Jobmaster Poster - International - Intelitek

Jobmaster Poster - International - Intelitek

Jobmaster Poster - International - Intelitek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mechatronics<br />

Mechatronics & Industrial Maintenance<br />

Program<br />

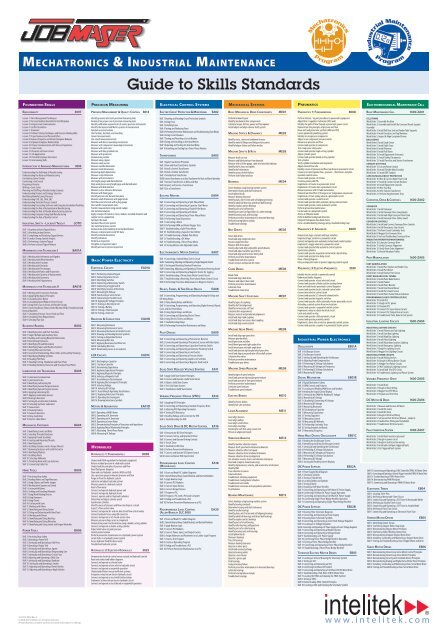

Guide to Skills Standards<br />

Foundation Skills<br />

Precision Measuring<br />

Electrical Control Systems<br />

Mechanical Systems<br />

Pneumatics<br />

Electromechanical Maintenance Cell<br />

Employability 3097<br />

Precision Measurement & Quality Control 8014<br />

Electric Circuit Protection & Monitoring<br />

EA02<br />

Basic Mechanical Drive Components<br />

ME01<br />

Pneumatics 1: Fundamentals 8068<br />

Basic Maintenance Cell<br />

1600-ZA01<br />

Lesson 1: Time-Management Techniques<br />

Lesson 2: Personal Qualities Desirable for the Workplace<br />

Lesson 3: Interpersonal Communication<br />

Lesson 4: Conflict Resolution<br />

Lesson 5: Teamwork<br />

Lesson 6: Problem-Solving Techniques and Decision-Making Skills<br />

Lesson 7: Proper Business and Personal Ethics<br />

Lesson 8: Business Etiquette and Ethical Computer Behavior<br />

Lesson 9: Employer-Employee Relationships<br />

Lesson 10: Proper Communication with Diverse Populations<br />

Lesson 11: Career Goals<br />

Lesson 12: Resumés and Cover Letters<br />

Lesson 13: Job Applications<br />

Lesson 14: Potential Employer Interviews<br />

Lesson 15: Interviewing Skills<br />

Introduction to Advanced Manufacturing 3096<br />

Understanding the Definition of Manufacturing<br />

Understanding the History of Manufacturing<br />

Considering Career Choices<br />

Conducting a Job Search<br />

Preparing a Resume<br />

Writing a Cover Letter<br />

Planning and Staffing a Manufacturing Company<br />

Understanding Product and Strategy Selection<br />

Identifying Manufacturing Processes<br />

Understanding CAD, CAE, CAM, CNC<br />

Understanding Statistical Process Control<br />

Understanding Forecasting Software and Computer Simulation Modeling<br />

Understanding the Role of Automation in Manufacturing<br />

Understanding the Role of Flexible Manufacturing Systems<br />

Understanding Computer Integrated Manufacturing<br />

Understanding the Role of Quality Control<br />

Industrial Safety - Lockout/Tagout<br />

Skill 1: Acquiring Lockout/Tagout Basics<br />

Skill 2: Attaching Lockout Devices<br />

Skill 3: Completing and Attaching Tagout Devices<br />

Skill 4: Conduct Energy Control Analysis<br />

Skill 5: Performing a Lockout/Tagout<br />

Skill 6: Perform Lockout/Tagout Release<br />

Mathematics for Technicians I<br />

Skill 1: Working with Arithmetic and Algebra<br />

Skill 2: Working with Whole Numbers<br />

Skill 3: Working with Fractions<br />

Skill 4: Working with Decimals<br />

Skill 5: Working with Percentages<br />

Skill 6: Working with Ratios and Proportions<br />

Skill 7: Working with Systems of Measurement<br />

Skill 8: Working with Geometry<br />

Skill 9: Working with Trigonometry<br />

Mathematics for Technicians II<br />

LOTO<br />

BA01A<br />

BA01B<br />

Skill 1: Working with Conversion Formulas<br />

Skill 2: Applying Mechanical Principles<br />

Skill 3: Calculating Drive Ratios<br />

Skill 4: Calculating Speed Reducer Service Factor<br />

Skill 5: Using Ohm’s Law in Series and Parallel Circuits<br />

Skill 6: Converting Binary, Binary Coded Decimal (BCD), Hexadecimal and<br />

Decimal Numbers<br />

Skill 7: Calculating Pressure, Force, Head and Flow<br />

Skill 8: Calculating Shim Requirements<br />

Skill 9: Selecting Pipe Size<br />

Blueprint Reading<br />

bA02<br />

Skill 1: Identifying Lines and their Functions<br />

Skill 2: Single, Multiple and Auxiliary View<br />

Skill 3: Reading and Locating Blueprint Dimensions<br />

Skill 4: Determining Tolerances<br />

Skill 5: Identifying Thread Dimensions<br />

Skill 6: Identifying Tapers and Machine Surfaces<br />

Skill 7: Cutting Plane and Sections<br />

Skill 8: Geometric Dimensioning, Wear Limits and Assembly Drawings<br />

Skill 9: Identifying Welding Symbols<br />

Skill 10: Reading Plot Plans<br />

Skill 11: Reading Footing, Foundation and Floor Plans<br />

Skill 12: Reading Reinforced Concrete and Structural Steel Prints<br />

Lubrication for Technicians<br />

Skill 1: Lubrication Fundamentals<br />

Skill 2: Lubrication Terms<br />

Skill 3: Identifying Lubricating Oils<br />

Skill 4: Identifying General Purpose Greases<br />

Skill 5: Identifying Special Purpose Greases<br />

Skill 6: Applying Lubricating Oils<br />

Skill 7: Applying Lubricating Greases<br />

Skill 8: Bearing Lubrication<br />

Skill 9: Setting Up a Lubrication Schedule<br />

Skill 10: Selecting Synthetic Lubricants<br />

Skill 11: Grease Guns<br />

Skill 12: Bearing Packers<br />

Skill 13: Grease Lubricators<br />

Skill 14: Drop Feed Oilers<br />

Skill 15: Electric Chain Oilers<br />

Mechanical Fasteners<br />

Skill 1: Identifying Screws and Bolts<br />

