M-Service & Geräte Peter Müller eK

M-Service & Geräte Peter Müller eK

M-Service & Geräte Peter Müller eK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

M<br />

Professional<br />

Video Measurement System<br />

mobile and fixed<br />

modular design<br />

Contents

2<br />

Contents<br />

CV System – The inspection kit<br />

The video zoom system for 2D measurement<br />

V-7000 inspection system<br />

CT-6000 – The drill measuring station<br />

CT-9000 – The measuring station for cooling channels and other specials<br />

CT-12000 – The measuring station for long drills<br />

EZ-1000 – The measuring system for saw blades<br />

TZS-1000 – The measuring system for grinding disks<br />

ADP-OKU / ADP-PP – The extension by the camera<br />

Metric – The measurement software<br />

4<br />

5<br />

7<br />

8<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15

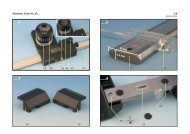

CV System: Simple, robust and<br />

cheap. The CV inspection module<br />

is an ideal solution when having to<br />

work with a fixed magnification.<br />

Magnifications of from 5x to<br />

3000x on the screen are possible.<br />

The lenses used have an optical<br />

magnification of from 0.5x to 30x.<br />

When they are to be installed in<br />

plant and machines the CV systems<br />

are delivered complete with screw<br />

threads. For stationary work the<br />

magnetic interchangeable lenses<br />

are quicker to use.<br />

The lights: LED ring lights with<br />

different angles of reflected beam<br />

and coaxial lights with current<br />

fed from the analog or USB 2.0<br />

cameras (1600 x 1200 or 2048 x<br />

1600 pixels). 150 Watt cold light<br />

sources or 50 Watt Xenon light<br />

sources which can be combined<br />

with ring lights or with gooseneck<br />

light guides produce perfect images.<br />

The small form of the cameras,<br />

lenses and tube pipes together<br />

with the CV system can in many<br />

cases be used to upgrade old systems<br />

which only have simple optics<br />

(ocular with lens) or limited space<br />

available for installation.<br />

Contents<br />

CV-System<br />

3

4<br />

Upgrading of grinding or milling<br />

machines with the CV system is<br />

fast and un-complicated.<br />

The large range of tripods available<br />

can ensure a stable position.<br />

The large number of XY sliding tables<br />

and measurement tables, ball<br />

tables and rotation tables makes<br />

positioning the samples much simpler.<br />

Use of the CV system together<br />

with our measurement software<br />

Metric, Metric Plus and Metric MT<br />

produces a professional measurement<br />

system.<br />

The Metric measurement software<br />

can be switched between 25 different<br />

languages. The standard<br />

version includes distance, angle,<br />

circular and radial measurements.<br />

Metric Plus has special measurement<br />

functions, e.g. for drills and<br />

millers, hardness measurement, a<br />

focus calculation module and DXF<br />

overlay. These make work procedures<br />

simple and comfortable. An<br />

Excel protocol system simplifies<br />

documentation (see the overview<br />

of functions on page 15).<br />

Uses of CV systems include application<br />

as plug-in systems for position<br />

recognition e.g. with length<br />

measurement systems (see the application<br />

photo on the upper left).<br />

We would be pleased to assemble<br />

the appropriate components to suit<br />

your particular requirements.<br />

Contents<br />

CV-System

Zoom systems: If the magnification<br />

has to be changed frequently<br />

then it can be more sensible to<br />

use raster zoom systems. Here the<br />

working distance inside the zoom<br />

range is not changed. In addition<br />

the zoom systems have a greater<br />

depth of focus than the CV systems.<br />

A raster zoom system consists of<br />

the zoom optics (6.5x or 12x), an<br />

adapter with an intermediate optic<br />

of 0.5x to 3.5x, the C-Mount adapter<br />

and the camera. It is assembled<br />

based on your requirements or<br />

based on a joint test carried out at<br />

your workshops. The zoom range<br />

can be changed by using additional<br />

supplementary lenses. The<br />

supplementary lenses determine<br />

the working distance.<br />

The supplementary lenses available<br />

are: 0.25x, 0.5x, 0.75x, 1.5x<br />

und 2x. The zoom lens without a<br />

supplementary lens is calculated<br />

as 1x. The working distances which<br />

this gives range between 356 mm<br />

and 36 mm.<br />

The individual click stops are calibrated<br />

and stored in the Metric. For<br />

the zoom lenses in the 6000 series<br />

these are five stops and for the<br />

12000 series a total eight stops.<br />

This number is multiplied by each<br />

supplementary lens used.<br />

Contents<br />

