Thermal cracking of ethane in tubular reactor

Thermal cracking of ethane in tubular reactor

Thermal cracking of ethane in tubular reactor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

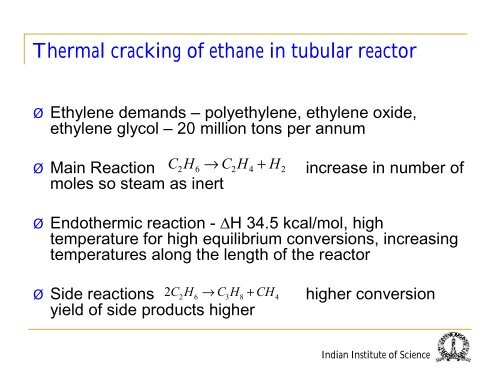

<strong>Thermal</strong> <strong>crack<strong>in</strong>g</strong> <strong>of</strong> <strong>ethane</strong> <strong>in</strong> <strong>tubular</strong> <strong>reactor</strong><br />

‣ Ethylene demands – polyethylene, ethylene oxide,<br />

ethylene glycol – 20 million tons per annum<br />

‣ Ma<strong>in</strong> Reaction CH → CH + H<br />

moles so steam as <strong>in</strong>ert<br />

2 6 2 4 2<br />

<strong>in</strong>crease <strong>in</strong> number <strong>of</strong><br />

‣ Endothermic reaction - ∆H 34.5 kcal/mol, high<br />

temperature for high equilibrium conversions, <strong>in</strong>creas<strong>in</strong>g<br />

temperatures along the length <strong>of</strong> the <strong>reactor</strong><br />

2C2H6 → CH<br />

3 8<br />

+ CH4<br />

‣ Side reactions<br />

yield <strong>of</strong> side products higher<br />

higher conversion<br />

Indian Institute <strong>of</strong> Science

Yield conversion diagram for <strong>ethane</strong> <strong>crack<strong>in</strong>g</strong><br />

Indian Institute <strong>of</strong> Science

Ethane <strong>crack<strong>in</strong>g</strong> <strong>reactor</strong><br />

Typical operat<strong>in</strong>g condn<br />

•L = 95 m<br />

•G = 68.68 kg/m2/s<br />

•P <strong>in</strong>let 2.99 atm, outlet 1.2 atm<br />

•T <strong>in</strong>let 680, outlet 820 C<br />

•Production 10000 tons/coil<br />

Indian Institute <strong>of</strong> Science

Balances<br />

mass<br />

dF<br />

dz<br />

j<br />

=<br />

R<br />

j<br />

4<br />

2<br />

t<br />

2<br />

dT 1 ⎡ πd<br />

t<br />

⎤<br />

energy = ⎢qz ( ) πdt + ∑−( ∆Hi)<br />

ri⎥<br />

dz ∑FC<br />

j pj ⎣<br />

4 i ⎦<br />

j<br />

πd<br />

dp ⎡2f ξ ⎤ du<br />

ρ ρ<br />

dz ⎣ d r ⎦ dz<br />

2<br />

momentum − = ⎢ + ⎥ fu +<br />

fu<br />

t<br />

π<br />

b i<br />

∑<br />

⎡RT<br />

F' 1 j<br />

u = =<br />

⎢<br />

A A⎢<br />

p<br />

⎢⎣<br />

F<br />

j<br />

⎤<br />

⎥<br />

⎥<br />

⎥⎦<br />

Indian Institute <strong>of</strong> Science

Simulation <strong>of</strong> <strong>ethane</strong> <strong>reactor</strong><br />

Indian Institute <strong>of</strong> Science

Hydrogenation <strong>of</strong> oil<br />

‣ Major demand – margar<strong>in</strong>e, shorten<strong>in</strong>gs, vanaspati<br />

‣ Vegetable oils – mixture <strong>of</strong> triglycerides - glycerol and<br />

fatty acids<br />

‣ Fatty acids – saturated (S) , monosaturated (cis, R1 and<br />

trans, R2) and diunsaturated (B). Hydrogenation to<br />

reduce odor or color, improve stability and <strong>in</strong>crease<br />

melt<strong>in</strong>g po<strong>in</strong>t.<br />

‣ Product requirements – some polyunsaturated (health)<br />

and R2 ( consistency and higher melt<strong>in</strong>g po<strong>in</strong>ts)<br />