Skill 2: Selecting Threaded Fasteners<br />

Skill 3: Applying Thread Standards<br />

Skill 4: Creating and Repairing Threads<br />

Skill 5: Identifying Nuts<br />

Skill 6: Installing Fasteners with a Torque Wrench<br />

Skill 7: Removing Fasteners with a Bolt Extractor<br />

Skill 8: Identifying Washers<br />

Skill 9: Installing Rivets<br />

Skill 10: Selecting Adhesives<br />

Skill 11: Attaching Hook and Loop Fasteners<br />

Skill 12: Connecting Cable Ties<br />

Hand Tools<br />

Skill 1: Practicing Shop Safety<br />

Skill 2: Reading Rulers and Tape Measures<br />

Skill 3: Using Calipers and Feeler Gauges<br />

Skill 4: Working with Squares and Levels<br />

Skill 5: Cutting with Knives<br />

Skill 6: Scribing and Punching Materials<br />

Skill 7: Using Work Holding Devices<br />

Skill 8: Using Hammers<br />

Skill 9: Using Chisels<br />

Skill 10: Cutting with Saws<br />

Skill 11: Working with Pliers<br />

Skill 12: Identifying and Using Cutters<br />

Skill 13: Filing and Deburring with Hand Tools<br />

Skill 14: Working with Drivers<br />

Skill 15: Identifying and Using Hex Keys<br />

Skill 16: Identifying and Using Wrenches<br />

Skill 17: Identifying and Using Socket and Torque Wrenches<br />

Power Tools<br />

Skill 1: Practicing Shop Safety<br />

Skill 2: Operating a Power Drill<br />

Skill 3: Setting Up and Operating a Drill Press<br />

Skill 4: Operating a Rotary Tool<br />

Skill 5: Setting Up and Operating a Jigsaw<br />

Skill 6: Setting Up and Operating a Reciprocating Saw<br />

Skill 7: Setting Up and Operating a Circular Saw<br />

Skill 8: Adjusting and Operating a Table Saw<br />

Skill 9: Setting Up and Operating a Bandsaw<br />

Skill 10: Setting Up and Operating a Sander<br />

Skill 11: Adjusting and Operating a Bench Grinder<br />

Skill 12: Adjusting and Operating an Angle Grinder<br />

bA03<br />

bA04<br />

bA05<br />

bA06<br />

Identify precision and semi-precision measuring tools<br />

Demonstrate proper care of precision measuring tools<br />

Identify calibration requirements of various precision instruments<br />

Identify the Imperial and Metric systems of measurement<br />

Calculate area and volume<br />

Use fractions, decimals, and rounding<br />

Convert measurements<br />

Use scaled measurement tools<br />

Measure with direct measuring instruments<br />

Measure with comparison measuring instruments<br />

Measure with steel rules<br />

Measure with line gradated rule<br />

Measure with protractor<br />

Demonstrate parallax<br />

Measure using calipers<br />

Measure using vernier<br />

Measure outside dimensions<br />

Measure inside dimensions<br />

Measuring depth dimensions<br />

Measure a step dimension<br />

Measure with micrometers<br />

Use height gauges and dial indicators<br />

Align work pieces using height gage and dial indicators<br />

Measure with dial indicator<br />

Measure a close tolerance dimension<br />

Measure with fixed gages<br />

Identify and use sine bar and sine plate<br />

Measure small dimensions with gage blocks<br />

Find the center of a hole with a plug gauge<br />

Use transfer measurement tools<br />

Transfer measurement using outside caliper<br />

Use statistical analysis<br />

Apply concepts of statistics, mean, median, standard deviation and<br />

sample size to a population<br />

Calculate the mean<br />

Calculate the extreme spread<br />

Use statistical process control<br />

Demonstrate understanding of normal distribution<br />

Measure, interpret and record SPC data<br />

Identify nominal dimensions<br />

Identify tolerances<br />

Perform an inspection<br />

Complete an inspection report<br />

Identify and use in-process inspection<br />

Basic Power Electricity<br />

Electrical Circuits<br />

Skill 1: Performing Lockout/Tagout<br />

Skill 2: Connecting a Basic Circuit<br />

Skill 3: Identifying Switches<br />

Skill 4: Connecting a Momentary Switch<br />

Skill 5: Connecting a Toggle Switch<br />

Skill 6: Identifying Sources of Electricity<br />

Skill 7: Measuring DC Voltage<br />

Skill 8: Constructing a Series Circuit<br />

Skill 9: Constructing a Parallel Circuit<br />

Skill 10: Applying DC Voltage Principles<br />

Skill 11: Testing an Electrolytic Cell<br />

Skill 12: Testing a Battery<br />

Skill 13: Testing a Thermocouple<br />

Skill 14: Testing a Solar Cell<br />

Resistors & Conductors<br />

Skill 1: Measuring Resistance<br />

Skill 2: Measuring Resistance in Series<br />

Skill 3: Measuring Resistance in Parallel Circuits<br />

Skill 4: Drawing and Reading Resistor Symbols<br />

Skill 5: Testing an Adjustable Resistor<br />

Skill 6: Measuring Wire Size<br />

Skill 7: Applying Resistance And Wire Size<br />

Skill 8: Calculating Wire Size<br />

Skill 9: Determining Losses in a Conductor<br />

LCR Circuits<br />

Skill 1: Discharging a Capacitor<br />

Skill 2 : Testing a Capacitor<br />

Skill 3: Determining Capacitance<br />

Skill 4: Applying Capacitance Principles<br />

