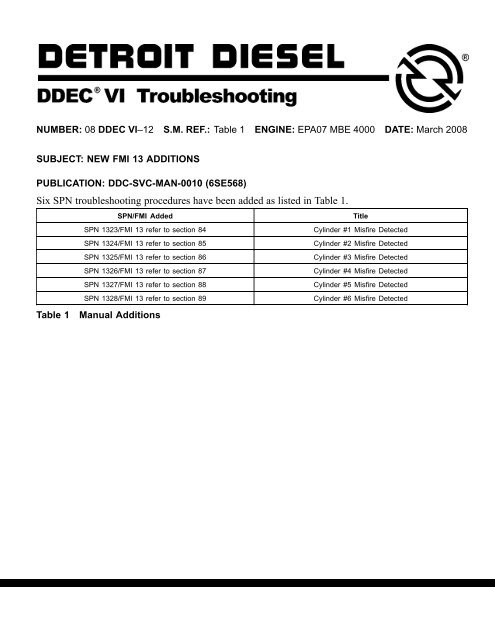

NUMBER: <strong>08</strong> <strong>DDEC</strong> <strong>VI</strong>–<strong>12</strong> S.M. REF.: Table 1 ENGINE: EPA07 MBE 4000 DATE: March 20<strong>08</strong><br />

SUBJECT: NEW FMI 13 ADDITIONS<br />

PUBLICATION: DDC-SVC-MAN-0010 (6SE568)<br />

Six SPN troubleshooting procedures have been added as listed in Table 1.<br />

SPN/FMI Added<br />

Title<br />

SPN 1323/FMI 13 refer to section 84<br />

Cylinder #1 Misfire Detected<br />

SPN 1324/FMI 13 refer to section 85<br />

Cylinder #2 Misfire Detected<br />

SPN 1325/FMI 13 refer to section 86<br />

Cylinder #3 Misfire Detected<br />

SPN 1326/FMI 13 refer to section 87<br />

Cylinder #4 Misfire Detected<br />

SPN 1327/FMI 13 refer to section 88<br />

Cylinder #5 Misfire Detected<br />

SPN 1328/FMI 13 refer to section 89<br />

Cylinder #6 Misfire Detected<br />

Table 1 Manual Additions

SPN 1323/FMI 13<br />

This diagnosis is typically a misfire has been detected in cylinder #1.<br />

SPN 1323/FMI 13 indicates a misfire event on cylinder #1, the entry conditions for this fault are:<br />

□ Engine speed: 1350 - 2200 rpm<br />

□ Engine load: Steady<br />

Cylinder misfire can occur due to any of the conditions below:<br />

□ Injector-wornorfaulty<br />

□ Fuel leak at transfer tube or high pressure fuel line<br />

□ Poor cylinder compression<br />

□ Valve lash maladjustment<br />

□ Cylinder kit failure<br />

□ Valve train failure<br />

Check as follows:<br />

1. Start and bring the engine up to operating temperature.<br />

2. Using DDDL 7.x perform the “Compression Test” service routine:<br />

[a] If cylinder #1 shows low compression, the issue is related to a possible mechanical failure<br />

such as valve lash, maladjustment, valve train damage, etc. Repair the cylinder concern.<br />

[b] If all cylinders are within 10% of each other, go to step 3.<br />

NOTE:<br />

Engine must be at idle while using this routine.<br />

3. Using DDDL 7.x access the “ISB” service routine.<br />

[a] If the “ISB” service routine results for cylinder #1 are +/- 100%, go to step 4.<br />

[b] If the “ISB” service routine results are not equal to +/- 100%, the fault may be intermittent.<br />

Continue to run the test for 3 minutes. If the above values are seen, go to step 4.<br />

[c] If ISC values are not +/- 100% after 3 minutes, obtain added information from the<br />

customer on the vehicle's operating conditions. Fault code “extended data” may be used in<br />

order to determine the engines operating range when the fault actually occurred. Obtain a<br />

DDDL log file of the condition and contact the Detroit Diesel Customer Support Center<br />

at 313–592–5800 for further instruction.

