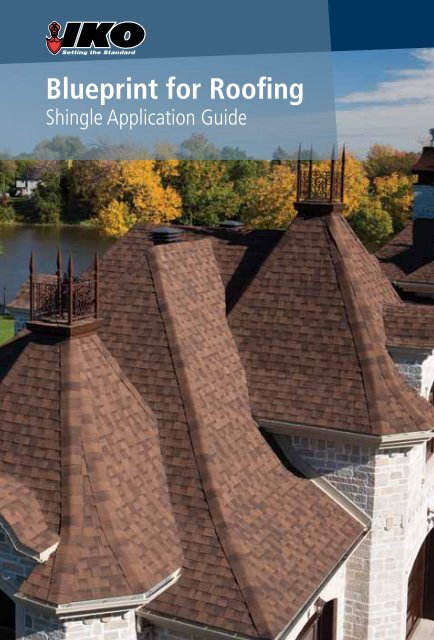

Blueprint for Roofing - Iko

Blueprint for Roofing - Iko

Blueprint for Roofing - Iko

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Blueprint</strong> <strong>for</strong> <strong>Roofing</strong><br />

Shingle Application Guide

TABLE OF CONTENTS<br />

Shingle Application Guide<br />

Table of Contents<br />

Introduction 4<br />

Part 1 Roof Types and Definitions 4<br />

Part 2 Measurements and Materials 5<br />

Part 3 Tool Requirements and Preparation 7<br />

Part 4 Safety 8<br />

Part 5 Deck Preparation and Roof Repair 9<br />

Part 6 Drip Edges, Eave Protection and Underlayment 10<br />

Part 7 Valley Construction 13<br />

Part 8 All Shingle Application 14<br />

A Armourshake Application 15<br />

B Crowne Slate Application 16<br />

C Cambridge/Grandeur Application 17<br />

D Royal Estate Application 18<br />

E Marathon Application 19<br />

Part 9 Re-<strong>Roofing</strong> 20<br />

Part 10 Low Slope - Roof-Fast Application 22<br />

Part 11 Ventilation 25<br />

Part 12 Flashings 27<br />

Part 13 Hips and Ridges 30<br />

Part 14 Inspection and Clean Up 32<br />

Part 15 Roof Care and Maintenance 32<br />

Part 16 Products 32<br />

Glossary 36<br />

3

INTRODUCTION<br />

Introduction<br />

You can re-roof your own home with the help of this easy-to-follow<br />

visual presentation.<br />

Using a simplified step-by-step approach, you may be able to save the cost of contract labor<br />

and still obtain professional results—along with the personal satisfaction of a job well done.<br />

Here’s what you do!<br />

• Play the program modules through completely.<br />

• Play them a second time and compare the in<strong>for</strong>mation with the installation<br />

instructions printed on the bundle wrappers and in<strong>for</strong>mation available through<br />

our website, www.iko.com.<br />

If you are a professional roofing contractor, consider joining IKO’s Shield Pro Plus<br />

Contractor Program that has been developed to help increase sales, become more profitable<br />

and expand your business opportunities; this program will help set you apart from your<br />

competitors. As a member of the elite Shield Pro Plus program, you will be given exclusive<br />

access to IKO’s Extended Iron Clad Protection, customized marketing tools to assist in<br />

promoting your business and an online tool with the ability to order warranties and access<br />

training tools from the com<strong>for</strong>t of your office. For additional in<strong>for</strong>mation or to obtain an<br />

enrollment package, please contact your local IKO sales representative.<br />

Note: All safety guidelines outlined by Government Safety and Fall<br />

Protection standards must be followed at all times.<br />

Part 1<br />

Roof Types and Definitions<br />

Most homes will have one of these roof styles:<br />

The Shed Roof<br />

The Hip Roof or Cottage<br />

Roof<br />

The Gable Roof<br />

The Gambrel Roof<br />

Every roof has similar features. For example, the ridge is at the top.<br />

The eaves are the horizontal, lower edges of a sloped roof. The hip runs from the ridge to<br />

the eaves on a Cottage Style Roof. A valley is the intersection of two sloping roof planes.<br />

4

Measurements and Materials PART 2<br />

Rake Edges<br />

Ridges<br />

Valleys & Dormers<br />

Hips<br />

Low Pitch Areas<br />

Eaves<br />

Part 2<br />

Measurements and Materials<br />

Calculations <strong>for</strong> square footage of the roofing surface can be made by<br />

simply adding up the areas of the various roof sections.<br />

The sum of the total area is then divided by the coverage of each bundle of shingles.<br />

Typically, an average 3-tab bundle covers 3 m 2 (32.3 square feet), while our architectural<br />

shingle bundles vary between 1.86 m 2 and 3.1 m 2 (20 and 33.3 square feet). It is advisable to<br />

add ten to fifteen percent to this area <strong>for</strong> material waste or loss based on your roof style.<br />

When using underlayment, the square measure of the roof may be used again to determine<br />

the number of rolls of underlayment required. We recommend our Number 15 Plain<br />

Asphalt Felt or RoofGard-SB or RoofGard-Cool Grey synthetic underlayment <strong>for</strong> this job.<br />

Drip Edging requirements are determined by measuring the lengths of the eaves and rake<br />

edges. An open metal valley flashing is recommended <strong>for</strong> the protection of valley areas.<br />

Depending on the roof design and the shingle chosen, closed cut and woven valleys may<br />

also be acceptable.<br />

A “pitch finder” tool can also be useful to measure the slope of the roof. You can<br />

determine the roof area by measuring the horizontal area of the roof or attic floor, and then<br />

multiplying by a factor which compensates <strong>for</strong> the slope of a roof.<br />

For ice dam protection along the eaves (or anywhere that is susceptible to water<br />

penetration), you’ll need IKO’s GoldShield Premium Ice & Water Protector, ArmourGard<br />

Ice & Water Protector, or StormShield Standard Ice & Water Protector. Asphalt plastic<br />

cement is used to seal at vents, stacks, or chimneys.<br />

5

PART 2<br />

Measurements and Materials<br />

IKO’s Ice & Water Protectors are modified<br />

bitumen roll roofing products with a<br />

self-adhesive backing that, once applied<br />

correctly, will provide superior protection<br />

against wind-driven rain and ice dams.<br />

Galvanized roofing nails are the best fastener to use <strong>for</strong> roofing, and they should be long<br />

enough to penetrate through the shingles and into the deck approximately 19 mm (¾")<br />

and through the deck if it is plywood or OSB. Nails no less than 6 mm (¼") longer will be<br />

required <strong>for</strong> capping the hips and ridges.<br />

IKO recommends our PRO 4 <strong>Roofing</strong> system. Shingles alone are sometimes not enough<br />

to protect your home. IKO has developed a superior multi-layered roofing system<br />

incorporating our industry-leading products. IKO’s Pro 4 <strong>Roofing</strong> System is setting the<br />

standard in protecting your home.<br />

IKO’s Shingles - Crowne Slate, Armourshake, Royal Estate, Cambridge, Grandeur and<br />

Marathon shingles are created using the industry’s most advanced technology and selected<br />

by consumers who demand the best in terms of quality, durability and value. Along with<br />

one of IKO’s quality shingles, your Pro 4 System includes these accessory products;<br />

• Eave Protection - GoldShield, ArmourGard, or StormShield Ice & Water<br />

Protectors. IKO’s Ice & Water Protectors provide a second line of defense against<br />

water penetration due to ice dams or wind-driven rain and the costly damage it<br />

can cause. This product is strongly recommended <strong>for</strong> sealing around vents, low<br />

pitch areas, ridges, hips, rake edges, chimneys, dormers, vent stacks, and skylights.<br />

• Underlayment - Asphalt Saturated Felt, RoofGard-SB or RoofGard-Cool Grey<br />

Underlayments, Use an asphalt saturated felt underlayment, or our innovative<br />

RoofGard-SB or RoofGard‐Cool Grey synthetic underlayment <strong>for</strong> total deck<br />

protection.<br />

• Roof Starters - Leading Edge Plus Starter Strips. Fast, Easy and Convenient.<br />

IKO’s Starter Strips are already cut to size saving valuable time during the<br />

installation of the first course of shingles. Compatible with all existing IKO<br />

Shingles, Leading Edge Plus includes a sealant strip at the bottom edge allowing<br />

<strong>for</strong> a tight seal.<br />

6

Tool Requirements and Preparation PART 3<br />

• Ridge Cap Shingles - Hip and Ridge, Hip & Ridge 12 Cap Shingles or Ultra HP TM<br />

High Profile Ridge Cap Shingles. Ridge cap shingles are required where roof<br />

planes meet, and provide additional protection along these high stress areas of the<br />

roof, enhancing your home’s aesthetic appeal by accentuating the roof line.<br />