Skill 5: Applying Magnetic Principles<br />

Skill 6: Inducing a Magnetic Field<br />

Skill 7: Assembling an Electromagnet<br />

Skill 8: Applying Electromagnetic Principles<br />

Skill 9: Inducing Voltage<br />

Skill 10: Inducing DC Voltage<br />

Skill 11: Assembling & Operating Transformers<br />

Skill 12: Applying Inductance Principles<br />

Skill 13: Operating Electromagnets<br />

Skill 14: Drawing Inductance Symbols<br />

Motors & Generators<br />

Skill 1: Operating a PMDC Motor<br />

Skill 2: Operating a DC Generator<br />

Skill 3: Operating an AC Generator<br />

Skill 4: Operating a Series Motor<br />

Skill 5: Demonstrating Principles of Reactance and Impedance<br />

Skill 6: Applying Phase Relationship Principles<br />

Skill 7: Illustrating Three-Phase Power<br />

Skill 8: Measuring AC Voltage<br />

Hydraulics<br />

EA01A<br />

EA01B<br />

EA01C<br />

EA01D<br />

Hydraulics 1: Fundamentals 8008<br />

Understand OSHA regulations for hydraulic equipment<br />

Release residual pressure in a hydraulic system<br />

Understand the principles of pressure and flow<br />

Read fluid power diagrams<br />

Draw and read hydraulic symbols (ANSI and ISO)<br />

Use a pressure gauge to measure pressure and flow<br />

Purge air from the hydraulic system<br />

Lubricate and adjust hydraulic pistons<br />

Measure power in a hydraulic system<br />

Read a flow meter<br />

Connect and operate hydraulic power unit<br />

Connect and operate hydraulic motor<br />

Connect, operate and test hydraulic cylinders<br />

Determine and adjust cylinder speed<br />

Synchronize cylinders<br />

Identify causes of pressure and flow rate drops in a circuit<br />

Inspect a flow control valve<br />

Connect and operate bi- and uni-directional flow control valves<br />

Connect hydraulic hoses using QD connector<br />

Connect and operate a 4/3 closed-center valve<br />

Measure pressure drops across a component<br />

Demonstrate power transformation using a double-acting cylinder<br />

Connect and operate a double-acting cylinder<br />

Adjust relief valve set point pressure<br />

Control piston location<br />

Perform preventive maintenance on a hydraulic power system<br />

Locate leaks in a hydraulic power system<br />

Assess hydraulic fluid filtration needs<br />

Troubleshoot hydraulic system<br />

Hydraulics 2: Electro-Hydraulics 3025<br />

Demonstrate electrical control versus manual and hydraulic control<br />

Read and understand ladder diagrams<br />

Connect and operate a solenoid valve<br />

Connect and operate a basic electro-hydraulic circuit<br />

Connect and operate a sequential operation<br />

Understand efficient versus inefficient systems<br />

Integrate a relay into an electro-hydraulic circuit<br />

Connect and operate a circuit with latched relays<br />

Implement a timer into an electro-hydraulic circuit<br />

Connect and operate a circuit based on sequential operation<br />

Skill 1 Drawing and Reading Circuit Protection Symbols<br />

Skill 2 Sizing Fuses<br />

Skill 3 Installing Fuses<br />

Skill 4 Testing and Replacing Fuses<br />

Skill 5 Performing Preventive Maintenance and Troubleshooting Fuse Blocks<br />

Skill 6 Sizing Circuit Breakers<br />

Skill 7 Testing and Resetting a Circuit Breaker<br />

Skill 8 Sizing and Installing an Overload Heater<br />

Skill 9 Adjusting and Testing the Overload Relay<br />

Skill 10 Installing and Setting Up a Three-Phase Monitor<br />

Transformers<br />

EA03<br />

Skill 1 Apply Transformer Principles<br />

Skill 2 Draw and Read Transformer Symbols<br />

Skill 3 Install a Control Transformer<br />

Skill 4 Install a Station Transformer<br />

Skill 5 Troubleshoot Transformer<br />

Skill 6 Connect Transformer as an Auto Transformer for Buck and Boost Operation<br />

Skill 7 Connect Transformers in Delta and Wye<br />

Skill 8 Inspect and Service a Transformer<br />

Skill 9 Size a Transformer<br />

Electric Motors<br />

Skill 1: Connecting and Operating a Split-Phase Motor<br />

Skill 2: Connecting and Operating a Capacitor-Start Motor<br />

Skill 3: Connecting and Operating a Shaded-Pole Motor<br />

Skill 4: Connecting and Operating a DC Motor<br />

Skill 5: Connecting and Operating a Three-Phase Motor<br />

Skill 6: Performing Visual Inspections<br />

Skill 7: Lubricating a Motor<br />

Skill 8: Performing DMM and Motor Megger Tests<br />

Skill 9: Troubleshooting a Split-Phase Motor<br />

Skill 10: Troubleshooting a Capacitor-Start Motor<br />

Skill 11: Troubleshooting a Shaded-Pole Motor<br />

Skill 12: Troubleshooting a DC Motor<br />

Skill 13: Troubleshooting a Three-Phase Motor<br />

Skill 14: Testing Motors with Adjustable Loads<br />

Electromagnetic Motor Starters<br />

EA04<br />

EA07<br />

Skill 1: Connecting a Control Relay Seal-In Circuit<br />

Skill 2: Connecting, Adjusting and Operating a Single Magnetic Starter<br />

Skill 3: Testing and Resetting Overload Protection<br />

Skill 4: Connecting, Adjusting, and Operating a Three-phase Reversing Starter<br />

