SW 702 Si Wire Electrode for Submerged Arc Welding ... - imosdg.ro

SW 702 Si Wire Electrode for Submerged Arc Welding ... - imosdg.ro

SW 702 Si Wire Electrode for Submerged Arc Welding ... - imosdg.ro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

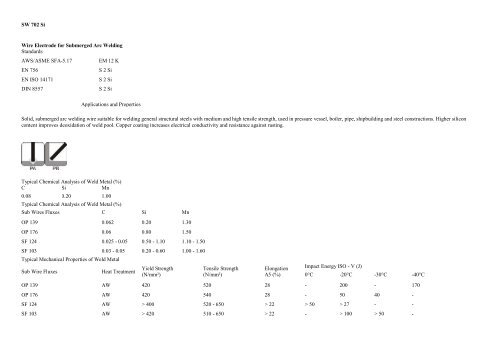

<st<strong>ro</strong>ng>SW</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>702</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>Si</st<strong>ro</strong>ng><br />

<st<strong>ro</strong>ng>Wire</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>Elect<strong>ro</strong>de</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>for</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>Submerged</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>Arc</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>Welding</st<strong>ro</strong>ng><br />

Standards<br />

AWS/ASME SFA-5.17<br />

EN 756<br />

EN ISO 14171<br />

DIN 8557<br />

EM 12 K<br />

S 2 <st<strong>ro</strong>ng>Si</st<strong>ro</strong>ng><br />

S 2 <st<strong>ro</strong>ng>Si</st<strong>ro</strong>ng><br />

S 2 <st<strong>ro</strong>ng>Si</st<strong>ro</strong>ng><br />

Applications and P<strong>ro</strong>perties<br />

Solid, submerged arc welding wire suitable <st<strong>ro</strong>ng>for</st<strong>ro</strong>ng> welding general structural steels with medium and high tensile strength, used in pressure vessel, boiler, pipe, shipbuilding and steel constructions. Higher silicon<br />

content imp<strong>ro</strong>ves deoxidation of weld pool. Copper coating increases electrical conductivity and resistance against rusting.<br />

Typical Chemical Analysis of Weld Metal (%)<br />

C <st<strong>ro</strong>ng>Si</st<strong>ro</strong>ng> Mn<br />

0.08 0.20 1.00<br />

Typical Chemical Analysis of Weld Metal (%)<br />

Sub <st<strong>ro</strong>ng>Wire</st<strong>ro</strong>ng>s Fluxes C <st<strong>ro</strong>ng>Si</st<strong>ro</strong>ng> Mn<br />

OP 139 0.062 0.20 1.30<br />

OP 176 0.06 0.80 1.50<br />

SF 124 0.025 - 0.05 0.50 - 1.10 1.10 - 1.50<br />

SF 103 0.03 - 0.05 0.20 - 0.60 1.00 - 1.60<br />

Typical Mechanical P<strong>ro</strong>perties of Weld Metal<br />

Sub <st<strong>ro</strong>ng>Wire</st<strong>ro</strong>ng> Fluxes<br />

Heat Treatment<br />

Yield Strength<br />

(N/mm²)<br />

Tensile Strength<br />

(N/mm²)<br />

Elongation<br />

A5 (%)<br />

Impact Energy ISO - V (J)<br />

0°C -20°C -30°C -40°C<br />

OP 139 AW 420 520 28 - 200 - 170<br />

OP 176 AW 420 540 28 - 50 40 -<br />

SF 124 AW > 400 520 - 650 > 22 > 50 > 27 - -<br />

SF 103 AW > 420 510 - 650 > 22 - > 100 > 50 -

Packing In<st<strong>ro</strong>ng>for</st<strong>ro</strong>ng>mation and <st<strong>ro</strong>ng>Welding</st<strong>ro</strong>ng> Current<br />

P<strong>ro</strong>duct Code<br />

Ø<br />

(mm)<br />

Weight / Box<br />

(kgs)<br />

4107208M15 1.60 15 K 300<br />

4107210M15 1.60 25 K 435<br />

Package Type<br />

Polarity<br />

4107211M15 2.40 25 K 435<br />

4107214M15 3.20 25 K 435<br />

4107216M15 4.00 25 K 435<br />

Storage and Drying In<st<strong>ro</strong>ng>for</st<strong>ro</strong>ng>mation<br />

1. Should be stocked on top of the wooden palletes in dry <strong>ro</strong>om. (relative humidity < 50%, <strong>ro</strong>om temperature > 20°C)<br />

2. Shouldn’t be exposed to high statical load and impact.