Datasheet - PMCCatalogue

Datasheet - PMCCatalogue

Datasheet - PMCCatalogue

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

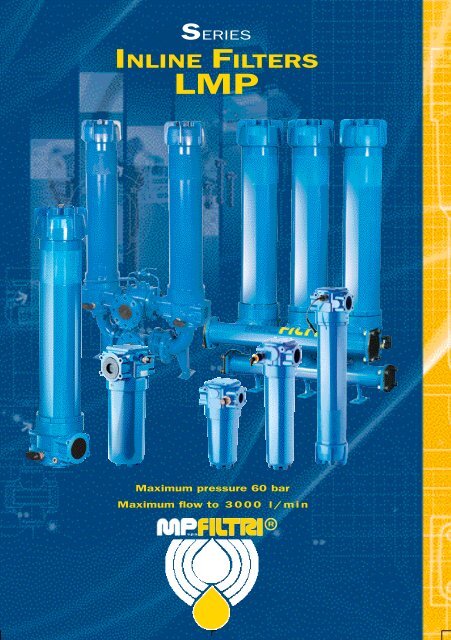

SERIES<br />

INLINE FILTERS<br />

LMP<br />

Maximum pressure 60 bar<br />

Maximum flow to 3 0 0 0 l / mi n<br />

s . p . a<br />

R

Foreword<br />

Filters are essential components in hydraulic systems since they perform a role of primary importance “Cleaning of the fluid”.<br />

Hydraulic systems require filtration products in order to reduce and maintain particulate contamination in-line with the ISO 4406<br />

cleanliness code.<br />

In-line filters in single and duplex designs are designed and built to meet market demands for applications in high pressure,<br />

Off-Line and in-line hydraulic systems.<br />

Studies conducted by our R&D department on filter bodies and filter elements led to the development of a line of products<br />

offering excellent technical features including a reduction in pressure drops combined with<br />

high dirt holding capacity of the filter elements.<br />

The choice of filter for a given application must take into account the technical characteristics of the hydraulic system and its<br />

components in relation to the work to be performed.<br />

Filter selection and sizing parameters<br />

1. Application type<br />

2. Type of filter(s)<br />

3. Sensitivity of components: to ISO 4406 class x/x/x<br />

4. Filtration efficiency: µm β x (c) ≥ 1.000<br />

5. Fluid type: HLP - HFC - HFD others<br />

6. Kinematic viscosity: mm 2 /sec (cSt)<br />

7. Operating temperature: min - max °C (°K)<br />

8. Working pressure: bar (MPa)<br />

9. Effective flow rate: l/min<br />

10. Maximum pressure drop: Δp bar (MPa)<br />

11. Bypass valve: with / without<br />

12. Differential indicator: pressure differential type Δp bar (MPa)<br />

4

Index<br />

Head at top<br />

In-line connection<br />

Series LMP400<br />

LMP900<br />

Head at top<br />

90° connection<br />

Series LMP401<br />

LMP901<br />

Head at bottom<br />

In-line connection<br />

Series LMP430<br />

LMP950<br />

Head at bottom<br />

90° connection<br />

Series LMP431<br />

LMP951<br />

INDEX<br />

Foreword<br />

Filter elements<br />

Sizing<br />

Differential indicators<br />

SAE flanges<br />

Page<br />

6<br />

8<br />

10<br />

12<br />

19<br />

FILTER<br />

LMP 400<br />

LMD 400/01/31<br />

LMP 900<br />

LMP 902-906<br />

LMP 950<br />

LMP 952-956<br />

LMD 951-953<br />

In-line filter working pressure<br />

In-line filter working pressure<br />

In-line filter working pressure<br />

In-line filter working pressure<br />

In-line filter working pressure<br />

In-line filter working pressure<br />

In-line duplex filter working pressure<br />

60/50 bar<br />

16 bar<br />

30 bar<br />

25 bar<br />

30 bar<br />

25 bar<br />

16 bar<br />

20<br />

32<br />

44<br />

54<br />

62<br />

70<br />

82<br />

Fixing accessories<br />

Operation and maintenance<br />

94<br />

96<br />

5

Foreword<br />

Installation in open circuits:<br />

Positioning<br />

Return filter mounted externally from the tank<br />

For large size systems.<br />

For flushing systems.<br />

Off-line filter<br />

For fluid power plants.<br />

For test benches.<br />

Over-boost filter<br />

Positioning between the boost pump and piston<br />

pump.<br />

Installations in closed circuits with the following<br />

functions:<br />

Working filter: down-stream from the hydrostatic transmission<br />

boost pump.<br />

Installations in forced lubrication circuits:<br />

In-line filter for low and medium pressures: protection of<br />

individual components or actuator.<br />

6

Hydraulic schematics<br />

HYDRAULIC SCHEMATICS<br />

Style S<br />

Style B<br />

B<br />

B<br />

D.I.<br />

D.I.<br />

A<br />

Filter without bypass valve, the entire flow must pass through<br />

the cartridge for maximum protection of the system in all<br />

operating conditions.<br />

A<br />

Filter with bypass valve, standard opening Δp 3.5 bar,<br />

filtration cannot be assured in all operating conditions. The<br />

flow that passes through the bypass valve is proportional to<br />

the differential pressure caused by clogging of the cartridge<br />

and variations in fluid viscosity related to temperature<br />

(see cold starts).<br />

Manifold<br />

version<br />

Duplex<br />

filter<br />

D.I. D.I. D.I.<br />

Filters with or without bypass valves, standard opening<br />

Δp 3.5 bar, mounted in parallel on 2 to 6 position<br />

multiple manifolds.<br />

Single differential indicator required.<br />

Duplex filter with or without bypass valve, standard<br />

opening Δp 3.5 bar.<br />

Two differential clogging indicators required.<br />

The filter is composed of a ball valve on the inlet connection,<br />

in 3-way execution layout “L” negative overlap, balancing<br />

connection between the two filters and double check valve on<br />

the outlet connection.<br />

7

Filter elements<br />

Description<br />

The filter elements are available with surface and depth<br />

filtration media.<br />

Surface media are made of stainless steel wire mesh,<br />

nominal filtration.<br />

Depth filtration media are made of inorganic fibre<br />

impregnated with epoxy resins, absolute filtration.<br />

Differential collapse pressure<br />

Mesh M<br />

Fibre A<br />

Cellulose P<br />

Mesh M<br />

Fibre A<br />

Δp 20 bar<br />

Δp 20 bar<br />

Δp 20 bar<br />

Δp 20 bar<br />

Δp 20 bar<br />

Serie N<br />

Serie N<br />

Serie N<br />

Serie W<br />

Serie W<br />

Support tubes - steel with heat-chemical treatment.<br />

Inner support tube - steel with heat-chemical treatment.<br />

Compatibility with fluids and filter elements<br />

Series N<br />

Composition of filtration media<br />

Series N-W: mesh M (style M25)<br />

Internal support mesh, filtration mesh, external support<br />

mesh.<br />

Series N-W: Fibre A<br />

Internal support mesh, filter media support,<br />

filtration media, prefilter media, external support mesh.<br />

Series N: Cellulose P<br />

Internal support mesh, cellulose filtration media,<br />

external support mesh.<br />

Reference standards<br />

All filter elements comply with the following<br />

ISO standards.<br />

I S O<br />

I S O<br />

I S O<br />

I S O<br />

I S O<br />

I S O<br />

I S O<br />

2941<br />

- Collapse and burst resistance<br />

2942<br />

- Bubble point test resistance.<br />

2943 - Compatibility with fluids.<br />

3723 - Resistance to axial deformation.<br />

3724 - Fatigue test with flow.<br />

3968 - Pressure drop.<br />

16889 - Filtration efficiency by means of Multipass.<br />

• The filter elements are compatible with:<br />

Mineral oils to ISO 2943 - 4<br />

Synthetic fluids.<br />

• Seals, standard in NBR compatible with:<br />

Mineral oils to ISO 2943 - 4<br />

Synthetic fluids.<br />

• FPM seals (test to ISO 2943), compatible with:<br />

Synthetic fluids type HS-HFDR-HFDS-HFDU<br />

To ISO 6743 - 4.<br />

Compatibility with fluids and W series<br />

filter elements<br />

Outer<br />

support<br />

mesh<br />

Prefilter<br />

media<br />

Inorganic microfibre<br />

Microfibre filtration media<br />

Inner support mesh<br />

Internal support<br />

Support<br />

tube<br />

• The filter elements are compatible with:<br />

Mineral oils to ISO 2943 - 4<br />

Aqueous emulsions<br />

Synthetic fluids, water and glycol.<br />

• Seals, standard in NBR compatible with:<br />

Mineral oils to ISO 2943 - 4<br />

Aqueous emulsions<br />

Synthetic fluids, water and glycol.<br />

• FPM seals (test to ISO 2943), compatible with:<br />

Synthetic fluids type HS-HFDR-HFDS-HFDU<br />

To ISO 6743 - 4.<br />

N . B. P series cellulose cartridges are compatible only with<br />

mineral oils to ISO 2943 - 4.<br />

8

Multipass test<br />

in compliance with new ISO 16889standard.<br />

Contaminant ISO MTD<br />

Multipass test<br />

in compliance with original<br />

ISO 4572 standard.<br />

Contaminant ACFTD<br />

Value β 2 10 75 100 200 1000 Value β 200<br />

Filtration efficiency in % 50% 90% 98.70% 99% 99.50% 99.90% Filtration efficiency in % 99.50%<br />