Part 3<br />

Tool Requirements and Preparation<br />

Proper and safe tools are the key to any successful job.<br />

• Ladders should always be sturdy and long enough to reach the roof area at the<br />

proper angle, approximately one quarter of the vertical height out from the wall<br />

and should extend about 1 m (3') above the eaves. Make sure your ladder or<br />

scaffolding is tied off at the roof edge and all locking devices are secured.<br />

• Vertical and horizontal chalk lines are applied to ensure accurate shingle<br />

alignment over the roof surface.<br />

• The roofing knife blade is hooked <strong>for</strong> cutting and fitting asphalt shingles.<br />

• The hammer may either be a well-balanced claw hammer or a specially designed<br />

roofer’s hatchet.<br />

• You will also need a nail apron and perhaps a pair of knee pads.<br />

• A caulking gun, putty knife or pointed trowel are used <strong>for</strong> applying the asphalt<br />

plastic cement.<br />

• Tin snips will be used to cut metal flashing materials. 7

PART 4<br />

Safety<br />

• A circular saw may be required <strong>for</strong> repairing or replacing damaged decking.<br />

• A pry-bar is a handy tool <strong>for</strong> lifting hard to get at shingles and flashings.<br />

• A square-edge shovel or pitch <strong>for</strong>k is an excellent tool <strong>for</strong> removing old shingles.<br />

• Galvanized roofing nails are the best fastener to use <strong>for</strong> roofing ensuring that they<br />

are driven straight so that the nail head is flush with the shingle surface.<br />

• Protect shrubbery, air conditioners, bay windows or other protrusions from falling<br />

debris by using tarps or sheets of plywood.<br />

• And a good-sized waste receptacle should be placed conveniently below the area<br />

being worked on.<br />

Be aware of those working with and<br />

around you. Make sure that everyone<br />

knows how to properly use the tools of<br />

trade, both manual and power.<br />

Part 4<br />

Safety<br />

Proper preparation and careful attention to what you are doing are important<br />

considerations <strong>for</strong> any undertaking. Learn and adhere to Government Safety and Fall<br />

Protection standards. Certain jurisdictions may require the shingle applicator to use fall<br />

arrest safety equipment when on roofs of certain heights and slopes. IKO recommends<br />

contacting your local building or labor department <strong>for</strong> more in<strong>for</strong>mation.<br />

Inspect the job site <strong>for</strong> possible hazards such as unstable ground conditions, or overhead<br />

electrical lines. Do not attempt to work in bad weather or on wet or icy surfaces.<br />

Beware of those working around you. Make sure that everyone knows how to properly use<br />

the tools of the trade, both manual and power.<br />

Keep your safety equipment clean and in good working order. When not in use, store your<br />

equipment in a safe place.<br />

8

Deck Preparation and Roof Repair PART 5<br />

Keep your safety equipment clean and in working<br />

order. When not in use, store your equipment in a<br />

safe place. You will want to be able to tie-off on<br />

steep roofs without worrying that a frayed rope or<br />

strap will break.<br />

Make sure you have proper footwear <strong>for</strong> good traction. Rubber-soled shoes are best. And<br />

never work alone. Avoid leaning away from the ladder to work and remember to tie it off<br />

to the eaves troughing each time it is moved. Keep the work area free of debris, which is a<br />

constant tripping hazard. Consider a trained professional roofer if the roof is steep!<br />

Note: All safety guidelines outlined by Government Safety and Fall<br />

Protection standards must be followed at all times.<br />

Part 5<br />

Deck Preparation and Roof Repair<br />

If the old shingles are to be removed, it’s recommended to strip one roof plane at a time and<br />

work in these sections through all steps up to and including the roof shingles. Start on the<br />

section farthest from the disposal bin so as not to walk on newly laid shingles.<br />

The deck must be dry <strong>for</strong> the job.<br />

Be sure that all old nails are removed or hammered down flush to the deck surface. It is<br />

essential to make all necessary repairs to the existing roof deck. A warped or uneven surface<br />

is difficult to work with during the re-roofing job and creates an unprofessional looking<br />

finished project.<br />

The deck should be applied in a staggered pattern bridged across roof rafters or roof<br />

trusses. Replace rotted, damaged, or warped sheathing or delaminated plywood as it can<br />

cause shingles to distort and/or buckle. If the entire deck is to be replaced, check the<br />

building codes to determine the required thickness and type of sheathing required in your<br />

municipality. Dimensional lumber is subject to expansion and contraction caused by<br />

temperature and humidity changes.<br />

9

PART 6<br />

Drip Edges, Eave Protection and Underlayment<br />

A deck built with plywood panels<br />

generally works well with asphalt<br />

shingles.<br />

To avoid buckling shingles, you should cover a dimensional deck with an<br />

inexpensive sheathing. Our Asphalt Shingle Limited Warranty does not<br />

cover buckling.<br />

Bad decks can cause shingles to distort<br />

and/or buckle.<br />

Soil stack and vent flashings can be used again if they’re in good condition, but you should<br />

consider replacing them with new ones.<br />

Part 6<br />

Drip Edges, Eave Protection and Underlayment<br />

Metal or plastic drip edge material nailed every 300 mm (12") may be applied to protect<br />

wooden edges from damage and to facilitate water run-off into the eavestrough.<br />

Note that IKO’s Pro 4 <strong>Roofing</strong> System recommends that along with IKO’s shingles,<br />

accessory items be utilized to ensure roof per<strong>for</strong>ms to its maximum capacity. Eave<br />

protection and underlayment are recommended components to the multi-layered system.<br />

Apply IKO’s GoldShield Premium Ice & Water Protector, ArmourGard Ice & Water<br />

Protector, or StormShield Standard Ice & Water Protector as ice dam protection along<br />

the eaves. For ideal protection, Ice & Water Protector should extend up the roof, 610 mm<br />

10

Drip Edges, Eave Protection and Underlayment PART 6<br />

(24") from the inside face of the exterior wall and over the drip edging. However, it<br />

is recommended to check your local building codes as it may require the Ice & Water<br />

Protector to extend further up the roof.<br />

Ice dams <strong>for</strong>m when melted snow runs down the roof to the eaves and freezes again, which<br />

<strong>for</strong>ces water back up underneath the shingles. Eave protection carries any water which<br />

backs up through the shingle and to the gutter.<br />

Ice dam.<br />

Trapped water.<br />

Melting snow.<br />

Ice dams <strong>for</strong>m when<br />

melted snow runs down<br />

the roof to the eaves<br />

and freezes again, which<br />

<strong>for</strong>ce water back up<br />

underneath the shingles.<br />

Eave protection carries any<br />

water which backs up through<br />

the shingles to the gutter.<br />

Inside face of stud.<br />

To apply StormShield and ArmourGard Ice & Water Protectors:<br />

1. Cut the membrane into 3 m to 4.5 m (10' to 15') lengths.<br />

2. Unroll and align with the lower edge of roof and tack top edge with four equally<br />

spaced temporary fasteners.<br />

3. Lift the lower half and remove the lower release film, exposing the adhesive surface.<br />

Carefully reposition the membrane down onto the deck and press firmly in place.<br />

Avoid wrinkles. Remove temporary fasteners.<br />

4. Fold top half down and remove release film. Carefully reposition the membrane up<br />

onto the deck and press firmly in place.<br />

To apply GoldShield Ice & Water Protector:<br />

1. Cut the membrane into 3 m to 4.5 m (10' to 15') lengths and reroll. Carefully slit<br />

the release paper on a 45° angle. Fold back the release paper exposing the adhesive<br />

backing. This corner will be used to hold the material in place as you begin installation.<br />

2. Unroll the next piece of material ensuring that there is an overlap of 90 mm (3 ½") Do<br />

not remove release film at this time. Unroll 1 m - 2 m (3' - 6') of membrane.<br />

3. Carefully slit the release paper at the top of the roll. DO NOT CUT THROUGH THE<br />

MEMBRANE.<br />

11

PART 6<br />

Drip Edges, Eave Protection and Underlayment<br />

4. Peel back approximately 150 mm (6") of the release paper to expose the adhesive. Peel<br />

the release paper in the opposite direction that you are applying the membrane.<br />

5. Pull the release paper in the direction that you are applying the membrane, applying<br />

pressure to the membrane as you proceed. The membrane will adhere to the deck.<br />

6. Once you have finished laying the membrane, go back to the beginning of the roll, and<br />

pull off the release paper at that end.<br />

Next, install the underlayment, overlapping the ice and water protector by 100 mm (4").<br />

Please note that a felt or synthetic underlayment, or equivalent, is strongly recommended<br />

beneath fiberglass shingles applied to slopes below 6:12. Please refer to the IKO Asphalt<br />

