Asset Management - Plant Maintenance Resource Center

Asset Management - Plant Maintenance Resource Center

Asset Management - Plant Maintenance Resource Center

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Asset</strong> <strong>Management</strong> – a source of additional profitability<br />

Businesses in the manufacturing, process or infrastructure industries have a large capital<br />

investment in the physical assets used in their operation.<br />

<strong>Maintenance</strong> is a significant part of direct operating cost for these businesses. With profit<br />

margins being increasingly squeezed, maintenance is one of the few areas where a business<br />

can improve profitability. <strong>Maintenance</strong> has traditionally been managed as a cost to be<br />

minimised rather than a strategic process that assures the profitability of the business.<br />

The first step to realising the full payback potential of a maintenance management program and<br />

it’s associated cost, is to understand that:<br />

• Optimising the life cycle of an asset depends on effective maintenance.<br />

• <strong>Maintenance</strong> management is a process.<br />

Programmed maintenance management increases the efficiency and life span of equipment,<br />

therefore increasing profitability. These ideas form part of the concept of “<strong>Asset</strong> Life Cycle<br />

<strong>Management</strong>”. To fully understand the benefits of addressing asset management issues, it is<br />

useful to define a model of “<strong>Asset</strong> Life Cycle <strong>Management</strong>” as a business management system.<br />

<strong>Asset</strong> Life Cycle <strong>Management</strong><br />

There are essentially three stages in the life cycle of an asset:<br />

1. Acquisition,<br />

2. Operation and <strong>Maintenance</strong>, and<br />

3. Disposal.<br />

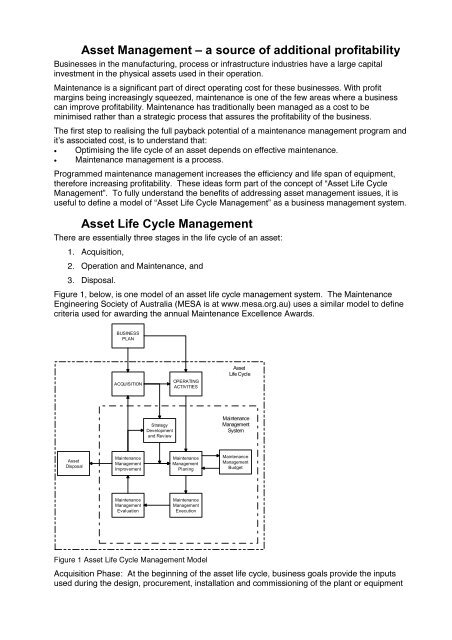

Figure 1, below, is one model of an asset life cycle management system. The <strong>Maintenance</strong><br />

Engineering Society of Australia (MESA is at www.mesa.org.au) uses a similar model to define<br />

criteria used for awarding the annual <strong>Maintenance</strong> Excellence Awards.<br />

BUSINESS<br />

PLAN<br />

ACQUISITION<br />

OPERATING<br />

ACTIVITIES<br />

<strong>Asset</strong><br />

Life Cycle<br />

Strategy<br />

Development<br />

and Review<br />

<strong>Maintenance</strong><br />

<strong>Management</strong><br />

System<br />

<strong>Asset</strong><br />

Disposal<br />

<strong>Maintenance</strong><br />

<strong>Management</strong><br />

Improvement<br />

<strong>Maintenance</strong><br />

<strong>Management</strong><br />

Planing<br />

<strong>Maintenance</strong><br />

<strong>Management</strong><br />

Budget<br />

<strong>Maintenance</strong><br />

<strong>Management</strong><br />

Evaluation<br />

<strong>Maintenance</strong><br />

<strong>Management</strong><br />

Execution<br />

Figure 1 <strong>Asset</strong> Life Cycle <strong>Management</strong> Model<br />

Acquisition Phase: At the beginning of the asset life cycle, business goals provide the inputs<br />

used during the design, procurement, installation and commissioning of the plant or equipment

[assets]. The specifications developed during this stage relate to the physical characteristics<br />

and capabilities of the required assets.<br />

Operation and <strong>Maintenance</strong> Phase: Business goals also define the requirements of how the<br />

assets will be operated. A known range of raw material will be processed into products and<br />

offered into the market place. Thus the business goals define the operating environment for the<br />

assets and the performance goals needed. The ability to deliver products to an eager market at<br />

lowest possible unit cost of production is the ultimate goal. Operational performance is defined<br />

as a combination of production rate, quality and yield targets. <strong>Asset</strong> dependability is defined in<br />

terms of reliability and availability targets.<br />

Disposal Phase: The end of the asset life cycle is reached when the asset is no longer capable<br />

of delivering the required operational performance, or cannot be cost effectively maintained to<br />

achieve the required levels of dependability. The options are either modification or disposal and<br />

replacement of the asset.<br />

Optimising the Operation and <strong>Maintenance</strong> Phase<br />

Optimal performance during this phase of the asset life cycle is only achieved by organisations<br />

that embrace a holistic approach. This encourages a close working link between the production<br />

and maintenance areas. They are jointly responsible for achieving business plan requirements.<br />

