PDA's 9th Annual Conference a Huge SUCCESS! - Polyurea ...

PDA's 9th Annual Conference a Huge SUCCESS! - Polyurea ...

PDA's 9th Annual Conference a Huge SUCCESS! - Polyurea ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PODIUM<br />

P O L Y U R E A D E V E L O P M E N T A S S O C I A T I O N<br />

V O L . 9 , N O . 2 | S E C O N D Q UA RT E R 2 0 0 8<br />

IN THIS ISSUE<br />

1 PDA’s <strong>9th</strong> <strong>Annual</strong><br />

<strong>Conference</strong> – An<br />

Industry Success!<br />

4 President’s Message<br />

7 Case Study - British<br />

Royal Navy (Exterior of<br />

Petroleum Reservoir<br />

and Rivets)<br />

13 International Market<br />

Research Study Update<br />

14 PDA Europe<br />

PDA’s <strong>9th</strong> <strong>Annual</strong> <strong>Conference</strong><br />

a <strong>Huge</strong> <strong>SUCCESS</strong>!<br />

By Erin Nied, Associate Director<br />

PDA’s 9 th <strong>Annual</strong> <strong>Conference</strong> was an<br />

Industry Success! The conference theme,<br />

“<strong>Polyurea</strong>: Where Technology Shapes<br />

Solutions,” was put into action as the 210<br />

attendees from 15 different countries had<br />

the opportunity to learn from case studies of projects<br />

incorporating polyurea, sessions focusing on<br />

construction specifications and new technologies.<br />

Keynote speaker, Charles Vander Kooi, who spoke<br />

about, “Four Principles to Negotiating,” gave<br />

attendees momentum the rest of the conference<br />

with his enthusiasm as he kicked off the General<br />

Session! For the second year, attendees could<br />

choose a track session meant to fit their specific<br />

membership category and precise presentations<br />

that appeal to their needs.<br />

PDA again offered the course, “Introduction to<br />

<strong>Polyurea</strong>” which is geared at educating new users<br />

of the technology in addition to providing more<br />

information to engineers and specifiers. Appearing<br />

for its third year in PDA’s educational line up was<br />

the course, “Surface Preparation.” This four-hour<br />

course was designed to train applicators the proper<br />

methods of preparing all types of surfaces prior to<br />

the application of polyurea. Both of these courses<br />

were well attended.<br />

PODIUM | FIRST QUARTER 2008 | 1

Don Dancey, Innovative<br />

Painting & Waterproofing<br />

gave a very insightful<br />

presentation on “<strong>Polyurea</strong>s<br />

Role in Submarines at<br />

a Southern California<br />

Amusement Park.”<br />

The 2008 Platinum Project Award Winner:<br />

Mario Lefebvre, Polyval Coatings, Inc.<br />

The 2008 Platinum Development Award Winner: Dennis<br />

Keich and Chad Weatherford, Specialty Products, Inc.<br />

Rob Loomis, Willamette Valley<br />

Company, accepts his Presidential<br />

Award for being such a great PDA<br />

President 2007-2008!<br />

Our PDA Spray Course Instructors Dudley<br />

Primeaux, Primeaux Associates LLC and Doug<br />

Commette, <strong>Polyurea</strong>.com, are always supporting<br />

PDA at our conferences!<br />

The Board of Directors gathers at the front of the<br />

hotel before a round of cocktails!<br />

The Mentalist somehow got Emily May,<br />

WillametteValley Company to light up the light<br />

blubs without plugging them in!<br />

Lee Hanson, The Hanson Group,<br />

closes out the <strong>Annual</strong> Awards Banquet<br />

by thanking our sponsors: The Dow<br />

Chemical Company and Graco.<br />

PDA hosted its fourth annual Platinum<br />

Poster Development & Project Awards,<br />

an opportunity for members to be<br />

recognized by PDA for exceptional<br />

applications and advances in polyurea<br />

technology. Posters were on display<br />

throughout the Platinum Poster<br />

Reception with winners announced<br />

at the <strong>Annual</strong> Business Meeting. The<br />

2008 Platinum Project Award winner<br />

is Polyval with Changi Waste Water<br />

Waterproofing <strong>Polyurea</strong> Project and the<br />

2008 Platinum Development Award<br />

winner is SPI with New Generations of<br />

Chemical Resistant <strong>Polyurea</strong>.<br />

The 4 th <strong>Annual</strong> PDA Awards Banquet<br />

was celebrated with a sumptuous meal,<br />

awards presentation and an evening<br />

of laughter with mentalist Christopher<br />

Carter. The attendees enjoyed<br />

watching fellow PDA members being<br />

tricked on stage by Christopher and<br />

were impressed with his mind readings<br />

skills!<br />

All in all, PDA’s 9 th <strong>Annual</strong><br />

<strong>Conference</strong> was a huge success and<br />

very well attended. The conference<br />

proceeding link is available for all<br />

PDA members in the ‘members only’<br />

section on the website. We hope to<br />

have back everyone who attended this<br />

year and help us spread the word to<br />

make this conference even bigger and<br />

better next year! PDA would also like<br />

to thank the Program Committee and<br />

Attendees for making this <strong>Conference</strong><br />

such a huge success!<br />

PODIUM | FIRST QUARTER 2008 |

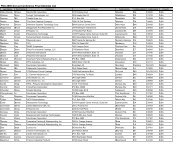

2008 ANNUAL CONFERENCE SPONSORS<br />

The <strong>Polyurea</strong> Development Association appreciates the support of our<br />

members. Their generous support enables the Association to keep meeting<br />

registration fees at a reasonable rate at the same time allowing us to present a<br />

quality program.<br />

Thank you to the following companies for their support.<br />

BASF Corporation<br />

Bayer MaterialScience<br />

Chidley & Peto Company<br />

CoatingsPro Magazine<br />

Custom Linings<br />

D.B. Becker Company, Inc.<br />

Dorsett & Jackson, Inc.<br />

Dow VORASTAR Spray<br />

G.K. Technochem PVT LTD<br />

Graco, Inc.<br />

The Hanson Group<br />

Huntsman Corporation<br />

Matteson-Ridolfi, Inc.<br />

Primeaux Associates, LLC<br />

Rebus, Inc.<br />

Ribelin Sales, Inc.<br />

The Sherwin-Williams Co.<br />

SSPC: The Society for Protective Coatings<br />

VersaFlex Inc.<br />

Visuron Technologies, Inc.<br />

X-Calibur Construction Services<br />

Thank you to the exhibitors at the<br />

PDA 2008 <strong>Annual</strong> <strong>Conference</strong> in Atlanta!<br />

Adhesive Systems Technology Corp.<br />

Advanced Resin Coatings<br />

CHLOR RID International, Inc.<br />

Clariant Corporation<br />

CoatingsPro Magazine<br />

Custom Linings, Inc.<br />

Diamond Liners, Inc.<br />

Finishing Today and Paint & Coating Industry<br />

(PCI) Magazine<br />

Gama Machinery USA, Inc.<br />

GlasCraft, Inc.<br />

Graco, Inc.<br />

J. Calman Industries LLC<br />

JPCL – PaintSquare<br />

Lehigh Technologies, Inc.<br />

Lonza, Inc.<br />

Quantum Technical Services Ltd.<br />

Reactamine Technology, LLC an Amber<br />

Chemical Company<br />

Rebus, Inc.<br />

Repi LLC<br />

Sherwin-Williams<br />

Specialty Products, Inc.<br />

Sponge-Jet, Inc.<br />

SSPC: The Society for Protective Coatings<br />

The Dow Chemical Company<br />

The Hanson Group, LLC<br />

The Sherwin-Williams Company<br />

PODIUM | FIRST QUARTER 2008 |

PRESIDENT’S<br />

MESSAGE<br />

First, I would like to thank Chalise, Erin, Ken and<br />

all those at Robstan for putting on an excellent<br />

PDA <strong>Conference</strong> in Atlanta. It was very well<br />

attended by over 200 manufacturers, formulators,<br />

architects, contractors, and applicators from over<br />

15 countries. The programs were well run and very<br />

timely. It is apparent that all that attended left with<br />

more knowledge and network connections than they<br />

came to the conference with. As I look back to the<br />

Lee Hanson beginning of the PDA over eight years ago, there<br />

The Hanson Group were a few people with a lot of knowledge about<br />

Duluth, GA spray polyureas. Today there are many experts in<br />

this field. The education, training, and promotion that the <strong>Polyurea</strong><br />

