DIGI@WAVE - Welding Generators

DIGI@WAVE - Welding Generators

DIGI@WAVE - Welding Generators

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DIGI@WAVE</strong>: digital logic for total control of c<br />

The <strong>DIGI@WAVE</strong> has been developed for applications demanding very high quality welding<br />

on all materials and thicknesses in the principal industrial sectors. Its man-machine interface<br />

is equipped with a wide graphic display on which the operator can navigate<br />

in the parameter bar. A highly developed setup program enables verification and adjustment<br />

of a very large number of the criteria needed for use in manual, automatic<br />

or robot-controlled modes of operation.<br />

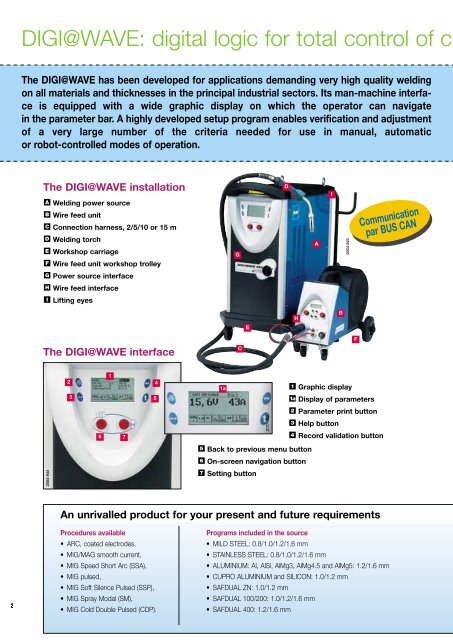

The <strong>DIGI@WAVE</strong> installation<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

<strong>Welding</strong> power source<br />

Wire feed unit<br />

Connection harness, 2/5/10 or 15 m<br />

<strong>Welding</strong> torch<br />

Workshop carriage<br />

Wire feed unit workshop trolley<br />

G<br />

D<br />

A<br />

I<br />

2004-943<br />

Communication<br />

par BUS CAN<br />

G<br />

Power source interface<br />

H<br />

Wire feed interface<br />

I<br />

Lifting eyes<br />

E<br />

H<br />

B<br />

The <strong>DIGI@WAVE</strong> interface<br />

C<br />

F<br />

1<br />

2 4<br />

3<br />

5<br />

1a<br />

1<br />

1a<br />

Graphic display<br />

Display of parameters<br />

2<br />

Parameter print button<br />

6 7<br />

2177-002<br />

3<br />

4<br />

Help button<br />

Record validation button<br />

2004-944<br />

5<br />

6<br />

7<br />

Back to previous menu button<br />

On-screen navigation button<br />

Setting button<br />

An unrivalled product for your present and future requirements<br />

2<br />

Procedures available<br />

• ARC, coated electrodes,<br />

• MIG/MAG smooth current,<br />

• MIG Speed Short Arc (SSA),<br />

• MIG pulsed,<br />

• MIG Soft Silence Pulsed (SSP),<br />

• MIG Spray Modal (SM),<br />

• MIG Cold Double Pulsed (CDP).<br />

Programs included in the source<br />

• MILD STEEL: 0.8/1.0/1.2/1.6 mm<br />

• STAINLESS STEEL: 0.8/1.0/1.2/1.6 mm<br />

• ALUMINIUM: Al, AlSi, AlMg3, AlMg4.5 and AlMg5: 1.2/1.6 mm<br />

• CUPRO ALUMINIUM and SILICON: 1.0/1.2 mm<br />

• SAFDUAL ZN: 1.0/1.2 mm<br />

• SAFDUAL 100/200: 1.0/1.2/1.6 mm<br />

• SAFDUAL 400: 1.2/1.6 mm