Shingle Limited Warranty or the bundle wrappers <strong>for</strong> further details.<br />

Underlayment comes in rolls. It must be unrolled, cut to convenient lengths, and laid out<br />

flat until completely relaxed be<strong>for</strong>e shingles are applied over it.<br />

Water resistant underlayment felts are<br />

recommended <strong>for</strong> a sound roofing system.<br />

Use only enough nails or staples to hold each run in place, overlapping the course below<br />

by approximately 50 mm (2") (100 mm (4") <strong>for</strong> RoofGard-SB or Cool-Grey) and ends by<br />

100 mm (4"). Never use a piece less than 2 m (6') in length. Underlayment should overlap<br />

hips and ridges by 150 mm (6"), and approximately 100 mm (4") extensions should be left at<br />

the chimney and any vertical projection from the roof surface.<br />

Apply metal drip edges over the underlayment at the rake edges.<br />

For slopes between 2:12 and 4:12, that is between 50 mm (2") of rise to 300 mm (12") of run<br />

and 100 mm (4") of rise to 300 mm (12") of run, shingles may be applied. However, in order<br />

to validate the Asphalt Shingle Limited Warranty, a full layer of an Ice & Water Protector or<br />

two layers of number 15 plain felt, cemented together to 610 mm (24") beyond the interior<br />

wall line, and then nailed <strong>for</strong> the rest of the roof, must be applied to roofs of these slopes.<br />

For shingled roof slopes between 2:12 and 3:12, we offer a 12-Year Limited Warranty,<br />

regardless of the shingle applied. If this same application procedure is followed <strong>for</strong> roof<br />

slopes between 3:12 and 4:12, a full Limited Material Warranty will be offered.<br />

12<br />

Do not apply Crowne Slate on a slope 4:12 or less.

Valley Construction PART 7<br />

Please note that IKO’s Ice & Water Protectors are vapor retarders. The space under the roof<br />

deck must be properly ventilated to avoid moisture condensation.<br />

Drip edge.<br />

483 mm<br />

(19")<br />

Courses cemented<br />

to a point at least<br />

610 mm (24")<br />

beyond interior<br />

wall line.<br />

914 mm (36")<br />

483 mm (19")<br />

Wall line.<br />

483 mm (19")<br />

430 mm (17")<br />

Deck.<br />

483 mm<br />

(19")<br />

Drip edge.<br />

Starter strip.<br />

Asphalt plastic cement<br />

or lap cement.<br />

305 mm (12") end lap.<br />

First and succeeding courses<br />

are 914 mm (36") wide with<br />

483 mm (19") lap.<br />

Application of<br />

underlayment on<br />

low slopes.<br />

Part 7<br />

Valley Construction<br />

There are several different valley application methods which include<br />

closed, open and woven.<br />

For longer roof per<strong>for</strong>mance, IKO strongly recommends open metal valleys. Complete<br />

the application of underlayment and valley flashing be<strong>for</strong>e the shingles are applied. The<br />

recommended flashing material is a 28-gauge galvanized metal or an equivalent corrosion<br />

resistant, non staining material (check with local codes). Center a 914 mm (36") width<br />

strip of an ice and water protector membrane in the valley. The product is tacked in place<br />

temporarily along one edge. Carefully peel away the backing, and put it in place, smoothing<br />

out any wrinkles. Start working from the eave, allowing additional pieces to overlap by at<br />

least 150 mm (6"). Remove the temporary nails.<br />

Center a minimum 610 mm (24") wide, minimum 28 gauge pre-finished/galvanized metal<br />

valley liner in the valley, and fasten with only enough nails to hold it in place, nailing at<br />

the edges only. Overlap each metal piece by at least 150 mm (6") and use asphalt plastic<br />

cement under each section of overlap. Snap two chalk lines the full length of the valley,<br />

150 mm (6") apart at the top 75 mm (3") on each side of the valley and increasing in width<br />

3 mm (⅛") per 300 mm (12") towards the bottom to a maximum of 200 mm (8"). When the<br />

shingles are being applied, lay them over the valley flashing, trim the ends to the chalk line<br />

and nail the shingles at least 50 mm (2") back from the chalk line. Cut a 50 mm (2") triangle<br />

off the top corner to direct water into the valley and embed the valley end of each shingle<br />

into a 75 mm (3") band of asphalt plastic cement.<br />

13

PART 8<br />

All Shingle Application<br />

Valley underlayment<br />

Underlayment<br />

Chalk lines<br />

diverge 3 mm<br />

per 300 mm<br />

(⅛" par 12")<br />

Asphalt plastic cement<br />

Valley centerline<br />

Metal valley flashing<br />

300 mm (12") top lap<br />

50 mm (2") clipped<br />

off corner at 45°<br />

Open Valley Application.<br />

End shingles trimmed to chalk<br />

line and set in 75 mm (3") width<br />

of cement<br />

Part 8<br />

All Shingle Application<br />

Whether you are applying Architectural or Traditional 3-Tab Shingles, it is recommended that<br />

you read and familiarize yourself with the application instructions provided on the back of each<br />

shingle wrapper. One cannot go wrong if those instructions are adhered to during the installation<br />

of IKO shingles. Although all types, styles, and sizes have a commonality to their application, each<br />

will have an individual installation feature that you must familiarize yourself with.<br />

Remember to always drive nails straight so that nail head is flush with, but not cutting into shingle<br />

surface. Also, if nail heads are left protruding, they can tear into the shingle that is applied on top<br />

of them.<br />

Starter Strip Application:<br />

For the starter strip, we recommend using IKO’s Leading Edge Plus, a starter course that has<br />

already been cut to size. Each 1 m (39 ⅜") x 337 mm (13 ¼") IKO Leading Edge Plus strip is<br />

per<strong>for</strong>ated lengthwise <strong>for</strong> separation into two (2) shingles.<br />

Note that IKO’s Pro 4 <strong>Roofing</strong> System recommends that along with IKO’s shingles, accessory<br />

items be utilized to ensure roof per<strong>for</strong>ms to its maximum capacity. Starter strips are<br />

recommended component to the multi-layered system.<br />

Take one IKO Leading Edge Plus strip and fold flat at the per<strong>for</strong>ation to separate. Take one of the<br />

separated shingles and remove approximately 508 mm (20"). Install this shingle on the lower left<br />

corner of the roof deck, granule side up, with the factory installed sealant adjacent to the eaves.<br />

14

Armourshake Application<br />

PART 8A<br />

The shingle should overhang the rake edge and eaves by 6 mm - 10 mm (¼" – ⅜"). Fasten<br />

the shingle to the roof deck with nails located 75 mm to 100 mm (3" to 4") from the eave<br />

edge and 25 mm (1") in from each end.<br />

Take the leftover 508 mm (20") piece shingle. Rotate the piece and align it vertically up<br />

the rake edge with the factory installed sealant adjacent to the outer edge of the roof. The<br />

shingle should overhang the rake edge by 6 mm - 10 mm (¼" – ⅜"). Fasten the shingle to<br />

the roof deck with fasteners located 75 mm to 100 mm (3" to 4") from the rake edge and<br />

25 mm (1") in from each end.<br />

Repeat these steps to the right lower corner of the roof deck. Apply full-length IKO Leading<br />

Edge Plus shingles to the remaining eave edge of the roof deck. Install the shingles granule<br />

side up with the factory applied sealant adjacent to the eaves. The shingles should overhang<br />

the rake edge and eaves by 6 mm - 10 mm (¼" – ⅜"). Fasten the shingles to the roof deck<br />

with nails located 75 mm to 100 mm (3" to 4") from the eave edge, 4 nails per shingle.<br />

Make certain the first course of field shingle lies flush with the edges of the fastened IKO<br />

Leading Edge Plus. In this way, the sealant on the IKO Leading Edge Plus shingles will<br />

adhere to the first-course field shingles and help keep them from lifting in high winds.<br />

As a general rule, all shingles must be applied properly. We assume no responsibility <strong>for</strong><br />

leaks or defects resulting from poor application or failure to properly prepare the surface<br />

to be roofed over, or failure to provide proper ventilation in accordance with minimum<br />

property standards requirements. Review all applicable building codes, minimum property<br />

standards and requirements prior to applying these shingles using the application<br />

instructions found on the bundle wrapper. Please use caution when stacking bundles on<br />

sloped roofs.<br />

Part 8A<br />

Armourshake Application<br />

Armour Starter Application:<br />

After applying the Leading Edge Plus starter strip shingle, install the Armour Starter shingle<br />

starting on the lower left corner of the roof deck, granule side up. Apply full-length IKO<br />