NOTICE:<br />

Never re-use a high pressure fuel line or transfer tube.<br />

4. Visually inspect the high pressure fuel line and transfer tube on cylinder #1 for any leakage<br />

or damage.<br />

[a] If any leakage or damage is found, replace the high pressure fuel line, and transfer tube.<br />

Refer to section "Removal of High Pressure Fuel Line and Transfer Tube" in the EPA07<br />

MBE 4000 Service Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).<br />

[b]<br />

If no leakage or damage is found, replace the #1 fuel injector, high pressure fuel line, and<br />

transfer tube. Refer to section Removal of Fuel Injector in the EPA07 MBE 4000 Service<br />

Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).

SPN 1324/FMI 13<br />

This diagnosis is typically a misfire has been detected in cylinder #2.<br />

SPN 1324/FMI 13 indicates a misfire event on cylinder #2, conditions for this fault are:<br />

□ Engine speed: 1350 - 2200 rpm<br />

Cylinder misfire can occur due to any of the conditions below:<br />

□ Injector-wornorfaulty<br />

□ Fuel leak at transfer tube or high pressure fuel line<br />

□ Poor cylinder compression<br />

□ Valve lash maladjustment<br />

□ Cylinder kit failure<br />

□ Valve train failure<br />

Check as follows:<br />

1. Start and bring the engine up to operating temperature.<br />

2. Using DDDL 7.x perform the “Compression Test” service routine:<br />

[a] If cylinder #2 shows low compression, the issue is related to a possible mechanical failure<br />

such as valve lash, maladjustment, valve train damage, etc. Repair the cylinder concern.<br />

[b] If all cylinders are within 10% of each other, go to step 3.<br />

NOTE:<br />

Engine must be at idle while using this routine.<br />

3. Using DDDL 7.x access the “ISB” service routine.<br />

[a] If the “ISB” service routine results for cylinder #2 are +/- 100%, go to step 4.<br />

[b] If the “ISB” service routine results are not equal to +/- 100%, the fault may be intermittent.<br />

Continue to run the test for 3 minutes. If the above values are seen, go to step 4.<br />

[c] If ISC values are not +/- 100% after 3 minutes, obtain added information from the<br />

customer on the vehicle's operating conditions. Fault code “extended data” may be used in<br />

order to determine the engines operating range when the fault actually occurred. Obtain a<br />

DDDL log file of the condition and contact the Detroit Diesel Customer Support Center<br />

at 313–592–5800 for further instruction.

NOTICE:<br />

Never re-use a high pressure fuel line or transfer tube.<br />

4. Visually inspect the high pressure fuel line and transfer tube on cylinder #2 for any leakage<br />

or damage.<br />

[a] If any leakage or damage is found, replace the high pressure fuel line, and transfer tube.<br />

RefertosectionRemovalofHighPressureFuel Line and Transfer Tube in the EPA07<br />

MBE 4000 Service Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).<br />

[b]<br />

If no leakage or damage is found, replace the #2 fuel injector, high pressure fuel line, and<br />

transfer tube. Refer to section Removal of Fuel Injector in the EPA07 MBE 4000 Service<br />

Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).

SPN 1325/FMI 13<br />

This diagnosis is typically a misfire has been detected in cylinder #3.<br />

SPN 1325/FMI 13 indicates a misfire event on cylinder #3, conditions for this fault are:<br />

□ Engine speed: 1350 - 2200 rpm<br />

Cylinder misfire can occur due to any of the conditions below:<br />

□ Injector-wornorfaulty<br />

□ Fuel leak at transfer tube or high pressure fuel line<br />

□ Poor cylinder compression<br />

□ Valve lash maladjustment<br />

□ Cylinder kit failure<br />

□ Valve train failure<br />

Check as follows:<br />

1. Start and bring the engine up to operating temperature.<br />

2. Using DDDL 7.x perform the “Compression Test” service routine:<br />

[a] If cylinder #3 shows low compression, the issue is related to a possible mechanical failure<br />

such as valve lash, maladjustment, valve train damage, etc. Repair the cylinder concern.<br />

[b] If all cylinders are within 10% of each other, go to step 3.<br />

NOTE:<br />

Engine must be at idle while using this routine.<br />

3. Using DDDL 7.x access the “ISB” service routine.<br />

[a] If the “ISB” service routine results for cylinder #3 are +/- 100%, go to step 4.<br />

[b] If the “ISB” service routine results are not equal to +/- 100%, the fault may be intermittent.<br />

Continue to run the test for 3 minutes. If the above values are seen, go to step 4.<br />

[c] If ISC values are not +/- 100% after 3 minutes, obtain added information from the<br />

customer on the vehicle's operating conditions. Fault code “extended data” may be used in<br />

order to determine the engines operating range when the fault actually occurred. Obtain a<br />

DDDL log file of the condition and contact the Detroit Diesel Customer Support Center<br />

at 313–592–5800 for further instruction.