Zoom systems<br />

5

6<br />

For a high degree of process reliability<br />

we recommend the use<br />

of motorised zoom systems, since<br />

with these you cannot forget to<br />

switch the lens set in the software.<br />

This switch is made automatically<br />

through the change of the measurement<br />

system in the measurement<br />

software. The zoom system is then<br />

switched by a stepping motor.<br />

The zoom lenses can be provided<br />

as desired either with or without<br />

a coaxial light reflection. A polarisation<br />

system can be integrated as<br />

an optional extra.<br />

A wide number of tripods, guides<br />

and individual brackets make<br />

available a wide number of possible<br />

configurations.<br />

XY sliding tables and manual and<br />

motorised XY measurement tables<br />

are also available. If desired the Z<br />

axis can also be delivered motorised<br />

(with or without a measurement<br />

system).<br />

Suitable accessory components allow<br />

space-saving installation in<br />

machines and devices. The zoom<br />

systems can be delivered in angled<br />

form or with deflection mirrors.<br />

Compile your system together with<br />

us and enjoy the resulting simple<br />

way of working and the excellent<br />

image quality.<br />

Contents<br />

Zoom systems

The V-7000 inspection system:<br />

The system designed for the rapid<br />

visual check of parts. It allows images<br />

to be stored immediately.<br />

V-7000 is a macro-zoom lens which<br />

allows a magnification of from 10x<br />

to 40x (on a 17“ PC monitor). The<br />

USB 2.0 camera (1600 x 1200<br />

pixels) together with the lighting<br />

(consisting of ring light and cold<br />

light source with 150 Watts) can<br />

show high quality images. The<br />

Metric BE software provided allows<br />

the images to be stored in a<br />

number of different formats. The<br />

system is delivered with or without<br />

a ball table. The associated tripod<br />

has an amplitude of 500 mm.<br />

Platinum: The platinum lens is<br />

distinguished by its extremely<br />

high depth of focus. The maximum<br />

magnification is 10x and can be<br />

adjusted by changing the distance<br />

to the object.<br />

The materials supplied include the<br />

tripod, and the cold light source<br />

with ring light.<br />

As alternatives both lens systems<br />

can be combined with heavy tripods,<br />

precision guides and with the<br />

XY sliding tables.<br />

Contents<br />

V-7000<br />

7

8<br />

CT-6000: The drill measurement<br />

and inspection area. A<br />

highly variable measurement area<br />

designed for the rapid and simple<br />

measurement of drills and similar<br />

geometries.<br />

Based on the raster zoom systems<br />

from the 6000 and 12000 series<br />

with an angled camera head, the<br />

supporting arm can be shifted to<br />

the right in order to be able to<br />

work with different supplementary<br />

lenses.<br />

The measurement table with a<br />

measurement area of 50x50 mm<br />

is fitted with two Mitutoyo Digimatic<br />

dial gauges. Alternatively<br />

manual measurement spindles can<br />

be used.<br />

As an option a manual or motorised<br />

measurement table with a<br />

100x100 mm measurement range<br />

can be supplied. A rotating table<br />

with a 180° graduation and<br />

guide grooves for the various prism<br />

take-ups is mounted on the XY<br />

Contents<br />

CT-6000

measurement table. Stops on the<br />

rear side and a range of different<br />

clamping bracket screws are also<br />

included in the materials delivered.<br />

A 150 Watt cold light source with<br />

ring light and diffuser guarantees<br />

an optimal image quality in the<br />

measurement software Metric Plus<br />

or Metric MT.<br />

CT-6000 Duo: A perforation in<br />

the XY measurement table and<br />

rotation table allows a special parallel<br />

bottom light to be used. As<br />

standard the cut-out for this and<br />

the mounting holes for the second<br />

support arm are in the base plate.<br />

The second zoom system can be<br />

used (for example) to measure<br />

threads. A joint test of the system<br />

produces the precise configuration.<br />

Contents<br />

CT-6000 Duo<br />

9

10<br />

CT-9000: The single-axis option<br />

amongst the three-axis versions.<br />

This model was developed<br />

to measure front surfaces in long<br />

round parts such as drills or blanks<br />

with cooling channels.<br />

The prism can be taken out, rotated<br />

through 180° and re-inserted.<br />

The use of suitable insert prisms<br />

allows very small diameters to be<br />

fixed with the appropriate clamping<br />

bracket screws. The stop on the<br />

reverse side allows the insertion of<br />

parts to be reproduced.<br />

The raster zoom system in the<br />