Armour Starter shingles to the eave edge of the roof deck. Make certain the Armour Starter<br />

shingles lie flush with the edges of the fastened IKO Leading Edge Plus.<br />

Armourshake Application:<br />

First Course: Start with a full shingle. Trim the rake end of the shingle slightly so it is flush<br />

with the rake. Apply the shingle flush with starter course at rake and eaves. Use 5 nails per<br />

shingle in the nail line approximately 25 mm (1") from each end and equally spaced along<br />

the shingle’s full length. Drive nails straight so that the nail head is flush with, but not<br />

cutting into, the shingle surface.<br />

15

PART 8B<br />

Crowne Slate Application<br />

Second Course: Start with a shingle from which 143 mm (5 ⅝") has been cut at the rake<br />

end. Align the end of the shingle with the alignment notch in the top edge of the first course<br />

shingle. Continue with full shingles along the second course.<br />

Third Course: Start with a shingle from which 286 mm (11 ¼") has been cut at the rake end.<br />

Use the appropriate alignment notch in the top edge of the second course shingle. Continue<br />

with full shingles along the third course.<br />

Fourth Course: Start with a shingle from which 429 mm (16 ⅞") has been cut at the rake<br />

end. Use the appropriate alignment notch in the top edge of the third course shingle.<br />

Continue with full shingles along the fourth course.<br />

Fifth Course: Start with a shingle from which 572 mm (22 ½") has been cut at the rake end.<br />

Use the appropriate alignment notch in the top edge of the fourth course shingle. Continue<br />

with full shingles along the fifth course.<br />

Sixth Course: Start with a shingle from which 714 mm (28 ⅛") has been cut at the rake end.<br />

Use the appropriate alignment notch in the top edge of the fifth course shingle. Continue<br />

with full shingles along the sixth course.<br />

Successive Courses: Repeat this pattern: Full shingle cut flush, 143 mm (5 ⅝") removed,<br />

286 mm (11 ¼") removed, 429 mm (16 ⅞") removed, 572 mm (22 ½") removed, 714 mm<br />

(28 ⅛") removed, full shingle cut flush, 143 mm (5 ⅝") removed, 286 mm (11 ¼") removed,<br />

429 mm (16 ⅞") removed, 571 mm (22 ½") removed, 714 mm (28 ⅛") removed etc.<br />

For added wind protection, use 6 nails per shingle and seal down each shingle with (3)<br />

25 mm (1") diameter spots of asphalt plastic cement placed under each tab.<br />

Underlayment<br />

Metal<br />

Drip<br />

Edge<br />

50 mm (2")<br />

100 mm (4")<br />

ArmourShake<br />

Shingle Application.<br />

Eave protection<br />

Metal Drip Edge<br />

Part 8B<br />

Crowne Slate Application<br />

16<br />

Due to shingle design, it is recommended to begin application at the left side of the roof and<br />

work across the roof to the right. This is a fully laminated two-layer shingle. Shingles should<br />

be laid flat (not bent) prior to installation to avoid distortions and buckles.<br />

First Course: Starting from the left rake edge, trim 229 mm (9") (one full tab) from the<br />

end of the shingle so that the tab is flush with the rake edge. Apply the shingle flush with

Cambridge/Grandeur Application<br />

PART 8C<br />

starter course at left rake edge and eaves. Use 5 nails per shingle placed in the nail line<br />

approximately 25 mm (1") in from each end and equally spaced along the shingle’s full<br />

length. Drive nails straight so that the nail head is flush with, but not cutting into, shingle<br />

surface. Continue across the roof with full shingles, overlapping each shingle as you<br />

proceed.<br />

Second Course: Start with a shingle from which one and one half tabs has been cut at the<br />

rake end. Apply with lower edge of the shingle 250 mm (10") above that of the first course.<br />

There are small shingle alignment slits at the sides and in the top edge of the shingle to aid<br />

installation, but chalk lines should always be used to ensure proper offset.<br />

Third and Succeeding Courses: Start the third course with a shingle from which two full<br />

tabs have been cut off. Cut off an additional half a tab to start each succeeding course,<br />

aligning the lower edge of the shingle 250 mm (10") above that of the preceding course.<br />

At the fifth course, repeat the sequence of the first four courses. For maximum wind<br />

protection, cement shingles at the rake edges.<br />

For added wind protection, use 8 nails per shingle and seal down each shingle with (5)<br />

25 mm (1") diameter spots of asphalt plastic cement spaced as shown on the shingle bundle<br />

wrapper.<br />

Crowne Slate<br />

Shingle Application.<br />

Part 8C<br />

Cambridge/Grandeur Application<br />

Note that these brands, Cambridge and Grandeur, are the same size so<br />

we will discuss installation collectively.<br />

First Course: Start with a complete shingle applied flush with starter course at rake and<br />

eave. Use 4 nails per shingle placed in the nail line 187 mm (7 ⅜") below the top edge,<br />

approximately 25 mm (1") and 330 mm (13") in from each end. Drive nails straight so that<br />

nail head is flush with, but not cutting into shingle surface. Continue across roof with full<br />

shingles.<br />

Second, Third and Fourth Courses: Trim off 250 mm, 508 mm, and 762 mm (10", 20",<br />

and 30") respectively, from the left end of the starting shingle and apply to overhang rake<br />

edge by 6 mm to 10 mm (¼" to ⅜"). Continue each course across the roof with full shingles<br />

butting ends loosely. Align the bottom edge of the shingles with the tops of the saw teeth of<br />

the shingles in the underlying course.<br />

Fifth and Succeeding Courses: Repeat the sequence of the first four courses up the roof. For<br />

maximum wind protection, cement shingles at rake edges.<br />

17

PART 8D<br />

Royal Estate Application<br />

For added wind protection, use 6 nails per shingle and seal down each shingle with (3)<br />

25 mm (1") diameter spots of asphalt plastic cement spaced evenly along the shingle.<br />

2nd, 3rd<br />

and 4th<br />

courses<br />

100 mm<br />

(4")<br />

760 mm<br />

50 mm (2")<br />

(30")<br />

508 mm<br />

(20")<br />

Eave protection<br />

250 mm<br />

(10")<br />

Underlayment<br />

Metal drip<br />

edge<br />

Laminated Shingle<br />

Application.<br />

First course<br />

Starter strip<br />

Part 8D<br />

Royal Estate Application<br />

First Course: Start with a complete shingle applied flush with starter course at rake and<br />

eave. Use 4 nails per shingle placed in the nail line 181 mm (7 ⅛") below the top edge,<br />

approx. 25 mm and 330 mm (1" and 13") in from each end. Drive nails straight so that nail<br />

head is flush with, but not cutting into shingle surface.<br />

Second, Third And Fourth Courses: Trim off 250 mm, 508 mm, and 762 mm (10", 20",<br />

and 30") respectively, from the left end of the starting shingle and apply to overhang rake<br />

edge by 6 mm to 10 mm (¼" to ⅜"). Continue each course across the roof with full shingles<br />

butting ends loosely. Align the bottom edge of the shingles with the tops of the cutouts of<br />

the shingles in the underlying course.<br />

Fifth And Succeeding Courses: Repeat the sequence of the first four courses up the roof.<br />

For maximum wind protection, cement shingles at rake edges.<br />

For added wind protection, use 6 nails per shingle and seal down each shingle with (3)<br />

25 mm (1") diameter spots of asphalt plastic cement spaced evenly along the shingle.<br />

Underlayment<br />

100 mm (4")<br />

50 mm (2")<br />

Royal Estate<br />

4th course<br />

3rd course<br />

2nd course<br />

First course<br />

Eave protection<br />

760 mm (30")<br />

508 mm (20")<br />

250 mm (10")<br />

Starter strip<br />

Shingle<br />

Application.<br />

Metal drip<br />

edge<br />

18

Marathon Application<br />

PART 8E<br />

Part 8E<br />

Marathon Application<br />

There are several approved offset methods <strong>for</strong> applying 3-Tab shingles.<br />

Half Tab Method<br />

There is the half tab method whereby each course after the first, has an additional half of a<br />

tab removed on the rake side, until it’s time to start over with a full shingle to complete the<br />

succeeding courses. It is important to note that the proper exposure <strong>for</strong> the 3-Tab shingle<br />

starts at the top of the cut-out and works down to the most exposed edge of the shingle.<br />

Exposing more or less than what is recommended could result in wind damage or leaks<br />

that are not protected by the Limited Warranty. This method can be employed when it is<br />

necessary <strong>for</strong> the cut-outs of every other course to be aligned vertically up the roof. When<br />

nailing 3-Tab shingles, use 4 nails per shingle placed 156 mm (6 ⅛") above the butt edge,<br />

25 mm and 330 mm (1" and 13") in from each end and 13 mm (½") above each cutout.<br />

Drive nails straight so that nail head is flush with, but not cutting into shingle surface.<br />