Skill 5: Connecting and Operating a Magnetic Starter for Jogging<br />

Skill 6: Troubleshooting a Three-phase Motor Control Circuit<br />

Skill 7: Troubleshooting a Reversing Three-phase Motor Control Circuit<br />

Skill 8: Performing Preventive Maintenance on Magnetic Starters<br />

Relays, Timers, & Time Delay Relays<br />

EA08<br />

Skill 1: Connecting, Programming, and Operating Analog On-Delay and<br />

Off-Delay Relays<br />

Skill 2: Using Analog Relays and Motors<br />

Skill 3: Connecting, Programming, and Operating Digital Interval, Repeat<br />

Cycle, and One Shot Relays<br />

Skill 4: Using Digital Relays and Motors<br />

Skill 5: Connecting and Operating Electric Timers<br />

Skill 6: Using Electric Timers and Motors<br />

Skill 7: Troubleshooting Relays<br />

Skill 8: Performing Preventative Maintenance on Relays<br />

Pilot Devices<br />

EA09<br />

Skill 1: Connecting and Operating a Photoelectric Detector<br />

Skill 2: Connecting and Operating a Photoelectric Sensor with Fiber Optics<br />

Skill 3: Connecting and Operating a Capacitive Proximity Switch<br />

Skill 4: Connecting and Operating an Inductive Proximity Switch<br />

Skill 5: Connecting and Operating a Limit Switch<br />

Skill 6: Connecting and Operating a Pressure Switch<br />

Skill 7: Connecting and Operating Liquid Level Switches<br />

Skill 8: Connecting and Operating a Magnetic Reed Switch<br />

Solid-State Reduced Voltage Starters<br />

Skill 1: Apply Solid State Starter Principles<br />

Skill 2: Connect and Operate a Solid State Starter<br />

Skill 3: Adjust a Solid State Starter<br />

Skill 4: Test Solid State Starters<br />

Skill 5: Troubleshoot Solid State Starter<br />

Variable Frequency Drives (VFDs)<br />

Skill 1: Applying VFD Principles<br />

Skill 2: Connecting and Operating a Variable Frequency Drive<br />

Skill 3: Adjusting VFD Operating Parameters<br />

Skill 4: Testing VFD Resistance<br />

Skill 5: Reading Voltage and Current on the VFD<br />

Skill 6: Troubleshooting the VFD<br />

Solid-State Drive & DC Motor Control<br />

Skill 1: Demonstrate DC Drive Principles<br />

Skill 2: Connect, Set Up, and Operate DC Drive<br />

Skill 3: Connect and Operate Braking Controls<br />

Skill 4: Test DC Drive<br />

Skill 5: Troubleshoot DC Drive<br />

Skill 6: Perform Preventive Maintenance<br />

Skill 7: Connect and Operate SCR Speed Control<br />

Skill 8: Connect and Operate TRIAC Speed Control<br />

Programmable Logic Control<br />

(MicroLogix)<br />

Skill 1: Draw and Read PLC Ladder Diagrams<br />

Skill 2: Convert Binary, Binary Coated Decimal, and Decimal Numbers<br />

Skill 3: Apply Boolean Logic<br />

Skill 4: Connect PLC Modules<br />

Skill 5: Connect Input Devices<br />

Skill 6: Connect Output Devices<br />

Skill 7: Program a PLC<br />

Skill 8: Program a PLC with a Personal Computer<br />

Skill 9: Debug and Troubleshoot a PLC<br />

Skill 10: Perform Preventive Maintenance on a PLC<br />

Programmable Logic Control<br />

(Allen-Bradley SLC 500)<br />

EA11<br />

EA12<br />

EA16<br />

EA18<br />

EA20<br />

Skill 1: Draw and Read PLC Ladder Diagram<br />

Skill 2: Convert Binary, Binary Coded Decimal, and Decimal Numbers<br />

Skill 3: Apply Boolean Logic<br />

Skill 4: Connect PLC Modules<br />

Skill 5: Connect Power, Input, and Output Circuits<br />

Skill 6: Assign Addresses and Parameters in a Ladder Logic Program<br />

Skill 7: Create a Test Program<br />

Skill 8: Create an Operating Program<br />

Skill 9: Debug and Troubleshoot a PLC<br />

Skill 10: Perform Preventive Maintenance on a PLC<br />

Perform lockout/tagout<br />

Identify mechanical drive components<br />

Calculate torque, friction, power and horsepower<br />

Install adjust and align colinear shaft system<br />

Machine Statics & Dynamics<br />

Identify stress, strain and combined stresses<br />

Identify material fatigue and fatigue stress points<br />

Identify fatigue failure and failure modes<br />

Machine Shafts & Keys<br />

Measure shaft run-out<br />

Measure and fabricate keys from keystock<br />

Measure with a feeler gauge, spirit level and dial indicator<br />

Identify shafts, keys and splines<br />

Identify shaft tolerances<br />

Identify causes of shaft failure<br />

Perform shaft failure analysis<br />

Bearings<br />

Select bearings using bearing number system<br />

Determine housing and shaft tolerances<br />

Install pillow blocks<br />

Measure bearing clearance<br />

Identify plain, anti-friction and self aligning bearings<br />

Identify radial ball bearings and thrust ball bearings<br />

Identify angular contact bearings<br />

Identify parts of a ball bearing<br />

Identify parts and configurations of a roller bearings<br />

Identify bearing seals and housings<br />

Perform preventive maintenance on mounted bearings<br />