Development Association has given to this industry are evident in all<br />

of these members with a vast knowledge of many different successful<br />

polyurea applications and technologies. All the volunteer members<br />

of PDA that serve on the various committees should be commended<br />

for doing a great job these past eight years. We have created an<br />

industry that is viable and growing at a tremendous rate. I hope to<br />

see many more people and companies join our organization and help<br />

carry the load into the future as <strong>Polyurea</strong>s expand into many different<br />

applications and far away geographies.<br />

During 2007, we commissioned a professional marketing company<br />

to conduct a global study of the <strong>Polyurea</strong> industry. The PDA paid over<br />

$65,000 for this study (sponsored completely by a few of our members)<br />

and the results are in and are very exciting. The study provides a<br />

breakdown of the <strong>Polyurea</strong> market by geography, chemistry, application<br />

and use. The growth trend is in the range of 15-25% annual growth,<br />

but is not inclusive of many of the OEM projects that are soon to be<br />

commercial. If all the large projects start that are in the queue, I do<br />

not believe that there are enough raw materials to supply this growth.<br />

It’s a good problem to have, but one that must be addressed today in<br />

order to secure <strong>Polyurea</strong>’s future. If you’d like to learn more about the<br />

direction that <strong>Polyurea</strong>s are going, purchase a copy of the market study.<br />

It is available to members today and nonmembers in May.<br />

In addition to the growth of <strong>Polyurea</strong> usage, we have seen the<br />

successful commencement of PDA Europe marked by their first annual<br />

conference held in Belgium in November. This conference was attended<br />

by over 150 representative companies. During the coming months, we<br />

are looking into the feasibility of creating an Asia subchapter of PDA. It<br />

is still in discussion, but there are many <strong>Polyurea</strong> opportunities in the<br />

Far East and there is a need for PDA training and education.<br />

Wrapping up my first Podium address, I’d like to invite you to get<br />

more involved with the PDA Organization. Don’t let some of these<br />

new technologies and applications slip past you. We need everyone’s<br />

involvement to sustain the education, training and promotion of<br />

<strong>Polyurea</strong>s and PDA. We will have a Mid-Year meeting of the committees<br />

in Kansas City and the <strong>Annual</strong> <strong>Conference</strong> will be in Albuquerque, NM<br />