12000 series can be precisely positioned<br />

using an XY measurement<br />

table with a range of 50 x 50 mm.<br />

The built-in micrometer screws<br />

from Mitutoyo can alternatively be<br />

replaced by manual measurement<br />

spindles. The whole XY table with<br />

the optics can be precisely adjusted<br />

to the centre of the prism by<br />

means of the precision guide and<br />

a fine focus. When used for the<br />

measurement of drill blanks with<br />

cooling channels the CT-9000 is<br />

fitted with a precision turntable.<br />

Contents<br />

CT-9000

CT-12000: The option suitable<br />

for long drills. The take-up prism<br />

can be rotated through 180° on<br />

the base plate. Fitted with a stop<br />

on the rear side, drills or parts with<br />

similar geometry can be mounted<br />

in a way which can be reproduced.<br />

The prism is open at the rear and<br />

can be easily positioned and locked<br />

using a knurled thumb screw. As<br />

with the preceding CT-9000 system<br />

the raster zoom system in the<br />

12000 series is mounted on an<br />

XY measurement table and fitted<br />

with 50 mm Mitutoyo Digimatic<br />

measurement axes. The precision<br />

guide is fitted with a length measurement<br />

system. This is read out<br />

by means of an interface with the<br />

Metric MT measurement software.<br />

An overview of the functions of the<br />

Metric MT system can be found on<br />

page 15.<br />

Contents<br />

CT-12000<br />

11

12<br />

EZ-1000: The saw blade measurement<br />

system. The new concept<br />

which provides two live images at<br />

the same time. Use of the series<br />

6000 raster zoom systems and the<br />

corresponding angular optics allow<br />

us to show the saw tooth from<br />

the side and from the front (or by<br />

swivelling) from above at the same<br />

time and, using the Metric measurement<br />

software, to measure and<br />

document both windows in real<br />

time.<br />

The system is designed for diameters<br />

of from 50 mm to 1000 mm.<br />

The vertical take-up of the saw<br />

blades meant that it was possible<br />

to produce a very space-saving<br />

basic design. The system can be<br />

screwed onto a tubular steel frame<br />

or where necessary screwed onto<br />

the wall.<br />

The take-ups for the saw blade<br />

guarantee a precise positioning of<br />

the saw blade which also allows<br />

the axial run-out of the blade to<br />

be controlled. Excellent images,<br />

produced by high-quality optics<br />

together with perfect illumination<br />

allow rapid working in an ergonomic<br />

posture.<br />

Contents<br />

EZ-1000

TZS-1000 MOT: The new grinding<br />

disk measurement system.<br />

We use telecentric optics and<br />

lighting to check the contour of<br />

grinding disks. Only in this way<br />

can we generate a distortion-free<br />

image over a longer distance.<br />

Depending on customer requirements<br />

telecentric optics with fixed<br />

focal lengths or a motorised telecentric<br />

zoom system can be used.<br />

Where the space available allows,<br />

with the manual systems the optics<br />

and the lighting are mounted<br />

next to each other on a precision<br />

guide.<br />

The grinding disks or other parts<br />

with a similar geometry can then<br />

be compared or measured by<br />

means of a DXF overlay in the<br />

Metric measurement software. Due<br />

to the complex nature of this topic<br />

a visit should always be made to<br />

your premises or to ours before<br />

the award of contract in order to<br />

use sample parts to configure the<br />

perfect system.<br />

Contents<br />

TZS-1000 MOT<br />

13

14<br />

ADP-OKU: Retrofitting of the<br />

stereo microscope. Retrofitting<br />

a stereo microscope (binocular)<br />

with an ocular adapter and analog<br />

or USB2.0 camera is no problem.<br />

Suitable intermediate adapters are<br />

available for the different diameters.<br />

The distortion created by<br />

the skewed view of the stereo microscope<br />

can be completely back<br />

calculated by the Autacalib calibration<br />

function and our special<br />

calibration disk. This allows precise<br />

measurement even with simple<br />

microscopes.<br />

When upgrading with a trinocular<br />

(with a third slot for a camera) a<br />

corresponding C-Mount adapter<br />

must be available. If you do not<br />

have this we can supply an adapter,<br />

provided you can describe the<br />

microscope, giving a precise type<br />

designation.<br />

ADP-PP: Retrofitting a profile<br />

projector with camera.<br />

Retrofitting with profile projectors<br />

with a CCD camera is also not<br />

a problem. Our adapter with an<br />

analog camera can be used in different<br />

types of profile projectors. If<br />

required the measurement systems<br />