Perform bearing failure analysis<br />

Troubleshoot bearings<br />

Belt Drives<br />

Select belt drives<br />

Install and align single belt drive<br />

Tension single belt drive<br />

Measure belt drive speed<br />

Install, adjust and align adjustable-speed sheaves<br />

Install and adjust variable-speed drive<br />

Install and align positive drive timing belt<br />

Perform preventive maintenance<br />

Troubleshoot belt drive system<br />

Install, connect and operate DC motor<br />

Chain Drives<br />

Break chain<br />

Install and align chain drive<br />

Measure and adjust chain slack<br />

Perform preventive maintenance<br />

Lubricate chain<br />

Troubleshoot chain drive<br />

Machine Shaft Couplings<br />

Identify types of couplings<br />

Identify shaft misalignment<br />

Identify and measure soft foot<br />

Calculate shim requirements<br />

Measure vertical and parallel misalignment<br />

Install and align rigid coupling<br />

Install and align two-piece chain coupling<br />

Install and align universal joint<br />

Machine Gear Drives<br />

Install and align spur gear drive<br />

Measure gear backlash<br />

Install gear train and idler<br />

Install bevel gear and right-angle drive<br />

Install worm gear and right-angle drive<br />

Install and operate right-angle helical gear drive<br />

Install and align a perpendicular offset shaft system<br />

Calculate drive ratios<br />

Perform preventive maintenance<br />

Troubleshoot gear drives<br />

Machine Speed Reducers<br />

Identify types of speed reducers<br />

Install and operate right-angle speed reducer<br />

Install and operate in-line speed reducer<br />

Perform preventive maintenance<br />

Lubricate speed reducers<br />

Troubleshoot speed reducers<br />

Electric Brakes<br />

Identify electric brakes<br />

Identify fail-safe operation<br />

Laser Alignment<br />

Laser align sheaves<br />

Laser align pulleys<br />

Laser align v-belt drives<br />

Laser align couplings<br />

Checking for soft foot using a laser tool<br />

Fill out an alignment report<br />

Vibration Analysis<br />

Identify machine vibration sources<br />

Measure shaft speed with vibration tachometer<br />

Measure vibration effects of speed<br />

Measure vibration from rotational imbalance<br />

Measure vibration from misalignment<br />

Use vibration severity charts and vibration tolerances<br />

Read and complete maintenance logs<br />

Identify displacement, velocity, and acceleration of vibration<br />

Identify RMS<br />

Trace vibration to source<br />

Isolate vibration<br />

Troubleshoot vibrating equipment<br />

Troubleshoot misalignment vibration<br />

Troubleshoot bent shafts<br />

Troubleshoot resonance and sympathetic vibrations<br />

Fix imbalance<br />

Bearing Maintenance<br />

Select bearings using bearing number system<br />

Identify bearing standards<br />

Determine housing and shaft tolerances<br />

Identify needle bearings<br />

Identify plain, anti-friction and self aligning bearings<br />

Identify radial ball bearings and thrust ball bearings<br />

Identify angular contact bearings<br />

Identify parts of a ball bearing<br />

Identify roller bearing configurations<br />

Identify parts of a roller bearing<br />

Identify bearing seals and housings<br />

Install pillow blocks<br />

Dismount bearings<br />

Press fit bearings<br />

Measure bearing clearance<br />

Operate an arbor press<br />

Install and remove bushings<br />

Operate bearing pullers<br />

Operate a cone heater<br />

Operate a grease gun<br />

Pack bearings<br />

Analyze bearing failure<br />

Perform preventive maintenance on mounted bearings<br />

Lubricate bearings<br />

Perform bearing failure analysis<br />

Troubleshoot bearings<br />

ME02<br />

ME03<br />

ME04<br />

ME05<br />

ME06<br />

ME07<br />

ME08<br />

ME09<br />

ME10<br />

ME11<br />

ME12<br />

ME13<br />

Perform lockout / tag out procedure on pneumatic equipment<br />

Adjust filter / regulator / lubricator (FRL) units<br />

Identify the path of flow through a pneumatic power circuit<br />

Demonstrate the principles of pressure and flow<br />

Draw and read pneumatic symbols (ANSI and ISO)<br />

Layout pneumatic plumbing system<br />

Identify air compressor components<br />

Adjust an air compressor pressure switch<br />

Measure air pressure and flow<br />

Connect and operate air compressor<br />

Test compressor safety valve<br />

Connect and operate single-acting cylinder<br />

Adjust cylinder speed<br />

Connect and operate double-acting cylinder<br />

Test cylinders<br />

Verify cylinder installation and alignment<br />

Adjust exhaust flow rate<br />

Identify causes of pressure and flow rate drops in pneumatic circuit<br />

Connect, test and operate flow-, pressure-, directional- and pilotoperated-control<br />