in January 2009.<br />

BOARD OF<br />

DIRECTORS<br />

Congratulations to the newly elected PDA Board Members!<br />

PRESIDENT<br />

Lee Hanson<br />

The Hanson Group, LLC<br />

770.495.9554<br />

lhanson@hansonco.net<br />

PRESIDENT ELECT<br />

Don Dancey<br />

Innovative Painting & Waterproofing<br />

714.257.0200<br />

don@waterproofingcontractor.com<br />

SECRETARY-TREASURER<br />

John Turnour<br />

Rebus, Inc<br />

610.497.4710<br />

jturnour@rebusinc.net<br />

IMMEDIATE PAST PRESIDENT<br />

Robert Loomis<br />

Willamette Valley Company<br />

541.484.9621<br />

07robl@wilvaco.com<br />

DIRECTORS<br />

Sean Boeger<br />

Poly-Pro Industrial Coatings, LLC<br />

203.961.9888<br />

boeger@polypro.net<br />

Kelin Bower<br />

PolyVers International<br />

713.466.4988<br />

kelin@polyvers.com<br />

Dan Canavan III<br />

D.B. Becker Co., Inc.<br />

908.730.6010<br />

dtcanavan3@dbbecker.com<br />

David Cerchie<br />

Versa Flex Inc.<br />

913.321.9000<br />

david@versaflex.com<br />

Tony Gargano<br />

Graco, Inc.<br />

612.623.6087<br />

agargano@graco.com<br />

Christiane Hackl<br />

BASF Corporation<br />

973.245.6525<br />

christiane.hackl@basf.com<br />

Jay Johnston<br />

Bayer MaterialScience<br />

412.777.2512<br />

jay.johnston@bayerbms.com<br />

Dudley Primeaux<br />

Primeaux Associates, LLC<br />

512.461.5023<br />

polyurea@flash.net<br />

Mark White<br />

Industrial Trim, LLC<br />

678.432.0397<br />

industrialtrim@industrialtrim.com<br />

INTERNATIONAL DIRECTORS<br />

Jackson Ang<br />

Naret Group of Companies Co., LTD<br />

01060502222<br />

sa08458@singnet.com.sg<br />

Marc Broekaert<br />

Huntsman Corporation<br />

3227588814<br />

marc_broekaert@huntsman.com<br />

Bernd Dietz<br />

REMA TIP TOP GmbH<br />

498121707255<br />

bernd.dietz@tiptop.de<br />

Tony LaGrange<br />

Quantum Technical Services, Ltd.<br />

780.454.9166<br />

tony@quantumchemical.com<br />

Sincerely, Lee Hanson, PDA President 2008-2009<br />

PODIUM | FIRST QUARTER 2008 |

IN MEMORY OF THOMAS E. DAVIS –<br />

POLYUREA PIONEER<br />

By Dudley J. Primeaux, II,<br />

Primeaux Associates, LLC<br />

A<br />

little over 20 years<br />

ago, Tom Davis<br />

was an engineer<br />

with Dunnage<br />

Engineering in<br />

Brighton, Michigan. Tom<br />

had heard of this new<br />

polyurea spray technology<br />

and thought that he could<br />

use to replace the slush<br />

molded PVC they used<br />

for dunnage protection in<br />

automotive applications.<br />

In a very short time, Tom<br />

was able to get this work<br />

into the facility, but saw the<br />

opportunity he could have<br />

Tom Davis, Visuron Technologies with his own work. After<br />

several discussions back<br />

and forth as well as heartto-heart<br />

communications<br />

with his wife and friend,<br />

Marcia Davis, they took<br />

their savings, left current<br />

employment and formed<br />

Visuron Technologies. “He was so excited, and you could see<br />

the passion in his eyes and heart, I am honored to have been<br />

there with him at the start,” claims good friend and associate<br />

Dudley J. Primeaux, II.<br />

Now Tom was a very smart engineer having spent much time<br />

working in automotive application areas. He was actually lead<br />

engineer and inventor in some very important inorganic ceramic<br />

coatings work still being used today.<br />

Many of us knew Tom as a Founding Father and past Board<br />

of Director of the PDA, committee member, exhibitor and<br />

presenter. Tom was even on front stage for several of the first<br />

PDA meetings trying to discuss that nasty thing of failures. He<br />

even shared with us a failure that cost him financially. But<br />

we have learned from our lessons and moved on to improve<br />

polyurea technology, equipment and application.<br />

Tom and his company, Visuron Technologies, was noted<br />

for its aromatic and aliphatic spray polyurea systems, the<br />

high chemical resistant coating / lining materials, the single<br />

component MIAC polyurea, the foul release systems, potable<br />

water approved systems, the robotic pipelining equipment and<br />

structural materials and the newly demonstrated commercial<br />

electrostatic spray applied polyurea.<br />

What many suppliers and applicators don’t realize is that Tom<br />

and his work set the stage for most of the materials and work<br />

performed by most of us today. Some of his first work dealt<br />

with asbestos / lead encapsulation and remediation work where<br />

he had strippable systems. He was the first to design and apply<br />

in-mold polyurea coating systems for soft-feel spa and hot-tub<br />

work. Many of his polyurea / geotextile secondary containment<br />

systems have been in use now for 15+ years. He solved bughole<br />

issues in concrete coating work using the adhered geotextile<br />

membrane system for both major secondary containment and<br />

aquarium lining projects. There was also EPS encapsulation<br />

projects for automotive end use, clear applied polyurea for<br />

decorative waterproofing, blast mitigation / structural support,<br />

roofing, underwater sealants and the first silicone backbone<br />

polyurea systems. Tom was a pioneer. Tom was a visionary.<br />

Tom was a husband, married to his friend and partner Marcia for<br />

20 years. Tom was a brother, with two older siblings, one living<br />

in California and one living in Michigan. He was a Father and<br />

Dad, having two sons and two daughters. He was a Grandfather<br />

(5) and a Great-Grandfather (2). He was a rescuer of his faithful<br />

companions Ginger and Val, who were by he and Marcia’s sides<br />

at all times.<br />

Tom was an honest, humble gentleman, simple at heart being<br />

a community volunteer, believer in the USA and supporter<br />

of our military and veterans. He would listen intently to<br />

conversations, share experiences and have a laugh or two. But<br />

most importantly, Tom was a Christian, and our friend.<br />

Every time Tom and his good friends spoke, whether it be at<br />

conventions / shows, job sites or on the telephone, he always<br />

found the time to discuss life, family and friends. It was talk<br />

much like childhood friends would do while sitting on the banks<br />

a soft flowing river on a warm spring day or in a freshly erected<br />

tree house. Tom had recently taken up flying model airplanes<br />

for relaxation. Even though he crashed and temporarily lost his<br />

first plane on an earlier run, he got another one and continued<br />

forward.<br />

We all have many fond memories and stories of Tom that will be<br />

with us forever. I am sure that many of you have the same.<br />

Our industry has lost an innovator, a pioneer, a leader, a<br />

volunteer, a team member and associate. To those of us here at<br />

PDA, we have lost a great friend.<br />

This article is memory of Tom Davis. It was excerpted<br />

from a memorial speech given by Dudley J. Primeaux, II at<br />

the 2008 PDA <strong>Conference</strong> in Atlanta, Georgia, USA. Tom<br />

Davis and Dudley were very close friends. He will always be<br />

remembered.<br />

PODIUM | FIRST QUARTER 2008 |

SAVE THE DATE!<br />

PDA’s 2008 Mid-Year Meeting<br />

August 26-28, 2008 –<br />

Embassy Suites,<br />

Kansas City – Plaza<br />

Kansas City, MO<br />

Make sure to SAVE THE DATE<br />

for PDA’s 2008 Mid-Year Meeting!<br />

This year’s meeting will focus on<br />

CONCRETE including job profiles,<br />

specification, green building<br />

and business!<br />

SAVE THE DATE!<br />

PDA’s 2009 <strong>Annual</strong> <strong>Conference</strong><br />

January 20-23, 2008 – Embassy Suites<br />

Albuquerque, NM<br />

NEW MEMBERS<br />

CONTRACTOR/APPLICATOR<br />

Applied Polymer<br />

Coatings, Inc.<br />

Brian Henry<br />

Olney, MD USA<br />

301.260.1922<br />

Centimark Corp.<br />

Pat McCoy<br />

Lenexa, KS USA<br />

913.227.0675<br />

Crown Painting, Inc.<br />

Mike Conversa<br />

Mokena, IL USA<br />

708.478.0505<br />

Denmax LLC<br />

Andrey Veretenov<br />

Reston, VA USA<br />

703.362.4488<br />

Dimensional<br />

Innovations<br />

Brian Georgie<br />

Overland Park, KS<br />

USA<br />

913.384.3488<br />

Fibre Tech Inc<br />

Scott Morris<br />

Largo, FL USA<br />

727.539.0844<br />

H.S.P.C. Ltd.<br />

Craig Johns<br />

Stoke on Trent,<br />

Staffordshire England<br />

00447768022461<br />

Hyperion<br />

Technologies Inc.<br />

Debbie Glenesk<br />

Calgary, AB Canada<br />

403.221.1410<br />

K & G Midwest Spray<br />

Coatings, LLC<br />

Gary Fish<br />

Richland Center, WI<br />

USA<br />

608.604.1901<br />

MacDonald<br />

Applicators Limited<br />

Andrew MacDonald<br />

Saint John, NB<br />

Canada<br />

506.633.1981<br />

Odle, Inc.<br />

John Linder<br />

Muncie, IN USA<br />

Premium Protective<br />

Coatings<br />

John Moyer<br />

Palmyra, PA USA<br />

717.821.4654<br />

Raschta Coatings Pty<br />

Ltd<br />

