Cell Line Development & Engineering

Cell Line Development & Engineering

Cell Line Development & Engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

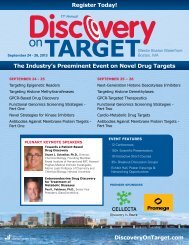

IBC’s 9th Annual<br />

<strong>Cell</strong> <strong>Line</strong> <strong>Development</strong><br />

& <strong>Engineering</strong><br />

Hear Case Studies from<br />

Genentech, Lonza,<br />

MedImmune, Abbott, Pfizer,<br />

Boehringer Ingleheim,<br />

Eli Lilly, BMS, Novartis<br />

& more...<br />

Improve All Aspects of Bioproduct <strong>Development</strong> by<br />

Leveraging Cutting-Edge Technical and Process Innovation<br />

May 20-22, 2013 • Hyatt Regency La Jolla at Aventine • La Jolla, CA<br />

Gain Perspectives from Exclusive Case Studies<br />

and Unpublished Data to Help You –<br />

➜ Develop a Custom <strong>Cell</strong> <strong>Line</strong> Toolbox with Diverse<br />

Product Quality Attributes<br />

➜ Utilize Molecular Assessment Programs to Balance<br />

Upstream Work with Downstream Payoffs<br />

➜ Apply Next Generation Sequencing Technologies in<br />

Biomanufacturing<br />

➜ Integrate Multiple Omics Data Sets to Understand<br />

Growth Rate Regulation in CHO<br />

➜ Overcome <strong>Cell</strong> <strong>Line</strong> and Process <strong>Development</strong><br />

Challenges for Biosimilars<br />

➜ Incorporate High Throughput Imaging to Increase<br />

the Assurance of Clonality<br />

Gold Sponsor: Silver Sponsor:<br />

Bronze Sponsors:<br />

Premier Publication:<br />

Keynote Presentations<br />

Coordinated Oscillations in Cortical<br />

Actin and Ca(2+) Correlate with<br />

Cycles of Vesicle Secretion<br />

Roy Wollman, Ph.D.<br />

Assistant Professor,<br />

Chemistry and Biochemistry<br />

University of California San Diego<br />

Higher-Faster-Further: Why It Makes<br />

Sense to Invest in Innovation to Achieve<br />

Disruptive Improvements<br />

Torsten W. Schulz, Ph.D.<br />

Director, <strong>Cell</strong> Culture,<br />

Boehringer Ingelheim Fremont, Inc.<br />

Featured Presentations<br />

Stable Depletion of miR-7 Expression<br />

for Improved Performance of<br />

a CHO Batch-Fed Culture<br />

Niall Baron, Ph.D.<br />

Senior Research Scientist, National<br />

Institute for <strong>Cell</strong>ular Biotechnology,<br />

Dublin City University, Ireland<br />

Technology Toolbox for <strong>Cell</strong> <strong>Line</strong><br />

<strong>Development</strong> – Towards High Speed,<br />

Yield and Clonal Stability<br />

Thomas Jostock, Ph.D.<br />

Novartis Leading Scientist<br />

Novartis Pharma AG, Switzerland<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong>

Join Industry Leaders at IBC’s 9th Annual<br />

<strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> & <strong>Engineering</strong><br />

May 20-22, 2013<br />

Hyatt Regency La Jolla at Aventine<br />

La Jolla, CA<br />

IBC’s <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> & <strong>Engineering</strong> conference is driven by the novel<br />

approaches and emerging tools that are designed to save you time and money<br />

during the process of selecting, developing and engineering your cell lines.<br />

In 3 information packed days, you hear experiences, successes and lessons<br />

learned from companies utilizing the rapidly expanding technology toolbox to<br />

dramatically improve the speed of cell line development, minimize risk, and<br />

increase process and product quality.<br />

Industry leaders and world-renowned academics share exclusive case studies and<br />

unpublished data, providing you with the information required to overcome your<br />

toughest challenges and help your company achieve:<br />

• The promise of ‘omics technologies in process development<br />

• High production stability with targeted integration<br />

• Improved cell density and prolonged viability with stable depletion of miR-7<br />

• Lead candidates with optimal stability, productivity, safety and delivery<br />

characteristics from early developability assessments<br />

• Improved collaboration at the interface of development and discovery<br />

• Better understanding of gene expression regulation with next<br />

generation sequencing<br />

• Big timeline reductions through engineering of host cell line and<br />

expression vector<br />

• In process control of glycosylation during high yield production<br />

Gain Recognition from Your<br />

Peers and Present a Poster<br />

Sponsored by:<br />

IBC’s <strong>Cell</strong> <strong>Line</strong> 2013 SAFC Young Investigator<br />

Poster Awards are dedicated to recognizing<br />

the recent achievements of graduate students,<br />

post docs and research scientists that are<br />

driving this field forward.<br />

Posters are reviewed and judged by the Scientific Advisory Committee<br />

for most novel application by a graduate student, post doc and research<br />

scientist. The three winning posters will be announced during the conference<br />

on Wednesday, May 22nd at 8am.<br />

The deadline to submit an abstract for inclusion in the conference materials is<br />

Monday, April 29, 2013 (Abstract and full payment of conference and poster<br />

fees must be received by this date.) After that date, posters are on a space<br />

available basis.<br />

To submit your poster and for additional details on the poster sizes and<br />

regulations, please visit www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong>. Only one poster<br />