Filter element (µm ©) µm<br />

A03

Filter sizing<br />

C o r rect sizing of the filter must be based on a variable<br />

p r e s s u r e drop depending on the application:<br />

• re t u r n filter<br />

Δp from 0.4 to 0.6 bar<br />

• filter on lubrication lines Δp from 0.3 to 0.5 bar<br />

• o f f-line fluid power plants Δp from 0.3 to 0.4 bar<br />

• o f f-line filter test benches Δp from 0.1 to 0.3 bar<br />

• o v e r-boost filter<br />

Δp from 0.4 to 0.6 bar<br />

The pre s s u r e drop calculation is per f o r med by adding<br />

together the value for the housing and the value for the<br />

filter element.<br />

The pre s s u r e drop in the housing is pro p o r tional to the<br />

fluid density kg/dm 3 ; all the graphs in the catalogue are<br />

re f e r red to mineral oil with density of 0.86 kg/dm 3 .<br />

The filter element pre s s u r e drop value is pro p o r t i o n a l<br />

to viscosity mm 2 /s, the Y values in the catalogue are<br />

re f e r red to viscosity of 30 mm 2 /s.<br />

Number of working cart r i d g e s<br />

installed in LMP - LMD filters<br />

LMP 210 1 1 c a r t r i d g e CU 210 1<br />

LMP 210 2 1 c a r t r i d g e CU 210 2<br />

LMP 210 3 1 c a r t r i d g e CU 210 3<br />

L M P 40 0 2 1 c a r t r i d g e CU 400 2<br />

L M P 40 0 3 1 c a r t r i d g e CU 400 3<br />

L M P 40 0 4 1 c a r t r i d g e CU 400 4<br />

L M P 40 0 5 1 c a r t r i d g e CU 400 5<br />

L M P 40 0 6 1 c a r t r i d g e CU 400 6<br />

LMD 400/401 4 1 c a r t r i d g e CU 400 4<br />

LMD 431 5 1 c a r t r i d g e CU 400 5<br />

LMD 431 6 1 c a r t r i d g e CU 400 6<br />

L M P 900 1 1 c a r t r i d g e CU 900<br />

L M P 900 2 2 c a r t r i d g e s CU 900<br />

L M P 902 2 4 c a r t r i d g e s CU 900<br />

L M P 903 2 6 c a r t r i d g e s CU 900<br />

L M P 950 2 1 c a r t r i d g e CU 950 2<br />

L M P 950 3 1 c a r t r i d g e CU 950 3<br />

L M P 952 3 2 c a r t r i d g e s CU 950 3<br />

L M P 953 3 3 c a r t r i d g e s CU 950 3<br />

L M P 954 3 4 c a r t r i d g e s CU 950 3<br />

L M P 955 3 5 c a r t r i d g e s CU 950 3<br />

L M P 956 3 6 c a r t r i d g e s CU 950 3<br />

L M D 951 3 1 c a r t r i d g e s CU 950 3<br />

L M D 952 3 2 c a r t r i d g e s CU 950 3<br />

L M D 953 3 3 c a r t r i d g e s CU 950 3<br />

Filter h o u s i n g Δp pressure drop<br />

The curves are plotted utilising mineral oil<br />

with density of 0.86 kg/dm 3 to ISO 3968.<br />

Δp varies proportionally with density.<br />

LMP 900 - 901<br />

F1 - 3” - Δp housing<br />

0 , 6 0<br />

0 , 4 5<br />

0 , 3 0<br />

0 , 1 5<br />

9 0 0<br />

F1 - 3”<br />

0 , 00<br />

0 30 0 60 0 90 0 12 00 15 00<br />

Flow rate l/min<br />

For Y values see next page:<br />

10<br />

9 0 1<br />

F1 - 3”<br />

Sizing data for single cartridge,<br />

head at top<br />

Δp Tot.<br />

Δpc Filter h o u s i n g<br />

Δpe Filter element<br />

Y Multiplication factor (see page 11)<br />

Q l/min = flow rate<br />

V1 = reference viscosity 30 mm 2 /s (cSt)<br />

V2 = operating viscosity in mm 2 /s (cSt)<br />

Δp Tot. = Δpc + Δpe<br />

Δpe = Y : 1000 x Q x (V2/V1)<br />

Calculation example with HLP Mineral Oil<br />

Variation in viscosity<br />

D a t a :<br />

Filter with in-line connections<br />

P r e s s u r e = 15 bar<br />

Flow rate = 700 l/min<br />

Viscosity = 46 mm 2 /s (cSt)<br />

Density = 0.86 kg/dm 3<br />

Filtration = 10 µ absolute<br />

With bypass valve<br />

Filter type - LMP 900 1 (see housings pressure drop<br />

graphs on page 52)<br />

Practical example<br />

Q<br />

= 700 l/min<br />

V 2 = 46 mm 2 /s (cSt)<br />

Pmax = 15 bar<br />

Filtration = 10 µ absolute<br />

Δp Tot. max = 0.6 bar (max. recommended value)<br />

Filter element series N, Δp max 20 bar<br />

Δpc = 0.13 bar (* see diagram)<br />

Δpe = (0.3166 : 1000) x 700 x (46/30) = 0.34 bar<br />

Δp Tot. = 0.13 + 0.34 = 0.47 bar<br />

Sized filter type:<br />

LMP 900 1 B A F1 A10 N P01<br />

Calculation examples with HFD fluid<br />

Variations in viscosity and density<br />

D a t a :<br />

Filter with in-line connections<br />

P r e s s u r e = 15 bar<br />

Flow rate = 700 l/min<br />

Viscosity = 46 mm 2 /s (cSt)<br />

Density = 1.1 kg/dm 3<br />

Filtration = 10 µ absolute<br />

With bypass valve<br />

Filter type - LMP 900 1 (see housings pressure drop<br />

graphs on page 52)<br />

Practical example<br />

Q<br />

= 700 l/min<br />

V 2<br />

= 46 mm 2 /s (cSt)<br />

Pmax = 15 bar<br />

Filtration = 10 µ absolute<br />

Δp Tot. max = 0.6 bar (max. recommended value)<br />

Filter element series N, Δp max 20 bar<br />

Δpc = 0.13 x (1.1/0.86)= 0.17<br />

Δpe = (0.3166 : 1000) x 700 x (46/30) = 0.34 bar<br />

Δp Tot. = 0.17 + 0.34 = 0.51 bar<br />

Filter type:<br />

LMP 900 1 B V F1 A10 N P01

Data for sizing multicartridge<br />

filters with head at top<br />

Δp Tot.<br />

Δpc Filter housing<br />

Δpe Filter element<br />

Y Multiplication factor (see below)<br />

Q l/min = flow rate<br />

V1 = reference viscosity 30 mm 2 /s (cSt)<br />

V2 = operating viscosity in mm 2 /s (cSt)<br />

Δp Tot. = Δpc + Δpe<br />

Δpe = Y : 1000 x Q x (V2/V1)<br />

For multicartridge filter sizing, the value of flow rate “Q l/min”<br />

must be divided by the number of cartridges.<br />

Calculation example with HLP Mineral Oil<br />

Variation in viscosity<br />

D a t a :<br />

Filter with in-line connections<br />

P r e s s u r e = 10 bar<br />

Flow rate = 1400 l/min<br />

Viscosity = 46 mm 2 /s (cSt)<br />

Density = 0.86 kg/dm 3<br />

Filtration = 6 µ absolute<br />

With bypass valve<br />

Filter type - LMP 952 number of installed cartridges 2<br />

(see housings pressure drop graphs on pages 78 to 79)<br />

Practical example<br />

Calculation examples with HFD fluid<br />

Variations in viscosity and density<br />

D a t a :<br />

Filter with in-line connections<br />

P r e s s u r e = 10 bar<br />

Flow rate = 1400 l/min<br />

Vi s c o s i t y = 46 mm 2 /s (cSt)<br />

Density = 1.1 kg/dm 3<br />

F i l t r a t i o n = 6 µ absolute<br />

With bypass valve<br />

Filter type - LMP 952<br />

(see housings pressure drop graphs on pages 78 to 79)<br />

Practical example<br />

Q<br />

= 1400 l/min<br />

V 2 = mm 2 /s (cSt)<br />

Pmax = 10 bar<br />

Filtration = 6 µ absolute<br />

Δp Tot. max = 0.6 bar (max. recommended value)<br />

Filter element series N, Δp max 20 bar<br />

Δpc = 0.1 x (1.1/0.86)= 0.127 bar<br />

Δpe = (0.4 : 1000) x (1400/2) x (46/30) = 0.43 bar<br />

Δp Tot. = 0.127 + 0.43 = 0.557 bar<br />

Filter type:<br />

LMP 952 B V F3 A06 N P01<br />

Filter housing Δp pressure drop<br />

The curves are plotted utilising mineral oil<br />

with density of 0.86 kg/dm 3 to ISO 3968.<br />

Δp varies proportionally with density.<br />

Q<br />

= 1400 l/min<br />

V 2 = 46 mm 2 /s (cSt)<br />

Pmax = 10 bar<br />

Filtration = 6 m absolute<br />

Δp Tot. max = 0.6 bar (max. recommended value)<br />

Filter element series N, Δp max 20 bar<br />

Δpc = 0.1 bar (* see diagram)<br />

Δpe = (0.4 : 1000) x (1400/2) x (46/30) = 0.43 bar<br />

Δp Tot. = 0.1 + 0.43 = 0.53 bar<br />

Sized filter type:<br />

LMP 952 B A F3 A06 N P01<br />

Multiplication factor “Y” for definition of the<br />

p re s s u re drop of filter elements.<br />

R e f e r ence viscosity 150 SUS<br />

0 , 45<br />

0 , 36<br />

0 , 27<br />

0 , 18<br />

0 , 09<br />

0 , 00<br />

LMP 952<br />

95 2<br />

0 50 0 10 00 15 00 20 00 25 00 30 00<br />

Flow rate l/min<br />

F i l t e r<br />

E l e m e n t<br />

Type<br />

CU 210 1<br />

2<br />

3<br />

CU 400 2<br />

3<br />

4<br />

5<br />

6<br />

CU 900 1<br />

CU 950 2<br />

3<br />

F i l t r a t i o n<br />

Serie N - W<br />

Serie N<br />

A 0 3 A 0 6 A 1 0 A 1 6 A 2 5 M 2 5 P 1 0 P 2 5<br />

5,3<br />

3<br />

1,55<br />

3,133<br />

2,150<br />

1,600<br />

1,000<br />

0,822<br />

0,860 0,6333 0,3166 0,300 0,2142 0,050<br />

1,030<br />

0,443<br />

3,92<br />

2,3<br />

1,33<br />

2,550<br />

1,700<br />

1,285<br />

0,833<br />

0,580<br />

0,8<br />

0,4<br />

1,9<br />

1,21<br />

0,69<br />

1,457<br />

0,940<br />

0,709<br />

0,475<br />

0,300<br />

0,5875<br />

0,2625<br />

1,66<br />

0,88<br />

0,49<br />

1,225<br />

0,781<br />

0,615<br />

0,340<br />

0,267<br />

0,4<br />

0,1833<br />

1,2<br />

0,68<br />

0,42<br />

0,780<br />

0,500<br />

0,400<br />

0,200<br />

0,175<br />

0,2571<br />

0,152<br />

0,098<br />

0,065<br />

0,049<br />

0,192<br />

0,102<br />

0,084<br />

0,057<br />

0,053<br />

0,050<br />

0,020<br />

0,48<br />

0,42<br />

0,23<br />

0,750<br />

0,400<br />

0,340<br />

0,240<br />

0,220<br />

-<br />

-<br />

0,41<br />

0,35<br />

0,17<br />

0,640<br />

0,340<br />

0,270<br />

0,190<br />

0,177<br />

-<br />

-<br />

1 1

Differential indicators<br />

A guarantee of maintenance of the correct ISO 4406 contamination class achieved through the use of the filters can be provided<br />

exclusively with the correct use of the specific differential indicators.<br />

The trip threshold of the indicator must be selected taking account of the maximum differential pressure indicated for each type<br />

of filter element and the trip pressure of the bypass valve, if incorporated in the filter.<br />