Brendan Duffy<br />

South Brisbane, QLD<br />

Australia<br />

61450310355<br />

S.B.P. Specialties<br />

Bob Condie<br />

Greely, ON Canada<br />

613.913.1684<br />

Valpolymer SRL<br />

Antonio Valli<br />

Credaro, BG Italy<br />

390354265011<br />

FORMULATOR/SYSTEM<br />

SUPPLIER<br />

Advanced Resin<br />

Coatings LLC<br />

Tom Wunderlin<br />

Millersville, MD<br />

USA<br />

410.925.3942<br />

Arnette Limited, Inc.<br />

R. Scott McPherson<br />

Richmond, MO USA<br />

816.776.3005<br />

Beijing Zhongtong<br />

New Building<br />

Materials Co.<br />

Zengke Sun<br />

Beijing, P.R. China<br />

+86-10-63819525<br />

Bondo/3M<br />

Corporation<br />

Jackie Johnson<br />

Atlanta, GA USA<br />

404.696.2730<br />

RAW MATERIAL SUPPLIER<br />

Evonik/Degussa<br />

Corporation<br />

Samy Saad<br />

Piscataway, NJ USA<br />

732.981.5157<br />

Guangzhou Supe<br />

Chemical Co., LTD<br />

Zairong Yan<br />

Cuangzhou,<br />

Guangdong China<br />

862034772182<br />

ARCHITECT/ENGINEER/<br />

SPECIFIER<br />

ICS Building<br />

Technologies<br />

Kenneth Rudd<br />

Cleveland, OH USA<br />

216.883.4100<br />

PromoGraphics Int’l,<br />

Inc.<br />

Michael Gerson<br />

Fort Lauderdale, FL<br />

USA<br />

954.801.6462<br />

Tru-Trac<br />

Manufacturering<br />

Tim O’Carroll<br />

Pretoria, Gauteng<br />

South Africa<br />

+24(0)126619531<br />

ACADEMIC/GOVERNMENT/<br />

STUDENT<br />

Qingdao<br />

Technological<br />

University<br />

Weibo Huang<br />

Qingdao, Shandong<br />

Province P.R. China<br />

+86-532-85071275<br />

CONSULTANT<br />

Kinetic Blending<br />

Steve Chandler<br />

Lakewood, WA USA<br />

253.984.9336<br />

EQUIPMENT DISTRIUBTOR<br />

CPI<br />

Randy Kugler<br />

Barberton, OH USA<br />

330.861.5200<br />

INDEPENDENT SALES<br />

REPRESENTATIVE<br />

Award Specialty<br />

Services<br />

Al Ward<br />

Dallas, GA USA<br />

678.363.5845<br />

PODIUM | FIRST QUARTER 2008 |

CASE STUDY<br />

BRITISH ROYAL NAVY<br />

(EXTERIOR OF PETROLEUM<br />

RESERVOIR AND RIVETS) By: Polyval Coatings Inc.<br />

Project: Waterproofing and corrosion protection on<br />

exterior and rivet joints<br />

Owner: British Royal Navy<br />

Contractor: Copas Coatings Inc.<br />

System: Mono Ferro Pur, Polyflex 202<br />

Surface: 20,000 p 2 / 1,857 m 2<br />

Completed: 2006<br />

Location: Singapore<br />

The Royal British Navy had been experiencing many<br />

different waterproofing and corrosion problems on the<br />

exterior of their petroleum reservoir tanks. They have over<br />

20 petroleum reservoirs which have been built over 40<br />

years ago. The reservoirs contain the diesel and kerosene<br />

they use to fill up the ships. Over the years the oil had<br />

been seeping through the rivets along the outside of the<br />

petroleum reservoir. Furthermore, it was very important<br />

to be repaired immediately as the damage created a poor<br />

aesthetic appearance of the tanks and there was loss of<br />

fuel. There were two possibilities; replace the tanks<br />

(which would take months and be extremely costly) or<br />

repair the rivets with <strong>Polyurea</strong> which would put back the<br />

installation in days and be very cost efficient.<br />

The decision was made and the Royal British Navy<br />

partnered with Polyval Coatings Inc., a PDA member, to<br />

become their <strong>Polyurea</strong> supplier. Polyval Coatings supplied<br />

a special <strong>Polyurea</strong> formulation that resisted against the<br />

petroleum products such as; crude oil, diesel, kerosene<br />

and jet fuel.<br />

Copas Coatings Inc. was selected as the general contractor<br />

for this project and the job began in 2006.<br />

This system was applied with one layer of Mono Ferro<br />

Pur, a moisture cure polyurethane primer, followed<br />

by one coat of Polyflex 202 at 2.00 mm D.F.T. (80<br />

mills). As a top coat, they applied one coat of aliphatic<br />

moisture cure polyurethane of Xymax. The Xymax<br />

line of products is used to protect the color stability<br />

and retain the gloss. It’s fast drying and curing<br />

time made it possible to put back the installation in<br />

operation in just a few days.<br />

PODIUM | FIRST QUARTER 2008 |

POLYUREA<br />

APPLICATOR SPRAY COURSE<br />

<strong>Polyurea</strong> Development Association<br />

GET THE EDGE ON YOUR COMPETITION.<br />

The <strong>Polyurea</strong> Development Association’s Applicator<br />

Spray Course is the most comprehensive training in the<br />

polyurea market today. If you’re serious about polyurea,<br />

don’t miss the opportunity to get ahead in the industry!<br />

2008 DATES:<br />

July 8-11<br />

October 7-10<br />

Location: Houston, Texas<br />

For more information and registration<br />

please visit PDA’s website:<br />

www.pda-online.org or call 816.221.0777<br />

SanRafaelBridge<br />

GasPipeline Asia<br />

SiliconeModified100%<strong>Polyurea</strong><br />

•Geltimefrom3seconds– 60minutes<br />

•BroadApplicationRange0120F<br />

•ExcellentTearandAbrasionResistance<br />

•Excellentflexibility<br />

Forafullrangeof100%<strong>Polyurea</strong>Technology<br />

Pleasecontactus<br />

Lawrenceville,Georgia30043<br />

Phone:(770)4830480Lawrenceville,Georgia30043<br />

ReactAmine® Technology, LLC<br />

Phone:(770)4830480<br />

Lawrenceville, GA. 30043<br />

(770) 483-0480<br />

PODIUM | FIRST QUARTER 2008 |

FROM THE SAFETY COMMITTEE<br />

Eight Major Mistakes (Or,<br />

What Not to Do When Workers’<br />

Compensation Rates Drop) By Frank Pennachio<br />

When workers’ compensation rates decline,<br />

don’t shift your attention to other parts of<br />

the business or become complacent.<br />

Throughout much of the country, declining workers’ compensation<br />

rates are music to employers’ ears. After all, that seems like longawaited<br />

good news, particularly since workers’ compensation is<br />

more often than not viewed as a necessity and a significant cost<br />

of doing business.<br />

Yet, looking at workers’ compensation as a business necessity or<br />

a commodity is a major fallacy. Although most employers fail to<br />

recognize it, workers’ compensation is a core business practice<br />

and a means for improving the bottom line.<br />

Rather than diverting attention and finances to other business<br />

priorities during periods of lower workers’ compensation rates,<br />

employers can benefit by taking steps to guarantee long-term<br />

savings. Here are eight mistakes employers should avoid so they<br />

can achieve long-term workers’ compensation savings.<br />

1. Confusing Lower Premium Rates with Cost Reductions<br />

Many employers are surprised to learn that a reduction in workers’<br />

compensation rates does not always mean a reduction in costs.<br />

Let’s begin with a basic understanding of what determines the<br />

cost of workers’ compensation insurance. Unlike other insurance,<br />

workers’ compensation functions like a credit line to finance the<br />

costs of injuries. As such, rates alone do not determine the overall<br />

cost An experience modification factor (Mod) tailors the cost of<br />

insurance to the individual loss performance of an employer. A<br />

workers’ compensation premium is calculated by this formula:<br />

Rate x $100 payroll x experience modifier.<br />

The Mod calculation is complex, but in general, an employer<br />

is compared with similar employers in the same industry<br />

classification and if past losses are lower than average, a credit<br />

rating reduces the premium. Conversely, if past losses are higher<br />

than average, a debit rating can actually increase costs in spite of<br />

lower rates.<br />

2. Becoming Complacent<br />

Declining rates act as blinders for many employers. With lower<br />

prices, it’s easy to shift focus away from injury management and<br />

cost containment to other, more pressing business matters.<br />

While increased attention to safety led to a decline in the number<br />

of workplace accidents, resulting in fewer claims and lower rates,<br />

claim frequency is only one part of the equation. The other part,<br />

claim cost including indemnity (lost wages) and medical care,<br />

continues to rise.<br />

In many industries where there are tight labor markets, wage<br />

gains are expected to trend higher, suggesting further increases<br />

in indemnity severity. At the same time, medical care costs have<br />

marched relentlessly upward since the mid 1990s.<br />

Even more disturbing is the fact that the growth in workers’<br />

compensation medical costs has been much steeper than in the<br />

health care industry as a whole, indicating that it is not only<br />

medical inflation but a mix of services and over-utilization that<br />

are driving up costs.<br />

If claims remain open and injury costs escalate, reserves (estimate<br />

of ultimate cost of injury) rise and adversely affect the employer’s<br />

experience modification factor, thus increasing costs. Employers<br />

