Flying Blackhawk's 850 HP Caravan - Blackhawk Modifications, Inc.

Flying Blackhawk's 850 HP Caravan - Blackhawk Modifications, Inc.

Flying Blackhawk's 850 HP Caravan - Blackhawk Modifications, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

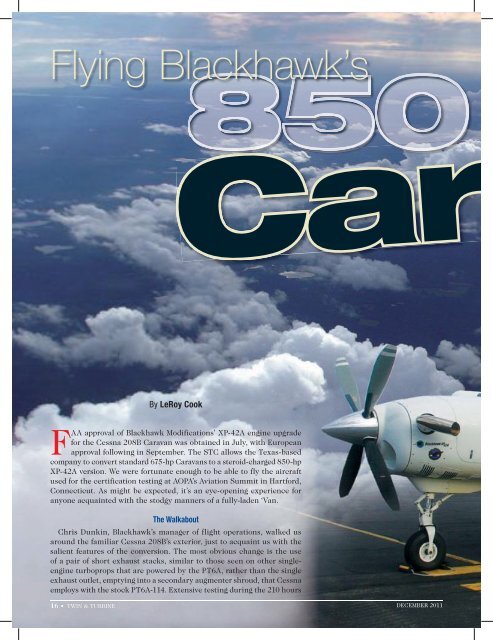

<strong>Flying</strong> <strong>Blackhawk</strong>’s<br />

Car<br />

By LeRoy Cook<br />

FAA approval of <strong>Blackhawk</strong> <strong>Modifications</strong>’ XP-42A engine upgrade<br />

for the Cessna 208B <strong>Caravan</strong> was obtained in July, with European<br />

approval following in September. The STC allows the Texas-based<br />

company to convert standard 675-hp <strong>Caravan</strong>s to a steroid-charged <strong>850</strong>-hp<br />

XP-42A version. We were fortunate enough to be able to fly the aircraft<br />

used for the certification testing at AOPA’s Aviation Summit in Hartford,<br />

Connecticut. As might be expected, it’s an eye-opening experience for<br />

anyone acquainted with the stodgy manners of a fully-laden ‘Van.<br />

The Walkabout<br />

Chris Dunkin, <strong>Blackhawk</strong>’s manager of flight operations, walked us<br />

around the familiar Cessna 208B’s exterior, just to acquaint us with the<br />

salient features of the conversion. The most obvious change is the use<br />

of a pair of short exhaust stacks, similar to those seen on other singleengine<br />

