ROBUSTUS: the new rotating bushing track system ... - Berco S.p.A

ROBUSTUS: the new rotating bushing track system ... - Berco S.p.A

ROBUSTUS: the new rotating bushing track system ... - Berco S.p.A

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Berco</strong>News<br />

english edition > year y<br />

16<br />

issue 59 > july 2010<br />

Free Company Information PeriodicP<br />

eriodical<br />

Editor-in-Chief: Silvia Ungaro<br />

Auth. n° n 17/94 of Court t of FerrF<br />

errara, a, 5-12-1994<br />

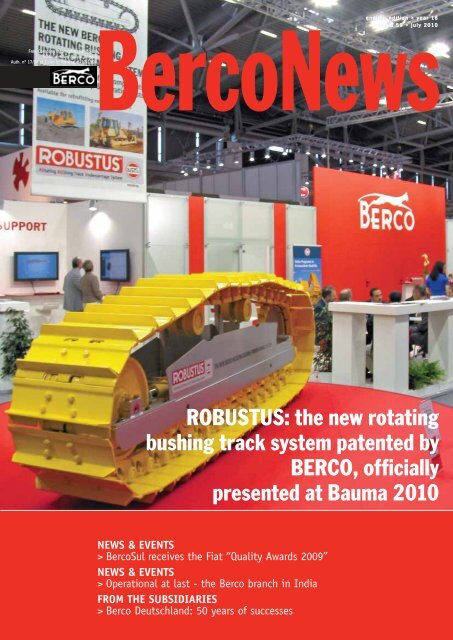

<strong>ROBUSTUS</strong>: <strong>the</strong> <strong>new</strong> <strong>rotating</strong><br />

<strong>bushing</strong> <strong>track</strong> <strong>system</strong> patented by<br />

BERCO, officially<br />

presented at Bauma 2010<br />

NEWS & EVENTS<br />

> <strong>Berco</strong>Sul receives <strong>the</strong> Fiat “Quality Awards 2009”<br />

NEWS & EVENTS<br />

> Operational at last - <strong>the</strong> <strong>Berco</strong> branch in India<br />

FROM THE SUBSIDIARIES<br />

> <strong>Berco</strong> Deutschland: 50 years of successes

Editorial<br />

2<br />

3<br />

4<br />

5<br />

6-7<br />

8<br />

9<br />

10-11<br />

IN THIS ISSUE:<br />

EDITORIAL<br />

Supporting <strong>the</strong> recovery<br />

with re<strong>new</strong>ed commitment<br />

NEWS & EVENTS<br />

Il Dr. Hippe visits Copparo<br />

<strong>Berco</strong>Sul receives<br />

<strong>the</strong> FIAT “Quality Awards 2009”<br />

NEWS & EVENTS<br />

Bauma 2010: signs of recovery<br />

on <strong>the</strong> earth moving machinery market<br />

PRODUCTS & SERVICES<br />

<strong>ROBUSTUS</strong>: <strong>the</strong> <strong>new</strong> <strong>rotating</strong><br />

<strong>bushing</strong> <strong>track</strong> <strong>system</strong><br />

New mining undercarriages:<br />

EX1800-3, EX1900-5<br />

FROM THE SUBSIDIARIES<br />

Operational at last<br />

<strong>the</strong> <strong>Berco</strong> branch in India<br />

<strong>Berco</strong> quality for <strong>the</strong> Chinese market<br />

PRODUCTS & SERVICES<br />

Much more than just<br />

suppliers of mining products<br />

FROM THE SUBSIDIARIES<br />

<strong>Berco</strong> Deutschland: 50 years of successes<br />

ENVIRONMENT & SAFETY<br />

Objective: “Zero accidents”<br />

<strong>Berco</strong>News is a six-monthly periodical published for <strong>Berco</strong><br />