need to understand what is impacting medical costs and measure<br />

key metrics such as cost per claim trends adjusted for diagnosis<br />

and severity.<br />

3. Focusing Only on Direct Costs<br />

Ask a business person how much he or she spends on workers’<br />

compensation and almost all will respond with the price of the<br />

premium. Yet, the direct costs of workers’ compensation often<br />

represent only 20 percent to 30 percent of the overall injury<br />

expenses.<br />

Indirect costs, including overtime, temporary labor, increased<br />

training, supervisor time, production delays, unhappy customers,<br />

increased stress and property or equipment damage represent<br />

several times the direct cost of the injury. A 2002 Safety Index<br />

report by Liberty Mutual tallied the direct cost of workplace<br />

injuries at $40.1 billion. The total financial impact of both direct<br />

and indirect costs was estimated to be as much as $240 billion.<br />

Injury costs – both direct and indirect – will have a much greater<br />

impact on an employers’ overall costs than rate decreases.<br />

4. Thinking That Rates Will Stay Low<br />

Historically, the workers’ compensation price cycle has repeated<br />

in a predictable pattern: Rates decline, insurance is purchased<br />

for a lower price, employers shift focus away from workers’<br />

compensation, claim costs do not fall in relationship to reduced<br />

rates and employers’ Mod increases, legislative reforms erode<br />

CONTINUED ON PAGE 10<br />

PODIUM | FIRST QUARTER 2008 |

CONTINUED FROM PAGE 9<br />

or become ineffective, insurance company profits diminish and<br />

rates increase.<br />

During a declining rate cycle, the plan expects that if rates go<br />

down, so should injury costs. If employers do not manage injury<br />

effectively and claims do not go down, the employer’s Mod will<br />

go up. When rates rise again, the increased Mod will wipe out<br />

any savings garnered during the declining rate cycle.<br />

5. Viewing Workers’ Compensation as an Expense<br />

Employers should recognize that workers’ compensation is more<br />

than a necessary expense; it is a controllable aspect of business<br />

that if managed properly will have a measurable and positive<br />

return on investment (ROI).<br />

In ROI Selling, authors Michael Nick and Kurt Koenig note<br />

three measures of ROI: “Return on investment occurs when a<br />

company realizes an increase in revenue, a reduction in cost or<br />

an avoidance of cost.”<br />

Viewing workers’ compensation as an ongoing process and not<br />

an expense can accomplish all three. When injuries do occur,<br />

employers can increase their revenues by getting employees<br />

back to work quickly and reduce their costs by managing the<br />

injury effectively. By recognizing that workers’ compensation<br />

begins at the date of hire, employers can avoid costs by hiring<br />

the right people.<br />

6. Separating Workers’ Compensation From Employee<br />

Retention<br />

Retaining skilled employees is one of the most difficult challenges<br />

facing businesses today. Turnover is extremely costly. According<br />

to estimates, it is anywhere from 50 percent to 150 percent of an<br />

employee’s annual salary.<br />

If a work-related injury is not managed properly, it can result in<br />

the unnecessary loss of a skilled, trained employee. The longer<br />

employees are away from the job, the less likely they are to<br />

return. Statistics show that if employees are not back to work<br />

within 12 weeks, they only have a 50 percent chance of ever<br />

returning.<br />

The fundamental reason for most lost time is not medical<br />

necessity but the non-medical decision-making and lack of a<br />

process that occurs after an employee is injured. The workplace<br />

response is key – studies show that employees’ satisfaction<br />

with their employer’s response has a much larger impact on<br />

employment stability than does their satisfaction with health care<br />

itself. Being guided by a plan that focuses on communication<br />

and return to work will be far more effective than declining rates<br />

in both reducing workers’ compensation costs and improving<br />

productivity.<br />

7. Devaluing Your Relationship With the Insurance Company<br />

or Agency<br />

In a time of declining rates and new competition, there is a<br />

tendency to shop for the lowest price. The insurance industry<br />

is not immune to the old adage, “You get what you pay for.”<br />

Chasing the lowest rate can result in poor service or having to<br />

deal with an insurance company’s unstable finances. In every<br />

“soft market” cycle, insurance companies have gone bankrupt<br />

and been unable to pay claims. It is critical for employers to<br />

investigate the insurer’s stability as well as its long-term<br />

commitment to the workers’ compensation market to mitigate<br />

the possibility of a financial failure.<br />

Furthermore, selecting an agent and carrier with an excellent<br />

understanding of workers’ compensation is very important. The<br />

added benefits of improved hiring practices, medical relationships<br />

and comprehensive injury management services will reduce both<br />

the number of claims and the costs of claims resulting in a lower<br />

Mod. Unlike declining rates, a reduced Mod is a guaranteed way<br />

to drive down costs over the long term.<br />

8. Measuring the Wrong Thing<br />

John Tukey, Ph.D., the prominent statistician, said, “When the<br />

right thing can only be measured poorly, it tends to cause the<br />

wrong thing to be measured well. And, it is often much worse to<br />

have a good measurement of the wrong thing, especially when<br />

it is so often the case that the wrong thing will, in fact, be used<br />

as a indicator of the right thing, than to have a poor measure of<br />

the right thing.”<br />

When workers’ compensation is treated as a commodity, the<br />

decision is reduced to the lowest possible common denominator<br />

– price. This shortsighted approach is equivalent to expecting<br />

gourmet food on a fast food budget. If employers are not<br />

measuring the true financial impact of work-related injuries, they<br />

cannot effectively manage them.<br />

When viewing workers’ compensation as a core business<br />

practice of comprehensive risk management, the focus shifts<br />

from price to tangible metrics that are driving claims costs.<br />

With this information, employers can address the underlying<br />

circumstances and conditions that are pushing up work-related<br />

injury costs and measure the value of their actions.<br />

The declining rate period provides an opportunity and a challenge<br />

for employers. The opportunity is to use the “found” money to<br />

implement practices that will improve their company and profits<br />

– better hiring, injury management and improved education and<br />

training. The one constant that separates employers from their<br />

competitors is their workforce. The challenge is to protect it.<br />

Frank Pennachio, CWCA, is a co-founder and director of<br />

curriculum at the Institute of WorkComp Professionals, an<br />

organization that tests and certifies insurance professionals<br />

with the skills and knowledge necessary to alert employers<br />

about the hidden costs and overcharges in the workers’<br />

compensation insurance system. He can be contacted at frank@<br />

workcompprofessionals.com.<br />

PODIUM | FIRST QUARTER 2008 | 10

MEMBERS IN THE NEWS<br />

PDA Members Author Chapters<br />

in New SSPC Publication<br />

The SSPC: The Society for<br />

Protective Coatings introduced<br />

their new book Selecting Coatings<br />

for Industrial and Marine<br />

Structures during the PACE2008<br />

<strong>Conference</strong> in Los Angeles,<br />

California. This new book, edited<br />

by Dr, Richard W. Drisko, discusses<br />

various coating chemistries used<br />

in protective coating applications.<br />

This includes two chapters on the<br />

polyurea chemistries.<br />

Chapter 7: Two-Component<br />

<strong>Polyurea</strong> Coatings / Linings, was<br />

written by Dudley J Primeaux<br />

II of Primeaux Associates LLC. Chapter 8: Polyaspartics, was<br />

written by Edward P Squiller and Ronald G Eritano of Bayer<br />

MaterialScience, LLC.<br />

The book is available through the SSPC at www.sspc.org.<br />

VersaFlex Incorporated<br />

Announces New Hire<br />

VersaFlex Incorporated is pleased to<br />

announce that Jamie House has been brought<br />

on board to lead ISO certification and head<br />

production quality control team.<br />

Jamie House attended Missouri Southern<br />

State University for Industrial Engineering,<br />

ASQ MEMBERS Certified Six IN THE Sigma NEWS Green Belt,<br />

ISO (Continued) 9001:2000 QMS Management<br />

Representative, PDA Certified <strong>Polyurea</strong> Applicator, Certified<br />