turboprops that are powered by the PT6A, rather than the single<br />

exhaust outlet, emptying into a secondary augmenter shroud, that Cessna<br />

employs with the stock PT6A-114. Extensive testing during the 210 hours<br />

16 TWIN & TURBINE DECEMBER 2011

avan<br />

An engine upgrade that takes a good Cessna<br />

airplane and makes it even better.<br />

DECEMBER 2011 TWIN & TURBINE 17

logged in <strong>Blackhawk</strong>’s recertification showed no CO<br />

contamination in the cockpit or cabin, owing to the<br />

precise “clocking” of the Frakes stacks installed on the<br />

PT6A-42A engine.<br />

Arizona Type Rating<br />

Quarter Page<br />

4/C Ad<br />

The test aircraft was fitted with a full APE (Aircraft<br />

Payload Extender) kit, which allows a gross weight<br />

increase to 9062 pounds (max landing weight is 9000<br />

pounds). The standard 208B ramp weight is 8785<br />

pounds. To take advantage of the weight increase, the<br />

XP42A approval requires installation of the APE kit’s<br />

minor changes, if the retrofitted aircraft is not already<br />

equipped with it. The APE kit includes larger mainwheel<br />

axles, an airflow fence on each wing’s outboard leading<br />

edge and a wavy aerodynamic device added to the<br />

inboard portion of each flap’s trailing edge.<br />

A 100-inch four-blade Hartzell propeller is part of the<br />

installation, replacing the 104-inch standard propeller.<br />

Standard TBO for the new engine is 3,600 hours. Credit<br />

Select Airparts<br />

Quarter<br />

Page<br />

4/C Ad<br />

18 TWIN & TURBINE DECEMBER 2011

is given for the service-life hours remaining on the<br />

traded-in PT6A-114. The original engine mount and<br />

accessories are used, but new vibration isolators are<br />

installed and the support ring’s mounts are increased<br />

from three to four. Typical weight increase is between<br />

20 and 40 pounds. The PT6A-42A engine is three inches<br />

longer, requiring installation of an all-new carbon-fiber<br />

composite cowling, which <strong>Blackhawk</strong> builds in-house at<br />

its Morgantown, Kentucky, composites facility.<br />

There’s ample workroom inside the cowling; someone<br />

listened to long-suffering maintenance technicians.<br />

Dunkin lifted the left cowling half to point out an<br />

engine oil sight glass, used to verify proper oil level<br />

without pulling a dipstick. A Concord RG-380E/44<br />

lead-acid battery is on the right side. The oil cooler in<br />

the nosecap is 40-percent larger than before and the<br />

adjoining air intake opening is bigger as well, with its<br />

angle changed to increase FOD dispersion.<br />

Aft of the firewall, most of the airplane is the same as<br />

it came from Cessna. The power quadrant in the cockpit<br />

is unchanged, but all the power gauges are replaced by<br />

<strong>Blackhawk</strong>’s own Digilog units that have digital vernier<br />

readouts as well as analog needle presentations. A<br />

new placard on the panel calls for a minimum of 130<br />

knots airspeed to be maintained when flying in icing<br />

conditions. Those are the only changes required.<br />

Dunkin related his experiences when conducting<br />

the natural icing tests. One sloppy autumn day,<br />

meteorologists directed him to a likely area in western<br />

Kansas, where icing was present between 5000 and<br />

9000 feet. He flew in the accumulating ice for 50<br />

uninterrupted minutes and never saw the airspeed<br />

deteriorate below 145 knots, even though the bootequipped<br />

aircraft picked up massive chunks of rime<br />

on unprotected areas. A meteorologist viewing photos<br />

of the flight pronounced it to be “near severe icing”.<br />

No further testing was needed.<br />

DECEMBER 2011 TWIN & TURBINE 19

Paul Bowen<br />

Half Page<br />

4/C Ad<br />

20 TWIN & TURBINE DECEMBER 2011

Going Up, Fast<br />

We climbed into the cockpit, pulled up the boarding<br />

ladders and went through the routine PT6A starting<br />

procedure; master on and fuel pump to normal, engage<br />

start switch and watch rotation begin on the Ng gauge,<br />

waiting for 15% Ng to introduce fuel. The lightoff and<br />

rise in rpm caused no more than a 750 C. indication<br />

on the ITT (start limit is 975 C). Once stabilized, we<br />

confirmed that the starter had been switched into<br />

generator mode and the avionics were flipped on.<br />

The cooperative Hartford, Connecticut tower offered<br />

to arrange for VFR flight following service as we exited<br />

their airspace to the east; Dunkin’s plan was to execute<br />

a max-performance climbout above Providence’s Class<br />

C environment. We quickly taxied to runway 21 for a<br />

prop governor test and advanced to high idle condition,<br />

extended ten degrees of flap and took the inertial<br />

separator handle out of “bypass” position. With the<br />

APE kit, extreme short-field takeoffs are approved with<br />

30 degrees of flap, versus 20 degrees for an unmodified<br />

airplane.<br />

Preferred<br />

Airparts<br />

Quarter<br />

Page<br />

4/C Ad<br />

The propeller wound up to 2000 rpm while we held<br />

the brakes, and we advanced the power lever to about<br />

2150 pounds of torque on the roll. The torque built to<br />

2200 as we lifted off at a leisurely 80 knots, halfway<br />

down the 4400-foot runway.<br />

Once past 95 knots, the flaps were brought up and I<br />

quickly accelerated the aircraft to 120 knots. Dunkin<br />

advised me to hold 115 in the climb; by doing so,<br />

visibility over the nose was nil. The VSI read 2000<br />

fpm initially, finally settling in at 1600 to 1700 fpm.<br />