employees, customers, suppliers and friends. The articles and<br />

photos can be copied only if expressly authorised by <strong>the</strong><br />

Editor.<br />

Front Cover: <strong>Berco</strong> stand at Bauma 2010<br />

Published by: BERCO S.p.A. - Communications Department<br />

Via 1° Maggio, 237 - 44034 Copparo (FE) Italy<br />

Tel. +39 0532 864116 - fax +39 0532 864462,<br />

e-mail: berco<strong>new</strong>s@berco.com<br />

Editor-in-Chief: Silvia Ungaro<br />

Tel. +39 0532 864116 - fax +39 0532 864462,<br />

e-mail: s.ungaro@berco.com<br />

Editorial Committee: E. Bacilieri, S. Bottacin, L. Guzzinati,<br />

S. Mastellari, G. Neodo, S. Salatini, S. Salvi, M. Seghieri,<br />

D. Musacci<br />

Editorial Secretary: D. Roversi<br />

Tel. +39 0532 864 270 - e-mail: d.roversi@berco.com<br />

Graphics and pagination: Communications Department<br />

Printed: Chinchio Industria Grafica S.p.A. (PD)<br />

Circulation: Italian 3800, English 4.000<br />

SUPPORTING THE<br />

RECOVERY WITH<br />

RENEWED<br />

COMMITMENT<br />

Dear readers,<br />

only a few months have<br />

passed since <strong>the</strong> last issue of<br />

our company magazine and<br />

we find ourselves operating<br />

in a situation quite different<br />

to <strong>the</strong> one in my last<br />

introductory notes.<br />

Even though our reference<br />

markets and main customers<br />

are not yet back to normal<br />

sales levels, we are<br />

witnessing a gradual but constant growth in demand -<br />

undifferentiated throughout <strong>the</strong> different geographical<br />

areas - on both <strong>the</strong> original equipment and spare parts<br />

markets.<br />

It is likely that this growth is greater than expected due to<br />

stock of previously unsold machines is virtually being<br />

depleted, <strong>the</strong> same is said of <strong>the</strong> essential components<br />

required for building <strong>new</strong> ones.<br />

In fact, our production volumes are almost double those of<br />

<strong>the</strong> last six months, taking us back up to about 75% of our<br />

total production capacity.<br />

In parallel, <strong>new</strong> branches and major investments - made<br />

recently to enable us to seize opportunities arising in<br />

rapidly growing markets such as China, India and Brazil -<br />

have begun to contribute to this growth.<br />

Thanks to <strong>the</strong> renowned quality of <strong>the</strong> components from<br />

Italy, local production and locally available services, <strong>the</strong>se<br />

branches are gaining <strong>new</strong> customers and rapidly acquiring<br />

larger market shares.<br />

Our ability to compete is expected to be streng<strong>the</strong>ned by<br />

<strong>the</strong> important production process rationalisation and<br />

optimisation measures to be introduced in our two - year<br />

investment plan, which will also have positive effects on<br />

company costs and efficiency, provided <strong>the</strong>y are<br />

implemented within <strong>the</strong> set times and with <strong>the</strong> active<br />

contribution of all personnel in <strong>the</strong> various production<br />

units.<br />

In addition, after being strongly penalised by exchange<br />

rates for a long period, <strong>the</strong> more favourable currency<br />

situation will help us to take on competitors who, up to<br />

now, have been able to gain ground in some areas mainly<br />

due to <strong>the</strong> weakness of <strong>the</strong>ir currencies.<br />

We are now able to look more optimistically at <strong>the</strong><br />

immediate future, in <strong>the</strong> hope that <strong>the</strong> signs of recovery<br />

glimpsed so far can transform <strong>the</strong>mselves into a stable,<br />

consolidated positive trend.

News & Events<br />

However, this is no time to sit back and deceive ourselves<br />

into thinking that everything is back to normal.<br />

On <strong>the</strong> contrary, we have to press ahead with re<strong>new</strong>ed<br />

determination and team spirit, using all our industrial and<br />

organisational talents to <strong>the</strong> best advantage and relying,<br />

even more, on <strong>the</strong> strength of our ideas and continuous<br />

product and process innovation.<br />

I am sure that we can count on <strong>the</strong> unstinting support and<br />

positive contribution of each single one of you, whatever<br />

your role, in order to emerge from <strong>the</strong> recent difficulties<br />

even stronger than before and, at long last, to look<br />

forward in <strong>the</strong> hope that <strong>the</strong> worst is now behind us.<br />

My kindest regards to yourselves, your co-workers and your<br />

families,<br />

Bruno Saturni,<br />

Managing Director<br />

DR. HIPPE VISITS COPPARO<br />

On <strong>the</strong> 30th April we had <strong>the</strong> pleasure of a visit to<br />