Metal drip edge<br />

Sealing strip<br />

Start third course<br />

with full strip<br />

minus first tab<br />

Start second course with<br />

full strip minus ½ tab<br />

Wood deck<br />

Eaves flashing strip<br />

Drip edge<br />

Starter full shingle<br />

minus 100 mm (4")<br />

with tabs cut-off<br />

Start first course<br />

with full strip<br />

3-Tab Shingle<br />

Application.<br />

Random Method<br />

A superior method of applying 3-Tab shingles (instead of taking a half tab, or approximately<br />

168 mm (6 ⅝") additional off of the shingle <strong>for</strong> each succeeding course after the first), allows<br />

the installer to remove approximately 143 mm (5 ⅝") additional from each succeeding<br />

course. There<strong>for</strong>e, the third course will have 286 mm (11 ¼") removed from the rake side<br />

of the shingle, the fourth course will have 429 mm (16 ⅞") removed, the fifth course will<br />

have 572 mm (22 ½") removed, the sixth course will have 714 mm (28 ⅛") removed, and<br />

the seventh course first shingle will be reduced by 857 mm (33 ¾"). Of course all of this<br />

measuring can be done with the aid of the gauge on your roofing hatchet or power nailer<br />

fixed at the shingle exposure of 143 mm (5 ⅝").<br />

19

PART 9<br />

Re-<strong>Roofing</strong><br />

This method of application has a significant advantage over the half tab method. This<br />

method will mask any small variations in the shingle alignment that are due to variations in<br />

deck squareness, normal production or shingle application processes.<br />

Please remind yourself that under no circumstance do you want the cut-outs of the shingles<br />

to be closer than 100 mm (4") when aligned with the next course both above and below. As<br />

well, you do not want the joints of the starter strips to be any closer than 100 mm (4") to the<br />

joints or cut-outs of the shingles in the first course.<br />

The random spacing method of applying 3-Tab shingles can be achieved by removing<br />

differing amounts from the rake tab. Generally, the following principles should be followed.<br />

• The width of any tab should be no less than ¼ of the overall dimension of that tab.<br />

• The cut-outs should not be located any less than 100 mm (4") laterally from the<br />

cut-outs in both the course above and the course below.<br />

• The width of the tabs at the rake must not repeat close enough to cause the eye to<br />

be able to follow a cut-out alignment.<br />

As an example, the first course can be a full shingle tab wide. The second course can start<br />

with ½ of the rake side tab being removed. The third course can start with ¼ of the rake<br />

side tab removed. The fourth course can start with ¾ of the rake side tab removed. The fifth<br />

course can be started with another ½ tab to the rake side.<br />

For added wind protection, use 6 nails per shingle and seal down each shingle with (3)<br />

25 mm (1") diameter spots of asphalt plastic cement spaced evenly along the shingle.<br />

Part 9<br />

Re-<strong>Roofing</strong><br />

If you feel that your roof deck is in good condition and needs no repair,<br />

you can re-roof over the existing layer of shingles. For best results, we<br />

recommend a technique called “nesting”.<br />

However, it is advised that you check your local building codes to ensure re-roofing over<br />

existing shingles is allowed <strong>for</strong> your area.<br />

Nesting, which minimizes an uneven appearance that can be caused by the underlying<br />

material, may also be used when applying metric-sized shingles over an existing roof of<br />

metric shingles.<br />

20

Re-<strong>Roofing</strong> PART 9<br />

If the old shingles have only a 125 mm (5") exposure, you will require 12.5% or ⅛ more<br />

3-tabs than you would if you stripped off to the deck.<br />

Begin with a “starter” strip. Remove the tabs plus enough from the top of the starter strip so<br />

that the remaining portion is equal in width to the exposure of the old shingles.<br />

Apply the starter strip so that it is even with the existing roof at the eaves, locating the<br />

factory applied adhesive along the eaves edge.<br />

Remove 100 mm (4") from the end of the first starter strip shingle to ensure that joints<br />

between adjacent starter strip shingles will be covered when the first course is applied.<br />

For the first course, you need to trim enough material from the bottom of the shingles to<br />

allow them to fit between the bottom of the tabs of the old third course and the eave edge of<br />

the new starter strip.<br />

Start with a full length shingle. Use 4 nails per shingle placed per the respective shingle’s<br />

application instructions. In this case, <strong>for</strong> Cambridge, that would be in the nailing line. You<br />

will require slightly longer nails, in order to penetrate through the old shingles and the roof<br />

deck.<br />

For the second and all succeeding courses, offset the shingles as you would <strong>for</strong> installation<br />

on a new deck.<br />

Place the top edge of the new shingle against the bottom edge of the tabs of the old shingle<br />

in the course above.<br />

Although the exposure of the first course is reduced when using this method, this will not<br />

be noticeable when viewed from the ground.<br />

For valleys, you must first build up the exposed valley area with Roof-Fast to a level flush<br />

with the old shingles.<br />

Center a minimum 610 mm (24") wide, minimum 28 gauge pre-finished/galvanized metal<br />

valley liner in the valley, and fasten with only enough nails to hold it in place, nailing at<br />

the edges only. Overlap each metal piece by at least 150 mm (6") and use asphalt plastic<br />

cement under each section of overlap. Snap two chalk lines the full length of the valley,<br />

150 mm (6") apart at the top and increasing in width 3 mm (⅛") per 300 mm (12") towards<br />

the bottom to a maximum of 200 mm (8"). When the shingles are being applied, lay them<br />

over the valley flashing, trim the ends to the chalk line, and cut a 50 mm (2") triangle off<br />

the top corner to direct water into the valley. Embed the valley end of each shingle into a<br />

75 mm (3") band of asphalt plastic cement, and nail the shingles 50 mm (2") back from the<br />

chalk line.<br />

21

PART 10<br />

Low Slope - Roof-Fast Application<br />

Special attention is required when working with existing flashings.<br />

If the existing flashing is in good condition, continue applying the new shingles over the<br />

existing shingles. Trim the new shingles to within 6 mm (¼") of the existing step flashing.<br />

Embed the last 75 mm (3") of these shingles in asphalt plastic cement.<br />

If the flashings need to be replaced, remove the counter flashing, cut away the old shingles<br />

covering the step flashings, and remove the flashing. Build up the areas of the exposed roof<br />

deck to a level even with the old shingles be<strong>for</strong>e applying new step flashings.<br />

When applying the new shingles, each shingle course will be covered by a step flashing.<br />

Flashings need to be at least 125 mm (5") high, and 125 mm (5") wide. Each flashing should<br />

overlap the one below by at least 75 mm (3"), but not be visible below the shingle top lap.<br />

Imbed each step flashing in a 75 mm (3") wide application of asphalt plastic cement, and<br />

nail in place. The end of each shingle overlapping a step flashing is also well embedded in<br />

plastic cement. Remember to reinstall counter-flashing over the step flashings.<br />

Existing vents and flashings around soil stacks may be used again, but it’s recommended<br />

that new flashings and vents be installed. Using the hooked blade knife, cut through the old<br />

shingles around the perimeter of the flashing apron and remove them. Fill in this space with<br />

a double layer of shingles.<br />

Apply courses of new shingles up to the hole in the roof deck. Cut away the shingles to<br />

reveal the hole. Plastic cement is applied at the edges and then the vent is nailed firmly in<br />

place. Continue shingling, cutting to fit around the vent. The cut shingles should be laid in a<br />

bed of asphalt plastic cement.<br />

Pipe flashings are installed in a similar fashion and asphalt plastic cement is used to seal the<br />

pipe. Nails used to secure flashings to the roof should be used sparingly and not be driven<br />

close to the pipe.<br />

A dab of plastic cement over the exposed nails is recommended to<br />

avoid leakage.<br />

Part 10<br />

Low Slope - Roof-Fast Application<br />

Some roof areas may not be suitable <strong>for</strong> shingles especially due to low slope (less than<br />

2:12 down to 1:12). In these areas the recommended product is Roof-Fast, a self-adhered<br />

membrane (SAM) system, ideal <strong>for</strong> low-slope roofing that combines the polymer chemistry<br />

of commercial grade modified bitumen membranes with the self-adhesive characteristics of<br />

an ice and water protector and the beauty of a granule surface.<br />

22

Low Slope - Roof-Fast Application PART 10<br />

The Roof-Fast system is comprised of Roof-Fast Cap which is a fiberglass rein<strong>for</strong>ced selfadhesive<br />

cap sheet in a variety of attractive mineral surface colors, with a release film on<br />

the back side. Roof-Fast Base MA is a fiberglass rein<strong>for</strong>ced nailable base with special film<br />

surface designed <strong>for</strong> use with self-adhered cap sheet. Roof-Fast 95, a self-adhering base<br />

sheet, is an alternative base sheet that may be used as part of the system.<br />