presentation will be allowed per registered attendee/author.<br />

Gold Sponsor<br />

Pall’s leading edge separation, purification, cell culture, analytical<br />

technologies and services play an essential role in the Life Sciences<br />

industry. Pall single-use and traditional filtration, chromatography,<br />

fluid handling, sampling, monitoring and quality assurance<br />

products and engineered systems, together with technical services<br />

in validation, assays and process optimization are applicable to all<br />

phases and scales of therapeutic, vaccine, and diagnostic product<br />

research, development and manufacturing.<br />

Silver Sponsor<br />

Life Technologies is a global leader in bioprocessing, supporting<br />

biologics based therapeutics and vaccines from molecule to market<br />

with leading brands such as Gibco ® cell culture products and cell<br />

therapy systems; POROS ® chromatography; and SEQ pharmaceutical<br />

analytics. Our portfolio of bioproduction services includes cell line<br />

development and media optimization.<br />

Bronze Sponsors<br />

Poster Award Sponsor<br />

Technology Workshop Sponsors<br />

Badge and Lanyard Sponsor<br />

Conference Supporter<br />

Exhibitors (as of January 11, 2013)<br />

ATR, Inc<br />

Molecular Devices<br />

Life Technologies<br />

Pall Life Sciences<br />

MaxCyte<br />

TAP Biosystems<br />

Drive Your Global Sales and Marketing<br />

IBC’s Bioprocessing Series events provide a number of<br />

sponsorship and exhibiting opportunities you can choose from<br />

to meet your goals before, during and after the event. IBC’s<br />

sponsorships ensure you the proper balance between attendees<br />

and exhibitors so you can spend more time developing<br />

your deals and less time searching for possible partners.<br />

Sponsorship/Exhibiting opportunities include Technology<br />

Workshops (including a thirty minute speaking slot); Session<br />

Sponsorships; Reception, Luncheon and Break Sponsorships;<br />

Delegate Focus Groups; Imprinted Giveaways; and much more.<br />

To learn more about sponsoring or exhibiting, please contact:<br />

A-L: Jennifer Thebodo at 508-614-1672<br />

or jthebodo@ibcusa.com<br />

M-Z: Ellen Moorehead at (508) 614-1406<br />

or emoorehead@ibcusa.com<br />

2 Register Early for Best Savings • www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> • 800-390-4078

Monday, May 20, 2013<br />

7:00 Registration and Coffee<br />

8:00 Chairwoman’s Opening Remarks – The Legal, Regulatory<br />

and Technical Landscape<br />

Laurie Donahue-Hjelle, Ph.D., Director, New Product <strong>Development</strong>,<br />

Life Technologies<br />

Keynote Addresses<br />

8:15 CASE STUDY Coordinated Oscillations in Cortical<br />

Actin and Ca(2+) Correlate with Cycles of<br />

Vesicle Secretion<br />

The actin cortex both facilitates and hinders the exocytosis<br />

of secretory granules. How cells consolidate these two<br />

opposing roles was not well understood. Here we show using multi-color<br />

fluorescent microscopy that antigen activation of mast cells induces<br />

oscillations in Ca(2+) and PtdIns(4,5)P(2) lipid levels that in turn drive<br />

cyclic recruitment of N-WASP and cortical actin level oscillations. These<br />

oscillations increase secretion efficiency, explaining how the actin cortex can<br />

function as a carrier as well as barrier for vesicle secretion.<br />

Roy Wollman, Ph.D., Assistant Professor, Chemistry and Biochemistry,<br />

University of California San Diego<br />

8:45 CASE STUDY • UNPUBLISHED DATA Higher-Faster-Further:<br />

Why It Makes Sense to Invest in Innovation to<br />

Achieve Disruptive Improvements – A Case<br />

Study About 2nd Generation Media <strong>Development</strong><br />

The pressure to reduce COGS will likely increase. The<br />

biopharmaceutical industry needs to pro-actively address this development<br />

by having the appropriate strategies to increase productivity significantly. This<br />

requires a dedicated commitment to innovative ideas that include state of the art<br />

scientific approaches for significant improvements. The case study correlates the<br />

investment in innovation with the outcome of a multi-year innovation project.<br />

Torsten W. Schulz, Ph.D., Director, <strong>Cell</strong> Culture,<br />

Boehringer Ingelheim Fremont, Inc.<br />

9:15 Speed Networking Refreshment Break and Poster/Exhibit Viewing<br />

Working Closer with Drug Discovery and Research to<br />

Improve <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> and Minimize Risk<br />

10:15 UNPUBLISHED DATA <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> for Novel<br />

Molecules - Perspectives from the Interface of<br />

Discovery and <strong>Development</strong><br />

Abstract not available at time of print. Please visit<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> for updates.<br />

Stephanie E. Rieder, Senior Scientist III, Global Biologics, AbbVie<br />

10:45 CASE STUDY • UNPUBLISHED DATA Molecular Assessment (MA)<br />

Programs – Balancing Upstream Work with<br />

Downstream Payoffs<br />

Producing recombinant proteins and antibodies with manufacturability<br />

problems often presents a significant barrier to the clinical and commercial<br />

feasibility of a project. Methods to identify problematic molecules early in the<br />

drug development process can serve a valuable purpose by either eliminating<br />

these molecules from consideration or by providing advance notice so that<br />

proactive steps can be taken to minimize timeline delays. This presentation<br />

describes selected Molecule Assessment (MA) considerations implemented at<br />

Genentech, highlighting examples identified at different stages in the process.<br />

Laura Simmons, Senior Scientist, Early Stage <strong>Cell</strong> Culture, Genentech, Inc.<br />

“Quite worthwhile!<br />

Informative, encompassing, broad and yet relevant topics.<br />

Great venue for discussion and interaction.”<br />

- Lynn Davis, Ph.D., Senior Research Biologist, Bend Research Inc.<br />

11:15 CASE STUDY • UNPUBLISHED DATA Surviving the Valley of Death - Pre-<br />

<strong>Cell</strong> <strong>Line</strong> Generation Strategies to Reduce Attrition in Later<br />

Stages of Biopharmaceutical <strong>Development</strong><br />

The majority of new biopharmaceutical candidates fail during preclinical<br />

and clinical development in what some describe as the ‘valley of death’<br />

of drug development. The challenge faced by drug developers is to find<br />

new ways of screening out early on in development those compounds<br />

that have a lower probability of success. Developability strategies applied<br />

before the development of production cell lines do address aspects<br />

of manufacturability, safety and delivery that could impact negatively<br />

later stages of development. They constitute an alternative approach to<br />

QbD, targeting risks present in the product itself. It is expected that the<br />

incorporation of this type of assessment early on in biopharmaceutical<br />

development will help reduce cost, attrition and development timelines.<br />

Jesús Zurdo, Ph.D., Head of Innovation, Biopharmaceutical <strong>Development</strong>,<br />

Lonza, United Kingdom<br />

11:45 Technology Workshop<br />

Simple Methods to Make Your <strong>Cell</strong> <strong>Line</strong> Shine<br />

