Spec Sheet - KPI-JCI

Spec Sheet - KPI-JCI

Spec Sheet - KPI-JCI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

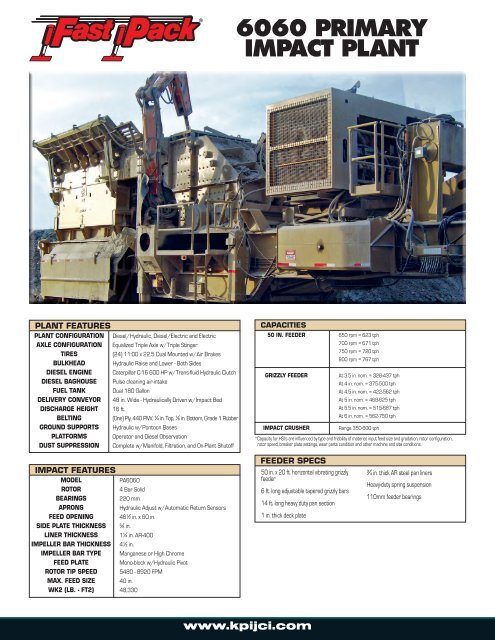

6060 PRIMARY<br />

IMPACT PLANT<br />

PLANT FEATURES<br />

PLANT CONFIGURATION Diesel/Hydraulic, Diesel/Electric and Electric<br />

AXLE CONFIGURATION Equalized Triple Axle w/Triple Stinger<br />

TIRES<br />

(24) 11:00 x 22.5 Dual Mounted w/Air Brakes<br />

BULKHEAD Hydraulic Raise and Lower - Both Sides<br />

DIESEL ENGINE Caterpillar C-16 600 HP w/Trans-fluid Hydraulic Clutch<br />

DIESEL BAGHOUSE Pulse cleaning air-intake<br />

FUEL TANK Dual 180 Gallon<br />

DELIVERY CONVEYOR 48 in. Wide - Hydraulically Driven w/Impact Bed<br />

DISCHARGE HEIGHT 16 ft.<br />

BELTING<br />

(One) Ply, 440 PIW, 1 ⁄4 in. Top, 1 ⁄8 in. Bottom, Grade 1 Rubber<br />

GROUND SUPPORTS Hydraulic w/Pontoon Bases<br />

PLATFORMS Operator and Diesel Observation<br />

DUST SUPPRESSION Complete w/Manifold, Filtration, and On-Plant Shutoff<br />

CAPACITIES<br />

50 IN. FEEDER 650 rpm = 623 tph<br />

700 rpm = 671 tph<br />

750 rpm = 720 tph<br />

800 rpm = 767 tph<br />

GRIZZLY FEEDER<br />

At 3.5 in. nom. = 328-437 tph<br />

At 4 in. nom. = 375-500 tph<br />

At 4.5 in. nom. = 422-562 tph<br />

At 5 in. nom. = 468-625 tph<br />

At 5.5 in. nom. = 515-687 tph<br />

At 6 in. nom. = 562-750 tph<br />

IMPACT CRUSHER<br />

Range 350-600 tph<br />

*Capacity for HSI’s are influenced by type and friability of material, input feed size and gradation, rotor configuration,<br />

rotor speed, breaker plate settings, wear parts condition and other machine and site conditions.<br />