Indian Institute <strong>of</strong> Science

Reactions<br />

1/2<br />

,<br />

1 4 H 5 6<br />

r −r ∝C r −r ∝C<br />

H<br />

2 2<br />

implies selectivity <strong>of</strong> monounsaturates over saturates<br />

proportional to (C H2 ) 1/2<br />

Indian Institute <strong>of</strong> Science

Yield conversion diagrams<br />

Indian Institute <strong>of</strong> Science

Balances<br />

dC<br />

j<br />

mass = Rj<br />

j = BR ,<br />

1, R2,<br />

M<br />

dt<br />

0<br />

2<br />

, b<br />

( ) ( )<br />

, ,<br />

,<br />

,<br />

−ka C − C = R C C<br />

dC<br />

L v H g H s H j H s<br />

H<br />

2 2 2 2<br />

( ) ( )<br />

, , , ,<br />

( )<br />

, ,<br />

1 1 1<br />

= +<br />

ka ka ka<br />

L<br />

dt<br />

v<br />

= ka C −C −ka C −C<br />

L v H g H b S S H b H s<br />

= ka C − C + R<br />

S S H b H s H<br />

2 2 2 2<br />

2 2 2<br />

L v S S<br />

Indian Institute <strong>of</strong> Science

Stirred tank batch <strong>reactor</strong><br />

‣ Desired conversion –<br />

batch time<br />

‣ Desired production rate<br />

and batch time – volume<br />

‣ Based on volume –<br />

<strong>in</strong>ternal design<br />

‣ Cool<strong>in</strong>g load<br />

∑<br />

i<br />

( ) ( )<br />

− Q = V −∆ H r = AUT −T<br />

i i K r<br />

Indian Institute <strong>of</strong> Science

Ammonia synthesis<br />

‣ Major demand – Fertilizer, chemicals,<br />

explosives, polyamides, pharmaceuticals; 150<br />

million tons per annum<br />

‣ Ma<strong>in</strong> reaction<br />

1 3<br />

N2 + H2 NH3,<br />

∆ H298K<br />

=−45.7 kJ/<br />

mol −<br />

2 2<br />

‣ High pressure, low temperatures favorable<br />

‣ Catalytic reaction – iron, promoted ruthenium<br />

1<br />

Indian Institute <strong>of</strong> Science

Ammonia synthesis – equilibrium<br />

Ammonia Mol fraction<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

1<br />

P = 300 atm<br />

200<br />

100<br />

50<br />

10<br />

3<br />

(A)<br />

0.0<br />

500 600 700 800 900<br />

Temperature (K)<br />

Ammonia Mol fraction<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0.0<br />

(B)<br />

T = 473 K<br />

523<br />

573<br />

623<br />

673<br />

723<br />

773<br />

0 100 200 300<br />

Pressure (Atm)<br />

Indian Institute <strong>of</strong> Science

Ammonia synthesis - balances<br />

mass<br />

dC<br />

j<br />

u ( , )<br />

s<br />

= ηRj Cj<br />

T<br />

dz<br />

energy<br />

dT 4U<br />

ρ<br />

fuc s p<br />

= ( Tr<br />

− T) + η( −∆H)<br />

r<br />

dz d<br />

catalyst<br />

1<br />

2<br />

r dr<br />

'<br />

2 i<br />

' '<br />

ie i i<br />

'<br />

1 d 2 dT<br />

2 ⎜ r λe<br />

⎟ Hr<br />

r dr dr<br />

t<br />

d ⎛ dC ⎞<br />

⎜ rD ⎟ =−R<br />

C T<br />

⎝ dr ⎠<br />

⎛ ⎞ =∆<br />

⎝ ⎠<br />

( , )<br />

Indian Institute <strong>of</strong> Science

Reactor simulation<br />

mol fraction<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

N 2<br />

H 2<br />

NH 3<br />

0.0<br />

0 1 2 3 4 5<br />

Length (m)<br />

temperature<br />

860<br />

840<br />

820<br />

800<br />

780<br />

760<br />

740<br />

720<br />

700<br />

680<br />

0 1 2 3 4 5<br />

Length (m)<br />

120<br />

100<br />

80<br />

rate at bulk conditions<br />

observed rate<br />

rate<br />

60<br />

40<br />

20<br />

0<br />

0 1 2 3 4 5<br />

Length (m)<br />

Indian Institute <strong>of</strong> Science

Optimal temperature<br />

4//<br />

/-8<br />

34/<br />

/-7<br />

3//<br />

/-6<br />

24/<br />

Dwsdms<br />

/-5<br />

/-4<br />

/-3<br />

2//<br />

14/<br />

1//<br />

/-2<br />

04/<br />

/-1<br />

0//<br />

/-0<br />

4/<br />

34/ 4// 44/ 5// 54/ 6//<br />

Sdl odq`stqd J<br />

/<br />

Indian Institute <strong>of</strong> Science

Fixed bed <strong>reactor</strong>s<br />

Indian Institute <strong>of</strong> Science

Ammonia – Multibed <strong>reactor</strong><br />

Conversion<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

r=0<br />

r/T=0<br />

Reactor 1<br />

Reactor 2<br />

Reactor 3<br />

0.0<br />

400 500 600 700 800 900<br />

Temperature<br />

Indian Institute <strong>of</strong> Science

Fixed bed <strong>reactor</strong>s<br />

Indian Institute <strong>of</strong> Science

Ammonia – Autothermal<br />

300<br />

1000<br />

T top<br />

-T 1L<br />

DT<br />

250<br />

200<br />

150<br />

100<br />

T top<br />

-T feed<br />

473<br />

491<br />

513<br />

523<br />

578<br />

623<br />

T feed<br />

K<br />

900<br />

800<br />

700<br />

600<br />

50<br />

500<br />

0<br />

400 500 600 700 800 900 1000<br />

T top<br />

400<br />

400 500 600 700 800 900 1000<br />

T top<br />

K<br />

Indian Institute <strong>of</strong> Science

Ammonia – Autothermal<br />

800<br />

750<br />

Conversion<br />

700<br />

650<br />

600<br />

550<br />

<strong>reactor</strong><br />

heat exchanger<br />

Conversion<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

r=0<br />

∂r/∂T=0<br />

500<br />

0 1 2 3 4 5 6<br />

Length<br />

0.1<br />

0.0<br />

600 650 700 750 800 850 900<br />

Temperature<br />

Indian Institute <strong>of</strong> Science