Tremendous efforts have gone into shortening stable cell line development.<br />

Once those months are invested, there is a desire for the selected clone to<br />

shine very quickly with regards to titer and sustainable product quality. This<br />

presentation will explore simple methods to attain next level titers in CHO<br />

fed-batch processes once you’ve selected your expression clone.<br />

Cynthia Hoy, Ph.D, Process Science Fellow, PD Direct® Services –<br />

Life Technologies<br />

12:15 Luncheon and Poster/Exhibit Viewing<br />

1:15 Chairman’s Remarks - Are ‘omics Approaches Anything<br />

other than Intellectual (Academic) Interest - Does Data<br />

Obtained have Track Record of Translating to Making a<br />

Difference in Processes<br />

Kevin McCarthy, Ph.D., Group Leader for <strong>Cell</strong> Sciences, EMD Serono Inc.<br />

Application, Integration and Characterization of ‘Omics<br />

in <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong><br />

1:30 UNPUBLISHED DATA Application of Genomic Technologies<br />

to <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong><br />

The recent publication of a draft CHO genome has set the stage for detailed<br />

molecular and genetic understanding of growth and protein production in<br />

mammalian cells, which will enable - the recognition of patterns of gene expression<br />

that correlate to process suitability and allow knowledge based selection of clones;<br />

development of pathway engineering strategies to improve the host cell line;<br />

process, media and feed development by optimisation of cellular responses.<br />

Nicole Borth, Ph.D., Professor, Department of Biotechnology,<br />

University of Bodenkultur, Austria<br />

2:00 UNPUBLISHED DATA <strong>Development</strong> of a CHO<br />

Mass Spectrometry Database<br />

New sequence information on Chinese hamster ovary cells offers the potential<br />

to improve the interpretation of CHO proteomic results, and thus a greater<br />

understanding of the underlying biological mechanisms of CHO cells in<br />

biopharmaceutical processes. In this presentation, we demonstrate the use<br />

of CHO-specific sequence information to improve the identification of CHO<br />

proteins using mass spectrometry-based proteomic analysis.<br />

Paula Meleady, Ph.D., Senior Research Scientist, Program Leader,<br />

Proteomics Core Facility, National Institute for <strong>Cell</strong>ular Biotechnology,<br />

Dublin City University, Ireland<br />

2:30 UNPUBLISHED DATA <strong>Engineering</strong> the CHO Genome for Improved<br />

Transgene Integration and Expression<br />

Epigenetic regulatory DNA elements prevent silencing and increase transgene<br />

integration and transcription for high and stable therapeutic production.<br />

We have sequenced the genome and transcriptome of a CHO cell line and of<br />

derived producer cell clones, yielding information on the integration locus,<br />

transgene integrity and copy number. Information on possible mechanisms<br />

allowing vector genomic integration was also obtained, providing approaches<br />

to further optimize transgene integration and expression.<br />

Nicolas Mermod, Ph.D., Professor, Director, Institute of Biotechnology,<br />

University of Lausanne, Switzerland<br />

For up-to-date program information and new abstracts, visit: www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> 3

Monday, May 20, 2013 (continued)<br />

3:00 CASE STUDY • UNPUBLISHED DATA Proteomic Analysis of Chinese<br />

Hamster Ovary (CHO) <strong>Cell</strong>s<br />

To complement the recent genomic sequencing of Chinese hamster ovary<br />

(CHO) cells, proteomic analysis was performed on CHO cells including the<br />

cellular proteome, secretome, and glycoproteome using mass spectrometry<br />

and multiple strategies. A total of 6164 grouped proteins were identified. This<br />

first large-scale proteomic analysis enhances the knowledge base about CHO<br />

capabilities for recombinant expression and cell line engineering.<br />

Deniz Baycin Hizal, Ph.D., Chemical and Biomolecular <strong>Engineering</strong>,<br />

Johns Hopkins University<br />

3:30 Networking Refreshment Break and Poster/Exhibit Viewing<br />

Proliferation and Integration of Data Sets<br />

4:00 Integrated miRNA, mRNA and Protein Expression Analysis<br />

Reveals the Role of Post-Transcriptional Regulation in<br />

Controlling CHO <strong>Cell</strong> Growth Rate<br />

To investigate the role of microRNA (miRNA) in the regulation of Chinese<br />

hamster ovary (CHO) cell growth, qPCR, microarray and quantitative LC-MS/<br />

MS analysis were utilised for simultaneous expression profiling of miRNA, mRNA<br />

and protein. In this presentation, the biological processes found to be correlated<br />

with CHO cell growth rate is discussed and the analysis of multiple datasets to<br />

identify potential miRNA-mediated regulation demonstrated.<br />

Colin Clarke, Ph.D., Postdoc, National Institute for <strong>Cell</strong>ular Biotechnology,<br />

Dublin City University, Ireland<br />

4:30 UNPUBLISHED DATA Using Metabolite Profiling Data to Make a<br />

Difference to CHO <strong>Cell</strong> Bioprocesses<br />

Metabolite profiling offers an ‘omics approach that enables a very<br />

immediate read-out of the status of CHO cells in culture. From an<br />

integrated analysis of profile changes, interpretations can be attained of<br />

metabolic phenotype associated with growth and/or recombinant protein<br />

production. This presentation illustrates our molecular understanding of<br />

relationships between feeding, cellular metabolism and desirable phenotype<br />

in CHO cells.<br />

Alan Dickson, Ph.D., Director, Centre of Excellence in Biopharmaceuticals,<br />

Professor of Biotechnology, University of Manchester, United Kingdom<br />

5:00 UNPUBLISHED DATA Genome-Scale Analysis of Chinese Hamster<br />

Ovarian <strong>Cell</strong> <strong>Line</strong>s<br />

Over the past 15 years, microbe-based engineering has advanced through<br />

three major innovations: 1) genome sequencing, 2) genome-scale metabolic<br />

models, and 3) tools for genome editing. These have allowed engineers to<br />

identify cellular parts, simulate product synthesis, and manipulate host<br />

genomes to enhance production. Similar advances are now upon us in the<br />

engineering of CHO cell lines for bioprocessing.<br />

Bernhard Palsson, Ph.D., Principal Investigator, Galletti Professor of<br />

Bioengineering, Adjunct Professor Medicine, University of California, San Diego<br />

