Developing an Asset Management Strategy - Plant Maintenance ...

Developing an Asset Management Strategy - Plant Maintenance ...

Developing an Asset Management Strategy - Plant Maintenance ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Strategic <strong>Asset</strong> M<strong>an</strong>agement Inc.<br />

Our description of Strategic <strong>Asset</strong> M<strong>an</strong>agement<br />

(SAM) begins with the key elements of success,<br />

namely Lead, Execute <strong>an</strong>d Enable.<br />

LEAD. There are hundreds of books written about<br />

leadership, <strong>an</strong>d each one has some valuable point to<br />

make. Frequently, though, the description is of<br />

individual leadership, <strong>an</strong>d often charismatic leadership.<br />

Leadership in the pl<strong>an</strong>t setting, in our opinion, is<br />

creating consistency of purpose <strong>an</strong>d action.<br />

M<strong>an</strong>ufacturing is a large set of complex <strong>an</strong>d<br />

interrelated systems of marketing, technology, fin<strong>an</strong>ce,<br />

hum<strong>an</strong> resources, execution functions <strong>an</strong>d equipment.<br />

Physical <strong>Asset</strong> M<strong>an</strong>agement then must take all of these<br />

into account.<br />

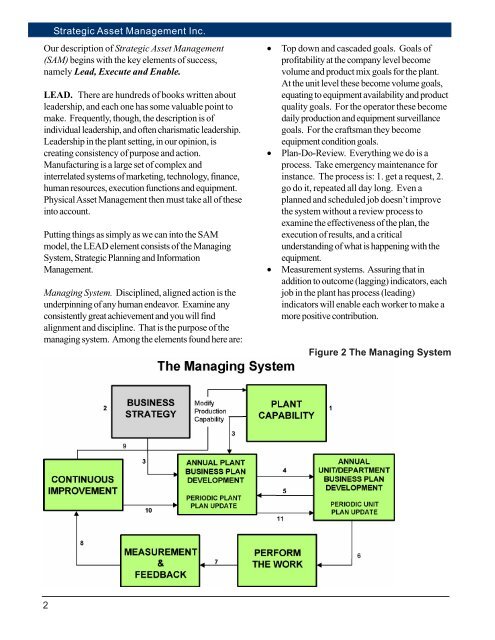

Putting things as simply as we c<strong>an</strong> into the SAM<br />

model, the LEAD element consists of the M<strong>an</strong>aging<br />

System, Strategic Pl<strong>an</strong>ning <strong>an</strong>d Information<br />

M<strong>an</strong>agement.<br />

M<strong>an</strong>aging System. Disciplined, aligned action is the<br />

underpinning of <strong>an</strong>y hum<strong>an</strong> endeavor. Examine <strong>an</strong>y<br />

consistently great achievement <strong>an</strong>d you will find<br />

alignment <strong>an</strong>d discipline. That is the purpose of the<br />

m<strong>an</strong>aging system. Among the elements found here are:<br />

• Top down <strong>an</strong>d cascaded goals. Goals of<br />

profitability at the comp<strong>an</strong>y level become<br />

volume <strong>an</strong>d product mix goals for the pl<strong>an</strong>t.<br />

At the unit level these become volume goals,<br />

equating to equipment availability <strong>an</strong>d product<br />

quality goals. For the operator these become<br />

daily production <strong>an</strong>d equipment surveill<strong>an</strong>ce<br />

goals. For the craftsm<strong>an</strong> they become<br />

equipment condition goals.<br />

• Pl<strong>an</strong>-Do-Review. Everything we do is a<br />

process. Take emergency mainten<strong>an</strong>ce for<br />

inst<strong>an</strong>ce. The process is: 1. get a request, 2.<br />

go do it, repeated all day long. Even a<br />

pl<strong>an</strong>ned <strong>an</strong>d scheduled job doesn’t improve<br />

the system without a review process to<br />

examine the effectiveness of the pl<strong>an</strong>, the<br />

execution of results, <strong>an</strong>d a critical<br />

underst<strong>an</strong>ding of what is happening with the<br />

equipment.<br />

• Measurement systems. Assuring that in<br />

addition to outcome (lagging) indicators, each<br />

job in the pl<strong>an</strong>t has process (leading)<br />

indicators will enable each worker to make a<br />

more positive contribution.<br />

Figure 2 The M<strong>an</strong>aging System<br />

2