valves<br />

Connect and operate a 3/2 Valve<br />

Control a piston with PBs<br />

Implement a 5/2 valve in a pneumatic circuit<br />

Implement a 5/2 valve into a pneumatic circuit<br />

Measure pressure with U-tube manometers<br />

Demonstrate the effect of changes in air temperature on pressure<br />

Implement a 3/2 air-spring valve in a pneumatic circuit<br />

Connect and operate a control circuit<br />

Connect and operate roller-operated, spring-returned valve<br />

Connect and operate a semi-automatic system<br />

Perform preventive maintenance<br />

Locate leaks in a pneumatic system<br />

Assess air filtration needs<br />

Perform bubble testing leak detection<br />

Interpret fluid power data book charts<br />

Form a troubleshooting strategy using a troubleshooting map<br />

Pneumatics 2: Advanced 8069<br />

Demonstrate logic constants and logic variables<br />

Implement logic control in a pneumatic circuit<br />

Connect and operate semi-automatic and automatic control systems<br />

Implement a toggle valve into a pneumatic circuit<br />

Connect and operate fully automatic control systems<br />

Synchronize cylinders<br />

Connect and operate sequential control with a timed delay<br />

Connect and operate time delay circuit<br />

Draw a Timing Diagram<br />

Using a single pilot valve to prevent opposing control signals<br />

Pneumatics 3: Electro-Pneumatics 3039<br />

Identify electric control vs pneumatic control<br />

Understand ladder diagrams<br />

Connect and operate a basic electrical circuit<br />

Connect and operate cylinder position sensing device<br />

Draw and read electro-pneumatic control diagrams<br />

Connect and operate electric solenoid control valve<br />

Connect wire electric control circuit<br />

Connect and operate 5/2 solenoid-solenoid valve<br />

Connect and operate magnetic switches<br />

Connect and operate a fully-automatic electro-pneumatic circuit<br />

Activating a control system from two locations<br />

Connect and operate a sequential control system<br />

Implement a relay in a basic electrical circuit<br />

Latch and unlatch a relay<br />

Connect and operate a fully automatic circuit<br />

Connect and operate proximity switch<br />

Implement a timer into an electro-pneumatic control system<br />

Connect and operate a counter in a pneumatic feeder system<br />

Industrial Power Electronics<br />

Oscilloscope<br />

Skill 1: Oscilloscope Screen<br />

Skill 2: Oscilloscope Controls<br />

Skill 3: Setting Up and Operating the Oscilloscope<br />

Skill 4: Adjusting Probe Compensation<br />

Skill 5: Performing AC Voltage Calculations<br />

Skill 6: Measuring AC Voltage and Frequency<br />

Skill 7: Performing DC Voltage Calculations<br />

Skill 8: Measuring DC Voltage<br />

Digital Multimeter<br />

Skill 1: Digital Multimeter Safety<br />

Skill 2: DMM Controls and Features<br />

Skill 3: Locating and Reading DMM Icons and Symbols<br />

Skill 4: Reading the Liquid Crystal Display<br />

Skill 5: Setting Up the DMM for Reading AC Voltage<br />

Skill 6: Measuring AC Voltage<br />

Skill 7: Calculating & Converting AC Voltage<br />

Skill 8: Measuring DC Voltage<br />

Skill 9: Measuring Resistance<br />

Skill 10: Discharging a Capacitor<br />

Skill 11 Measuring Capacitance<br />

Skill 12: Testing Capacitors<br />

Skill 13: Measuring Current<br />

Skill 14: Measuring DC Millivolts<br />

Skill 15: Performing Continuity Tests<br />

Skill 16: Testing Grounds and Bonds<br />

Skill 17: Measuring Frequency<br />

Hand Held Digital Oscilloscope<br />

Skill 1: Reading the Oscilloscope Screen<br />

Skill 2: Identifying and Using Oscilloscope Controls<br />

Skill 3: Setting Up and Operating the Oscilloscope<br />

Skill 4: Performing AC Voltage Calculations<br />

Skill 5: Measuring AC Voltage and Frequency<br />

Skill 6: Performing DC Voltage Calculations<br />

Skill 7: Measuring DC Voltage<br />

Skill 8: Storing and Recalling Screen Displays<br />

DC Power Supplies<br />

EB01A<br />

EB01B<br />

EB01C<br />

EB02A<br />

Skill 1: Power Supply Block Diagram<br />

Skill 2: Schematic Symbols<br />

Skill 3: Testing a Transformer<br />

Skill 4: Locating Diodes and Symbols<br />

Skill 5: Testing a Diode<br />

Skill 6: Drawing a Half-Wave Rectifier<br />

Skill 7: Connecting and Operating a Half-Wave DC Power Supply<br />

Skill 8: Confirming Full-Wave DC Power Supply Operation<br />

Skill 9: Connecting and Operating a Full-Wave DC Power Supply<br />

Skill 10: Confirming Single-Phase Bridge Rectifier Operation<br />

Skill 11: Connecting and Operating Single-Phase Bridge Rectifier<br />

DC Power Supplies<br />

EB02B<br />

Skill 1: Drawing Filter Schematic Diagrams<br />

Skill 2: Connecting and Operating a Power Supply<br />

Skill 3: Drawing Zener Schematic Symbols<br />

Skill 4: Connecting and Operating a Zener Diode Voltage Regulator<br />

Skill 5: Locating an IC Voltage Regulator<br />

Skill 6: Connecting and Operating a DC Power Supply with an IC Voltage Regulator<br />