5:30 Cocktail Reception in Poster/Exhibit Hall<br />

Tuesday, May 21, 2013<br />

7:30 Coffee<br />

8:00 Chairman’s Opening Remarks<br />

Rodney Combs, M.S., Associate Research Fellow, Bioprocess R&D, Culture<br />

Process <strong>Development</strong>, World Wide Pharmaceutical Sciences, Pfizer Inc.<br />

Approaches to Improve Process and Product Quality<br />

8:15 CASE STUDY Clonality – Challenges, Approaches and<br />

Lessons Learned<br />

Abstract not available at time of print. Please visit<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> for updates.<br />

Pamela Hawley-Nelson, Ph.D., Associate Director, Process <strong>Cell</strong> Culture,<br />

MedImmune<br />

8:45 Use of QPCR and DNA Sequencing Tools to Ensure<br />

Product Quality and Safety<br />

Quantitative PCR (Q-PCR) and DNA sequencing are tools that enable rapid,<br />

sensitive and precise quantitation, detection and identification of critical<br />

cellular and process impurities in cell culture manufacturing and product<br />

purification. Additionally, these tools can be utilized in development and<br />

characterization of production cell lines and in routine monitoring of cell line<br />

stability. In this presentation, the applications of these technologies and present<br />

data demonstrating the performance of assays for impurity assessment, cell line<br />

characterization, contaminant detection and identification are reviewed.<br />

Michael T. Brewer, Director, Head of Pharma Analytics, Life Technologies<br />

9:15 UNPUBLISHED DATA High-Throughput Product Quality Assays for<br />

<strong>Cell</strong> <strong>Line</strong> and Process <strong>Development</strong><br />

Here we present high-throughput (HTP) analytical assays to facilitate rapid<br />

product quality using 96-well plate formats. These HTP product quality assays<br />

include HTP protein quantitation followed by HTP protein purification and<br />

product quality analyses. With these HTP analytical product quality assays we can<br />

assess product quality in the early stage of clone screening, as well as expedite the<br />

cell line and process development.<br />

Shashi Prajapati, Ph.D., Senior Scientist, <strong>Cell</strong> Culture <strong>Development</strong>,<br />

High Throughput Analytical Group. Biogen Idec<br />

9:45 Networking Refreshment Break and Poster/Exhibit Viewing<br />

10:15 CASE STUDY • UNPUBLISHED DATA Impact of Media Components and<br />

Process Parameters on Product Color<br />

Health Authorities expect that companies monitor and control the color<br />

of liquid formulations of monoclonal antibodies. <strong>Cell</strong> culture conditions<br />

and media components were investigated and shown to influence color.<br />

Mechanisms that could explain these effects are discussed. Some process<br />

changes that reduced color also decreased titer, and strategies for reducing<br />

color which avoid productivity impact are discussed.<br />

Natarajan Vijayasankaran, Ph.D., Senior Engineer, Late Stage <strong>Cell</strong> Culture,<br />

Genentech, Inc.<br />

10:45 CASE STUDY • UNPUBLISHED DATA Viability and Productivity<br />

Improvement on Mammalian Fed Batch Culture<br />

Abstract not available at time of print. Please visit<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> for updates.<br />

Wenge Wang, Ph.D., Senior Principal Scientist, Bioprocess Research and<br />

<strong>Development</strong>, Pfizer Inc.<br />

11:15 Technology Workshop<br />

A New Bench Scale Single-Use<br />

Bioreactor System<br />

<strong>Development</strong> of a new bench scale “rocker style” single use bioreactor<br />

will be described, with discussion of physical parameters for design space<br />

definition and performance measurement; with comparison to industry<br />

standard systems. Presentation will conclude with results from CHO<br />

batch culture trials for design validation, showing significant increases in<br />

achievable cell densities and cell productivity.<br />

Charles G. Golightly, Global Product Manager, Pall Life Sciences<br />

11:45 Luncheon and Poster/Exhibit Viewing<br />

Send a group of 3 and the 4th goes FREE!<br />

It’s a fact – attendees walk away with the most value when they<br />

experience it with a peer – there is just too much information available<br />

for one person to capture it all. As a result, we are pleased to offer a<br />

4th free registration when you register 3 people at the standard rate.<br />

For more information call our group sales advocate at 646-895-7445.<br />

4 Register Early for Best Savings • www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> • 800-390-4078

Tuesday, May 21, 2013 (continued)<br />

12:55 Chairman’s Remarks<br />

Andy Lin, Ph.D., Process Research & <strong>Development</strong>, Genentech, Inc.<br />

Approaches to Improve <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> Efficiencies,<br />

Resources and Timelines – What is the Impact<br />

1:00 CASE STUDY • UNPUBLISHED DATA Strategies to Fast/Lean POC and<br />

Risk Mitigation<br />

Fast/lean to PoC is highly desired for drug development. However, fast/lean<br />

cell line generation could potentially result in the identification of clonal cell<br />

lines that are only suitable for early-phase development and result in the<br />

need to change cell lines for commercial development, which can pose a<br />

significant challenge in demonstrating consistency of processes/products. In<br />

this presentation, we share recloning case studies as a potential mitigation<br />

strategy to the risks associated with fast/lean to PoC approaches.<br />

Luhong He, Ph.D., Senior Research Scientist, Eli Lilly and Company<br />

1:30 Streamlining Antibody <strong>Development</strong> Using Large Scale,<br />

CHO Transient Gene Expression (TGE) Followed by Rapid<br />

Production of CHO Stable Pools<br />

Antibody production for early stage antibody development activities is<br />

commonly conducted using transiently transfected HEK cells to produce<br />

adequate quantities of antibody for characterization, while later stage<br />

screening and biomanufacturing rely on CHO-based stable cell lines.<br />

Migration from HEK to CHO cell backgrounds can lead to manufacturing<br />

challenges and changes in post translational modifications that can alter<br />

the antibody’s therapeutic potential. The time line of antibody development<br />

can be greatly streamlined using large scale transient gene expression<br />

(TGE) directly within CHO cells. CHOS cells can be transfected with >95%<br />

transfection efficiency and cell viability using MaxCyte flow electroporation.<br />

MaxCyte transiently transfected CHO cells produce antibody titers > 400<br />

mg/L, enabling greater than 1 gram of protein from 1g/L.<br />

James Brady, Ph.D., MBA, Director of Technical Applications, MaxCyte<br />

2:00 CASE STUDY • UNPUBLISHED DATA Accelerating <strong>Cell</strong> <strong>Line</strong> Screening and<br />