Indicator housing ( M a t e r i a l s )<br />

• Brass<br />

P r e s s u r e<br />

• Max. working pre s s u re : 420 bar (42 MPa)<br />

Te m p e r a t u re<br />

• From -35°C to +110°C<br />

S e a l s<br />

• HNBR<br />

• FPM<br />

C o m p a t i b i l i t y<br />

• Housings compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

Synthetic fluids, water and glycol.<br />

• V and H series FPM and HNBR seals, compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

Synthetic fluids, water and glycol.<br />

For synthetic fluids type HS-HFDR-HFDS-HFDU,<br />

series V FPM seals.<br />

1 2

1 3<br />

Order code<br />

Order code<br />

1 2 3 4<br />

1 2 3 4 5 6 7 8<br />

Example: 1 E 7<br />

Example: NM 8 C 11 P01<br />

1 - Differential trip pressure<br />

1 1,2 bar ± 10% (only for style V - E)<br />

2 - Styles<br />

V Visual<br />

1 - Styles<br />

NR Electrical<br />

KR Electrical-Visual<br />

NM Electrical IP 67<br />

E<br />

Electrical-Visual<br />

Z<br />

Visual<br />

J Electrical-Visual-Thermostat controlled<br />

3 - Differential trip pressure<br />

6 2 bar ± 10%<br />

7 5 bar ± 10%<br />

4 - Seals<br />

FPM Standard<br />

x Others on request<br />

Seal for indicator/filter head, Bonded Seal.<br />

N<br />

K<br />

NE<br />

Electrical<br />

Electrical-Visual<br />

Electronic<br />

2 - Differential trip pressure<br />

2 1,2 bar ± 10%<br />

6 2 bar ± 10%<br />

7 5 bar ± 10%<br />

3 - Power supply voltage*<br />

(only for style K - KR)<br />

1 24 Volt<br />

4 - Seals<br />

2 110 Volt (only DC voltage for KR style)<br />

3 220 Volt (excluding style KR)<br />

ADAPTER<br />

Order code<br />

ICPAP01<br />

H<br />

V<br />

x<br />

HNBR Standard<br />

FPM<br />

Others on request<br />

5 - Thermostat (only for style NM)<br />

A<br />

Without<br />

C 50°<br />

6 - Electrical connector (only for style NM)<br />

11 AMP Superseal connector<br />

7 - Opzioni (only for style NE)<br />

CLOGGING INDICATOR SELECTION<br />

Filter for forced lubrication with or without bypass indicator<br />

opening value Δp 1.2 - Δp 2 bar.<br />

S<br />

T<br />

8 - Options<br />

Standard<br />

Double contact 75% - 100%<br />

6 sec. signalling delay<br />

Return or in-line filter with bypass valve indicator opening<br />

value Δp 2 bar.<br />

P 0 1<br />

MP standard<br />

Off-line and over-boost filter, without bypass valve indicator<br />

opening value Δp 2 bar - 5 bar.<br />

Seal for indicator/filter head, flat profiled.<br />

* Other power supply voltages on request.

