Continuous Blowdown System

Continuous Blowdown System

Continuous Blowdown System

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

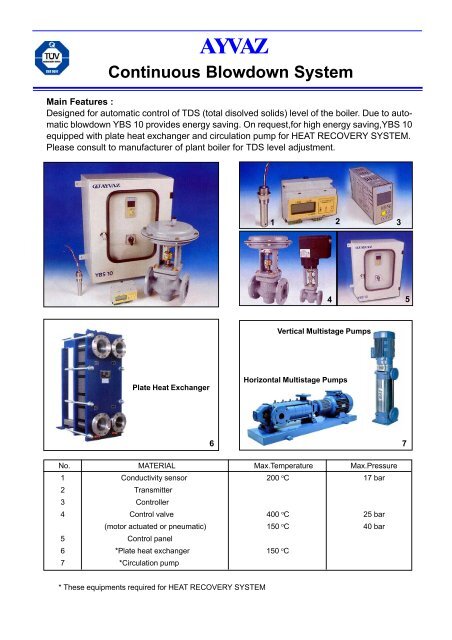

<strong>Continuous</strong> <strong>Blowdown</strong> <strong>System</strong><br />

Main Features :<br />

Designed for automatic control of TDS (total disolved solids) level of the boiler. Due to automatic<br />

blowdown YBS 10 provides energy saving. On request,for high energy saving,YBS 10<br />

equipped with plate heat exchanger and circulation pump for HEAT RECOVERY SYSTEM.<br />

Please consult to manufacturer of plant boiler for TDS level adjustment.<br />

1 2 3<br />

4 5<br />

Vertical Multistage Pumps<br />

Plate Heat Exchanger<br />

Horizontal Multistage Pumps<br />

6 7<br />

No. MATERIAL Max.Temperature Max.Pressure<br />

1 Conductivity sensor 200 o C 17 bar<br />

2 Transmitter<br />

3 Controller<br />

4 Control valve 400 o C 25 bar<br />

(motor actuated or pneumatic) 150 o C 40 bar<br />

5 Control panel<br />

6 *Plate heat exchanger 150 o C<br />

7 *Circulation pump<br />

* These equipments required for HEAT RECOVERY SYSTEM

CONTINUOUS BLOWDOWN SYSTEM<br />

STEAM<br />

MAKE-UP<br />

WATER<br />

CONDENSATE<br />

TANK<br />

BOILER<br />

BLOWDOWN AMOUNT RELATED HEAT LOSS<br />

Feedwater conductivity Blow amount supported to feedwater <strong>Blowdown</strong> amount Heat loss<br />

(25 0 c) % kg/h year/kg<br />

100 2 102 11.341<br />

200 4 208 23.127<br />

400 8 435 48.367<br />

800 16 952 105.852<br />

1000 20 1250 138.986<br />

1500 30 2143 238.278<br />

2000 40 3333 370.592<br />

Process pressure : 10 bar/Capacity : 5000 kg/h<br />

Working hours : 16 hr/day/Working days : 340 days/year<br />

Blow amount supported to feedwater %<br />

10<br />

8<br />

6<br />

4<br />

2<br />

%<br />

µs/cm (25 o C)<br />

100 200 400 100 200 400<br />

Feedwater conductivity Feedwater conductivity<br />

Heat loss<br />

48.4<br />

23.2<br />

11.3<br />

µs/cm (25 o C)

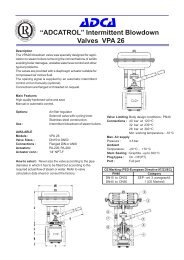

INTERMITTENT BLOWDOWN VALVE (With Timer)<br />

<br />

Main Features<br />

Besides continuous blowdown intermittent<br />

blowdown contributes to boiler safety<br />

and trouble-free operation. Intermittent<br />

blowdown ensures that precipitated solids<br />

and sludge are cleared from the boiler so<br />

that they cannot accumulate in the bottom<br />

of the boiler. A programmer controlled<br />

blowdown system with rapid-action intermittent<br />

blowdown valve is used for this<br />

purpose.<br />

DBV 10 Contains :<br />

1 - Ball valve (stainless steel)<br />

2 - Cyling timer<br />

3 - Pneumatic actuator<br />

4 - Solenoid valve<br />

5 - Limit switch<br />

PRESSURE (PSI)<br />

PRESSURE (bar)<br />

14<br />

TEMPERATURE o F<br />

210<br />

116.5<br />

Dimensions : mm<br />

MATERIAL Stainless Steel Carbon Steel<br />

Body ASTM A351-CF8M ASTM A3216-WC8<br />

346.5<br />

Cap ASTM A351-CF8M ASTM A3216-WC8<br />

128.5<br />

Ball ASTM A351-CF8M ASTM A3216-WC8<br />

Steam ASTM A276-316 ASTM A276-316<br />

O150<br />

3O87<br />

140<br />

18<br />

Ball seat RTFE RTFE<br />

Gasket RTFE RTFE<br />

Thrust Washer RTFE RTFE<br />

O 80<br />

46.5<br />

50.5<br />

MATERIAL Stainless Steel Carbon Steel<br />

81.5<br />

O-Ring Viton Viton<br />

Handle ASTM A351-CF8 ASTM A351-CF8<br />

84<br />

Disc spring 50CrV4 50CrV4<br />

152.5<br />

Internal AISI 304 AISI 304<br />

Bolt AISI 304 AISI 304<br />

120<br />

Nut AISI 304 AISI 304<br />

Steam Packing PTFE PTFE<br />

18