Selection Using a Multiplexed 24 Well Microbioreactor and<br />

Streamlined Purification<br />

Abstract not available at time of print. Please visit<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> for updates.<br />

Jessica Wuu, Ph.D., M.S., Senior Scientist, Process Sciences,<br />

Abbott Laboratories<br />

2:30 CASE STUDY • UNPUBLISHED DATA Faster Upstream <strong>Development</strong> for<br />

Therapeutic Proteins: The Contribution of the GS-KO Host<br />

<strong>Cell</strong> <strong>Line</strong><br />

The GS Gene Expression System is widely used for cGMP manufacturing<br />

of therapeutic proteins using mammalian cells. Currently, thirteen licensed<br />

products are manufactured using the GS System. Although the system is<br />

well established, Lonza is continually improving the GS System. Recent<br />

improvements have focussed on a number of areas including reducing<br />

the time for cell line development. The latter was achieved partly through<br />

introduction of a GS-knockout version, CHOK1SV GS-KO, of its standard<br />

CHO host. This talk describes some of work to develop and characterise<br />

the new host cell line, along with comparative performance data from 10 L<br />

bioreactor cultures, and the benefits from switching to the new host.<br />

Andrew Racher, Ph.D., Head of Process <strong>Development</strong> Sciences,<br />

Lonza Biologics plc, United Kingdom<br />

3:00 Networking Refreshment Break and Poster/Exhibit Viewing<br />

Premier Publication:<br />

Media Partners:<br />

<br />

Tribute to the Legacy of Marty Sinacore –<br />

Reflections and State-of-the-Art Advances<br />

3:30 Chairman’s Remarks<br />

Sadettin S. Ozturk, Ph.D., Senior Director, Head of Process <strong>Development</strong>,<br />

MassBiologics<br />

3:45 A Tribute to Marty Sinacore<br />

Marty Sinacore has been one of the contributors of<br />

developing today’s technology used for mammalian cell<br />

based production. Besides being a great scientist Marty has<br />

been the mentor of countless young scientists that now are<br />

part of the backbone of our community. In this<br />

presentation, Tim and Thomas highlight some of<br />

Marty’s work and how it influenced the way we do cell<br />

based manufacturing today.<br />

Tim Charlebois, Ph.D., Vice President,<br />

Technology & Innovation Strategy, Pfizer Inc.<br />

Thomas Ryll, Ph.D., Senior Director, <strong>Cell</strong> Culture <strong>Development</strong>, Biogen Idec<br />

4:30 UNPUBLISHED DATA <strong>Development</strong> of a Custom <strong>Cell</strong> <strong>Line</strong> Toolbox<br />

with Diverse Product Quality Attributes<br />

Although the simplicity of having a single, well characterized host upon<br />

which to initiate cell line engineering has many advantages, a one size<br />

fits all approach does have its drawbacks. The range of product quality<br />

attributes achievable will be limited by the intrinsic phenotype of said host<br />

and may not overlap with the optimum profile for a given therapeutic. With<br />

the increased sophistication of engineering tools enabling precise genome<br />

editing or mRNA depletion, it’s now relatively straight forward to develop<br />

modified hosts with tailored made phenotypes. The end result being the cell<br />

line engineer can develop a “toolbox” of varied hosts that can be employed<br />

to insure that critical quality attributes or biosimilarity is achievable.<br />

Scott Estes, Ph.D., Director, <strong>Cell</strong> Culture <strong>Development</strong>, Biogen Idec<br />

5:00 The Impact of ‘Omics Technologies on Process<br />

<strong>Development</strong> – The Promise and the Reality<br />

It was just over 10 years ago that the use of ‘omics technologies started<br />

to make their way into bioprocess development. For many early adopters<br />

of the technology, the promise was a better fundamental understanding<br />

of cell biology that would lead to engineered cell lines that would be<br />

optimized for production of secreted biotherapeutics. That isn’t what<br />

happened, however.<br />

Mark Melville, Ph.D., Senior Director, Bioprocess <strong>Development</strong>,<br />

Epirus Biopharmaceuticals<br />

5:30 CASE STUDY • UNPUBLISHED DATA Preservation of a Balanced <strong>Cell</strong><br />

Culture Environment for Fed-Batch Processes<br />

This presentation demonstrates with examples the effect of cell culture<br />

imbalance on cell growth and productivity, as well as specific solutions to<br />

remedy these issues. A simple solution to revive the drop in cell viability<br />

observed during the late stage of cell culture is also discussed. Finally, a<br />

systematic approach of medium feeding to achieve high cell density, high<br />

viability, and high titer process is also described.<br />

Yen-Tung Luan, M.S., Associate Research Fellow, Bioprocess R&D, Pfizer Inc.<br />

“By narrowly targeting the technologies used<br />

at the border of R&D of biotherapeutics, this event provides<br />

an intensive 3-day review of current, valuable information<br />

for this highly specialized group.”<br />

- Pam Hawley-Nelson, Ph.D., Associate Director,<br />

Process <strong>Cell</strong> Culture, MedImmune<br />

For up-to-date program information and new abstracts, visit: www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> 5

6:00 Dinner Symposium (Special registration required) Tuesday, May 21, 2013 (continued)<br />

Please join us for this highly interactive 3 hour evening exchange in a roundtable format, which encourages participants to share their experiences<br />

and concerns amongst several discussion topics that include:<br />

What Is the State-of-the-Art in Expression<br />

Are We Hitting Our Limits<br />

Moderators:<br />

Laurie Donahue-Hjelle, Ph.D., Director, New Product <strong>Development</strong>,<br />

Life Technologies<br />

Andrew Racher, Ph.D., Head of Process <strong>Development</strong> Sciences,<br />

Lonza Biologics plc, United Kingdom<br />

Are There Any Emerging Platforms that Could Supersede CHO<br />

Moderators:<br />

Rodney Combs, M.S., Associate Research Fellow, Bioprocess R&D, Culture<br />

Process <strong>Development</strong>, World Wide Pharmaceutical Sciences, Pfizer Inc.<br />

Jesús Zurdo, Ph.D., Head of Innovation, Biopharmaceutical <strong>Development</strong>,<br />