Differential indicator dimensions<br />

35<br />

Ch. 30<br />

Ch. 32<br />

Ch. 30<br />

SERIES Z<br />

43,5<br />

SERIES V<br />

SERIES NR - KR<br />

44<br />

Ch. 32 Ch. 32<br />

SERIES E<br />

SERIES J<br />

Ch. 27<br />

SERIES NM con Termostato<br />

Ch. 27<br />

SERIES NM senza Termostato<br />

31<br />

32<br />

35<br />

Ch. 30<br />

Ch. 30<br />

Ch. 27<br />

SERIES N - K - NE SERIES NE...T ICPAP01<br />

1 4

STYLE<br />

TECHNICAL CHARACTERISTICS<br />

SERIES Z VISUAL<br />

Standard visual indicator with manual reset.<br />

Nylon signalling button.<br />

Button depressed position = cartridge clean.<br />

Button raised position, Red = cartridge clogged.<br />

Weight: 118 g.<br />

Tightening torque:<br />

65 Nm.<br />

SERIES V VISUAL<br />

Cover and lens in nylon.<br />

Visual indicator green<br />

Visual indicator red<br />

= cartridge clean.<br />

= cartridge clogged.<br />

Weight: 137 g.<br />

Tightening torque:<br />

95 Nm.<br />

SERIES E<br />

ELECTRICAL/VISUAL<br />

Connector EN 175301-803 A/ISO 4400<br />

Protection rating IP 65<br />

Max. contact rating 5 A/250V ~<br />

Power supply voltage 230 V ~<br />

3<br />

2<br />

N.C.<br />

N.O.<br />

2<br />

3<br />

Connector<br />

DIN 43650 Microswitch contact<br />

Cablegland PG 9<br />

Cover and lens in nylon.<br />

Visual indicator green<br />

Visual indicator red<br />

= cartridge clean.<br />

= cartridge clogged.<br />

1<br />

1<br />

Weight: 188 g.<br />

Tightening torque:<br />

95 Nm.<br />

SERIES J ELECTRICAL/VISUAL WITH THERMOSTAT CONTROL<br />

Connector EN 175301-803 A/ISO 4400<br />

Protection rating IP 65<br />

Max. contact rating 5 A/250V ~<br />

Power supply voltage 230 V ~<br />

Connector<br />

DIN 43650 Microswitch contact<br />

Cable gland PG 9<br />

Cover and lens in nylon<br />

3<br />

2<br />

1<br />

N.C.<br />

N.O.<br />

T 30°C<br />

2<br />

3<br />

1<br />

Visual indicator green<br />

= cartridge clean.<br />

Visual indicator red<br />

= cartridge clogged.<br />

CONTACT<br />

N.O.<br />

Operation on reaching temperature of +30°C<br />

Weight: 198 g.<br />

Tightening torque:<br />

95 Nm.<br />

1 6

STYLE<br />

TECHNICAL CHARACTERISTICS<br />

SERIES K<br />

ELECTRICAL/VISUAL<br />

Connector EN 175301-803 A/ISO 4400<br />

Protection rating P 65<br />

Max. contact rating 5 A/250V ~<br />

Power supply voltage<br />

24V DC - 115V DC/AC - 230V AC<br />

3<br />

2 N.C.<br />

2<br />

N.O.<br />

3<br />

LED<br />

1<br />

4<br />

1<br />

Connector<br />

DIN 43650 Microswitch contact<br />

Cable gland PG 9<br />

SIGNALLING LEDS<br />

GREEN LED<br />

= Cartridge clean.<br />

RED LED<br />

= Cartridge clogged.<br />

We i g h t : 183 g.<br />

Tightening torq u e :<br />

65 Nm.<br />

SERIES N ELECTRICAL<br />

Connector EN 175301-803 A/ISO 4400<br />

Protection rating IP 65<br />

Max. contact rating 5 A/250V ~<br />

Power supply voltage 230 V ~<br />

3<br />

2<br />

N.C.<br />

N.O.<br />

2<br />

3<br />

1<br />

Connector<br />

DIN 43650 Microswitch contact<br />

Cable gland PG 9<br />

We i g h t : 183 g.<br />

Tightening torq u e :<br />

65 Nm.<br />

1<br />

SERIES KR ELECTRICAL/VISUAL<br />

Connector EN 175301-803 A/ISO 4400<br />

Protection rating IP 65<br />

Max. contact rating 0.8 A/24V DC<br />

0.17 A/115V DC<br />

Power supply voltage 24V - 115V DC<br />

3<br />

2 N.C.<br />

2<br />

N.O.<br />

3<br />

LED<br />

1<br />

4<br />

1<br />

Connector<br />

DIN 43650 Reed switch<br />

Cable gland PG 9<br />

SIGNALLING LEDS<br />

GREEN LED<br />

RED LED<br />

Weight : 123 g.<br />

Tightening torq u e :<br />

= Cartridge clean.<br />

= Cartridge clogged.<br />

65 Nm.<br />

SERIES NR ELECTRICAL<br />

Connector EN 175301-803 A/ISO 4400<br />

2<br />

3<br />

N.C.<br />

N.O.<br />

2<br />

3<br />

Protection rating IP 65<br />

Max. contact rating<br />

0.17 A/115V DC<br />

Max power supply voltage 1 max 120V DC<br />

Connector<br />

DIN 43650 Reed switch<br />

Cable gland PG 9<br />

1<br />

Weight : 123 g.<br />

1<br />

Tightening torq u e :<br />

65 Nm.<br />

SERIES NM.A ELECTRICAL<br />

Connector<br />

AMP Superseal<br />

Cable and cablegland<br />

PVC<br />

Max. contact rating<br />

0.17 A/115V DC<br />

Max power supply voltage max 120V DC<br />

Protection rating IP 67<br />

Contacts<br />

N.O.<br />

Weight : 110 g.<br />

Tightening torq u e :<br />

65 Nm.<br />

1 7

STYLE<br />

TECHNICAL CHARACTERISTICS<br />

SERIES NM.C ELECTRICAL/THERMOSTAT<br />

Connector<br />

AMP Superseal<br />

Cable and cable gland<br />

PVC<br />

Max. contact rating<br />

0.17 A/115V DC<br />

Max power supply voltage<br />

max 120V DC<br />

Protection rating IP 67<br />

N.O. Contacts<br />

Thermostat (N.O.)<br />

Switching +50°C<br />

T 50°C<br />

Weight : 136 g.<br />

Tightening torq u e :<br />

65 Nm.<br />

SERIES NE ELECTRONIC<br />

1= + 24 VCC<br />

2= Out 4 - 20 mA<br />

3= - 24 VCC<br />

3<br />

2<br />

1<br />

Protection rating IP 65<br />

Power supply voltage from<br />

19 to 28 VCC<br />

Output signal<br />

4 - 20 mA<br />

Input impedance<br />

100 Ohm<br />

Non-linearity + hysteresis<br />

≤10% of full scale<br />

Thermal deviation from zero<br />

< 5 % of full scale from 0°C to +60°C<br />

Operating temperature<br />

from -20°C to +80°C<br />

Storage temperature<br />

from -35°C to +110°C<br />

Connector DIN 43650<br />

Cable gland PG 9<br />

We i g h t : 200 g.<br />

Tightening torq u e :<br />

65 Nm.<br />

INDICATOR NE...T ELECTRONIC<br />

1= + 24 VCC<br />

2= Out 4 > 20 mA<br />

3= Out N.O. 20 mA<br />

4= Out N.O. 16 mA<br />

5= - 24 VCC<br />

4<br />

5<br />

3<br />

1 2<br />

Protection rating IP 67<br />

Power supply voltage from<br />

19 to 28 VCC<br />

Output signal<br />

4 - 20 mA<br />

Input impedance<br />

100 Ohm<br />

Non-linearity + hysteresis<br />

≤10% of full scale<br />

Thermal deviation from zero<br />

< 5% of full scale from 0°C to +70°C<br />

N° 1 N.O. alarm threshold 16 mA (75% of full scale)<br />

N° 2 N.O. alarm threshold 20 mA (100% of full scale)<br />

Fixed timer interval<br />

thresold N° 1 and N° 2 6 seconds<br />

Operating temperature<br />

from -20°C to +80°C<br />

Storage temperature<br />

from -35°C to +110°C<br />

Connector M12 5 pin IEC 60947-5-2<br />

We i g h t : 350 g.<br />

Tightening torq u e :<br />

65 Nm.<br />

ADAPTER ICPAP01<br />

IN<br />

OUT<br />

Adapter for oil outlet and pressure sensing up-stream and down-stream from<br />

the filter element.<br />

IN/OUT connections G 1/4”<br />

Orientation of IN/OUT connections 360°<br />

Material: Phosphated stainless steel<br />

Seals: NBR (others on request)<br />

1 8

Sizes / Connections to SAE flange<br />

FLANGE SAE 3000 PSI<br />

E Depth<br />

A<br />

D<br />

B<br />

Connection to 3000 psi SAE flange<br />

Dimension<br />

2”<br />

SAE<br />

3000 PSI<br />

M<br />

2”<br />

SAE<br />

3000 PSI<br />

UNC<br />

2 1/2”<br />

SAE<br />

3000 PSI<br />

M<br />

2 1/2”<br />

SAE<br />

3000 PSI<br />

UNC<br />

3”<br />

SAE<br />

3000 PSI<br />

M<br />

3”<br />

SAE<br />

3000 PSI<br />

UNC<br />

4”<br />

SAE<br />

3000 PSI<br />

M<br />

4”<br />

SAE<br />

3000 PSI<br />

UNC<br />

A<br />

51<br />

51<br />

63<br />

63<br />

73<br />

73<br />

99<br />

99<br />

B<br />

77,77<br />

77,77<br />

88,90<br />

88,90<br />

106,38<br />

106,38<br />

130,18<br />

130,18<br />

C<br />

42,88<br />

42,88<br />

50,80<br />

50,80<br />

61,93<br />

61,93<br />

77,77<br />

77,77<br />

D<br />

M12<br />

1/2” UNC<br />

M12<br />

1/2” UNC<br />

M16<br />

5/8” UNC<br />

M16<br />

5/8” UNC<br />

E<br />

20<br />

20<br />

20<br />

20<br />

25<br />

25<br />

25<br />

25<br />

FLANGE DIN PN 16<br />

G<br />

C o n n e c t i o n<br />

Flange IN-OUT<br />

DIN<br />

PN16<br />

DN80<br />

DIN<br />

PN16<br />

DN100<br />

A<br />

73<br />

99<br />

A<br />

E<br />

F<br />

E<br />

F<br />

G<br />

160<br />

200<br />

18<br />

180<br />

220<br />

18<br />

SAE flange connections available on in-Line filters<br />

Filter<br />

SAE 3000 PSI<br />

DIN PN16<br />

Type<br />

2 ” 2 1 / 2 ” 3 ” 4 ”<br />

DN80<br />

DN100<br />

LMP400/1<br />

X<br />

X<br />

LMP430/1<br />

X<br />

X<br />

LMD400/1/31<br />

LMP900/1<br />

LMP902/3<br />

LMP950/1<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

LMP952/3/4/5/6<br />

X<br />

LMD951/2/3<br />

X<br />

X X X<br />

1 9

2 0<br />

LMP 210

SERIES<br />

LMP 210<br />

Working pressure<br />

60 bar<br />

Style S<br />

Style B<br />

B<br />

B<br />

D.I.<br />

D.I.<br />

A<br />

A<br />

2 1

Technical data<br />

Filter housing ( M a t e r i a l s )<br />

• Head: Anodised Aluminium<br />

• Housing: Anodised A l u m i n i u m<br />

• Bypass valve: Nylon<br />

P r e s s u re<br />

• Working pre s s u re: 60 bar (6 MPa)<br />

• Test pre s s u re: 90 bar (9 MPa)<br />

• Burst pre s s u re: 180 bar (18 MPa)<br />

• Pulsed pre s s u re fatigue test: 1.000.000 cycles<br />

with pre s s u re from 0 to 60 bar (6 MPa)<br />

Te m p e r a t u r e<br />

• From -25°C to +110°C<br />

Bypass valve<br />

• Opening pre s s u re 3.5 bar ±10%<br />

• Other opening pre s s u res on re q u e s t .<br />

Δp Elements type<br />

• Series N and W elements: 20 bar<br />

• Oil flow from exterior to interior.<br />

S e a l s<br />

• Standard NBR series A<br />

• Optional FPM<br />

series V<br />

Weights (kg)<br />

L e n g t h<br />

• LMP210 - 1 3.5<br />

• LMP210 -2 4.4<br />

• LMP210 - 3 5 . 4<br />

Volumes (d m 3 )<br />

L e n g t h<br />

• LMP210 - 1 1.5<br />

• LMP210 -2 2<br />

• LMP210 - 3 2.7<br />

Connections<br />

In-line Inlet/Outlet LMP 210<br />

C o m p a t i b i l i t y<br />

• Housings compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• The filter elements are compatible with:<br />

Mineral oils to ISO 2943, Synthetic fluids<br />

Aqueous emulsions, water and glycol<br />

(series W re q u i re d ).<br />

• NBR seals series A, compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• V series FPM seals, compatible with:<br />