There are many definitions of maintenance, however it must be defined and managed as a<br />

“process”, in order to achieve optimum pay back from expenditure. Hence the need to identify a<br />

maintenance management system as an integral part of the asset life cycle management model<br />

shown in Figure 1.<br />

During the operation and maintenance phases of the asset life cycle there are three critical<br />

factors needed to realise optimal performance.<br />

1. <strong>Plant</strong> [assets] must be managed to achieve the required dependability goals in the most<br />

cost effective way. To do this, a strategy is developed for maintaining assets with a focus<br />

on the asset’s function. The asset function defines what is needed to achieve operating<br />

performance targets. Thus, effective maintenance is about preservation of asset function<br />

to deliver the required operating performance, rather than just preservation of the asset<br />

itself. The development of a strategy in this way provides the method for defining and<br />

managing an accurate and realistic maintenance budget. This is basically a technical<br />

matter that has been done effectively by application of processes such as PM<br />

Optimisation (Visit www.pmoptimisation.com.au for additional information.)<br />

2. Processes need to be established in order to efficiently manage maintenance activity,<br />

evaluate performance against targets, and initiate any required improvement actions.<br />

The processes should reflect the “plan, do, check and act” cycle of continuous<br />

improvement. The improvement actions that will be taken are determined by the<br />

prevailing business needs at that stage of the asset’s life. This is also a technical matter<br />

but is not usually addressed within an organisation unless an asset life cycle<br />

management model similar to that depicted in Figure 1 is adopted. Without such a<br />

model, it is difficult to gain acceptance and management commitment to the concept of<br />

maintenance as a process that plays an important role in achieving business profitability.<br />

My experience shows that this is most easily done if the business employs a systems<br />

approach to organising itself, and quality management principals have been deployed<br />

within the organisation.<br />

3. People need to be effectively engaged to realise the potential of the plant by using<br />

established management processes. People need to understand their role, responsibility<br />

and goals in terms of the maintenance management processes. This helps people<br />

understand how to achieve their performance goals and will ultimately lead to the<br />

achievement of business goals. People are the means of achieving performance and<br />

dependability targets that assure the achievement of business goals. This is not a<br />

technical matter, and so, is often not perceived as an integral part of asset and<br />

maintenance management. <strong>Maintenance</strong> management personnel are usually managed<br />

according to a prescribed HR doctrine within the organisation. It would be far more

effective if HR policies for these people were tailored to suit the “<strong>Plant</strong> , Process and<br />

People” approach to maintenance management.<br />

Twenty years of experience working in manufacturing and process industry has shown me that<br />

these factors are usually dealt with in isolation. There are many organisations that have spent<br />

millions of dollars on maintenance software, reliability analysis programs and forming self<br />

managed work teams, but still have not achieved the required business results. The poor results<br />

are caused by a failure to successfully link all three of these critical factors to address asset life<br />

cycle management. Failures of this kind, only reinforces the workforce perception that they are<br />

experiencing another one of those “flavour of the month” management fads.<br />

Addressing all three factors, delivers synergetic asset management to your business. When this<br />

happens:<br />

• Business goals drive decisions for the use and care of assets.<br />

• Production and maintenance work together as manufacturing teams to develop<br />

mutual targets.<br />

• Performance and dependability targets become drivers for business profitability.<br />

• All resources are optimised, not just maintenance resources.<br />

Results achieved by an organisation that has been successful in integrating these factors as<br />

part of their asset management system include:<br />

• Profit increases of 25-60%<br />

• Productivity increases of 20-50%<br />

• Machine downtime reduced by up to 98%<br />

• <strong>Maintenance</strong> cost reductions up to 30%<br />

<strong>Asset</strong> management needs to be considered as a holistic management system. This will ensure<br />

that good decisions for the use and care of equipment are consistently made and implemented<br />

– decisions, which constitute the best business value. The purpose of such a management<br />

system is to ensure assets remain capable of delivering the performance required by the<br />

business, over the asset life cycle.<br />

There is huge untapped potential for Australian industry to improve performance and<br />

profitability. Effectively deploying asset and maintenance management practices will guarantee<br />

that your business goals are realised. Every business needs to manage assets for their entire<br />

life cycle. Angelo Agresti is principal of <strong>Asset</strong> Capability <strong>Management</strong>.