of integrated XY measurement tables<br />

can in addition be read out<br />

by an interface. The measurement<br />

functions of the Metric MT are<br />

usable over the whole range of<br />

the XY measurement table. Here<br />

we require precise details of the<br />

measurement system. To provide<br />

these please ask for a copy of our<br />

detailed questionnaire.<br />

Contents<br />

ADP-OKU

Metric functions<br />

Yes No Option<br />

Std. Plus MT Functions Subfunctions<br />

Right mouse button Context menu<br />

Link objects via button bar<br />

Analyse sensor<br />

Engine controls<br />

File<br />

Load image<br />

Save image<br />

Save image sequence<br />

TWAIN Acquire<br />

TWAIN<br />

Print image<br />

Print protocol<br />

Printer setup<br />

Video<br />

On / Off<br />

Freeze frame<br />

Display<br />

Select frame grabber / USB-camera when there is more than 1 source<br />

Measure<br />

Distance Point to point<br />

Point to point with subsidiary lines<br />

Point to line<br />

Circle to circle<br />

Circle to line<br />

Chain dimension<br />

Distance to the DXF<br />

Hardness measurement<br />

Circular area difference with six results<br />

Angle 3 point<br />

4 point<br />

A dimension<br />

Z dimension<br />

Area Circle<br />

Polygon<br />

Freehand figure<br />

Special circle measurements Diameter MCC<br />

Diameter MIC<br />

Gaussian form deviation<br />

Tschebyscheff form deviation<br />

Diameter LSC<br />

Wall thickness measurement<br />

Borers + Cutters Measurement WQ<br />

Measurement SU<br />

Measurement angle in circle<br />

Measurement angle 4C<br />

Measurement layer thickness<br />

Radius<br />

Diameter<br />

Freehand circle<br />

Circle segment<br />

Numbering<br />

Material fraction<br />

Shut down<br />

Reference<br />

Crosshairs Fixed<br />

Simple<br />

Simple, rotatable<br />

Doubled<br />

Doubled, rotatable<br />

Variable angle<br />

V angle<br />

Off<br />

Scale On/Off<br />

Screen Reticule<br />

Tolerance circles<br />

Registermark<br />

Multiform screen<br />

Overlay<br />

DXF overlay<br />

Text with circle<br />

Text with arrow<br />

Text input<br />

Draw sharp<br />

Settings<br />

Character colour 6 different<br />

Line thickness 1 to 3 pixels<br />

Font<br />

Measurement systems up to 100 items<br />

Add<br />

Remove<br />

Edit measurement system<br />

Calibrate Manual<br />

Automatic<br />

Scale vertical<br />

Metric program options<br />

Menu selection<br />

Quick select buttons<br />

Load settings<br />

Change password<br />

Save settings<br />

Table<br />

Add object<br />

Remove object<br />

Dimension object<br />

Show table<br />

Show Excel table<br />

Draw table<br />

Load table<br />

Save table<br />

New table<br />

Help<br />

Show Help<br />

About<br />

Archive<br />

Copy (to clipboard)<br />

Insert (from clipboard)<br />

Pixel magnifier<br />

Double-check<br />

DXF quickload list<br />

Excel keyword table<br />

Excel transfer button<br />

Contents<br />

Metric – simple to use:<br />

Measurement software shouldn’t<br />

result in the user losing time. The<br />

Metric measurement software is an<br />

alternative to other available programs,<br />

which are often complicated<br />

to use. Metric can be switched<br />

between 25 different languages, a<br />

feature which has led to the program<br />

being used all over the world.<br />

Metric can be used to make measurements<br />

in the live image. The program<br />

is available in three versions:<br />

Metric Standard, Metric Plus and<br />

Metric MT.<br />

Metric Standard has functions<br />

such as distance, radii and circle<br />

measurements; crosshairs in the<br />

form of a simple or double crosshair;<br />

an overlay function, labelling<br />

option, hotkeys.<br />

Metric Plus includes further functions<br />

such as DXF overlay, special<br />

circular measurements, special<br />

measurement functions for grinders<br />

and drills, timing module, measurement<br />

of weld penetration and<br />

coating thickness, focus calculation<br />

module and many other useful<br />

extras.<br />

Metric MT has the additional ability<br />

to link measurements. Metric<br />

MT can also read out manual and<br />

motorised XY measurement tables<br />

and spindles with measurement<br />

systems. This is partly achieved by<br />

means of an additional interface.<br />

The left-hand column shows an<br />

overview of the functions of the<br />

three Metric versions.<br />

Metric demosoftware:<br />

www.m-service.de<br />

15

M-<strong>Service</strong> & <strong>Geräte</strong><br />

<strong>Peter</strong> <strong>Müller</strong> e.K.<br />

Siefenfeldchen 184<br />

D-53332 Bornheim · Germany<br />

Phone: +49(0)2222 62105<br />

Fax: +49(0)2222 65974<br />

www.m-service.de<br />

info@m-service.de<br />

M