To begin applying the Roof-Fast system using the Roof-Fast Base MA, start at the lowest<br />

edge of the roof. Prepare a starter strip by cutting the base sheet lengthwise in half and lay<br />

flat on the clean, dry deck. Leave a minimum 50 mm (2") of base sheet overhanging roof<br />

edge to cover any exposed joints in the wood facia where water could penetrate. Fasten the<br />

Roof‐Fast Base MA at 457 mm (18") on center in a row down the approximate center of the<br />

starter sheet leaving upper edge free of fasteners <strong>for</strong> later steps in installation. The preferred<br />

nail of choice <strong>for</strong> this application is a 25 mm (1") diameter steel cap nail.<br />

Lay out a full width base sheet overlapping the starter sheet by a minimum of 75 mm (3").<br />

Fasten through the overlap with 25 mm (1") disk nails 229 mm (9") on center working from<br />

the center of the sheet outwards. Ensure the sheet lays flat and wrinkle free at all times.<br />

Fasten the center of the sheet with two rows of nails 457 mm (18") apart in a staggered<br />

<strong>for</strong>mation starting from the center and working outwards.<br />

Repeat this step until the entire surface has been covered.<br />

Prior to beginning the drip edge installation, prime surface of drip edge/metal flashing with<br />

primer <strong>for</strong> self adhering membrane and allow to dry. Turn down 50 mm (2") overlap from<br />

starter strip along the drip edge area and secure with roofing nails at 229 mm (9") on center<br />

to fascia. Cut a strip of Roof-Fast Cap 300 mm (12") wide and lay across roof edge granular<br />

side down. Using the drip edge/metal flashing as a guide, score the release film the width<br />

of the drip edge with the back of a utility knife. Remove scored release film closest to roof<br />

edge and place primed drip edge/metal flashing over scored area of Roof-Fast. Fasten with<br />

roofing nails at 229 mm (9") on center staggered approximately 25 mm (1") in from inside<br />

metal edge.<br />

To complete base sheet installation, secure base sheet at remaining perimeters with 25 mm<br />

(1") steel cap nails 229 mm (9") on center.<br />

To apply the Cap Sheet, start at the lowest point of the roof and roll out full width Roof‐Fast<br />

Cap Sheet. Cut to desired length, dry fit to roof edge in final position and allow to relax.<br />

Make sure the 90 mm (3 ½") sidelap on the Roof-Fast Cap is opposite, (furthest away), from<br />

drip edge/metal flashing. Using the butterfly technique, while kneeling on the upper half of<br />

positioned cap sheet fold back ½ of the width towards you to expose release film. Remove<br />

remaining release film from 300 mm (12") inverted cap sheet strip. Remove exposed release<br />

23

PART 10<br />

Low Slope - Roof-Fast Application<br />

film from Roof-Fast cap, (½ width), and slowly “walk” cap sheet into place over base sheet.<br />

Fold down the upper unadhered cap sheet, remove release film and gently place into final<br />

position.<br />

Use a roller to ensure consistent contact of Roof-Fast Cap to the Base Sheet. In hot weather<br />

it may be best to limit the length of individual pieces of Roof-Fast to a maximum of 4 m<br />

(12') <strong>for</strong> ease of handling. Roll out second cap sheet, cut to size, dry fit into final position<br />

and allow to relax. Ensure second sheet overlaps the 90 mm (3 ½") side lap of the first sheet.<br />

Repeat the procedure <strong>for</strong> installation of first sheet remembering to remove release film<br />

covering the side lap on the first sheet. Continue up the roof repeating this procedure until<br />

all surface is covered.<br />

To apply an end lap to the Roof-Fast Cap Sheet, cut a section of cap sheet that overlaps the<br />

adhered section by 150 mm (6"). Apply a 150 mm (6") bead of mastic sealant with a trowel<br />

on the overlap section. Peel off release film and press firmly. Remove remaining release<br />

film on back of cap sheet and firmly press onto base sheet. Use a roller to ensure consistent<br />

contact of Roof-Fast Cap to the Base Sheet.<br />

The IKO End Lap is granulefree<br />

and protected with a peel<br />

off foil release strip. Some cap<br />

sheets may not have an End<br />

Lap feature; in these cases use<br />

cemented end lap procedure<br />

above.<br />

150 mm (6")<br />

Release poly - To be<br />

removed prior to<br />

seaming.<br />

Roof Slope<br />

90 mm<br />

(3 ½")<br />

Down slope roll<br />

The IKO 45° angle<br />

cut provides<br />

additional<br />

adhesion at the<br />

junction between<br />

successive sheets.<br />

This feature is<br />

on Roof‐Fast<br />

membranes only.<br />

Roof-Fast (SAM)<br />

Application Field<br />

of Roof.<br />

For the alternate base application, using the Roof-Fast 95 Base, apply a coat of self-adhering<br />

primer to the full deck and allow to dry. Cut sheet to size and using the butterfly technique,<br />

while kneeling on the upper half of positioned base cap sheet, fold back half of the width<br />

towards you, remove release film and slowly “walk” base sheet into place. Fold down the<br />

upper unadhered cap sheet, remove release film and gently place into position.<br />

As an optional application, where roof area and roof slope allow, instead of starting with<br />

a half-width of Roof-Fast Base MA, use a full-width of IKO’s GoldShield Premium Ice<br />

& Water membrane. In this installation, at eaves/rakes, the drip edge is installed over<br />

the GoldShield and below the fastened base sheet layer. The drip edge should be set in<br />

continuous bands of asphalt cement to ensure water-tightness with the membrane layers.<br />

24

Ventilation PART 11<br />

Part 11<br />

Ventilation<br />

Proper ventilation is necessary to mitigate attic heat build-up, and to avoid condensation<br />

problems that may cause dampness to rot the roof deck and distort the roofing materials.<br />

The air in your home is laden with moisture from cooking, laundry, bathing, the respiration<br />

of plants and animals and the evaporation from plumbing fixtures. Water vapor is a serious<br />

concern during the winter months when the home is generally closed up tight. At that time,<br />

the water vapor generated in the home typically migrates up into the attic since the ceiling<br />

vapor barrier is rarely 100% perfect. Without proper ventilation, this excess moisture will<br />

remain in the attic, condense, and cause damage. As warm moist air meets the colder air<br />

along the inside of the roof deck, condensation will <strong>for</strong>m. This condensation may eventually<br />

lead to rotting wood in the attic and may also drip onto the insulation and reduce its<br />

effectiveness. Ice damming occurs as the warm moist air raises the temperature of the snow<br />

on the roof and melts it. The water then runs down the roof where it re-freezes as it reaches<br />

the colder area at the eaves.<br />

Roof vents come in different<br />

shapes and sizes. Never mix<br />

different type of vents on the<br />

same roof.<br />

If your attic is under-vented, your roof rafters or trusses, roof deck and shingles are<br />

invaded by the moisture. This will reduce the life of the asphalt shingles. To minimize these<br />

problems, it is important to have proper ventilation. Remember, good venting involves<br />

both intake and exhaust. The intake must be at the eaves and the exhaust must be at or near<br />

the ridge. The venting must be balanced with approximately 50% at the intake or eaves and<br />

50% at the ridge.<br />

With proper ventilation, air will circulate freely under the roof deck and carry away water<br />

vapor be<strong>for</strong>e it can condense. One of the best methods is a combination of continuous<br />

eaves and ridge vents that together provide uni<strong>for</strong>m natural draft ventilation from the<br />

bottom to the top of the attic space. Louvre and vent openings should not be covered<br />

during the winter. Eaves or soffit vents should not be blocked by insulation.<br />

25

PART 11<br />

Ventilation<br />

There are several venting products on the market today that work well at the ridge of the<br />

roof. Ask your local distributor <strong>for</strong> more in<strong>for</strong>mation.<br />

When determining the need <strong>for</strong> additional vents, the minimum specification underlined in<br />

building codes <strong>for</strong> net free ventilation area, that is, the area permitting unrestricted airflow,<br />

of 0.1 m2 <strong>for</strong> 14 m2 (1 ft2 <strong>for</strong> 150 ft2) of attic floor space is recommended. When vents<br />

are located at eaves or soffits and near the roof’s peak or along the ridge <strong>for</strong> maximum net<br />

airflow, the net free vent area may be reduced to a minimum 0.1 m2 <strong>for</strong> 28 m2 (1 ft2 <strong>for</strong><br />