<strong>Blackhawk</strong>’s brochure says the XP42A has double<br />

the climb rate of a standard <strong>Caravan</strong>, and when we<br />

compared numbers with the standard and modified<br />

charts, it appeared to be true; under similar conditions,<br />

a 675-hp 208B would manage around <strong>850</strong> fpm.<br />

With torque tweaked occasionally to keep 2200<br />

pounds pulling us upward, the ITT started out at 730<br />

degrees C. and rose to no more than 750 at the top of our<br />

climb, 11,500 MSL. Only about 8 minutes had elapsed<br />

since our sea-level liftoff. The -42A Pratt had kept its<br />

2200 pounds of torque until 10,500 feet. Temperature<br />

was about 16 degrees over standard ISA and takeoff<br />

weight was estimated at 7700 pounds.<br />

As we leveled off with 2100 pounds of torque and 750<br />

degrees on the ITT, the airspeed settled at 165 knots<br />

IAS, computing to a TAS of 202, while burning 460<br />

PPH of Jet-A. The standard 208B’s book showed that<br />

only 1370 pounds of torque would have been available<br />

at 12,000 feet, providing a TAS of about 158 knots.<br />

In all fairness, Dunkin pointed out, our TAS would<br />

have been ten knots or so less if we had been at full<br />

gross weight.<br />

Great Lakes<br />

Aero Products<br />

Quarter<br />

Page<br />

4/C Ad<br />

DECEMBER 2011 TWIN & TURBINE 21

With power reduced to 1900<br />

pounds torque, we lost about<br />

10 knots of speed, cutting fuel<br />

flow to 400 PPH. Dunkin then<br />

demonstrated a quiet-cruise mode<br />

by backing away a bit of torque<br />

and slowing the propeller rpm to<br />

1700, bringing torque back up to<br />

2200 pounds, but in a much quieter<br />

environment for the passengers.<br />

Handling at cruise remained trucklike<br />

but benign, just as the <strong>Caravan</strong><br />

has always been.<br />

We experimented with slowflight<br />

at 80 knots and full flaps, which<br />

turned out to be a thoroughly honest<br />

bit of flying, simply lighter on the<br />

control feel but still ponderous in<br />

response. We did not essay a full<br />

stall, but Dunkin assured us that<br />

nothing has changed over the simple<br />

Skyhawk manners we have come<br />

to expect in the 208. Because the<br />

FAA insisted on duplicating the<br />

certification criteria, a complete<br />

spin program has been flown,<br />

comprising some 115 spins.<br />

Going Down, Fast<br />

Because one of the major markets<br />

for the XP42A mod is for skydiving<br />

centers, we experimented with<br />

the skydive descent at flight idle,<br />

pushing over to reach the 180-<br />

knot redline. With the VSI pegged<br />

solid at 3000 fpm down, we timed<br />

an eardrum-splitting 4000 fpm<br />

descent, then quickly resumed a<br />

500 fpm letdown. Combining the<br />

improved climb rate and rapid<br />

descent, skydive centers will be<br />

able to take four loads per hour to<br />

the top of the non-oxygen altitudes.<br />

Cleared to land back at Hartford’s<br />

Brainard airport, we slowed to 175<br />

knots, where ten degrees flap was<br />

permitted, which reduced speed to<br />

150 knots so we could extend twenty<br />

degrees of flap. The final flap limit is<br />

125 knots. A defunct set of runways<br />

a few miles east of the airport, the<br />

former Rentschler Field from World<br />

War II, tempted us, but, fortunately,<br />

Dunkin caught my mistake before<br />

it became serious.<br />

Cessna avoiding any equivalentlevel-of-safety<br />

games when certifying<br />

its big single under FAR Part 23,<br />

preferring to meet the 61-knot Vso<br />

stall speed limitation with pure<br />

aerodynamic wizardry, at least at<br />

the standard airplane’s 8,500-pound<br />

landing weight.<br />

As with all <strong>Caravan</strong>s, approach<br />

and landing chores are simple; no<br />

landing gear to extend, no switches<br />

to throw, just slow to as little 80<br />

knots and drive to the runway. We<br />

indulged in a 90-knot “high-speed”<br />

22 TWIN & TURBINE DECEMBER 2011

final for the benefit of following<br />

traffic, followed by an easy<br />

touchdown on the tall gear. A bit of<br />

reverse brought us to a halt in short<br />

order; as it turned out, the inbound<br />

jet was bringing FAA Administrator<br />

Randall Babbitt to the Summit. As<br />

with all PT6A-powered airplanes,<br />

particularly those with four-blade<br />

props, one must be judicious with<br />

the power reduction to idle during<br />

landing, which produces a rapid<br />

increase in drag and a sudden<br />

touchdown.<br />

After shutting down and lowering<br />

the gangplank to debark, we felt<br />

it was apparent that <strong>Blackhawk</strong>’s<br />

XP42A modification takes the 208B<br />

<strong>Caravan</strong> to a new level of capability.<br />

To repeat CEO’s Jim Allmon’s<br />

statement, “Cessna built a good<br />

airplane, we just made it better”.<br />

We have to agree.<br />

T&T<br />

Turbines Training<br />

Center<br />

Half Page<br />

4/C Ad<br />

MAINTENANCE<br />

Northeast Air <strong>Inc</strong>.<br />

Sixth Page<br />

4/C Ad<br />

All scheduled and non-scheduled maintenance by our friendly, experienced technicians<br />

Qualified to work on Citation, KingAir, Twin Commander, and Pilatus<br />

Avionics<br />

Legacy: partial and full glass cockpit completions<br />

Garmin GTN650 and GTN750 installations<br />

XM Weather, traffic and mode S upgrades<br />

info@northeastair.com<br />

www.northeastair.com Portland Jetport (KPWM) Maine<br />

CRS #FTUR030E<br />

DECEMBER 2011 TWIN & TURBINE 23