Lonza, United Kingdom<br />

How Do We Leverage the CHO Genome Info<br />

Moderators:<br />

Kelvin Lee, Ph.D., Gore Professor of Chemical <strong>Engineering</strong>, Delaware<br />

Biotechnology Institute Faculty Fellow, University of Delaware<br />

Alan Dickson, Ph.D., Director, Centre of Excellence in Biopharmaceuticals,<br />

Professor of Biotechnology, University of Manchester, United Kingdom<br />

Viral Risk Mitigation Strategies<br />

Moderators:<br />

Andy Lin, Ph.D., Process Research & <strong>Development</strong>, Genentech, Inc.<br />

Pamela Hawley-Nelson, Ph.D., Associate Director, Process <strong>Cell</strong> Culture,<br />

MedImmune Inc<br />

Phase-Appropriate, Regulatory Expectations Regarding <strong>Cell</strong><br />

<strong>Line</strong> and <strong>Cell</strong> Culture Processes (Bulk Culture, Non-GMP for<br />

First Human Dose (FHD))<br />

Moderators:<br />

Luhong He, Ph.D., Senior Research Scientist, Eli Lilly and Company<br />

Stephanie E. Rieder, Senior Scientist III, Global Biologics, AbbVie<br />

Agenda:<br />

6:00-7:00 pm Discussion Groups<br />

7:00-8:00 pm Dinner<br />

8:00-9:00 pm Dessert and summaries from each discussion<br />

Additional registration fee required – see page 7 for details<br />

Wednesday, May 22, 2013<br />

7:30 Coffee<br />

8:00 Chairman’s Remarks and Announcement of Poster Winners<br />

Kevin J. Kayser, Ph.D., Director, <strong>Cell</strong> Sciences and <strong>Development</strong>, SAFC<br />

Applying Disruptive Technologies and Their Impact on<br />

<strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> and <strong>Engineering</strong><br />

8:15 <strong>Cell</strong> <strong>Line</strong> <strong>Engineering</strong> Applications of Zinc Finger<br />

Nuclease(ZFN) Technology to Reduce the Risk Profile in<br />

Therapeutic Manufacturing Processes<br />

Zinc Finger Nucleases (ZFNs) are a class of engineered DNA-binding proteins that<br />

facilitate targeted editing of the genome by creating double-strand breaks in DNA at<br />

user-specified locations. We have conducted significant research and development<br />

work to deploy ZFN technology across biopharmaceutical applications. SAFC has<br />

created several new commercial available Chinese Hamster Ovary (CHO) cell lines<br />

with modifications in specific genes of interest. Example cell lines include CHO<br />

GS-/- and CHO dhfr-/- deletions. This talk begins with an overview of the ZFN<br />

technology and specific CHO cell line engineering applications but focuses on<br />

current research to create CHO cell lines with reduced risk profiles.<br />

Kevin J. Kayser, Ph.D., Director, <strong>Cell</strong> Sciences and <strong>Development</strong>, SAFC<br />

8:45 UNPUBLISHED DATA Next Generation Sequencing Technologies and<br />

Applications in Biomanufacturing<br />

The rapid pace of development of technologies for high throughput analysis of<br />

nucleic acid sequence information is beginning to have an important impact<br />

on cell line development. In this presentation, we discuss an overview of the<br />

variety of next generation sequencing technologies that are available and being<br />

employed to study mammalian cell lines and discuss impact of the application of<br />

these technologies to problems relevant to the biomanufacturing community.<br />

Kelvin H. Lee, Ph.D., Gore Professor of Chemical <strong>Engineering</strong>, Director of the<br />

Delaware Biotechnology Institute, University of Delaware<br />

9:15 CASE STUDY • UNPUBLISHED DATA Generic Characterization of Stable<br />

CHO <strong>Line</strong>s by Next Generation Sequencing<br />

One of the major challenges in biologic drug development is product<br />

heterogeneity as a result of contamination, mutation or alternative splicing in<br />

transcription. Traditional methods such as cloning and Sanger sequencing, etc.<br />

are inefficient and even incompetent in detection of generic variants, especially<br />

in low amount. NGS, a powerful tool in decipher genetic information, was<br />

applied on the task and was demonstrated as a perfect fit in molecular<br />

characterization of biotherapeutics during drug development.<br />

Junjian Liu, Ph.D., Senior Scientist, Global Biologics, Abbott Laboratories<br />

9:45 Networking Refreshment Break<br />

Featured Presentations –<br />

Applying Novel <strong>Development</strong> & <strong>Engineering</strong> Strategies<br />

10:15 Stable Depletion of miR-7 Expression for Improved<br />

Performance of a CHO Batch-Fed Culture<br />

MicroRNAs are an important group of cellular genetic<br />

regulators that display several attractive traits as engineering<br />

targets. Their ability to influence the expression of multiple<br />

proteins and not require the cellular translational machinery means they<br />

might be useful in modifying entire cellular pathways without placing<br />

increased metabolic burden on producer cells. We report on the effect of<br />

constitutive depletion of miRNA-7 using decoy transcripts on the growth and<br />

productivity of CHO cells in fed-batch culture.<br />

Niall Baron, Ph.D., Senior Research Scientist, National Institute for <strong>Cell</strong>ular<br />

Biotechnology, Dublin City University, Ireland<br />

10:45 CASE STUDY • UNPUBLISHED DATA Technology Toolbox<br />

for <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> – Towards High<br />

Speed, Yield and Clonal Stability<br />

State of the art CHO platforms allow generation of high<br />

yielding production cell lines with short cycle times. Our<br />

strategy for further optimizing speed and yield of our CHO platform<br />

combines internal efforts with systematical screening and evaluation of<br />

external know-how. By integrating internal and external technologies we<br />

are aiming for further reducing cycle times and screening efforts of cell line<br />

development. Some novel vector technologies that we have evaluated to<br />

improve our platform towards high yielding fast processes, including a new<br />

selection marker and a targeted integration technology, will be presented.<br />

Thomas Jostock, Ph.D., Novartis Leading Scientist, Novartis Pharma AG,<br />

Switzerland<br />

11:15 Technology Workshop Opportunity<br />

For more information, please contact Jennifer Thebodo at 508-614-1672<br />

or jthebodo@ibcusa.com<br />

11:45 Lunch on Your Own<br />

New to the Field<br />

Consider Attending IBC’s Two-Day Intensive Training Course:<br />

<strong>Cell</strong> Culture and Fermentation Bioprocessing (separate registration required)<br />