Hazardous Waste Manager per 40 CFR 265.16 . 12 years of<br />

Industrial Chemical manufacturing Diamond Liners, experience, Inc. specializing<br />

in quality improvement Announces and cost New Website reduction projects.<br />

Utilizing 5-S, Six Sigma, and Lean methodologies. Joined<br />

Launch<br />

VersaFlex Incorporated October 2007 to aid in product quality<br />

improvement and plant continued efficiency from page 11 improvements. Currently<br />

implementing ISO 9001:2000 quality systems for certification.<br />

“Our goal is to be on the cutting edge of<br />

internet technology in our industry and<br />

our new website is an innovative method<br />

Diamond Liners E-Commerce Site Features<br />

of continuing to offer the same hands-on<br />

Ratio Check expertise, sales and support that we pride<br />

ourselves on offering to our customers,”<br />

Precision Monitoring System Insures Against Costly Application<br />

said John Bender.<br />

Errors<br />

Santa Fe Springs, CA –– Diamond Liners, Inc., a polyurea<br />

plural component application spray expert and a leading sales<br />

and service provider for OEMs and contractors, launched their<br />

503.7-07: Specification<br />

new website, www.diamondliners.com last year. The website’s<br />

primary function is e-commerce, for Crack offering Repair a full catalog by of parts<br />

and equipment. Diamond Liners offers the Ratio Check precision<br />

monitoring system as a Epoxy customer Injection insurance policy against<br />

application errors.<br />

This Specification gives requirements for<br />

repairing cracks in concrete by injection of<br />

two-component epoxy-resin adhesive. Available<br />

in hard copy or PDF format<br />

To learn more or to order this document, go<br />

to www.concrete.org. $29.50 (ACI members<br />

$18.00); Order Code 503707.EM.<br />

The Ratio Check is ideal for high volume, high risk jobs and<br />

production operations. The compact system attaches directly to<br />

Graco Reactors and other plural-component pumps. The monitor<br />

checks the ratio of the flow of material. The Ratio Check shuts<br />

off the machine before an error becomes large enough to incur<br />

substantial corrective costs. When an off-ratio scenario is detected,<br />

it sounds an audible alarm accompanied by a red flashing light<br />

and immediately shuts down the pumps. The alarm also has an<br />

easy reset feature.<br />

The Ratio Check is completely installed next to the pump<br />

controls for customer convenience and runs on a 110-volt circuit.<br />

Continuous monitoring with LED readouts of all components<br />

helps to ensure early and accurate warnings against errors.<br />

Diamond Liners co-owner John Bender provides further benefits<br />

that customers can expect from using the product.<br />

“There never seems to be enough time to do a spray job right<br />

the first time. But we all will take the time to correct a failed job.<br />

The Ratio Check can save you time by stopping you before the<br />

failure,” he says.<br />

The newly renovated Diamond Liners e-commerce site allows<br />

customers more flexibility and options when it comes to purchasing<br />

manufacturing and foam insulation spray equipment, parts, safety,<br />

testing equipment and more. Graco Reactor and other pluralcomponent<br />

system owners should visit www.diamondliners.<br />

com for more Ratio Check Monitor specifications and to order it<br />

directly online.<br />

CONTACT: Danette Bender, Diamond Liners, Inc.,<br />

562-781-1045.<br />

ATTENDING AN<br />

INDUSTRY<br />

TRADESHOW<br />

<br />

<br />

<br />

<br />

BUSINESS BITS (Continued)<br />

PODIUM | FIRST QUARTER 2008 | 11

PDA APRIL<br />

SPRAY COURSE<br />

By: Erin Nied, Associate Director<br />

PDA’s April Spray Course in Houston, Texas was a huge success!<br />

The course was taught by two of the most respected leaders in<br />

the polyurea industry, Dudley Primeaux II and Doug Commette.<br />

This course helps to identify the many elements involved in the<br />

successful operation and set-up of polyurea spray equipment.<br />

Although designed for the applicators, the course provides an indepth<br />

analysis of commercially available equipment designs and<br />

necessary hardware components to assure successful operation and<br />

spray application of polyureas.<br />

Applicator Spray Course Attendees learned the fundamentals of polyurea such<br />

as the polyurea properties and testing procedures, safety, jobsite planning and<br />

preparation, equipment start-up, surface preparation and much much more!<br />

A BIG Thank you to Polyvers!<br />

On behalf of the <strong>Polyurea</strong> Development Association and the <strong>Polyurea</strong><br />

Training Group instructors, we would like to extend our gratitude<br />

for your assistance in making our January Applicator Spray Course<br />

in Houston, Texas a success. Your commitment and support for our<br />

Spray Course was above and beyond and we thank you!<br />

Applicator Spray Course Attendees got the chance to<br />

individually learn to spray polyurea<br />

Applicator Spray Course Attendees<br />

PODIUM | FIRST QUARTER 2008 | 12

PDA INDUSTRY MILESTONE<br />

The <strong>Polyurea</strong> Development<br />

Association (PDA) has released the<br />

first comprehensive independent<br />

study of markets for pure polyurea<br />

and hybrid systems obtainable in the<br />

world. The Study of the Global <strong>Polyurea</strong><br />

Industry is now available for purchase to<br />

the general public. The study was funded<br />

by the PDA as part of its ongoing effort to<br />

promote clarity and understanding of the<br />

rapidly expanding polyurea technology<br />

industry worldwide.<br />

By design, this inaugural industry study<br />

defines the size of the supply base for<br />

polyurea products on a global basis, and<br />

has individual data compiled for North<br />

America, Europe, Asia and the rest of the<br />

world. It establishes a baseline of data<br />

on polyurea technology in the industry<br />

that can be referenced and used to chart<br />

Thank you<br />

to the Sponsors<br />

of the Global<br />

<strong>Polyurea</strong><br />

Industry Study:<br />

Study of the Global <strong>Polyurea</strong><br />

Industry Available!<br />

By: Ken Bowman, Executive Director<br />

industry direction and trends in coming<br />

years. This furthers the position of<br />

PDA as the main industry resource for<br />

polyurea technology information.<br />

Compilations of the data and the<br />

projections contained in the report are the<br />

product of Ducker Worldwide (Ducker),<br />

an independent global market research<br />

firm based in Troy, Michigan that has<br />

provided strategic intelligence and<br />

consulting services to the chemicals and<br />

industrial marketplace since 1961.<br />

This study was sponsored by forwardthinking<br />

PDA members and important<br />

corrosion related industry associations<br />

including SSPC, NACE and CoatingsPro<br />

Magazine. This generous sponsorship<br />

allowed PDA to complete the important<br />

task of global data gathering.<br />

♣ PLATINUM SPONSORSHIP<br />

BASF Corporation<br />

Bayer Corporation<br />

♣ GOLD SPONSORSHIP<br />

The Dow Chemical Company<br />

♣ SILVER SPONSORSHIP<br />

NACE/CoatingsPro Magazine<br />

SSPC<br />

Table of Contents<br />

& Introduction<br />

For more information about<br />

what is covered in the study,<br />

Please click here.<br />

PDA Exclusive!<br />

The PDA Member price for the study<br />

is $3,500.00 and non-Member<br />

price is $4,500.00, e-mail Erin at<br />

erin@robstan.com or contact PDA<br />

Headquarters at 816.221.0777 for<br />

more information or to place your<br />

order today!<br />

PODIUM | FIRST QUARTER 2008 | 13

PDA EUROPE 2008<br />

ANNUAL CONFERENCE<br />

AND TABLE TOP EXHIBITION<br />

18 – 20 November 2008<br />

Austria Trend Parkhotel Schönbrunn, Vienna<br />

Companies wanting to find out about the very latest developments in the polyurea<br />

industry should register to attend the second <strong>Polyurea</strong> Development Association<br />

