Millable vs. Castable Urethanes - TSE Industries, Inc.

Millable vs. Castable Urethanes - TSE Industries, Inc.

Millable vs. Castable Urethanes - TSE Industries, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TSE</strong> <strong>Industries</strong>, <strong>Inc</strong>.<br />

Millathane® <strong>Millable</strong> Polyurethane Division<br />

4370 112th Terrace North<br />

Clearwater, FL 33762 (USA)<br />

727-573-7676 or 800-237-7634 www.tse-industries.com<br />

COMPARISON OF MILLATHANE® MILLABLE POLYURETHANE<br />

<strong>vs</strong>.<br />

CASTABLE POLYURETHANE ROLL COMPOUNDS<br />

1. This report compares the properties of Millathane 76 and Millathane 66<br />

(polyester millable urethanes) to a castable urethane prepolymer system,<br />

over a range of hardness.<br />

2. From the enclosed data, Millathane millable urethanes have a property<br />

advantage at low hardness, while castable urethanes have an advantage at<br />

high hardness.<br />

3. <strong>Millable</strong> urethanes can be used to make excellent low durometer roll<br />

coverings. At 50 to 70 Durometer A, the tear and compression set<br />

properties of Millathane millable urethanes are superior to cast urethane.<br />

4. At 90 Durometer A, the castable urethane physical properties are much<br />

better than those of millable polyurethanes.<br />

5. The main advantage of using Millathane millable urethanes are that they<br />

can be processed on conventional rubber equipment (mills and internal<br />

mixers). Millathane millable urethane rolls can be made by injection,<br />

transfer, and compression molding techniques. Large industrial rolls can<br />

also be built via extrusion methods or strip winding of calendered stock.<br />

Millathane millable urethane is used by custom rubber roll manufacturer to<br />

make urethane rolls. This enables custom roll manufacturers to use<br />

Millathane millable urethane in markets where high performance is<br />

demanded, without purchasing expensive casting equipment.<br />

6. Data found on the following pages is based on the following polyurethane<br />

elastomers.<br />

Millathane 76 Sulfur Cured TDI/Polyester (<strong>Millable</strong> PU)<br />

Millathane 66 Peroxide Cured MDI/Polyester (<strong>Millable</strong> PU)<br />

Vibrathane 6012 MDI/Polyester/Butane diol (<strong>Castable</strong> PU)<br />

The recommendations for the use of our products are based on tests believed to be reliable. However, we do not guarantee the results to be<br />

obtained by others under different conditions. Nothing in this literature is intended as a recommendation to use our products so as to infringe<br />

on any patent. Millathane® and Thanecure® are registered trademarks of <strong>TSE</strong> <strong>Industries</strong>, <strong>Inc</strong>.

55 DUROMETER<br />

Millathane® Millathane 66 Cast Polyester<br />

76<br />

Hardness Shore A 55 55 55<br />

100% Modulus, psi (MPa) 180 (1.3) 550 (3.9) 210 (1.5)<br />

Tensile Strength, psi (MPa) 5275 (37.1) 5750 (40.4) 3000 (20.7)<br />

Elongation, % 735 670 560<br />

Tear Die C, lb/in (kN/m) 239 (41.8) 254 (44.4) 180 (31.5)<br />

Compression Set, Method B 40 25 --<br />

22 hrs @ 70°C, % set<br />

Bashore Resilience, % 15 40 53<br />

60 - 65 Shore A DUROMETER<br />

Millathane 76 Millathane 66 Cast Polyester<br />

Hardness Shore A 60 65 65<br />

100% Modulus, psi (MPa) 179 (1.3) 316 (2.2) 320 (2.2)<br />

Tensile Strength, psi (MPa) 4340 (30.5) 4730 (33.3) 5300 (29.6)<br />

Elongation, % 708 491 500<br />

Tear Die C, lb/in (kN/m) 232 (40.6) 344 (60.2) 240 (42)<br />

Compression Set, Method B 45 22 --<br />

22 hrs @ 70°C, % set<br />

Bashore Resilience, % 16 35 44<br />

70 – 75 Shore A DUROMETER<br />

Millathane 76 Millathane 66 Cast Polyester<br />

Hardness Shore A 70 70 75<br />

100% Modulus, psi (MPa) 435 (3.1) 492 (3.5) 450 (3.1)<br />

Tensile Strength, psi (MPa) 5295 (37.2) 4300 (30.2) 5600 (38.6)<br />

Elongation, % 590 540 460<br />

Tear Die C, lb/in (kN/m) 455 (79.6) 329 (57.6) 330 (57.8)<br />

Compression Set, Method B 46 21 --<br />

22 hrs @ 70°C, % set<br />

Bashore Resilience, % 15 30 38<br />

85 - 90 Shore A DUROMETER<br />

Millathane 76 Millathane 66 Cast Polyester<br />

Hardness Shore A 90 90 85<br />

100% Modulus, psi (MPa) 1250 (8.7) 2200 (15.5) 750 (5.2)<br />

Tensile Strength, psi (MPa) 4400 (31.0) 2600 (18.3) 6200 (42.7)<br />

Elongation, % 275 160 430<br />

Tear Die C, lb/in (kN/m) 443 (77.5) 478 (83.6) 500 (87.5)<br />

Compression Set, Method B 35 25 --<br />

22 hrs @ 70°C, % set<br />

Bashore Resilience, % 13 32 34

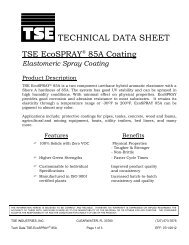

MILLATHANE® MILLABLE POLYURETHANE<br />

ROLL COMPOUNDS<br />

Shore A Durometer 55 55 60 65 70 70 90 90<br />

Millathane 76 100.0 100.0 100.0 100.0<br />

Millathane 66 100.0 100.0 100.0 100.0<br />

Zinc Stearate 0.5 0.5 0.5 0.5<br />

Stearic Acid 0.25 0.5 0.25 0.25<br />

Hi Sil 243LD 5.0<br />

Titanium Dioxide 0.5<br />

N990 Black 0.2<br />

N330 Black 25.0 60.0<br />

Ricon P 30/D 0.5<br />

AC 617A 0.5 0.5 0.5 0.5 2.0 1.0<br />

Dicup 40C 6.0 6.0 6.0 6.0<br />

MBTS 4.0 4.0 4.0 4.0<br />

MBT 2.0 2.0 2.0 2.0<br />

THANECURE® ZM 1.0 1.0 1.0 1.0<br />

Sulfur 1.5 1.5 1.5 2.0<br />

N220 Black 30.0 25.0 20.0 55.0<br />

N550 Black 45.0<br />

Cumar P-10 5.0 5.0 5.0 5.0<br />

TP-95 3.0 8.0 3.0 5.0 5.0<br />

SR-350 10.0