NOTICE:<br />

Never re-use a high pressure fuel line or transfer tube.<br />

4. Visually inspect the high pressure fuel line and transfer tube on cylinder #3 for any leakage<br />

or damage.<br />

[a] If any leakage or damage is found, replace the high pressure fuel line, and transfer tube.<br />

RefertosectionRemovalofHighPressureFuel Line and Transfer Tube in the EPA07<br />

MBE 4000 Service Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).<br />

[b]<br />

If no leakage or damage is found, replace the #3 fuel injector, high pressure fuel line, and<br />

transfer tube. Refer to section Removal of Fuel Injector in the EPA07 MBE 4000 Service<br />

Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).

SPN 1326/FMI 13<br />

This diagnosis is typically a misfire has been detected in cylinder #4.<br />

SPN 1326/FMI 13 indicates a misfire event on cylinder #4, conditions for this fault are:<br />

□ Engine speed: 1350 - 2200 rpm<br />

Cylinder misfire can occur due to any of the conditions below:<br />

□ Injector-wornorfaulty<br />

□ Fuel leak at transfer tube or high pressure fuel line<br />

□ Poor cylinder compression<br />

□ Valve lash maladjustment<br />

□ Cylinder kit failure<br />

□ Valve train failure<br />

Check as follows:<br />

1. Start and bring the engine up to operating temperature.<br />

2. Using DDDL 7.x perform the “Compression Test” service routine:<br />

[a] If cylinder #4 shows low compression, the issue is related to a possible mechanical failure<br />

such as valve lash, maladjustment, valve train damage, etc. Repair the cylinder concern.<br />

[b] If all cylinders are within 10% of each other, go to step 3.<br />

NOTE:<br />

Engine must be at idle while using this routine.<br />

3. Using DDDL 7.x access the “ISB” service routine.<br />

[a] If the “ISB” service routine results for cylinder #4 are +/- 100%, go to step 4.<br />

[b] If the “ISB” service routine results are not equal to +/- 100%, the fault may be intermittent.<br />

Continue to run the test for 3 minutes. If the above values are seen, go to step 4.<br />

[c] If ISC values are not +/- 100% after 3 minutes, obtain added information from the<br />

customer on the vehicle's operating conditions. Fault code “extended data” may be used in<br />

order to determine the engines operating range when the fault actually occurred. Obtain a<br />

DDDL log file of the condition and contact the Detroit Diesel Customer Support Center<br />

at 313–592–5800 for further instruction.

NOTICE:<br />

Never re-use a high pressure fuel line or transfer tube.<br />

4. Visually inspect the high pressure fuel line and transfer tube on cylinder #4 for any leakage<br />

or damage.<br />

[a] If any leakage or damage is found, replace the high pressure fuel line, and transfer tube.<br />

RefertosectionRemovalofHighPressureFuel Line and Transfer Tube in the EPA07<br />

MBE 4000 Service Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).<br />

[b]<br />

If no leakage or damage is found, replace the #4 fuel injector, high pressure fuel line, and<br />

transfer tube. Refer to section Removal of Fuel Injector in the EPA07 MBE 4000 Service<br />

Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).

SPN 1327/FMI 13<br />

This diagnosis is typically a misfire has been detected in cylinder #5.<br />

SPN 1327/FMI 13 indicates a misfire event on cylinder #5, conditions for this fault are:<br />

□ Engine speed: 1350 - 2200 rpm<br />

Cylinder misfire can occur due to any of the conditions below:<br />

□ Injector-wornorfaulty<br />

□ Fuel leak at transfer tube or high pressure fuel line<br />

□ Poor cylinder compression<br />

□ Valve lash maladjustment<br />

□ Cylinder kit failure<br />

□ Valve train failure<br />

Check as follows:<br />

1. Start and bring the engine up to operating temperature.<br />

2. Using DDDL 7.x perform the “Compression Test” service routine:<br />

[a] If cylinder #5 shows low compression, the issue is related to a possible mechanical failure<br />

such as valve lash, maladjustment, valve train damage, etc. Repair the cylinder concern.<br />

