Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

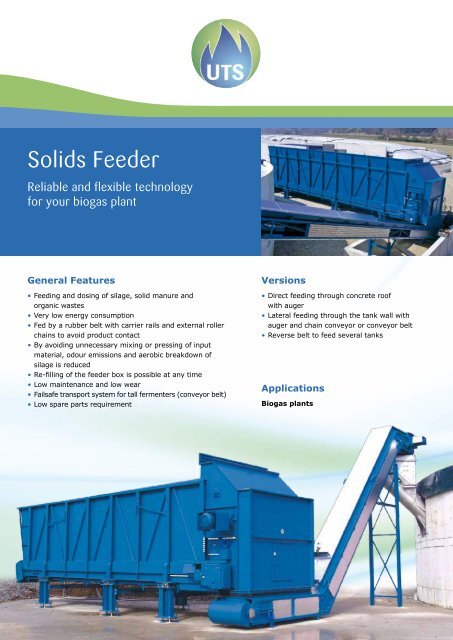

<strong>Solids</strong> <strong>Feeder</strong><br />

Reliable and flexible technology<br />

for your biogas plant<br />

General Features<br />

• Feeding and dosing of silage, solid manure and<br />

organic wastes<br />

• Very low energy consumption<br />

• Fed by a rubber belt with carrier rails and external roller<br />

chains to avoid product contact<br />

• By avoiding unnecessary mixing or pressing of input<br />

material, odour emissions and aerobic breakdown of<br />

silage is reduced<br />

• Re-filling of the feeder box is possible at any time<br />

• Low maintenance and low wear<br />

• Failsafe transport system for tall fermenters (conveyor belt)<br />

• Low spare parts requirement<br />

Versions<br />

• Direct feeding through concrete roof<br />

with auger<br />

• Lateral feeding through the tank wall with<br />

auger and chain conveyor or conveyor belt<br />

• Reverse belt to feed several tanks<br />

Applications<br />

<strong>Biogas</strong> plants

Technical Features<br />

• Dosing station<br />

- Volume: 8 – 65 m³, larger volumes upon request<br />

- Connected load: 19 kW (with direct feeding);<br />

23 kW (with feeding system)<br />

- Average power consumption: ~ 4 kW<br />

(with direct feeding); ~ 6.5 kW (with conveyor system)<br />

- Operating width: 2.25 m (standard) – 1.85 m (at 8 m³)<br />

- Discharge rate: ~ 80 kg/min – 120 kg/min for<br />

silages<br />

- Filling height: starting at 2.80 m<br />

- 3 milling drums with screw elements and teeth<br />

(width 2.25 m or 1.85 m)<br />

- Chain conveyor belt with 40° slope or conveyor belt<br />

up to 19° slope<br />

- Central lubrication and automatic chain oiling<br />

Accessories and Options<br />

• Weighing with large display<br />

• Special dosing and feeding technology for<br />

a wide range of input materials<br />

• Diagonal screw for vertical feeding<br />

• Wear protection in VA or Betoplan<br />

• Bottom chain cover to avoid losses due<br />

to leakage or dust<br />

<strong>UTS</strong> Products GmbH<br />

Oestinghausener Straße 12<br />

D-59510 Lippetal<br />

Tel. +49 2923 61094 0<br />

Fax +49 2923 61094 100<br />

<strong>UTS</strong> <strong>Biogas</strong>technik GmbH<br />

Zeppelinstraße 8<br />

D-85399 Hallbergmoos<br />

Tel. +49 811 99884 0<br />

Fax +49 811 99884 450<br />

www.uts-biogas.com<br />

© idealit.com