Synthetic fluids type HS-HFDR-HFDS-HFDU<br />

To ISO 2943<br />

Filter housing Δp pressure drop<br />

The curves are plotted utilising mineral oil<br />

with density of 0.86 kg/dm 3 to ISO 3968.<br />

Δp varies proportionally with density.<br />

0 , 9<br />

0 , 6<br />

0 , 3<br />

0 , 0 0<br />

Valves<br />

5 , 4 0<br />

3 , 6 0<br />

1 , 8 0<br />

0 , 0 0<br />

LMP 210 - Δp Housing<br />

0 60 12 0 18 0 24 0 30 0<br />

Flow rate l/min<br />

Bypass valve pressure drop<br />

Type<br />

A<br />

B<br />

C<br />

LMP 210<br />

A<br />

A<br />

B<br />

C<br />

B / C<br />

0 60 12 0 18 0 24 0 30 0<br />

Flow rate l/min<br />

Filter housing and valves Δp pressure drop connection<br />

Connection<br />

(dimensions page 23)<br />

G1 - G4 - G7- F1 - F4<br />

G2 - G5 - G8 - F2 - F5<br />

G3 - G6 - G9 - F3 - F6<br />

Bypass valve<br />

Recommended maximum flow rate<br />

- Pre s s u re drop of filter assembly equal to Δp 0,6 bar.<br />

- Oil kinematic viscosity 30 mm 2/s ( s C t ).<br />

- Density 0,86 kg/dm 3 .<br />

- Connections of filter under test G 3”.<br />

Filter Flow rate l/min Series N<br />

e l e m e n t Filter lenght<br />

type 1 2 3<br />

2 2<br />

Filter Element Area<br />

Filter element in stainless steel mesh<br />

Length<br />

Type<br />

1 2 3<br />

CU 210 3100 4950 7520<br />

Values expressed in cm 2<br />

A 03 98 140 190<br />

A 06 120 162 200<br />

A 10 175 205 235<br />

A 16 185 225 245<br />

A 25 208 235 250<br />

M 25 265 270 270<br />

P10 245 250 260<br />

P25 250 255 268

Dimensions<br />

LMP 210<br />

1 2 0<br />

B<br />

A<br />

D<br />

I N<br />

O U T<br />

I N<br />

Ø 1 0 1<br />

Ch. 30<br />

1 0<br />

Indicator port<br />

Plug T2 - Ch. 30<br />

Threaded Connections<br />

Type<br />

Connection “A”<br />

E<br />

Depth 12 mm<br />

G1<br />

G 1<br />

M 8<br />

G2<br />

G 1 1/4”<br />

M 8<br />

G3<br />

G 1 1/2”<br />

M 8<br />

G4<br />

1” NPT<br />

5/16” UNC<br />

F i x i n g<br />

h o l e s<br />

G5<br />

G6<br />

1 1/4” NPT<br />

1 1/2” NPT<br />

5/16” UNC<br />

5/16” UNC<br />

E<br />

G7<br />

SAE 16 1 5/16” 12 UN<br />

5/16” UNC<br />

9 8<br />

G8<br />

G9<br />

SAE 20 1 5/8” 12 UN<br />

SAE 24 1 7/8” 12 UN<br />

5/16” UNC<br />

5/16” UNC<br />

Filter<br />

Length<br />

1<br />

2<br />

3<br />

H<br />

mm<br />

360<br />

492<br />

630<br />

Flanged Connections<br />

Type Connection “A”<br />

F1 1” SAE - 3000 psi/M<br />

F2 1 1/4” SAE - 3000 psi/M<br />

“B”<br />

52 , 37<br />

58 , 72<br />

“C”<br />

26 , 19<br />

30 , 18<br />

“D”<br />

M 10<br />

M 10<br />

E<br />

Depth 12 mm<br />

M 8<br />

M 8<br />

F3<br />

1 1/2” SAE - 3000 psi/M<br />

6 9 , 8 5<br />

3 5 , 7 1<br />

M 1 2<br />

M 8<br />

F4<br />

1” SAE - 3000 psi/UNC<br />

5 2 , 3 7<br />

2 6 , 1 9<br />

3/8” UNC<br />

5/16” UNC<br />

F5<br />

1 1/4” SAE - 3000 psi/UNC<br />

5 8 , 7 2<br />

3 0 , 1 8<br />

7/16” UNC<br />

5/16” UNC<br />

F6<br />

1 1/2” SAE - 3000 psi/UNC<br />

6 9 , 8 5<br />

3 5 , 7 1<br />

1/2” UNC<br />

5/16” UNC<br />

2 3

LMP 210 spare parts<br />

3 c<br />

3 d<br />

4<br />

3 a<br />

1<br />

3 b<br />

2<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series LMD 401<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

Filter element<br />

1<br />

See order table<br />

3<br />

Seals kit<br />

1<br />

NBR<br />

FPM<br />

02050435 02050436<br />

3a<br />

O-Ring filter element<br />

1<br />

O-R 144 Ø 39,69 x 3,53<br />

3b<br />

O-Ring housing<br />

1<br />

O-R 4375 Ø 94,84 x 3,53<br />

3c<br />

Seal<br />

1<br />

01030058 01030046<br />

3d<br />

O-Ring<br />

2<br />

O-R 2050 Ø 12,42 x 1,78<br />

4<br />

Indicator plug<br />

1<br />

T2H<br />

T2V<br />

-<br />

Indicators<br />

1<br />

See order table<br />

2 4

LMP 210 ordering information<br />

Filter assembly<br />

LMP210<br />

1 2 3 4 5 6<br />

7<br />

Example: LMP210 2 B A G3 A10 N P01<br />

Filter Element<br />

1 5 3 6 7<br />

CU210<br />

Example: CU210 2 A10 A N P01<br />

1 - Sizes<br />

1<br />

6 - Filter element<br />

A03 3 µm A16 16 µm<br />

Absolute filtration<br />

Inorganic<br />

microfibre<br />

2<br />

A06 6 µm A25 25 µm<br />

ßx (c) ≥ 1 0 0 0<br />

3<br />

A10 10 µm<br />

3 - Valves<br />

M25 25 µm M90 90 µm<br />

Nominal Filtration<br />

Metal mesh<br />

S<br />

Without by-pass<br />

M60 60 µm<br />

B<br />

With by-pass<br />

4 - Seals<br />

A<br />

NBR<br />

P10 10 µm<br />

P25 25 µm<br />

Nominal Filtration<br />

Cellulose<br />

V<br />

FPM<br />

7 - Filter elements series<br />

5 - Connections<br />

Threaded<br />

G 1<br />

G 1”<br />

G 2 G 1 1/4”<br />

Flanged<br />

F 1 1” SAE 3000 psi/M<br />

F 2 1 1/4” SAE 3000 psi/M<br />

N<br />

W<br />

8 - Options<br />

a - Filter<br />

Δp 20 bar<br />

Δp 20 bar Compatible with fluid FH AFH BFH C<br />

(not available for filter element Pxx)<br />

G 3<br />

G 1 1/2”<br />

F 3<br />

1 1/2” SAE 3000 psi/M<br />

P01<br />

MP Standard filters<br />

G 4<br />

1” NPT<br />

F 4<br />

1” SAE 3000 psi/UNC<br />

G 5<br />

1 1/4” NPT<br />

F 5<br />

1 1/4” SAE 3000 psi/UNC<br />

DIFFERENTIAL INDICATORS<br />

See catalogue IL LINE filter (code: CMP 1007 UK 001 B)<br />

G 6<br />

1 1/2” NPT<br />

F 6<br />

1 1/2” SAE 3000 psi/UNC<br />

G 7<br />

SAE 16 1 5/16” 12UN<br />

G 8<br />

SAE 20 1 5/8” 12UN<br />

G 9<br />

SAE 24 1 7/8” 12UN<br />

MP Filtri - The filter functions as described in this bulletin are valid exclusively for original MP Filtri filter elements and<br />

replacement parts. All rights reserved<br />

The data in this publication are purely guideline. MP Filtri reserves the right to make changes to the models described herein at any time it deems fit in relation to technical or<br />

commercial requirements. The colours of the products shown on the cover are purely guideline. Copyright. All rights reserved.<br />

2 5

2 6<br />

LMP 400 - 401<br />

430 - 431

SERIES<br />

LMP 400 - 401<br />

430 - 431<br />

Working pressure<br />

60/50 bar<br />

Style S<br />

Style B<br />

B<br />

B<br />

D.I.<br />

D.I.<br />

A<br />

A<br />

2 7

Technical data<br />

Filter h o u s i n g ( M a t e r i a l s )<br />

• Head: Anodised Aluminium<br />

• Housing: Anodised A l u m i n i u m<br />

• Bypass valve: Steel<br />

P r e s s u re<br />

LMP 400 lenght: 2 - 3 - 4<br />

• Working pre s s u re: 60 bar (6 MPa)<br />

• Test pre s s u re: 90 bar (9 MPa)<br />

• Burst pre s s u re: 180 bar (18 MPa)<br />

• Pulsed pre s s u re fatigue test: 1.000.000 cycles<br />

with pre s s u re from 0 to 60 bar (6 MPa)<br />

LMP 400 lenght: 5 - 6<br />

• Working pre s s u re: 50 bar (5 MPa)<br />

• Test pre s s u re: 75 bar (7,5 MPa)<br />

• Burst pre s s u re: 150 bar (15 MPa)<br />

• Pulsed pre s s u re fatigue test: 1.000.000 cycles<br />

with pre s s u re from 0 to 50 bar (5 MPa)<br />

Te m p e r a t u r e<br />

• From -25°C to +110°C<br />

• The filter elements are compatible with:<br />

Mineral oils to ISO 2943, Synthetic fluids<br />

Aqueous emulsions, water and glycol<br />

(series W re q u i re d ).<br />

• NBR seals series A, compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• V series FPM seals, compatible with:<br />