300 ft2) <strong>for</strong> a balanced system, ventilation should be equal at the undereave and at or near<br />

the ridgeline. One square foot of net free area <strong>for</strong> every one hundred and fifty square feet of<br />

insulated ceiling area is required <strong>for</strong> low sloped roofs. The net free area is usually stamped<br />

right on the vent by the manufacturer.<br />

Proper ventilation.<br />

Improper ventilation.<br />

summer<br />

winter<br />

under-eave<br />

or<br />

soffit ventilation<br />

For new roof vents, a hole should be cut the same size as the vent hole. Ideally you should<br />

center a 1 m by 1 m (3' by 3') section of one of our IKO’s Ice & Water Protectors over the<br />

new vent hole.<br />

Cut away any ice and water protector now covering up the hole. Shingle up to the bottom<br />

of the vent opening, and remove any shingle material that may be covering the hole.<br />

Apply plastic cement around the edges and nail the vent securely in place.<br />

Continue shingling, cutting to fit around the vent. Each cut shingle should be laid in a bead<br />

of cement. A dab of asphalt plastic cement over the exposed nails is recommended to avoid<br />

leakage.<br />

Several manufacturers now supply specialized ridge vents. To use these vents, install shingle<br />

courses up the roof to the ridge so that the ridge caps will cover the sealing strip on both<br />

faces of the roof at the ridge. Cut away the roof decking to reveal 25 mm (1") of space on<br />

both sides of the ridge joist. At both ends of the ridge, apply ridge cap shingles as already<br />

outlined, to cover at least 300 mm (12") of the ridge.<br />

26

Flashings PART 12<br />

For rigid ridge vents, center the ridge vent over the ridge, and overlap the installed ridge<br />

cap shingles so that the nails and sealing strip are covered. Nail to the deck using the nailing<br />

marks supplied by the vent manufacturer.<br />

For rapid ridge vents, measure length of ridge and cut fabric to size. Center vent over slot<br />

on one end with nail lines upwards and fasten with two nails. Roll out along entire ridge,<br />

pull out slack, and fasten with two nails at opposite end.<br />

Beginning from the end of the ridge opposite the direction of the prevailing winds, apply<br />

ridge cap shingles over the ridge vent, exposing each piece in the same manner as be<strong>for</strong>e.<br />

Nail the caps to the ridge vent following the nailing guide on the vent, as provided by the<br />

vent manufacturer.<br />

Part 12<br />

Flashings<br />

Roof planes that butt against vertical walls at the end of the shingle course are protected by<br />

metal step flashing at least 125 mm high and 125 mm wide (5" high and 5" wide). When<br />

applying the new shingles, each shingle course will be covered by a step flashing.<br />

There are two simple rules to follow:<br />

• Each flashing should overlap the one below by at least 75 mm (3"), but not be<br />

visible below the shingle top lap<br />

• Imbed each step flashing in a 75 mm (3") wide application of asphaltic plastic<br />

cement, and nail in place. Then the end of each shingle overlapping a step flashing<br />

must also be well embedded in plastic cement.<br />

Flashing installation.<br />

27

PART 12<br />

Flashings<br />

The metal step flashing shingles are rectangular in shape and style, approximately 250 mm<br />

(10") long and at least 50 mm (2") wider than the face of the shingle being used. For<br />

instance, when using metal flashing shingles with a typical 143 mm (5 ⅝") exposure, the size<br />

of the flashing will be 250 mm x 200 mm (10" x 8"). The 250 mm (10") length is bent in half<br />

so that 125 mm (5") will reach up the wall surface and the other 125 mm (5") will extend<br />

onto the roof deck. Note: Other step flashing sizes are also acceptable.<br />

To install the flashing shingle on the first course, place it over the end of the starter strip.<br />

Place it so the tab of the end shingle covers it completely. Secure the horizontal flange to the<br />

roof deck using two nails. Do not fasten the flashing shingle to the vertical wall. This will<br />

allow the flashing shingle to move with any expansion and contraction that may occur with<br />

the roof deck. Place the second step flashing shingle over the end shingle in the first course<br />

by positioning it 143 mm (5 ⅝") above the bottom edge of the exposed asphalt shingle.<br />

Make sure that the tab of the shingle in the second course will cover it completely. Secure<br />

the horizontal flange to the roof. The second and succeeding courses will follow with the<br />

end shingles flashed as in preceding courses.<br />

Chimney flashings are secured to the roof over top of the shingles and counter or cap<br />

flashings are secured to the chimney, providing a waterproof seal.<br />

Flashing at front and side of chimney<br />

Application of corner flashing at rear of chimney<br />

Application of flashing over cricket<br />

Application of flashing over ridge of cricket<br />

28

Flashings PART 12<br />

Application of counter flashing at side and rear of<br />

chimney<br />

Application of counter flashing<br />

For pipe flashings around soil stacks, shingle up to the bottom of the stack. Apply plastic<br />

cement around the edges, and then slide the new flashing over the soil pipe and into place.<br />

Nails used to secure flashings to the roof should be used sparingly, not be drive close to the<br />

pipe, and where recommended by the manufacturer.<br />

Continue shingling, cutting to fit around the stack. Each cut shingle should be laid in a<br />

bead of cement. A dab of plastic cement over the exposed nails is recommended to avoid<br />

leakage.<br />

Application of shingle over<br />

vent pipe.<br />

Application of flange.<br />

29

PART 13<br />

Hips and Ridges<br />

Application of shingles<br />

around flashing.<br />

Part 13<br />

Hips and Ridges<br />

Apply shingles up to a hip or ridge from both sides of the roof be<strong>for</strong>e finishing the<br />

intersection.<br />

Note that IKO’s Pro 4 <strong>Roofing</strong> System recommends that along with IKO’s shingles,<br />

accessory items be utilized to ensure roof per<strong>for</strong>ms to its maximum capacity. Hip and Ridge<br />

cap shingles are a recommended component to the multi-layered system.<br />

130 mm<br />

(5 ⅛")<br />

146 mm<br />

(5 ¾")<br />

25 mm<br />

(1")<br />

To apply the ridge shingles, bend<br />

each shingle along the centerline<br />

so that it will extend an equal<br />

distance on each side of the hip<br />

or ridge.<br />

Hip & Ridge 12 Ridge Cap Shingles are specially made ridge cap shingles that are<br />

lightweight and per<strong>for</strong>ated to give you 3 pieces, each 300 mm (12") wide. The shingles<br />

are easy to separate, even at the site of application! Hip & Ridge 12 are fiberglass asphalt<br />

shingles equipped with an SBS modified adhesive sealant <strong>for</strong> maximum wind protection.<br />

Prior to application in cold weather, storing the shingles in a heated area will allow <strong>for</strong><br />

easier bending.<br />

30

Hips and Ridges PART 13<br />

Ridge cap shingles may be applied in a traditional “single” dimensional thickness and<br />

appearance. To obtain a three-dimensional effect, (which is recommended, but not<br />

required), apply hip and ridge shingles double thickness by stacking 2 pieces on top of one<br />

another, the lower piece extending about 19 mm (¾") further than the top piece.<br />

• Separate Hip & Ridge 12 shingles into thirds, using the per<strong>for</strong>ation marks as a<br />

guide.<br />

• These shingles are designed <strong>for</strong> a 130 mm (5 ⅛") exposure. (For a neater<br />

appearance, the top of each side of each piece can be trimmed on a 25 mm (1")<br />

taper.)<br />

• Bend each piece over the hip or ridge, and nail 130 mm (5 ⅛") above the butt edge,<br />

25 mm (1") in from each edge, exposing each piece 130 mm (5 ⅛").<br />

• Apply hip pieces starting at the lower end of the hip, working up toward the ridge.<br />

On hip roofs, apply ridge pieces starting at each end, meeting in the middle. On<br />

gable roofs, apply ridge pieces starting at the end opposite to the prevailing wind<br />

direction and continue to the other end.<br />

The final shingle should be set in cement, and the exposed nail heads of the final shingle<br />

should be covered with cement.<br />

Ultra HP Hip & Ridge shingles are specially constructed ridge cap shingles designed to<br />

provide a high-quality, high-profile alternative to using cut-up shingles to protect this<br />

important area.<br />

Apply the shingles with an 210 mm (8 ¼") exposure (even with notch), beginning at the<br />

bottom of the hip, or from the end of the ridge opposite the direction of the prevailing<br />

winds. Form the shingle to the roof deck prior to nailing. For steeper roofs, it may be<br />

necessary to push down slightly on the sides of the shingle. Use two nails, one on each side<br />

of the shingle, located 19 mm (¾") back from the shingle notch. In high wind areas, seal<br />

down each IKO UltraHP shingle with two 25 mm (1") spots of asphalt plastic cement. For<br />

added roof definition, IKO UltraHP may also be installed at gable and rake edges.<br />