Skill 7: Connecting and Operating a Bleeder Resistor<br />

Skill 8: Connecting and Operating a Voltage Divider<br />

Skill 9: Troubleshooting a DC Power Supply<br />

Skill 10: Confirming Three-Phase Bridge Rectifier Operation<br />

Skill 11: Testing a Three-Phase Bridge Rectifier<br />

Skill 12: Connecting and Operating a Three-Phase Bridge Rectifier<br />

Skill 13: Troubleshooting a Three-Phase Bridge Rectifier<br />

Thyristor Electric Motor Drives<br />

Skill 1: Locating an SCR and Drawing the Schematic Symbol<br />

Skill 2: Testing an SCR<br />

Skill 3: Connecting and Operating an SCR<br />

Skill 4: Confirming Full-Wave SCR Control<br />

Skill 5: Connecting and Operating a Full-Wave SCR DC Motor Drive<br />

Skill 6: Troubleshooting a Full-Wave SCR DC Motor Drive<br />

Skill 7: Locating the TRIAC and drawing the TRIAC Symbol<br />

Skill 8: Testing a TRIAC<br />

Skill 9: Demonstrating TRIAC Control Principles<br />

Skill 10: Locating a DIAC and Drawing the Schematic Symbol<br />

EB03<br />

CELL FRAME<br />

Work Order 1: Assemble the Base<br />

Work Order 2: Assemble and Install the Conveyor Mount Support<br />

Assembly<br />

Work Order 3: Install Pull Box, End and Feeder Tube Supports<br />

Work Order 4: Install Crossbars and Top Members<br />

Work Order 5: Inspect & Align Completed Frame<br />

ENCLOSURES<br />

Work Order 6: Install Load Center<br />

Work Order 7: Install Cable Trays<br />

Work Order 8: Install Wireway<br />

Work Order 9: Install Pull Boxes<br />

Work Order 10: Install Equipment Enclosures<br />

Work Order 11: Install Safety Disconnects<br />

Work Order 12: Install Fuse Box and Station Transformer<br />

CONDUIT & FITTINGS<br />

Work Order 13: Cut and Ream Conduit<br />

Work Order 14: Install Flexible Metal Conduit<br />

Work Order 15: Install EMT Conduit<br />

LOW VOLTAGE & CIRCUIT PROTECTION<br />

Work Order 16: Wire & Connect Main Power Cord<br />

Work Order 17: Install & Connect Circuit Breakers<br />

Work Order 18: Install Equipment Grounds<br />

Work Order 19: Wire Fuse Box<br />

Work Order 20: Wire Station Transformer<br />

Work Order 21: Perform Megohmmeter Tests<br />

Conveyor, Drive & Controls<br />

CONVEYOR<br />

Work Order 1: Install Conveyor<br />

Work Order 2: Install Conveyor Drive Components<br />

Work Order 3: Install and Align Conveyor Drive Chain<br />

Work Order 4: Install Conveyor Drive Safety Guard<br />

CONVEYOR CONTROLS<br />

Work Order 5: Install and Connect Conveyor Drive Controls<br />

Work Order 6: Install Emergency Stop Circuits<br />

Work Order 7: Perform Circuit Continuity Tests<br />

Work Order 8: Megger Test Conveyor Drive<br />

Work Order 9: Test and Troubleshoot Conveyor Drive<br />

PREDICTIVE/PREVENTIVE MAINTENANCE<br />

Work Order 10: Lubricate Conveyor Drive<br />

Work Order 11: Verify Conveyor Alignment<br />

Work Order 12: Verify Drive Chain Alignment<br />

Work Order 13: Obtain Vibration Profiles<br />

Part Manipulation<br />

PART MANIPULATION<br />

Work Order 1: Install Part Stacker and Feeder Tray<br />

Work Order 2: Install Part Kicker<br />

Work Order 3: Install Stacker Part Sensor<br />

PAINT, BAKE AND COOL TUNNEL<br />

Work Order 4: Install Paint Bake Heaters<br />

Work Order 5: Install Tunnel<br />

Work Order 6: Install Paint Nozzles<br />

Work Order 7: Install Cool Down Blower<br />

Work Order 8: Install Part Count Sensor<br />

Work Order 9: Install Paint Tunnel Status Indicators<br />

PROGRAMMABLE LOGIC CONTROLLER (PLC)<br />

Work Order 10: Install PLC<br />

Work Order 11: Rough-in PLC power<br />

Work Order 12: Program PLC<br />

Work Order 13: Connect PLC input Sensor Circuits<br />

Work Order 14: Connect PLC Output Device Circuits<br />

Work Order 15: Troubleshoot Paint, Bake & Cool System<br />

Industrial Lighting Circuits<br />

INDUSTRIAL LIGHTING CIRCUITS<br />

Work Order 1: Install Fluorescent Task Lighting<br />

Work Order 2: Install Low Bay Lighting<br />

Work Order 3: Install High Bay Lighting<br />

Work Order 4: Install Flood Lighting<br />

Work Order 5: Install Hazardous Location Lighting<br />

Work Order 6: Install Emergency Lighting<br />

Work Order 7: Rough-In Lighting Circuits<br />

Work Order 8: Megger Test Lighting Circuits<br />

INDUSTRIAL POWER CIRCUITS<br />

Work Order 9: Install Wiring Devices<br />

Work Order 10: Rough-In Wiring Device Circuits<br />

Work Order 11: Megger Test Power Circuits<br />

Work Order 12: Wire Lighting & Lighting Control<br />

Work Order 13: Install and Test GFCI Circuit<br />

Work Order 14: Troubleshoot Lighting and Power System<br />

Variable Frequency Drive<br />

Work Order 1: Install Drive<br />

Work Order 2: Rough-in Drive Wiring<br />

Work Order 3: Megger Test VFD Wires<br />

Work Order 4: Program and Test Drive<br />

DC Motor & Drive<br />

Work Order 1: Measure and Remove AC Motor<br />

Work Order 2: Install DC motor<br />

Work Order 3: Install DC drive<br />

Work Order 4: Rough-in DC Drive Wiring<br />

Work Order 5: Set Up and Test DC Drive (Manual - jumpers)<br />

Work Order 6: Finalize Drive Wiring and Installation<br />

Work Order 7: Troubleshoot DC Drive System<br />

Fault Insertion System<br />

Work Order 1: Install fault insertion sub panel<br />

Work Order 2: Rough-in power circuit<br />

Work Order 3: Rough-in fault insertion wiring<br />

Work Order 4: Install and configure triggered faults<br />

Work Order 5: Test triggered fault system<br />

1600-ZA02<br />

1600-ZA03<br />

1600-ZA04<br />

1600-ZA05<br />

1600-ZA06<br />

1600-ZA07<br />

Skill 11: Connecting and Operating a DIAC-Controlled TRIAC AC Motor Drive<br />

Skill 12: Connecting and Operating a Schmitt Trigger-Controlled TRIAC AC Motor Drive<br />