Synthetic fluids type HS-HFDR-HFDS-HFDU<br />

To ISO 2943<br />

Filter Element Area<br />

Filter element in stainless steel mesh<br />

Length<br />

Type 2 3 4 5 6<br />

CU 400<br />

3300 4950 6550 10200 15300<br />

Values expressed in cm 2<br />

Filter housing Δp pressure drop<br />

The curves are plotted utilising mineral oil<br />

with density of 0.86 kg/dm 3 to ISO 3968.<br />

Δp varies proportionally with density.<br />

Bypass valve<br />

• Opening pre s s u re 3.5 bar ±10%<br />

• Other opening pre s s u res on re q u e s t .<br />

0 , 9<br />

LMP 400 - 401 - Δp housing<br />

G 1 G 2 F 1<br />

F 2<br />

Δp Elements type<br />

• Series N and W elements: 20 bar<br />

0 , 6<br />

• Oil flow from exterior to interior.<br />

S e a l s<br />

• Standard NBR<br />

• Optional FPM<br />

Weights (kg)<br />

L e n g t h<br />

• LMP400 - 2 6.7<br />

• LMP400 -3 7.3<br />

• LMP400 - 4 8.1<br />

• LMP400 - 5 11.3<br />

• LMP400 - 6 14 . 4<br />

series A<br />

series V<br />

Volumes (d m 3 )<br />

L e n g t h<br />

• LMP400 - 2 3.5<br />

• LMP400 -3 5<br />

• LMP400 - 4 6.5<br />

• LMP400 - 5 9.5<br />

• LMP400 - 6 13.5<br />

Connections<br />

In-line Inlet/Outlet LMP 400 - 430<br />

90° Inlet/outlet LMP 401 - 431<br />

0 , 3<br />

0 , 00<br />

0 18 0 36 0 54 0 72 0 90 0<br />

Flow rate l/min<br />

Valves<br />

Bypass valve pressure drop<br />

LMP 400 - By-pass<br />

9<br />

6<br />

3<br />

C o m p a t i b i l i t y<br />

• H o u s i n g s compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

0 , 0 0<br />

0 14 0 28 0 42 0 56 0 70 0<br />

Flow rate l/min<br />

2 8

Option P 0 2 for LMP 430/431<br />

Recommended maximum flow rate<br />

Recommended maximum flow rate for filters installed on<br />

lubrication lines, re t u rn or in-line filters is defined by the<br />

maximum oil velocity in the connections.<br />

For filters mounted on Off-Line lines the maximum<br />

recommended flow rate is defined by the pre s s u re dro p<br />

of the filter element.<br />

Filter for pressurised lubrication, max.<br />

oil velocity 2.5 m/sec.<br />

Return or in-line filter, max oil<br />

velocity 5 m/sec.<br />

Oil velocity<br />

2,5 m/sec.<br />

5 m/sec.<br />

1 1/2” 2” 2 1/2”<br />

120<br />

240<br />

Option P02 “Internal tube for<br />

reduced flow rate” is<br />

recommended for flow rate<br />

values below 100/150 I/min.<br />

The use of option P02 makes<br />

it easier to fill the housing<br />

with the operating fluid.<br />

P02 “ I n t e rnal tube for<br />

reduced flow rates”<br />

C o n n e c t i o n s<br />

300<br />

600<br />

500<br />

1000<br />

Recommended maximum flow rate<br />

- Pre s s u re drop of filter assembly equal to<br />

Δp 0.6 bar.<br />

- Oil kinematic viscosity 30 mm 2 /s (cSt).<br />

- Density 0.86 kg/dm 3 .<br />

- Connections of filter under test G 2 1/2”.<br />

Filter Flow rate F i l t e r<br />

e l e m e n t l / m i n l e n g t h<br />

t y p e Series N<br />

A 03 180<br />

A 06 215<br />

A 10 325<br />

A 16 360<br />

A 25 460<br />

M 25 660<br />

P10 470<br />

P25 500<br />

A 03 245<br />

A 06 295<br />

A10 420<br />

A 16 460<br />

A 25 540<br />

M 25 700<br />

P10 580<br />

P25 600<br />

A 03 305<br />

A 06 350<br />

A 10 480<br />

A 16 510<br />

A 25 575<br />

M 25 720<br />

P10 600<br />

P25 630<br />

A 03 405<br />

A 06 445<br />

A 10 550<br />

A 16 600<br />

A 25 660<br />

M 25 740<br />

P10 640<br />

P25 670<br />

A 03 450<br />

A 06 520<br />

A 10 610<br />

A 16 630<br />

A 25 670<br />

M 25 740<br />

P10 650<br />

P25 670<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Flow rate l/min.<br />

