Biogas Plant Halberstadt - UTS Biogas

Biogas Plant Halberstadt - UTS Biogas

Biogas Plant Halberstadt - UTS Biogas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>UTS</strong> <strong>Biogas</strong> Ltd<br />

<strong>UTS</strong> <strong>Biogas</strong> Ltd<br />

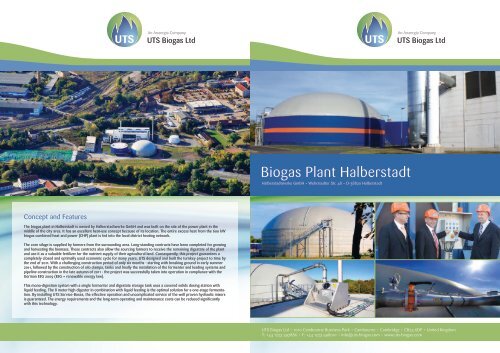

<strong>Biogas</strong> <strong>Plant</strong> <strong>Halberstadt</strong><br />

<strong>Halberstadt</strong>werke GmbH • Wehrstedter Str. 48 • D-38820 <strong>Halberstadt</strong><br />

Concept and Features<br />

The biogas plant in <strong>Halberstadt</strong> is owned by <strong>Halberstadt</strong>werke GmbH and was built on the site of the power plant in the<br />

middle of the city area. It has an excellent heat–use concept because of its location. The entire excess heat from the 600 kW<br />

biogas combined heat and power (CHP) plant is fed into the local district heating network.<br />

The corn silage is supplied by farmers from the surrounding area. Long-standing contracts have been completed for growing<br />

and harvesting the biomass. These contracts also allow the sourcing farmers to receive the remaining digestate of the plant<br />

and use it as a valuable fertilizer for the nutrient supply of their agricultural land. Consequently, this project guarantees a<br />

completely closed and optimally used economic cycle for many years. <strong>UTS</strong> designed and built the turnkey project to time by<br />

the end of 2011. With a challenging construction period of only six months - starting with breaking ground in early summer<br />

2011, followed by the construction of silo clamps, tanks and finally the installation of the fermenter and loading systems and<br />

pipeline construction in the late autumn of 2011 - the project was successfully taken into operation in compliance with the<br />

German EEG 2009 (EEG = renewable energy law).<br />

This mono-digestion system with a single fermenter and digestate storage tank uses a covered solids dosing station with<br />

liquid feeding. The 8 meter high digester in combination with liquid feeding is the optimal solution for a one-stage fermentation.<br />

By installing <strong>UTS</strong> Service-Boxes, the effective operation and uncomplicated service of the well proven hydraulic mixers<br />

is guaranteed. The energy requirements and the long-term operating and maintenance costs can be reduced significantly<br />

with this technology.<br />

<strong>UTS</strong> <strong>Biogas</strong> Ltd • 1010 Cambourne Business Park • Cambourne • Cambridge • CB23 6DP • United Kingdom<br />

T: +44 1223 597886 • F: +44 1223 598001 • info@uts-biogas.com • www.uts-biogas.com

Technical Details:<br />

Commissioning year: 2011<br />

Net electricity production: per year 4,920 MWh<br />

Mixers / Service-Box<br />

Pumps<br />

Gas pipes<br />

Substrate pipes<br />

Heating<br />

Fermenter<br />

Technology building<br />

Digestate storage tank<br />

Gas cooling unit<br />

Gas flare<br />

CHP<br />

Tanker filling station<br />

Control room<br />

Liquid feeding pump<br />

Solids feeder 65m³<br />

Condensate water collection<br />

Silage leachate pit<br />

Weighing bridge<br />

CHP installed: 600 kW el<br />

Net heat production:<br />

Electrical output: per day 14,400 kWh<br />

Substrates:<br />

Thermal output: per day 14,600 kWh<br />

Production of Raw <strong>Biogas</strong>: per year approx. 2,240,000 Nm³<br />

per year 4,986 MWh<br />

corn silage approx. 25 t/d<br />

3<br />

32 / 8 m<br />

6.435 m³<br />

13<br />

11<br />

8<br />

2<br />

9<br />

9<br />

4<br />

10<br />

1<br />

22 / 8 m<br />

2.850 m³<br />

7<br />

12<br />

5<br />

6<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13