Skill 13: Troubleshooting a TRIAC Motor Drive<br />

Skill 14: Demonstrating PWM Principles<br />

Skill 15: Connecting and Operating a PWM DC Motor Drive<br />

Electronic Timers<br />

EB04<br />

Skill 1: Locating Timer Pins<br />

Skill 2: Verifying a Monostable Timer Circuit<br />

Skill 3: Connecting and Operating a 555 Timer in Monostable Mode<br />

Skill 4: Verifying an Astable Timer Circuit<br />

Skill 5: Connecting and Operating a 555 Timer in Astable Mode<br />

Skill 6: Verifying a Pulse Train Circuit<br />

Skill 7: Connecting and Operating an Electronic Pulse Train<br />

Stepper Motor Drives<br />

EB05<br />

Skill 1: Identifying Detent Torque<br />

Skill 2: Confirming Stepper Motor Step Angle<br />

Skill 3: Demonstrating Stepper Motor Principles<br />

Skill 4: Confirming Stator Winding Connections<br />

Skill 5: Demonstrating Unipolar Stepper Motor Drive<br />

Skill 6: Installing, Connecting and Monitoring a Stepper Motor Drive<br />

Skill 7: Testing and Troubleshooting a Basic Stepper Motor and Drive<br />

Servo Motor Drives<br />

EB06<br />

Skill 1: Demonstrating Closed-Loop Servo Motor Control Principles<br />

Skill 2: Demonstrating Closed-Loop Servo Motor Principles<br />

Skill 3: Demonstrating Servo System Feedback Device Principles<br />

Skill 4: Demonstrating Analog and Digital Servo Motor Drive Principles<br />

Skill 5: Installing, Connecting and Monitoring a Basic Servo Motor Drive<br />

Skill 6: Testing and Troubleshooting a Basic Servo Motor Drive<br />

35-PO10-JM02 Rev-C<br />

© 2008-2010 intelitek, inc. All rights reserved.<br />

All specifications, available courses and listed skills subject to change.<br />

w w w . i n t e l i t e k . c o m

Mechatronics<br />

Mechatronics & Industrial Maintenance<br />

Program<br />

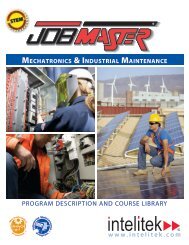

Guide to Career Pathways<br />

JobMaster Certifications<br />

Maintenance Technician - Level I<br />

Maintenance Technician - Level II<br />

Maintenance Technician - Level III<br />

Foundation Skills<br />

Employability (3097)<br />

Introduction to Advanced Manufacturing (3096)<br />

Industrial Safety - Lockout/Tagout (LOTO)<br />

Mathematics for Technicians I (BA01A)<br />

Mathematics for Technicians II (BA01B)<br />

Blueprint Reading (BA02)<br />

Lubrication for Technicians (BA03)<br />

Mechanical Fasteners (BA04)<br />

Hand Tools (BA05)<br />

Power Tools (BA06)<br />

Precision Measurement<br />

Precision Measurement and Quality Control (8014)<br />

Mechanical Systems<br />

Basic Mechanical Drive Components (ME01)<br />

Machine Statics and Dynamics (ME02)<br />

Machine Shafts and Keys (ME03)<br />

Bearings (ME04)<br />

Belt Drives (ME05)<br />

Chain Drives (ME06)<br />

Machine Shaft Couplings (ME07)<br />

Machine Gear Drives (ME08)<br />

Speed Reducers (ME09)<br />

Electric Brakes (ME10)<br />

Basic Power Electricity<br />

Electrical Circuits (EA01A)<br />

Resistors and Conductors (EA01B)<br />

LCR Circuits (EA01C)<br />

Motors & Generators (EA01D)<br />

Pneumatics<br />

Pneumatics 1: Fundamentals (8068)<br />

Hydraulics<br />

Hydraulics 1: Fundamentals (8008)<br />

Mechanical Systems<br />

Laser Alignment (ME11)<br />

Vibration Analysis (ME12)<br />

Bearing Maintenance (ME13)<br />

Electrical Control Systems<br />

Electric Circuit Protection And Monitoring (EA02)<br />

Transformers (EA03)<br />

Electric Motors (EA04)<br />

Electromagnetic Motor Starters (EA07)<br />

Relays, Timers, and Time Delay Relays (EA08)<br />

Pilot Devices (EA09)<br />

Solid-State Reduced Voltage Starters (EA11)<br />

Variable Frequency Drives (VFDs) (EA12)<br />

Solid-State Drive and DC Motor Control (EA16)<br />

Industrial Power Electronics<br />

Oscilloscope (EB01A)<br />

Digital Multimeter (EB01B)<br />

Hand Held Digital Oscilloscope (EB01C)<br />

DC Power Supplies (EB02A)<br />

Single-Phase and Three-Phase Power Supplies (EB02B)<br />

Thyristor Electric Motor Drives (EB03)<br />

Electronic Timers (EB04)<br />

Stepper Motor Drives (EB05)<br />

Servo Motor Drives (EB06)<br />

Pneumatics<br />

Pneumatics 2: Advanced (8069)<br />

Pneumatics 3: Electro-Pneumatics (3039)<br />

Hydraulics<br />

Hydraulics 2: Electro-Hydraulics (3025)<br />

Electrical Control Systems<br />

Programmable Logic Control - MicroLogix (EA18)<br />

Programmable Logic Control -Allen-Bradley SLC 500 (EA20)<br />

Electromechanical Maintenance Cell<br />

Basic Maintenance Cell (ZA01)<br />

Conveyor, Drive And Controls (ZA02)<br />

Part Manipulation (ZA03)<br />

Industrial Lighting Circuits (ZA04)<br />

Adjustable Frequency Drive (ZA05)<br />

DC Motor Drive (ZA06)<br />

Fault Insertion System (ZA07)<br />

In-Demand Green-Tech Skills!<br />

Demand is high for skilled workers in the<br />

green technology sector! Industries involved in<br />

harnessing renewable energy sources, conserving<br />

natural resources and reducing pollution face a<br />

shortage of qualified entry-level candidates<br />

possessing critical skills.<br />

These “in-demand” jobs include:<br />

•solar photovoltaic (PV) system installers<br />

•wind-turbine <br />

technicians<br />

•clean-energy <br />

production<br />

technicians<br />

JobMaster certification<br />

provides the critical skills needed<br />

to fill this demand!<br />

Key<br />

Increased Demand Green occupation<br />

Enhanced Skills Green occupation<br />

New and Emerging Green occupation<br />

Per the US Bureau of Labor Statistics<br />

Level I Careers<br />

The Level 1 Maintenance Technician Certification serves as a strong foundation<br />

for a rewarding career in industrial maintenance. Upon completion, trainees<br />

possess the skills to qualify for entry level quality control, electrical and<br />

mechanical technician positions.<br />

Some sample careers include:<br />

Position<br />

Industrial Maintenance Assistant<br />

Assembly Technician/ Inspector<br />

Electric Equipment Assembler<br />

Quality Control / Test Technician<br />

Wind Turbine Service Technician<br />

Repair Technician<br />

Mechanical Maintenance Technician<br />

Tool Repair Technician<br />

Machinery Maintenance Technician<br />

Security Installation Technician<br />

Field Service Technician<br />

Solar Photovoltaic Installer<br />

Industrial Maintenance Mechanic<br />

i<br />

e<br />

n<br />

i<br />

i<br />

i<br />

e<br />

n<br />

i<br />

n<br />

Level II Careers<br />

With more advanced fluid power and motor control skills, the Level II<br />

certification leads to rewarding positions in automation, process control<br />

and power plant operations. This Certification builds a foundation in motor<br />

installation, maintenance and control and delivers in-demand skills in system<br />

automation with programmable logic controllers.<br />

Sample career choices include:<br />

Position<br />

Motor Control Assembler<br />

Installation Technician<br />

Telecommunications Line Installer<br />

Electric Motor Repair Technician<br />

Instrument and Controls Technician<br />

Heavy Equipment Technician<br />

Marine Electrician<br />

Process Control Technician<br />

Fluid Power Technician<br />

Motor Control Technician<br />

Hydroelectric Plant Technician<br />

Mechanical Engineering Technician<br />

Industrial Electrician<br />

Career Pathways<br />

Electrical Engineering Technician<br />

Telecommunications Technician<br />

i<br />

n<br />

i<br />

e<br />

e<br />

Level III Careers<br />

The Level III Technician Certification is the highest level certification available in<br />

Industrial Maintenance program. Covering full plant installation, maintenance<br />

and troubleshooting, Level III Technicians possess all the skills necessary for full<br />

plant operations. Certified trainees can obtain high level positions leading to<br />

supervisory and management careers:<br />

Position<br />

Environmental Engineering Technician<br />

Industrial Engineering Technician<br />

Electromechanical Technician<br />

Millwright<br />

Electrical Lineworker<br />

Avionics Technician<br />

Maintenance Supervisor<br />

PLC Programmer / Controls Engineer<br />

Engineering Technician<br />

Solar Energy Installation Manager<br />

Power Plant Operator<br />

Substation Instrument & Control Technician<br />

Industrial Safety and Health Engineer<br />

Industrial Engineer<br />

Industrial Production Manager<br />

Quality Control Systems Manager<br />

Wind Energy Operations Manager<br />

n<br />

e<br />

e<br />

i<br />

i<br />

i<br />

n<br />

n<br />

i<br />

i<br />

i<br />

n<br />

35-PO10-JM02 Rev-C<br />

© 2008-2010 intelitek, inc. All rights reserved.<br />

All specifications, available courses and listed skills subject to change.<br />

w w w . i n t e l i t e k . c o m