Europe (PDA Europe) annual conference. The event, named “Taking <strong>Polyurea</strong><br />

to the Next Level”, will take place from 18 to 20 November at the Austria Trend<br />

Parkhotel Schönbrunn, Vienna.<br />

SUBMIT A PAPER!<br />

By presenting a paper at this<br />

conference, you provide your<br />

organisation with invaluable<br />

industry visibility; gain recognition<br />

amongst your peers; reinforce<br />

your expertise within the POLYUREA<br />

community; and create the opportunity of<br />

advising suppliers of your needs.<br />

Papers are invited from polyurea coating<br />

professionals - from raw material<br />

suppliers to applicators.<br />

Possible topics include:<br />

• case studies on the use of polyurea<br />

coatings<br />

• new technical developments or<br />

chemistry<br />

• environmental and stewardship issues<br />

(REACH, regulatory developments,<br />

approvals etc)<br />

• application technologies<br />

The short summary and presenter’s<br />

biography of the accepted papers will be<br />

included in the official event booklet.<br />

Submission conditions:<br />

• Presentations must not focus on<br />

promotion of a company or its<br />

products.<br />

• All abstracts must be in English and e-<br />

mailed using the Abstract Submission<br />

Form<br />

• Abstracts should be limited to 250<br />

words and accompanied by presenter's<br />

biography of 100 words and photo<br />

• Include the names of all authors of the<br />

presentation.<br />

• The invitation to submit an abstract<br />

does not constitute an offer to pay<br />

travel or accommodation<br />

• By submitting an abstract, you<br />

grant the organisers permission to<br />

include the electronic format of the<br />

presentation in the conference cd<br />

rom for the event - unless otherwise<br />

noted.<br />

• The PDA Europe Programme<br />

Committee will review all abstracts.<br />

The committee reserves the right<br />

to accept and reject abstracts for<br />

inclusion in the program.<br />

• Responsibility for the accuracy of<br />

abstracts rests with the author.<br />

• An abstract which does not adhere to<br />

these requirements is unlikely to be<br />

accepted.<br />

• Further instructions on presentation<br />

requirements will be provided in the<br />

notification letter and in additional<br />

correspondence.<br />

Deadlines:<br />

Abstract Submission Form :<br />

5th May 2008<br />

Powerpoint Presentations :<br />

15th October 2008<br />

PDA EUROPE BOARD<br />

OF DIRECTORS<br />

President<br />

Marc Broekaert<br />

Huntsman<br />

marc_broekaert@huntsman.com<br />

Treasurer<br />

Patrick Merlin<br />

ALBEMARLE Corporation<br />

patrick.merlin@albemarle.com<br />

President-elect<br />

Bernd Dietz<br />

Rema Tip Top<br />

Bernd.Dietz@tiptop.de<br />

MEMBERS<br />

Werner Bertleff<br />

BASF<br />

werner.bertleff@basf.com<br />

Karl H. Wührer<br />

Bayer MaterialScience AG<br />

karl-heinrich.wuehrer@bayermaterialscience.com<br />

Dominique Smits<br />

De Neef Conchem<br />

d.smits@deneef.eu<br />

Romuald Bartczak<br />

Flexguard<br />

romuald@flexguard.be<br />

Alain Descampe<br />

Imexfa sa<br />

a.descampe@imexfa.be<br />

Michael Byrne<br />

Liquid Plastics<br />

mnb@liquidplastics.co.uk<br />

Alain van Oorsouw<br />

Elastogran<br />

alain.vanoorsouw@elastogran.nl<br />

International Directors<br />

Murph Mahaffey<br />

GlasCraft<br />

mahaffeym@glascraft.com<br />

Alliance Director<br />

Lee Bower<br />

Polyvers<br />

lee@polyvers.com<br />

PDA EUROPE SECRETARIAT<br />

Rachel Barlow<br />

Dana Popp<br />

Françoise Maon<br />

Avenue Marcel Thiry 204, Brussels, Belgium<br />

Tel: +32 2 774 9611<br />

Fax: +32 2 774 9690<br />

E-mail: pda-europe@keleneurope.com<br />

PODIUM | FIRST QUARTER 2008 | 14

SPONSORSHIP<br />

OPPORTUNITIES<br />

The PDA Europe <strong>Conference</strong> provides a great marketing<br />

opportunity to a targeted audience and is an excellent place<br />

to network. Don’t miss the opportunity to profile your<br />

company during the second industry event and sponsor a<br />

conference function. The sponsorship opportunities are now<br />

open on our website.<br />

TABLE TOPS<br />

The table top exhibition will be running along the annual<br />

conference, providing the opportunity to promote your<br />

company and products to a wide audience. The exhibition<br />

space will be located directly outside the conference room<br />

where lunches and breaks will be held.<br />

The exhibitors’ description and logo will be included in the<br />

official event booklet. In addition when booking your table<br />

top space, your company will get 1 delegate place for free.<br />

Exhibitors can either use the tables provided by the hotel<br />

or bring their own displays.<br />

Please note that table top places are limited and that we<br />

allocate spaces on a first come-first served basis.<br />

For further details and to download the Abstract Submission<br />

Form, Sponsorship and Exhibition Forms, please visit the PDA<br />

Europe website: www.pda-europe.org<br />

Details about registration, hotel reservation, conference<br />

programme, polyurea trainings and live demonstrations will<br />

follow soon!<br />

PDA EUROPE NEWS:<br />

April 2008 – PDA Europe new website<br />

was launched.<br />

Visit http://pda-europe.org for updated information on membership,<br />

events, industry resources and news!<br />

April 2008 – PDA Europe presence at Euromaintenance Fair in<br />

Brussels<br />

Dominique Smits (De Neef Conchem) and Tom Waisfisch<br />

(Megacoatings) represented PDA Europe at the 1<strong>9th</strong> edition of the<br />