IMPACT FEATURES<br />

MODEL<br />

PA6060<br />

ROTOR<br />

4 Bar Solid<br />

BEARINGS<br />

220 mm<br />

APRONS<br />

Hydraulic Adjust w/Automatic Return Sensors<br />

FEED OPENING 46 1 ⁄2 in. x 60 in.<br />

SIDE PLATE THICKNESS 5<br />

⁄8 in.<br />

LINER THICKNESS 1 1 ⁄4 in. AR-400<br />

IMPELLER BAR THICKNESS 4 1 ⁄2 in.<br />

IMPELLER BAR TYPE Manganese or High Chrome<br />

FEED PLATE<br />

Mono-block w/Hydraulic Pivot<br />

ROTOR TIP SPEED 5480 - 8920 FPM<br />

MAX. FEED SIZE 40 in.<br />

WK2 (LB. - FT2) 48,330<br />

FEEDER SPECS<br />

50 in. x 20 ft. horizontal vibrating grizzly<br />

feeder<br />

6 ft. long adjustable tapered grizzly bars<br />

14 ft. long heavy duty pan section<br />

1 in. thick deck plate<br />

3<br />

⁄4 in. thick AR steel pan liners<br />

Heavy-duty spring suspension<br />

110mm feeder bearings<br />

www.kpijci.com

6060 PRIMARY<br />

IMPACT PLANT<br />

GRADATION - OPEN CIRCUIT<br />

SCREEN ANALYSIS OF PRODUCT FROM<br />

PA6060 PRIMARY IMPACT CRUSHER<br />

AT VARIOUS DISCHARGE OPENINGS, OPENING MEASURED ON CLOSED SIDE.<br />

SIEVE DESIGNATION STANDARD CLOSED SIDE SETTING<br />

US mm Decimal 1" 2" 3" 4" 5"<br />

8" 200.0 8.00 96 88<br />

7" 175.0 7.00 Values Are Percent Passing 100 90 83<br />

6" 150.0 6.00 94 85 77<br />

5" 125.0 5.00 100 89 79 71<br />

4 1 / 2 " 112.5 4.50 99 83 75 66<br />

4" 100.0 4.00 94 80 70 63<br />

3 1 / 2 " 90.0 3.50 88 75 65 59<br />

3" 75.0 3.00 100 83 70 61 55<br />

2 1 / 2 " 63.0 2.50 96 77 63 56 49<br />

2" 50.0 2.00 93 70 58 50 44<br />

1 1 / 2 " 37.5 1.59 85 61 51 42 36<br />

1 1 / 4 " 31.5 1.25 80 55 47 38 32<br />

1" 25.0 1.00 71 51 41 33 28<br />

3 / 4 " 19.0 0.75 62 44 35 28 22<br />

WEIGHTS AND DIMENSIONS<br />

AXLE SPACING 51 in.<br />

KINGPIN<br />

80,619 lbs.<br />

REAR AXLE EACH 19,117 lbs.<br />

REAR AXLE TOTAL 57,351 lbs.<br />

TAG<br />

57,520 lbs.<br />

TOTAL WEIGHT 195,490 lbs.<br />

TRAVEL HEIGHT 15 ft. - 6 in.<br />

TRAVEL LENGTH 75 ft. - 5 in.<br />

TRAVEL WIDTH 11 ft. - 5 in.<br />

MATERIAL FLOW<br />

1 / 2 " 12.5 0.50 50 34 28 21 16<br />

3 / 8 " 9.5 0.375 43 27 23 15 11<br />

4M 4.75 0.187 30 22 18 8 6<br />

8M 2.36 0.094 15 13 10 5 4<br />

16M 1.18 0.047 7 6 6 3 3<br />

30M 0.60 0.023 4 4 5 2 2<br />

50M 0.30 0.012 3 3 4 1 1<br />

100M 0.15 0.006 2 2 2<br />

200M 0.075 0.003 1 1 1<br />

NOTE: Gradations for HSI’s are influenced by type and friability of material, input feed size and gradation, rotor configuration,<br />

rotor speed, breaker plate settings, wear parts condition and other machine and site conditions<br />

NOTE: SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE <strong>KPI</strong>/<strong>JCI</strong> 3.5 PG 02/09<br />

Because <strong>KPI</strong>-<strong>JCI</strong>, AMS and BTI may use in their catalogs & literature, field photographs of it’s products which may have been modified by the owners, products furnished by <strong>KPI</strong>-<strong>JCI</strong>, AMS and BTI may not necessarily be as illustrated therein. Also continuous design progress makes it necessary that specifications be subject to<br />

change without notice. All sales of the products of <strong>KPI</strong>-<strong>JCI</strong>, AMS and BTI are subject to the provisions of it’s standard warranty. <strong>KPI</strong>-<strong>JCI</strong>, AMS and BTI does not warrant or represent that their products meet any federal, state, or local statutes, codes, ordinances, rules, standards or other regulations, including OSHA and MSHA,<br />

covering safety, pollution, electrical wiring, etc. Compliance with these statutes and regulations is the responsibility of the user and will be dependent upon the area and the use to which the product is subjected by the user. In some photographs, guards may have been removed for illustrative purposes only. This equipment<br />

should not be operated without all guards attached in their normal position. Placement of guards and other safety equipment is often dependent upon the area and how the product is used. A safety study should be made by the user of the application and , if required additional guards, warning signs and other safety devices<br />

should be installed by the user, wherever appropriate before operating the products.<br />

1-800-542-9311<br />

Astec Industries Companies