East and West Coast Locations:<br />

May 14-15, 2013 in San Diego, CA •June 12-13, 2013 in Cambridge, MA<br />

Full course details available at www.IBCLifeSciences.com/Courses<br />

6 Register Early for Best Savings • www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> • 800-390-4078

12:55 Chairman’s Remarks<br />

Lisa J. Graham, Ph.D., P.E., Senior Vice President, Bend Research Inc.<br />

Developing <strong>Cell</strong> <strong>Line</strong>s for Biosimilars<br />

1:00 Glycoexpress: A Toolbox of Human <strong>Cell</strong> <strong>Line</strong>s for the<br />

Production of Glycooptimized Biotherapeutics<br />

Glycosylation is the major post-translational modification of biotherapeutics<br />

that depends on the cell line used for production. By establishment of the<br />

GlycoExpress toolbox we have generated a set of glycoengineered human cell<br />

lines for the high yield production of fully human glycoproteins. Currently, five<br />

different cell lines are established which allow the production of glycoproteins<br />

with different glycosylation features.<br />

Steffen Goletz, Ph.D., Chief Executive Officer, Chief Scientific Officer,<br />

Glycotope GmbH, Germany<br />

1:30 UNPUBLISHED DATA Challenges in <strong>Cell</strong> <strong>Line</strong> and Process<br />

<strong>Development</strong> for NBEs and Biosimilars<br />

In developing NBEs and biobetters, speed, titer and an excellent product<br />

quality are all key elements, while for biosimilars, matching the originator<br />

product quality is the essential target. Here, we show how the use of our<br />

integrated BI-HEX platform which is based on well characterized cell lines<br />

and thorough understanding of USP and DSP processes is used to achieve<br />

fast and reliable development of high-titer cell lines and manufacturing<br />

processes, and how understanding of the process can be used to influence<br />

product quality attributes to successfully meet the target.<br />

Till Wenger, Ph.D., Associate Director, <strong>Cell</strong> Biology, <strong>Cell</strong> Culture II, Process<br />

Science, Boehringer Ingelheim, Germany<br />

2:00 2nd Generation Sequencing for <strong>Cell</strong> <strong>Line</strong> Characterization<br />

during Biosimilar <strong>Development</strong><br />

Biosimilar cell line development is a multi-step process, based on quality by<br />

design principles to generate a cell line producing a recombinant protein<br />

as similar to the originator’s protein as possible. Essential part of cell line<br />

development is genetic characterization. In addition to standard techniques,<br />

2nd generation sequencing technologies enable deeper look into the parts of<br />

genome and transcriptome interesting for cell line developers.<br />

Dominik Gaser, Ph.D., Senior Scientist, <strong>Cell</strong> & Molecular Biology,<br />

Sandoz Biopharmaceuticals, Slovenia<br />

2:30 Networking Refreshment Break<br />

Implementation of Analytical Tools and Strategies to<br />

Help Improve Clone Selection, Process Monitoring,<br />

Understanding and <strong>Development</strong><br />

3:00 UNPUBLISHED DATA High Throughput Imaging During <strong>Cell</strong> <strong>Line</strong><br />

<strong>Development</strong> to Increase the Assurance of Clonality<br />

We are developing a fluorescent high throughput automated imaging protocol that<br />

can provide direct evidence on whether the cell line originated from one cell during<br />

the cloning step. To accommodate the throughput of the cell line development<br />

workflow at Genentech, fluorescent cell staining and automated fluorescent cell<br />

counting are used to reduce the need to manually inspect brightfield images. Since<br />

image data is acquired to track clone growth for all clones during the single-cell<br />

cloning process, confluence data or other electronic data can be used to drive<br />

automated hit-picking from the 384-well plates thus increasing efficiency and<br />

reducing ergonomic stress. We discuss the challenges and solutions implemented<br />

during the development of this protocol.<br />

David Shaw, Ph.D., Scientist, Early Stage <strong>Cell</strong> Culture, Genentech, Inc.<br />

3:30 CASE STUDY • UNPUBLISHED DATA Data Integration Methodology<br />

that Leverages Coupled Bioreactor Analytics, Automated<br />

Sampling, and Applied Mathematics to Redefine Bioreactor<br />

Operation; Case Study Example Illustrating Impact on <strong>Cell</strong><br />

Culture Productivity<br />

Process analytics can provide key links between process operation and product<br />

quality by enabling better data to strategically meet dynamic nutrient requirements<br />

of cell cultures. Individual analytics tools can also be coupled using the right data<br />

integration and applied mathematics techniques to provide “real time” guidance<br />

for process design and operation. Examples are shown, including a case study<br />

linking dielectric spectroscopy frequency spectra with the onset of apoptosis,<br />

which can then be linked to changes in cell performance and productivity.<br />

Lisa J. Graham, Ph.D., P.E., Senior Vice President, Bend Research Inc.<br />

Wednesday, May 22, 2013 (continued)<br />

4:00 CASE STUDY • UNPUBLISHED DATA LC-MS/MS and Data Searching<br />

Strategies for Sequence Variance Detection<br />

Mass spectrometry provides a powerful tool for detecting low-abundance<br />

sequence variants within monoclonal antibodies. However, it is challenging<br />

to perform data analysis in a highly efficient and error-free manor. The use of<br />

currently available LC-MS instruments with high levels of sensitivity, precision<br />

and accuracy in combination with proteomic and statistical software allow<br />

for semi automation of data analysis for sequence variant analysis.<br />

Hangtian Song, Ph.D., Research Investigator I, Global Manufacturing and<br />

Supply, Bristol-Myers Squibb Co.<br />

4:30 Scale-Down Automated Purification and Protein Analytics<br />

to Facilitate <strong>Cell</strong> <strong>Line</strong> Screening/PQ Analysis<br />

Abstract not available at time of print. Please visit<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> for updates.<br />