O f f-Line filter, filter element recommended maximum<br />

p re s s u re drop must be equal to Δp 0.2 ÷ 0.3 bar.<br />

2 9

Dimensions<br />

LMP 400 LMP 401<br />

Length 2-3-4 Length 2-3-4<br />

1 7 0<br />

4 8 5 3<br />

8 8 , 9<br />

E<br />

I N<br />

O U T<br />

Fixing holes<br />

and surf a c e<br />

D<br />

D<br />

5 0 , 8<br />

I N<br />

A<br />

C<br />

B<br />

A<br />

A<br />

O U T<br />

C<br />

Fixing holes<br />

and surf a c e<br />

B<br />

B<br />

A<br />

B<br />

7 8 8 3<br />

Flanged IN/OUT<br />

connections<br />

E<br />

Depth 20 mm<br />

Threaded IN/OUT<br />

connections<br />

E<br />

Depth 20 mm<br />

Length<br />

Filter<br />

H<br />

mm<br />

2” SAE<br />

3000 psi/M<br />

2 1/2” SAE<br />

3000 psi/M<br />

2” SAE<br />

3000 psi/UNC<br />

2 1/2” SAE<br />

3000 psi/UNC<br />

M 1 2<br />

M 1 2<br />

1/2” UNC<br />

1/2” UNC<br />

G 1 1/2”<br />

G 2”<br />

1 1/2” NPT<br />

2” NPT<br />

SAE 24 - 1 7/8”- 12 UN<br />

SAE 32 - 2 1/2”- 12 UN<br />

M 12<br />

M 12<br />

1/2” UNC<br />

1/2” UNC<br />

1/2” UNC<br />

1/2” UNC<br />

A<br />

B<br />

C<br />

2<br />

3<br />

4<br />

378<br />

478<br />

578<br />

B reather plug - G 3/8” - Ch. 8<br />

Indicator connection - P l u g T2 - Ch. 30<br />

Bypass valve - Ch. 17<br />

3 0<br />

D<br />

Oil drain plug - G 3/8” - Ch. 8

LMP 400<br />

LMP 401<br />

Length 5 - 6 Length 5 - 6<br />

1 7 0<br />

4 8 5 3<br />

8 8 , 9<br />

E<br />

I N<br />

O U T<br />

Fixing holes<br />

and surf a c e<br />

Version P02<br />

Ø 174<br />

Version P01<br />

D<br />

5 0 , 8<br />

I N<br />

A<br />

C<br />

B<br />

A<br />

A<br />

O U T<br />

C<br />

Fixing holes<br />

and surf a c e<br />

B<br />

B<br />

A<br />

B<br />

7 8 8 3<br />

Length<br />

Filter<br />

5<br />

6<br />

H<br />

mm<br />

828<br />

1158<br />

H1<br />

mm<br />

120<br />

120<br />

H2<br />

mm<br />

660<br />

990<br />

A<br />

B<br />

C<br />

D<br />

B reather plug - G 3/8” - Ch. 8<br />

Indicator connection - P l u g T2 - Ch. 30<br />

Bypass valve - Ch. 17<br />

Oil drain plug - G 3/8” - Ch. 8<br />

3 1

LMP 430<br />

LMP 431<br />

Length 5 - 6 Length 5 - 6<br />

B<br />

D<br />

8 0 7 8<br />

Fixing holes<br />

and surf a c e<br />

B<br />

O U T<br />

B<br />

D<br />

D<br />

B<br />

5 0 , 8<br />

D<br />

I N<br />

A<br />

A<br />

Ø 174<br />

Fixing holes<br />

and surf a c e<br />

O U T<br />

I N<br />

5 3 4 8<br />

1 7 0<br />

E<br />

8 8 , 9<br />

3 2

Flanged IN/OUT<br />

connections<br />

2” SAE<br />

3000 psi/M<br />

2 1/2” SAE<br />

3000 psi/M<br />

2” SAE<br />

3000 psi/UNC<br />

2 1/2” SAE<br />

3000 psi/UNC<br />

E<br />

Depth 20 mm<br />

M 1 2<br />

M 1 2<br />

1/2” UNC<br />

1/2” UNC<br />

Flanged IN/OUT<br />

connections<br />

G 1 1/2”<br />

G 2”<br />

1 1/2” NPT<br />

2” NPT<br />

SAE 24 - 1 7/8”- 12 UN<br />

SAE 32 - 2 1/2”- 12 UN<br />

E<br />

Depth 20 mm<br />

M 12<br />

M 12<br />

1/2” UNC<br />

1/2” UNC<br />

1/2” UNC<br />

1/2” UNC<br />

A<br />

B<br />

D<br />

B reather plug - G 3/8” - Ch. 8<br />

Indicator connection - P l u g T2 - Ch. 30<br />

Oil drain plug - G 3/8” - Ch. 8<br />

Length<br />

Filter<br />

5<br />

6<br />

H<br />

mm<br />

828<br />

1158<br />

H1<br />

mm<br />

660<br />

990<br />

3 3

LMP400/401 spare parts<br />

Length 2, 3, 4<br />

3f<br />

3f<br />

4 4<br />

3g<br />

3d 3e<br />

3e 3d<br />

1<br />

3a<br />

3b<br />

2<br />

3c<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series<br />

LMP 400/401 2 - 3 - 4<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

Filter Element<br />

1<br />

See order table<br />

3<br />

Seals kit<br />

1<br />

NBR FPM<br />

02050391 02050392<br />

3a<br />

Filter element O-Ring<br />

1<br />

O-R 3237<br />

Ø 59,99 x 2,62<br />

3b<br />

O-Ring for housing<br />

1<br />

O-R 4525<br />

Ø 132,95 x 3,53<br />

3c<br />

Oil drain plug<br />

1<br />

G 3/8” with seal<br />

3d<br />

Bonded seal<br />

2<br />

01030058 01030046<br />

3e<br />

O-Ring<br />

2<br />

O-R 2050<br />

Ø 12,42 x 1,78<br />

3f<br />

Breather plug<br />

2<br />

01029436<br />

3g<br />

By-pass plug O-Ring<br />

1<br />

O-R 3193<br />

Ø 48,90 x 2,62<br />

4<br />

Indicator connection plug<br />

2<br />

T 2 H<br />

T 2 V<br />

-<br />

Indicators<br />

1<br />

See order table<br />

3 4

LMP 400/401 spare parts<br />

Length 5, 6<br />

3f<br />

3f<br />

4<br />

3d 3e<br />

4<br />

3e 3d<br />

3a<br />

3g<br />

1<br />

3b<br />

2<br />

5<br />

3c<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series<br />

LMP 400/401 5 - 6<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

Filter Element<br />

1<br />

See order table<br />

3<br />

Seals kit<br />

1<br />

NBR FPM<br />

02050393 02050394<br />

3a<br />

Filter element O-Ring<br />

2<br />

O-R 3237<br />

Ø 59,99 x 2,62<br />

3b<br />

O-Ring for housing<br />

2<br />

O-R 4525<br />

Ø 132,95 x 3,53<br />

3c<br />

3d<br />

Oil drain plug<br />

Bonded seal<br />

1<br />

2<br />

G 3/8” with seal<br />

01030058 01 03 00 46<br />

3e<br />

3f<br />

O-Ring<br />

Breather plug<br />

2<br />

2<br />

O-R 2050<br />

Ø 12,42 x 1,78<br />

01029436<br />

3g<br />

By-pass plug O-Ring<br />

1<br />

O-R 3193<br />

Ø 48,90 x 2,62<br />

4<br />

Indicator connection plug<br />

2<br />

T 2 H<br />

T 2 V<br />

5<br />

Housing spigot<br />

1<br />

01044108<br />

-<br />

Indicators<br />

1<br />

See order table<br />

3 5

LMP430/431 spare parts<br />

Length 5, 6<br />

3f<br />

5<br />

3b<br />

6<br />

2<br />

1<br />

3a<br />

3d 3e<br />

3c<br />

4<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series<br />

LMP 430/431 5 - 6<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

Filter Element<br />

1<br />

See order table<br />

3<br />

Seals kit<br />

1<br />

NBR FPM<br />

02050395 02050396<br />

3a<br />

Filter element O-Ring<br />

2<br />

O-R 3237<br />

Ø 59,99 x 2,62<br />

3b<br />

O-Ring for housing<br />

2<br />

O-R 4525<br />

Ø 132,95 x 3,53<br />

3c<br />

Oil drain plug<br />

2<br />

G 3/8” with seal<br />

3d<br />

Bonded seal<br />

2<br />

01030058 01030046<br />

3e<br />

O-Ring<br />

2<br />

O-R 2050<br />

Ø 12,42 x 1,78<br />

3f<br />

Breather plug<br />

1<br />

01029436<br />

4<br />

Indicator connection plug<br />

2<br />

T2H<br />

T2V<br />

5<br />

Housing spigot<br />

1<br />

Spigot no by-pass 01044108<br />

Spigot with by-pass 02001414<br />

6<br />

Tube assembly<br />

1<br />

Length 5 - 02025041<br />

Length 6 - 02025042<br />

-<br />

Indicators<br />

1<br />

See order table<br />

3 6

Ordering information LMP400÷431<br />

Filter assembly<br />

LMP<br />

1 2 3 4 5 6<br />

7 8 a<br />

Example: LMP 400 4 B A G3 A10 N P01<br />

Filter Element<br />

CU 400<br />

2 6 4 7 8 b<br />

Example: CU400 4 A10 A N P01<br />

1 - Sizes<br />

40 0 43 0<br />

40 1 43 1<br />

2 - Filter length<br />

2<br />

3 LMP 430 - 431 excluded<br />

4<br />

5<br />

6<br />

6 - Filter element<br />

A03 3 µm A16 16 µm<br />

A06 6 µm A25 25 µm<br />

A10 10 µm<br />

M25 25 µm M90 90 µm<br />

M60 60 µm<br />

P10 10 µm<br />

P25 25 µm<br />

Absolute filtration<br />

Inorganic<br />

microfibre<br />

ßx (c) ≥ 1000<br />

see page 9<br />

Nominal Filtration<br />

Metal mesh<br />

see page 9<br />

Nominal Filtration<br />

Cellulose<br />

see page 9<br />

3 - Valves<br />

S<br />

B<br />

4 - Seals<br />

A<br />

V<br />

5 - Connections<br />

Type<br />

G1 G 1 1/2”<br />

G2 G 2”<br />

G3<br />

G4<br />

G5<br />

G6<br />

F1<br />

F2<br />

F3<br />

F4<br />

Without by-pass<br />

With by-pass<br />

NBR<br />

FPM (series P10 - P25<br />

filter elements excluded)<br />

1 1/2” NPT<br />

2” NPT<br />

SAE 24 (1 7/8” 12 UN)<br />

SAE 32 (2 1/2” 12 UN)<br />

2” SAE 3000 PSI/M<br />

2 1/2” SAE 3000 PSI/M<br />

2” SAE 3000 PSI/UNC<br />

2 1/2” SAE 3000 PSI/UNC<br />

7 - Filter elements series<br />

N<br />

W<br />

8 - Options<br />

a - Filter<br />

P01<br />

P02<br />

P02<br />

Pxx<br />

MP Standard filters<br />

LMP 400 - 401<br />

Maintenance from base of housing (lengths 5 and 6 only)<br />

Customer request<br />

b - Filter elements<br />

P01<br />

Pxx<br />

Δp 20 bar<br />

Δp 20 bar (aqueous emulsions - water and glycol, not<br />

available for series P10 - P25 filter elements)<br />

LMP 430 - 431<br />

With internal tube for reduced flow rate<br />

MP Standard filters<br />

Customer request<br />

DIFFERENTIAL INDICATORS (see page 12)<br />

MP Filtri - The filter functions as described in this bulletin are valid exclusively for original MP Filtri filter elements and<br />

replacement parts. All rights reserved<br />

The data in this publication are purely guideline. MP Filtri reserves the right to make changes to the models described herein at any time it deems fit in relation to technical or<br />

commercial requirements. The colours of the products shown on the cover are purely guideline. Copyright. All rights reserved.<br />

3 7

3 8<br />

LMD 400 - 401<br />

431

SERIES<br />

LMD 400 - 401<br />

431<br />

LMD 431<br />

Working pre s s u re<br />

16 bar<br />

LMD 401<br />

LMD 400<br />

LMD 400 - 401 - 431<br />

Duplex filter<br />

D.I.<br />

D.I.<br />

3 9

Technical data<br />

Filter h o u s i n g s ( M a t e r i a l s )<br />

• Head: Anodised Aluminium<br />

• Housing: Anodised Aluminium<br />

• Manifolds: Steel - Painted black<br />

• Bypass valve: Steel / Stainless steel<br />

• 3-way ball valve: - Steel h o u s i n g s<br />

- Stainless steel ball<br />

• Valve: phosphated steel - ASI 304<br />

P r e s s u re<br />

• SAE Flange<br />

• Working pre s s u re: 16 bar (1.6 MPa)<br />

• Test pre s s u re :<br />

Te m p e r a t u r e<br />

• From -25°C to +110°C<br />

Bypass valve<br />

25 bar (2.5 MPa)<br />

• Opening pre s s u re 3.5 bar ±10%<br />

• Other opening pre s s u res on re q u e s t .<br />

Filter elements Δp<br />

• Series N and W elements: 20 bar<br />

• Oil flow from exterior to interior.<br />

S e a l s<br />

• Standard FPM<br />

Weights (kg)<br />

L e n g t h<br />

• LMD400/401 4 60<br />

• LMD400/401 5 65<br />

• LMD400/401 6 72<br />

• LMD431 5 68<br />

• LMD431 6 75<br />

Volumes (d m 3 )<br />

L e n g t h<br />

• LMD400/401/431 4 18<br />

• LMD400/401/431 5 24<br />

• LMD400/401/431 6 32<br />

series V<br />

C o n n e c t i o n s<br />

Inlet/Outlet<br />

• Twin ver tically mounted (excluded version LMD400)<br />

• I n - l i n e<br />

C o m p a t i b i l i t y<br />

• H o u s i n g s compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• The filter elements are compatible with:<br />