[b] If all cylinders are within 10% of each other, go to step 3.<br />

NOTE:<br />

Engine must be at idle while using this routine.<br />

3. Using DDDL 7.x access the “ISB” service routine.<br />

[a] If the “ISB” service routine results for cylinder #5 are +/- 100%, go to step 4.<br />

[b] If the “ISB” service routine results are not equal to +/- 100%, the fault may be intermittent.<br />

Continue to run the test for 3 minutes. If the above values are seen, go to step 4.<br />

[c] If ISC values are not +/- 100% after 3 minutes, obtain added information from the<br />

customer on the vehicle's operating conditions. Fault code “extended data” may be used in<br />

order to determine the engines operating range when the fault actually occurred. Obtain a<br />

DDDL log file of the condition and contact the Detroit Diesel Customer Support Center<br />

at 313–592–5800 for further instruction.

NOTICE:<br />

Never re-use a high pressure fuel line or transfer tube.<br />

4. Visually inspect the high pressure fuel line and transfer tube on cylinder #5 for any leakage<br />

or damage.<br />

[a] If any leakage or damage is found, replace the high pressure fuel line, and transfer tube.<br />

RefertosectionRemovalofHighPressureFuel Line and Transfer Tube in the EPA07<br />

MBE 4000 Service Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).<br />

[b]<br />

If no leakage or damage is found, replace the #5 fuel injector, high pressure fuel line, and<br />

transfer tube. Refer to section Removal of Fuel Injector in the EPA07 MBE 4000 Service<br />

Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).

SPN 1328/FMI 13<br />

This diagnosis is typically a misfire has been detected in cylinder #6.<br />

SPN 1328/FMI 13 indicates a misfire event on cylinder #6, conditions for this fault are:<br />

□ Engine speed: 1350 - 2200 rpm<br />

Cylinder misfire can occur due to any of the conditions below:<br />

□ Injector-wornorfaulty<br />

□ Fuel leak at transfer tube or high pressure fuel line<br />

□ Poor cylinder compression<br />

□ Valve lash maladjustment<br />

□ Cylinder kit failure<br />

□ Valve train failure<br />

Check as follows:<br />

1. Start and bring the engine up to operating temperature.<br />

2. Using DDDL 7.x perform the “Compression Test” service routine:<br />

[a] If cylinder #6 shows low compression, the issue is related to a possible mechanical failure<br />

such as valve lash, maladjustment, valve train damage, etc. Repair the cylinder concern.<br />

[b] If all cylinders are within 10% of each other, go to step 3.<br />

NOTE:<br />

Engine must be at idle while using this routine.<br />

3. Using DDDL 7.x access the “ISB” service routine.<br />

[a] If the “ISB” service routine results for cylinder #6 are +/- 100%, go to step 4.<br />

[b] If the “ISB” service routine results are not equal to +/- 100%, the fault may be intermittent.<br />

Continue to run the test for 3 minutes. If the above values are seen, go to step 4.<br />

[c] If ISC values are not +/- 100% after 3 minutes, obtain added information from the<br />

customer on the vehicle's operating conditions. Fault code “extended data” may be used in<br />

order to determine the engines operating range when the fault actually occurred. Obtain a<br />

DDDL log file of the condition and contact the Detroit Diesel Customer Support Center<br />

at 313–592–5800 for further instruction.

NOTICE:<br />

Never re-use a high pressure fuel line or transfer tube.<br />

4. Visually inspect the high pressure fuel line and transfer tube on cylinder #6 for any leakage<br />

or damage.<br />

[a] If any leakage or damage is found, replace the high pressure fuel line, and transfer tube.<br />

RefertosectionRemovalofHighPressureFuel Line and Transfer Tube in the EPA07<br />

MBE 4000 Service Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).<br />

[b]<br />

If no leakage or damage is found, replace the #6 fuel injector, high pressure fuel line, and<br />

transfer tube. Refer to section Removal of Fuel Injector in the EPA07 MBE 4000 Service<br />

Manual (DDC-SVC-MAN-0023 (6SE4<strong>12</strong>).

ADDITIONAL SER<strong>VI</strong>CE INFORMATION<br />

Additional service information is available in one of the <strong>DDEC</strong> <strong>VI</strong> troubleshooting guides.<br />

Detroit Diesel®, DDC®, Series 60® and the spinning arrows design are registered trademarks of Detroit Diesel Corporation.<br />

© Copyright 20<strong>08</strong> Detroit Diesel Corporation. All rights reserved. Printed in U.S.A.