Ling Santora, Ph.D., Senior Scientist III, AbbVie<br />

5:00 Close of Conference<br />

3EASY WAYS<br />

TO REGISTER:<br />

Industry Fees By March 1, 2013<br />

By March 29,<br />

2013 By April 26, 2013<br />

Standard Rate<br />

After April 26, 2013<br />

Main Conference Plus<br />

Dinner Symposium (Tues PM)<br />

$2299 $2399 $2499 $2699<br />

Main Conference Only $1899 $1999 $2099 $2299<br />

Academic/Govt. Fees* By March 1, 2013<br />

By March 29,<br />

Standard Rate<br />

2013 By April 26, 2013 After April 26, 2013<br />

Main Conference Plus<br />

Dinner Symposium (Tues PM)<br />

$1599 $1699 $1799 $1999<br />

Main Conference Only $1199 $1299 $1399 $1599<br />

Present a Poster to Enhance Your Conference Experience<br />

All poster presenters must be registered conference attendees. The fee to present a poster in addition<br />

to your conference registration is:<br />

Vendors/Supplier*: $300 Pharma/Biotech: $100 Academic/Government: FREE<br />

* Vendor rate is for exhibiting/sponsoring companies and/or posters that upon review are of<br />

commercial/product focus<br />

Venue and Accommodations<br />

Hyatt Regency La Jolla<br />

3777 La Jolla Village Drive, San Diego, CA<br />

Priority Code: B13189PDFWDL<br />

CALL<br />

800.390.4078 or EMAIL<br />

+1.941.554.3500 @ reg@ibcusa.com<br />

WEB<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong><br />

Special Conference Rate<br />

$229 Per Night Plus Tax<br />

Tel: 858-552-1234 • Central Reservations: 402-592-6464 or 1-888-421-1442<br />

www.lajolla.hyatt.com<br />

Please call the hotel directly at the numbers above before April 19, 2013 to be included in IBC’s dedicated<br />

room block for this conference. Please identify yourself as a participant in IBC’s <strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> and<br />

<strong>Engineering</strong> conference to receive the reduced room rate. Be sure to make you reservations as soon as possible<br />

as rooms tend to fill up very quickly and all reservations are subject to availability.<br />

Additional Registration Information<br />

For onsite registrations, please add $100.<br />

Program content and speakers subject to change. Conference badges are non-transferable and lost badges will<br />

not be replaced without payment of the full conference registration fee.<br />

Please note that payment is required in advance of the conference. Please make check(s) (in U.S. funds drawn<br />

on a U.S. bank) payable to IBC Life Sciences and attach to the registration form. Confirmation of your booking<br />

will be sent. Should you elect to pay by MasterCard, Visa or American Express, please send your credit card<br />

number, expiration date, name as it appears on card and signature along with the registration form.<br />

Registration Substitutions/Cancellations: If you need to make any changes or have any questions, please feel free to<br />

contact IBC’s customer service team via email at reg@ibcusa.com. Cancellations must be in writing and must be received<br />

by IBC prior to 10 business days before the start of the event. Upon receipt of a timely cancellation notice, IBC will issue<br />

a credit voucher for the full amount of your payment, which may be applied towards registration fees at any future IBC<br />

event held within 6 months after issuance (the “Expiration Date”). All credit vouchers shall automatically expire on the<br />

Expiration Date and shall thereupon become void. In lieu of issuance of a credit voucher, at your request, IBC will issue a<br />

refund less a $595 processing fee per registration. Registrants are advised that no credit vouchers or refunds will be issued<br />

for cancellations received 10 business days or less prior to start of the event, including cancellations due to weather or<br />

other causes beyond the Registrant’s control. IBC therefore recommends that registrants allow for unexpected delays in<br />

making travel plans. Substitutions are welcome at any time. If for any reason IBC decides to cancel this conference, IBC<br />

accepts no responsibility for covering airfare, hotel or other costs incurred by registrants, including attendees, sponsors,<br />

speakers and guests.<br />

SPECIAL NEEDS: If you have a disability or special dietary needs, please let us know in order that<br />

we may address your special needs for your attendance at this show. Please send your special<br />

needs via email to custserv@ibcusa.com. <br />

For up-to-date program information and new abstracts, visit: www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong> 7

IBC’s 9th Annual<br />

<strong>Cell</strong> <strong>Line</strong> <strong>Development</strong> & <strong>Engineering</strong><br />

May 20-22, 2013 • Hyatt Regency La Jolla at Aventine • La Jolla, CA<br />

Keynote Presentations<br />

Coordinated Oscillations in Cortical<br />

Actin and Ca(2+) Correlate with Cycles<br />

of Vesicle Secretion<br />

Roy Wollman, Ph.D.<br />

Assistant Professor,<br />

Chemistry and Biochemistry<br />

University of California San Diego<br />

Higher-Faster-Further: Why It Makes<br />

Sense to Invest in Innovation to Achieve<br />

Disruptive Improvements<br />

Torsten W. Schulz, Ph.D.<br />

Director, <strong>Cell</strong> Culture,<br />

Boehringer Ingelheim Fremont, Inc.<br />

Featured Presentations<br />

Stable Depletion of miR-7 Expression<br />

for Improved Performance of a CHO<br />

Batch-Fed Culture<br />

Niall Baron, Ph.D.<br />

Senior Research Scientist, National<br />

Institute for <strong>Cell</strong>ular Biotechnology,<br />

Dublin City University, Ireland<br />

Technology Toolbox for <strong>Cell</strong> <strong>Line</strong><br />

<strong>Development</strong> – Towards High Speed,<br />

Yield and Clonal Stability<br />

Thomas Jostock, Ph.D.<br />

Novartis Leading Scientist<br />

Novartis Pharma AG, Switzerland<br />

IBC’s 9th Annual<br />

<strong>Cell</strong> <strong>Line</strong> <strong>Development</strong><br />

& <strong>Engineering</strong><br />

May 20-22, 2013<br />

Hyatt Regency La Jolla at Aventine<br />

La Jolla, CA<br />

Improve All Aspects of Bioproduct <strong>Development</strong> by Leveraging<br />

Cutting-Edge Technical and Process Innovation<br />

“<br />

This is an outstanding venue for bringing together experts<br />

in the field, vendors, scientists and other interested parties,<br />

and the collaborative and open environment has always<br />

”<br />

been rewarding. This meeting is on my calendar every year!<br />

– Gene Lee, Ph.D., Director, Protein and <strong>Cell</strong> Sciences, EMD Serono<br />

www.IBCLifeSciences.com/<strong>Cell</strong><strong>Line</strong>