Mineral oils to ISO 2943, Synthetic fluids<br />

Aqueous emulsions, water and glycol (series W re q u i re d ).<br />

• NBR seals series A, compatible with:<br />

Mineral oils to ISO 2943 - aqueous emulsions<br />

synthetic fluids, water and glycol.<br />

• V series FPM seals, compatible with:<br />

Synthetic fluids type HS-HFDR-HFDS-HFDU<br />

To ISO 2943<br />

Filter Element Area of Working H o u s i n g/H o u s i n g s<br />

Filter element in stainless steel mesh<br />

LMD 400/401/431 Length<br />

Type<br />

4 5 6<br />

CU400<br />

Filter h o u s i n g s Δp pressure drop<br />

The curves are plotted utilising mineral oil<br />

with density of 0.86 kg/dm 3 to ISO 3968.<br />

Δp varies proportionally with density.<br />

Valves<br />

9<br />

LMD 400/401/431<br />

Δp H o u s i n g s<br />

0 , 6<br />

0 , 5<br />

0 , 4<br />

0 , 3<br />

0 , 2<br />

0 , 1<br />

0 , 00<br />

10 0 20 0 30 0 40 0 50 0 60 0<br />

Flow rate l/min<br />

Bypass valve pressure drop<br />

For individual filter<br />

6550 10200 15300<br />

Values expressed in c m 2<br />

LMD 400/401/431<br />

Bypass valve<br />

6<br />

3<br />

0 , 0 0<br />

0 14 0 28 0 42 0 56 0 70 0<br />

Flow rate l/min<br />

4 0

Recommended maximum flow rate<br />

Option P02 “Internal tube for<br />

reduced flow rate” is<br />

recommended for flow rate<br />

values below: 150 l/min.<br />

The use of option P02 makes<br />

it easier to fill the housing<br />

with the operating fluid.<br />

P02 “ I n t e rnal tube for<br />

reduced flow rates”<br />

Recommended maximum flow rate for filters installed on<br />

lubrication lines, re t u rn or in-line filters is defined by the<br />

maximum oil velocity in the connections.<br />

For filters mounted on Off-Line lines the maximum<br />

recommended flow rate is defined by the pre s s u re dro p<br />

of the filter element.<br />

Recommended maximum flow rate<br />

- Pre s s u re drop of filter assembly equal to<br />

Δp 0.6 bar.<br />

- Oil kinematic viscosity 30 mm 2 /s (cSt).<br />

- Density 0.86 kg/dm 3 .<br />

Filter<br />

e l e m e n t<br />

t y p e<br />

Flow rate<br />

I / m i n<br />

Series N<br />

A 0 3 2 6 5<br />

A 0 6 3 1 0<br />

A 1 0 4 1 0<br />

A 1 6 4 3 0<br />

A 2 5 4 8 5<br />

P10 5 0 0<br />

P25 5 2 0<br />

M 2 5 5 7 0<br />

A 0 3 3 5 5<br />

A 0 6 3 8 5<br />

A10 4 6 5<br />

A 1 6 5 0 0<br />

A 2 5 5 4 0<br />

P10 5 3 0<br />

P25 5 4 0<br />

M 2 5 5 8 0<br />

A 0 3 3 9 0<br />

A 0 6 4 4 0<br />

A 1 0 5 1 0<br />

A 1 6 5 2 0<br />

A 2 5 5 6 0<br />

P10 5 4 0<br />

P25 555<br />

M 2 5 5 9 0<br />

F i l t e r<br />

Type<br />

LMD 400<br />

LMD 401<br />

LMD 400<br />

LMD 401<br />

LMD 431<br />

LMD 400<br />

LMD 401<br />

LMD 431<br />

Length<br />

4<br />

5<br />

6<br />

Filter for pressurised lubrication, max.<br />

oil velocity 2.5 m/sec.<br />

Return or in-line filter, max oil<br />

velocity 5 m/sec.<br />

Flange Connection<br />

F l a n g e<br />

2 1/2” SAE 3000 psi<br />

B<br />

D<br />

Oil velocity<br />

C o n n e c t i o n s<br />

2 1/2”<br />

C o n n e c t i o n s<br />

Flange IN-OUT<br />

2 1/2”<br />

SAE<br />

3000 psi/M<br />

2 1/2”<br />

SAE<br />

3000 psi/UNC<br />

2,5 m/sec.<br />

5 m/sec.<br />

500<br />

1000<br />

Flow rate l/min<br />

A<br />

B<br />

C<br />

D<br />

63<br />

88,90<br />

50,80<br />

M12<br />

63<br />

88,90<br />

50,80<br />

1/2” UNC<br />

4 0

Dimensions<br />

LMD 400<br />

LMD 400<br />

Length 4<br />

Length 5 - 6<br />

A<br />

B<br />

A<br />

B<br />

Version P02<br />

I<br />

I<br />

Version P01<br />

M 1 2<br />

Filter fixing holes LMD 400<br />

8 8 , 9<br />

2 5 3 , 1 8 8 , 9<br />

Length Length L e n g t h<br />

4 5 6<br />

A<br />

2 5 5<br />

2 5 5<br />

2 5 5<br />

B<br />

2 5 5<br />

2 5 5<br />

2 5 5<br />

C<br />

1 2 0<br />

1 2 0<br />

1 2 0<br />

D<br />

5 1 3<br />

7 6 5<br />

1 0 9 5<br />

E<br />

3 5 1<br />

3 5 1<br />

3 5 1<br />

F<br />

2 8 5<br />

2 8 5<br />

2 8 5<br />

G<br />

1 9 5<br />

1 9 5<br />

1 9 5<br />

H 1<br />

1 2 0<br />

1 2 0<br />

1 2 0<br />

R<br />

H 2<br />

-<br />

6 6 0<br />

9 9 0<br />

I<br />

3 4 2<br />

3 4 2<br />

3 4 2<br />

R<br />

2 5 5<br />

2 5 5<br />

2 5 5<br />

4 1

LMD 401 LMD 401<br />

Length 4 Length 5 - 6<br />

Version P02<br />

I<br />

Version P01<br />

I<br />

A<br />

F<br />

Ve r s i o n<br />

F1 - F2<br />

G<br />

Ve r s i o n<br />

F3 - F4<br />

R<br />

Length Length L e n g t h<br />

4 5 6<br />

Length Length L e n g t h<br />

4 5 6<br />

A<br />

6 4 0<br />

6 4 0<br />

6 4 0<br />

G<br />

1 5 6<br />

1 5 6<br />

1 5 6<br />

B<br />

2 5 0<br />

2 5 0<br />

2 5 0<br />

H 1<br />

1 2 0<br />

1 2 0<br />

1 2 0<br />

C<br />

2 2 8<br />

2 2 8<br />

2 2 8<br />

H2<br />

-<br />

6 6 0<br />

9 9 0<br />

D<br />

5 1 3<br />

7 6 5<br />

1 0 9 5<br />

I<br />

4 7 0<br />

4 7 0<br />

4 7 0<br />

E<br />

7 9 6<br />

1 0 4 8<br />

1 3 7 8<br />

R<br />

2 5 5<br />

2 5 5<br />

2 5 5<br />

F<br />

1 5 6<br />

1 5 6<br />

1 5 6<br />

4 2

LMD 431<br />

Length 5 - 6<br />

I<br />

F<br />

Ve r s i o n<br />

F1 - F2<br />

G<br />

Ve r s i o n<br />

F3 - F4<br />

A<br />

Length L e n g t h<br />

5 6<br />

A<br />

6 4 0<br />

6 4 0<br />

B<br />

2 5 0<br />

2 5 0<br />

C<br />

1 7 0<br />

1 7 0<br />

D<br />

2 2 8<br />

2 2 8<br />

R<br />

E<br />

1 1 6 5<br />

1 4 9 5<br />

F<br />

1 5 6<br />

1 5 6<br />

G<br />

1 5 6<br />

1 5 6<br />

Filter fixing holes LMD 431<br />

H<br />

6 6 0<br />

9 9 0<br />

M<br />

Ø 15 - No. 4 holes<br />

I<br />

M<br />

47 0<br />

53 0<br />

47 0<br />

53 0<br />

N<br />

1 0 0<br />

1 0 0<br />

R<br />

2 5 5<br />

2 5 5<br />

4 3

LMD 400<br />

LMD 431<br />

C<br />

A<br />

B<br />

A<br />

B<br />

B<br />

A<br />

C<br />

B<br />

D<br />

A Indicator connection plug T2 Ch. 30<br />

B Oil drain plug G 1/2” Ch. 10<br />

C Compensation valve<br />

D B reather plug G 1/2” Ch. 10<br />

D i ff e rential indicator:<br />

LMD 400 - 401 - 431<br />

Fit one indicator per individual filter assembly<br />

LMD 401<br />

A<br />

D<br />

D<br />

C<br />

A<br />

4 3

LMD 400 spare parts<br />

3<br />

4 b<br />

4 b<br />

1<br />

5 a<br />

5 b<br />

3<br />

4 b<br />

5 c<br />

5 d<br />

4 a<br />

2<br />

5 a<br />

5 b<br />

7<br />

6<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series LMD 400<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

3-way ball valve<br />

PN 16<br />

1<br />

2 1/2” SAE 3000 psi/M 02001440<br />

2 1/2” SAE 3000 psi/UNC 02001441<br />

3<br />

One-way valve<br />

2<br />

02001429<br />

4<br />

Seals kit<br />

1<br />

02050399<br />

4a<br />

Flat seal<br />

2<br />

To DN 65<br />

4b<br />

IN-OUT O-Ring<br />

4<br />

O-R 4287<br />

5<br />

Threaded fasteners kit<br />

1<br />

02049062<br />

5a<br />

Allen screw<br />

16<br />

UNI 5931 - M12 x 35 - 10.9<br />

5b<br />

Circlips<br />

16<br />

UNI 1751-B 12<br />

5c<br />

Screw hexagon head<br />

8<br />

UNI EN 24017 - M16 x 40 - 10.9<br />

5d<br />

Circlips<br />

8<br />

UNI 1751-B 16<br />

6<br />

Kit ball valve with hose fitting<br />

1<br />

02025043<br />

7<br />

Filter<br />

2<br />

See order table<br />

LMP400xF2..... pag. 31<br />

-<br />

Indicators<br />

2<br />

See order table<br />

4 4

LMD 401 spare parts<br />

4 b<br />

5 a<br />

5 b<br />

1<br />

4 a<br />

3<br />

2<br />

5 d<br />

5 c<br />

5 b<br />

6<br />

7<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series LMD 401<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

3-way ball valve<br />

PN 16<br />

1<br />

2 1/2” SAE 3000 psi/M 02001440<br />

2 1/2” SAE 3000 psi/UNC 02001441<br />

3<br />

One-way valve<br />

2<br />

02001429<br />

4<br />

Seals kit<br />

1<br />

02050399<br />

4a<br />

Flat seal<br />

2<br />

To DN 65<br />

4b<br />

IN-OUT O-Ring<br />

4<br />

O-R 4287<br />

5<br />

Mounting set accessories<br />

1<br />

02049062<br />

5a<br />

Allen screw<br />

16<br />

UNI 5931 - M12 x 35 - 10.9<br />

5b<br />

Circlips<br />

16<br />

UNI 1751-B 12<br />

5c<br />

Screw hexagon head<br />

8<br />

UNI EN 24017 - M16 x 40 - 10.9<br />

5d<br />

Circlips<br />

8<br />

UNI 1751-B 16<br />

6<br />

7<br />

Kit ball valve with hose fitting<br />

Filter<br />

1<br />

2<br />

02025043<br />

See order table<br />

LMP401xF2..... pag. 31<br />

-<br />

Indicators<br />

2<br />

See order table<br />

4 5

LMD 431 spare parts<br />

1<br />

6<br />

4 a<br />

7<br />

4 b<br />

3<br />

4 b<br />

5 c<br />

5 d<br />

2<br />

5 b<br />

5 a<br />

Pos.<br />

Description<br />

Qty<br />

FILTER Series LMD 431<br />

1<br />

Filter assembly<br />

1<br />

See order table<br />

2<br />

3-way ball valve<br />

PN 16<br />

1<br />

2 1/2” SAE 3000 psi/M 02001440<br />

2 1/2” SAE 3000 psi/UNC 02001441<br />

3<br />

One-way valve<br />

2<br />

02001429<br />

4<br />

Seals kit<br />

1<br />

02050399<br />

4a<br />

Flat seal<br />

2<br />

To DN 65<br />

4b<br />

IN-OUT O-Ring<br />

4<br />

O-R 4287<br />

5<br />

Threaded fasteners kit<br />

1<br />

02049062<br />

5a<br />

Allen screw<br />

16<br />

UNI 5931 - M12 x 35 - 10.9<br />

5b<br />

Circlips<br />

16<br />

UNI 1751-B 12<br />

5c<br />

Screw hexagon head<br />

8<br />

UNI EN 24017 - M16 x 40 - 10.9<br />

5d<br />

Circlips<br />

8<br />

UNI 1751-B 16<br />

6<br />

Kit ball valve with hose fitting<br />

1<br />

02025043<br />

7<br />

Filter<br />

2<br />

See order table<br />

LMP431xF2..... pag. 31<br />

-<br />

Indicators<br />

2<br />

See order table<br />

4 6

LMD400/401/431 ordering information<br />

Filter assembly<br />

LMD<br />

1 2 3 4 5 6<br />

7<br />

8 a<br />

Example: LMD 400 5 B V F1 A10 N P01<br />

Filter Element<br />

2 6 4 7 8b<br />

CU 400<br />

Example: CU400 5 A10 A N P01<br />

1 - Sizes<br />

40 0<br />

40 1<br />

43 1<br />

6 - Filter element<br />

A03 3 µm A16 16 µm<br />

A06 6 µm A25 25 µm<br />

A10 10 µm<br />

Absolute filtration<br />

Inorganic<br />

microfibre<br />

ßx (c) ≥ 1000<br />

see page 9<br />

2 - Filter length<br />

4 LMD 431 excluded<br />

M25 25 µm M90 90 µm<br />

M60 60 µm<br />

Nominal Filtration<br />

Metal mesh<br />

see page 9<br />

5<br />

6<br />

3 - Valves<br />

4 - Seals<br />

S Without by-pass<br />