Euromaintenance Fair which took place in Brussels between 8 and 10<br />

April.<br />

March 2008 – PDA Europe Presence at<br />

UTECH Europe 2009<br />

<strong>Polyurea</strong> Development Association Europe will play a key role at<br />

the upcoming UTECH Europe 2009 <strong>Conference</strong>, by organising a<br />

full morning session devoted to the recent technical and commercial<br />

development of this exciting new technology.<br />

All aspects of the technology, including its position in the<br />

international marketplace, will be covered in a series of papers from<br />

the major partners in the PDA-Europe as well as other presentations<br />

from companies active in the sector. The UTECH Europe 2009 event,<br />

a major international conference and exhibition for the sector, will run<br />

31 st March – 2 nd April 2009 in the Maastricht Exhibition and Congress<br />

Centre (MECC) in Maastricht, the Netherlands.<br />

The <strong>Polyurea</strong> session will complement the full afternoon of<br />

presentations being coordinated by ISOPA (the European Diisocyanate<br />

and Polyols Producers Association) on the second day of the conference,<br />

1 April. This is planned to involve a variety of specialists addressing<br />

key issues including an overview of polyurethane sustainability; users’<br />

experiences of ISOPA’s safe-working programme — Walk the Talk;<br />

and the latest status of the European Union’s REACH legislation<br />

(Registration, Evaluation and Authorisation of Chemicals), which is<br />

now well into implementation.<br />

PDA EUROPE MEMBER COMPANIES<br />

Aceto Europe<br />

Adcos NV<br />

Advanced Plastics Benelux BV<br />

Albemarle Europe SPRL<br />

Alpina Sicherheitssysteme GmbH<br />

Aplicamus-Sinalizacao E revestimentos<br />

LDA<br />

Azelis Benelux NV<br />

BASF Aktiegesellschaft<br />

BASF Construction Chemicals Europe AG<br />

Baule UK limited<br />

Bayer Materialscience AG<br />

BCA NV<br />

Brayan International FZE<br />

Carboline Norge<br />

Chemique Adhesives & Sealants Ltd.<br />

CMCI<br />

Collano Ltd.<br />

Collinda<br />

De Neef Conchem<br />

Dominator Aps<br />

Dow Hyperlast<br />

ECC NV<br />

Elastogran<br />

Elastomonotoki LTD<br />

Elmico<br />

Erik Kalland<br />

ESP Benelux<br />

Flexcoat Industries BV<br />

Flexguard BVBA<br />

FluidSystems GmbH&Co. KG<br />

Foam Spray LTD<br />

Fosroc International<br />

Garraf Maquinaria<br />

GlasCraft<br />

Graco NV<br />

Harzlack Ltd<br />

Hercules GMBH<br />

Huntsman Europe<br />

Imexfa SA<br />

Improrep Canarisas S.L.<br />

Investigation y desarrollo de polyurea<br />

(IDP)<br />

Isothane<br />

JB-Services BVBA<br />

Julio Crespo SA<br />

Kobato BV<br />

Leighs Paints<br />

Lindberg & Lund AS<br />

Liquid Plastics Limited<br />

Lonza LTD<br />

Pearl Insulation Materials Industries LLC<br />

Polinvent LTD<br />

Polycraft GmbH<br />

Polymer Institut<br />

Polyvers International LLC<br />

Prokol Polymers & Compunds BV<br />

Pultex Kunststofftechnikhandel GMBH<br />

Puran<br />

Rema Tip Top GMBH<br />

Seal Systems Ireland Limited<br />

Sigor Hesselberg<br />

Sinitalia SRL<br />

Tambour <strong>Polyurea</strong><br />

Too Kazkor<br />

Uniplastic-Pu AG<br />

United Foam ApS<br />

PODIUM | FIRST QUARTER 2008 | 15

ADVERTISE IN THE PODIUM!!<br />

In past issues of the Podium many companies<br />

have taken advantage of advertising.<br />

Our Podium new design is attracting<br />

more and more people to read our<br />

publication daily! Here are our new<br />

ad rates:<br />

1 page, 4 color ad = $600<br />

½ page, 4 color ad = $350<br />

¼ page, 4 color ad = $250<br />

If you would like to advertise in the<br />

1st Quarter issue of 2008 please<br />

contact us ASAP! If you have any<br />

questions, please contact Erin Nied at<br />

PDA headquarters: 816.221.0777 or erin@robstan.com.<br />

HELP US HELP YOU!<br />

Take advantage of your PDA membership and send us your case studies! This is free<br />

PR and advertising for your company and your products. We would love to publish your<br />

case study in the next and future issues of the Podium. If you would like to submit a<br />

case study (or press release or anything pertaining to our industry) for our 1st quarter<br />

issue of 2008, please send it to Erin Nied at erin@robstan.com.<br />

SPORT PDA<br />

APPAREL<br />

PDA APPAREL<br />

ON SALE NOW!<br />

Show your support for PDA by<br />

wearing PDA apparel! Show Enjoy your the support for PDA<br />

holidays and take advantage<br />

by wearing<br />

of<br />

PDA apparel!<br />

these low prices for a<br />

Enjoy<br />

limited<br />

the<br />

time.<br />

holidays and take<br />

Please contact PDA Headquarters at<br />

advantage of these low prices<br />

816.221.0777 to order.<br />

for a limited time. Please<br />

contact PDA Headquarters<br />

at 816.221.0777 to order.<br />

<br />

<br />

<br />

<br />

<br />

Wear our stylish 100%<br />

cotton golf shirt.<br />

Was $39.99<br />

Now $24.99!<br />

Wear our 100% cotton twill<br />

<br />

baseball cap.<br />

Was $24.99<br />

Now $16.99!<br />

<br />

PUBLISHER’S STATEMENT<br />

Podium is published by the<br />

<strong>Polyurea</strong> Development Association (PDA),<br />

14 W. Third St., Suite 200<br />

Kansas City, Missouri 64105<br />

816.221.0777<br />

Editor, Erin Nied<br />

Executive Director, Ken Bowman<br />

E-mail: kenb@robstan.com<br />

Copyright © 2008<br />

<strong>Polyurea</strong> Development Association<br />

All Rights Reserved<br />

EDITORIAL POLICY<br />

Podium is the official publication of<br />

the <strong>Polyurea</strong> Development Association.<br />

The magazine provides a medium for<br />

expressing views and opinions without<br />

approving, disapproving or guaranteeing<br />

the validity or accuracy of any data, claim<br />

or opinion appearing under a byline, or<br />

obtained or quoted from an acknowledged<br />

source. The opinions expressed by<br />

authors do not necessarily reflect the<br />

official views of PDA.<br />

CALENDAR OF EVENTS 2008<br />

MAY<br />

15-17<br />

AIA 2008 National Convention<br />

and Design Exposition<br />

Boston Convention and<br />

Exhibition Center<br />

Boston, MA<br />

www.aia.org<br />

JUNE<br />

2-5<br />

American Coatings Show<br />

Charlotte Convention Center<br />

Charlotte, NC<br />

www.american-coatings-show.<br />

com<br />

3-6<br />

CONSTRUCT2008<br />

Las Vegas Convention Center<br />

Las Vegas, NV<br />

www.csinet.org<br />

JULY<br />

8-11<br />

PDA Applicator Spray Course<br />

Polyvers Facility<br />

Houston, TX<br />

www.pda-online.org<br />

AUGUST<br />

18-21<br />

MegaRust<br />

Galt House Hotel & Suites<br />

Louisville, KY<br />

www.nstcenter.com<br />

26-28<br />

PDA’s Mid-Year Meeting<br />

Embassy Suites - Plaza<br />

Kansas City, MO<br />

www.pda-online.org<br />

OCTOBER<br />

7-11<br />

PDA Applicator Spray Course<br />

Polyvers Facility<br />

Houston, TX<br />

www.pda-online.org<br />

NOVEMBER<br />

18-21<br />

PDA Europe’s 2 nd <strong>Annual</strong><br />

<strong>Conference</strong><br />

Austria Trend Parkhotel<br />

Schönbrunn, Vienna<br />

www.pda-europe.org<br />

DECEMBER<br />

8-11<br />

Ecobuild<br />

Washington Convention Center<br />

Washington D.C.<br />

www.ecobuildfall.com<br />

8 | FOURTH QUARTER 2007 | PODIUM<br />

PODIUM | FIRST QUARTER 2008 | 16