Several manufacturers now supply specialized ridge vents. To use these vents, install shingle<br />

courses up the roof to the ridge so that the ridge caps will cover the sealing strip on both<br />

faces of the roof at the ridge.<br />

Cut away the roof decking to reveal the appropriate space based on vent manufacturer’s<br />

specifications. At both ends of the ridge, apply ridge caps as already outlined, to cover<br />

at least 300 mm (12") of the ridge. Center the ridge vent over the ridge, and overlap the<br />

installed ridge caps so that the nails and sealing strip are covered. Nail to the deck using the<br />

nailing marks supplied by the vent manufacturer. Nails should be a minimum of 50 mm (2")<br />

to ensure penetration through vent, shingle and into roof deck.<br />

31

PART 14<br />

Inspection and Clean Up<br />

Beginning from the end of the ridge opposite the direction of the prevailing winds, apply ridge<br />

caps over the ridge vent, exposing each piece in the same manner as be<strong>for</strong>e. Nail the caps to<br />

the ridge vent following the nailing guide on the vent, as provided by the vent manufacturer.<br />

Part 14<br />

Inspection and Clean Up<br />

Be<strong>for</strong>e leaving the job, it is necessary to clean up all debris from the<br />

roof, valleys and gutters.<br />

Remove the protective tarps you laid down earlier to easily get rid of old shingles, wrappers,<br />

granules and nails. It’s recommended you flush out eavestroughs to ensure unobstructed<br />

water flow, and to give your job a professional finish. The use of a magnetic sweeper is<br />

recommended to rid the yard and driveway of nails and metallic debris.<br />

Part 15<br />

Roof Care and Maintenance<br />

Congratulations! We knew you could do it.<br />

While your roof will provide years of protection, there are some aspects of continuing roof<br />

care that you should be aware of to ensure maximum roof per<strong>for</strong>mance.<br />

Keep gutters and roof surfaces clear of all debris. This will allow water to flow freely off the<br />

roof. Keep trees trimmed to prevent damage from branches scuffing the roof surface.<br />

Make semi-annual inspections of the roof to evaluate its general condition in terms of<br />

potential leakage problems. The best time <strong>for</strong> this in the spring and fall after the severe<br />

weather conditions have passed.<br />

Inspect the underside of the roof deck from the attic to detect leaks. Flashings are the most<br />

vulnerable points. Water stains will be evident if there has been some leakage or severe<br />

condensation.<br />

Part 16<br />

Products<br />

IKO manufactures a full line of asphalt roofing shingles. These shingles feature fiberglass<br />

mats, and are available in several popular styles in a variety of colors.<br />

Now that you’ve seen how easy it is to re-roof your home, it’s time to<br />

select the shingle that will exactly meet your requirements.<br />

32

Products PART 16<br />

We make one of the finest 3-Tab shingles on the market: Time-tested and true, IKO<br />

Traditional 3-Tab shingles are one of our most popular shingle designs. The traditional<br />

3-Tab design shingle gets its name from the three tabs incorporated into its profile.<br />

IKO Traditional 3-Tab shingles, the Marathon Series, are available in a wide variety of<br />

colors and available with Limited Warranty lengths of 30, 25 or 20 years and Limited Wind<br />

Warranty coverage up to 60 miles per hour or 97 kilometers per hour.<br />

Traditional 3-Tab shingle<br />

For dimensional thickness and strength, choose IKO laminated<br />

architectural shingles<br />

IKO Crowne Slate, with its hybrid, two-piece construction is coated<br />

with our own IKO-SBS modified asphalt which makes these shingles<br />

extremely durable and impact-resistant, with a UL2218 Class 4 Rating.<br />

Their dimensional thickness and profile evokes the beautiful contours<br />

and natural appearance of slate tiles. Plus, we’ve embedded ceramiccoated<br />

copper granules into the top layer, making the roof algae<br />

resistant. This premium fiberglass-based shingle comes with a Limited<br />

Lifetime Warranty and features a Limited Algae-Resistance Warranty.<br />

Armourshake Laminated Designer shingles provide a dimensional<br />

thickness that enhances the rough-hewn, random-cut appearance,<br />

texture and profile of classic wood shakes and feature an algae resistant<br />

system with a Limited Algae-Resistance Warranty. Featuring a UL2218<br />

Class 4 Rating, this premium fiberglass-based shingle comes with a<br />

Limited Lifetime Warranty.<br />

Although Royal Estate can be installed as simply and easily as a standard<br />

laminated shingle, it offers a remarkable slate-like appearance. This<br />

shingle is distinguished by a uniquely synchronized manufacturing<br />

process which results in distinctly colored tabs. Along with a Limited<br />

Lifetime Warranty, this shingle is offered in rich hues of Harvest Slate,<br />

Mountain Slate, Shadow Slate and Taupe Slate.<br />

33

PART 16<br />

Products<br />

Grandeur stands up to the competition just as effectively as it does the<br />

weather. Most roofing shingles will provide quality protection against<br />

the simpler elements of nature, such as wind, rain, snow and average<br />

temperatures. IKO’s Grandeur shingles, with a Limited Lifetime<br />

Warranty, are designed to withstand Mother Nature’s <strong>for</strong>ces with its<br />

superior UL2218 Class 4 impact resistance rating. Engineered to last and<br />

built to per<strong>for</strong>m, providing superior resistance against thermal cycling<br />

and high winds. Grandeur shingles offer the added protection of algae<br />

resistant granules to keep the roof looking beautiful, even in regions of<br />

heavy rainfall and high humidity.<br />

The IKO Cambridge shingles are laminated to provide a remarkable<br />

dimensional thickness, not only <strong>for</strong> strength, durability and weather<br />

resistance, but also to create an extraordinarily beautiful look to your<br />

home. These premium fiberglass shingles are offered with a Limited<br />

Lifetime Warranty in a wide array of unique and striking colors. IKO<br />

Cambridge shingles are also available with an algae resistant system with<br />

a Limited Algae-Resistance Warranty.<br />

All IKO shingles are quality manufactured to IKO’s rigid specifications, using only the<br />

highest quality raw materials.<br />

IKO also offers a selection of roofing accessories, which include our Ice & Water Protection;<br />

GoldShield, ArmourGard and StormShield, Hip & Ridge products, Roof-Fast, various felts<br />

and synthetic underlayment and Leading Edge Plus Starter strips.<br />

To aid in your shingle and color selection, you can also use the IKO RoofViewer TM<br />

interactive shingle selector tool, available on-line and on CD.<br />

IKO ROOFViewer is an interactive tool<br />

which allows the customer to easily select a<br />

shingle style and color to co-ordinate with<br />

brick or siding and trim. It’s an easy way of<br />

finding out how your house will look with<br />

a particular shingle.<br />

34<br />

To ensure complete satisfaction, please make your final color selection<br />

from several full size shingles and view a sample of the product<br />

installed on a home.

Products PART 16<br />

Please note product availability varies by plant. For additional in<strong>for</strong>mation on IKO’s full<br />

line of superior roofing products, talk to your IKO dealer, visit the website at www.iko.com,<br />

or contact United States 1-888-IKO-Roof, Eastern Canada 1-888-766-2468 or Western<br />

Canada 1-800-661-1034.<br />

Thank you <strong>for</strong> considering IKO <strong>Roofing</strong> Products.<br />

35

GLOSSARY<br />

Glossary<br />

Algae Discoloration: A type of black roof discoloration caused by algae. Sometimes referred<br />

to as fungus growth.<br />

Asphalt: A bituminous waterproofing agent applied to roofing materials during<br />

manufacture.<br />

Asphalt Plastic Cement: An asphalt-based cement used to bond roofing materials. Also<br />

known as flashing cement or mastic; typically con<strong>for</strong>ms to ASTM D 4586 (Asbestos Free) or<br />

CGSB 37-GP-5MA.<br />

Backsurfacing: Fine mineral matter applied to the back side of shingles to keep them from<br />

sticking together. IKO uses backsurfacing materials such as talc, dolomite and mineral fines.<br />

Blisters: Bubbles that may appear on the surface of asphalt roofing after installation.<br />

Bridging: A method of re-roofing with larger-sized shingles.<br />

Bundle: A package of shingles.<br />

Butt Edge: The lower edge of the shingle tabs.<br />

Caulk: To fill a joint with mastic or asphalt cement to prevent leaks.<br />

Chalk Line: A line made on the roof by snapping a taut string or cord dusted with chalk.<br />

Used <strong>for</strong> alignment purposes.<br />

Closed Cut Valley: A method of valley treatment in which shingles from one side of the<br />

valley extend across the valley while shingles from the other side are trimmed 50 mm (2")<br />

from the valley centerline. The valley flashing is not exposed.<br />

Counter Flashing: That portion of the flashing attached to a vertical surface to prevent<br />

water from migrating behind the base flashing.<br />

Course: A row of shingles or roll roofing running the length of the roof.<br />

Coverage: Amount of weather protection provided by the roofing material. Depends on the<br />

number of layers of material between the exposed surface of the roofing and the deck; i.e.,<br />