Copparo by Dr. Alan Hippe, member of <strong>the</strong><br />

ThyssenKrupp AG Executive Board since 2009 with<br />

corporate responsibility for <strong>the</strong> entire administration<br />

and finance area.<br />

Dr. Hippe, on his first visit to <strong>Berco</strong>, was accompanied<br />

by Erkan Keles, a board member in <strong>the</strong> Components<br />

Technology business area with responsibility for<br />

Management Control.<br />

The visit began with an introductory talk on <strong>the</strong><br />

company and ended with a tour round <strong>the</strong> factory,<br />

during which Dr. Hippe commented favourably on<br />

<strong>the</strong> high technological level of our lines and <strong>the</strong><br />

important role played by <strong>Berco</strong> in its market.<br />

BERCOSUL RECEIVES THE<br />

FIAT “QUALITY AWARD 2009”<br />

From left to right: Mr. Bacilieri, <strong>Berco</strong>'s Director of Administration, Mr. Keles,<br />

Components Technology business area board member, Mr. Hippe, ThyssenKrupp AG<br />

Executive Board member and Mr. Bruno Saturni, Managing Director of <strong>Berco</strong><br />

QUALITAS AWARDS 2009, <strong>the</strong> prestigious<br />

awards ceremony for <strong>the</strong> best suppliers<br />

to <strong>the</strong> FIAT group in Brazil, took place<br />

at <strong>the</strong> beginning of June.<br />

For <strong>the</strong> first time <strong>the</strong> prize went to<br />

<strong>Berco</strong>Sul, exclusive supplier of<br />

undercarriage components for CNH<br />

machines in Brazil.<br />

The plaque was presented by <strong>the</strong><br />

Chairman and <strong>the</strong> Director of Purchasing<br />

of CNH Brazil to Giovanni Pelà, <strong>Berco</strong>sul's<br />

General Manager.<br />

Several of <strong>the</strong> FIAT group's top managers<br />

were amongst <strong>the</strong> speakers at <strong>the</strong> event.<br />

In many of <strong>the</strong> speeches, <strong>the</strong> need to<br />

develop “global competitiveness” was<br />

stressed, meaning that intrinsic product<br />

quality alone is not sufficient for<br />

overcoming <strong>the</strong> challenge of world<br />

markets.<br />

The choice of suppliers is still, in <strong>the</strong><br />

main, based on <strong>the</strong> technical<br />

characteristics of <strong>the</strong> product, but o<strong>the</strong>r<br />

essential factors such as <strong>the</strong> quality of<br />

pre - and after-sales services, just-in-time<br />

logistics and willingness to discuss<br />

alternative solutions are nowadays taken<br />

into account when selecting a restricted<br />

group of strategic suppliers.<br />

For eight years consecutively, FIAT has<br />

been <strong>the</strong> leading seller in Brazil, which<br />

is now <strong>the</strong> fourth most important car<br />

market in <strong>the</strong> world.<br />

Usually, <strong>the</strong>se awards are won by<br />

automotive suppliers, as <strong>the</strong>y produce<br />

<strong>the</strong> largest volume of components<br />

purchased by <strong>the</strong> FIAT group in Brazil.<br />

The fact that <strong>the</strong> award went to <strong>Berco</strong>sul,<br />

which operates exclusively in <strong>the</strong> earthmoving<br />

market, shows that <strong>the</strong> joint<br />

efforts made to overcome <strong>the</strong> crisis,<br />

<strong>the</strong> stronger partnership with CNH<br />

represented by <strong>the</strong> signing of a long-term<br />

contract and <strong>the</strong> investments made to<br />

streng<strong>the</strong>n stock and improve <strong>the</strong> quality<br />

of <strong>the</strong> service have outweighed overall<br />

sales volumes.<br />

It is with pride that I thank <strong>the</strong> <strong>Berco</strong>sul<br />

team for helping <strong>the</strong> company achieve<br />

this prestigious award.<br />

Giovanni Pelá<br />

General Manager, <strong>Berco</strong>sul<br />

BN59 > july 2010<br />

3

News & Events<br />

BAUMA 2010:<br />

SIGNS OF RECOVERY<br />

ON THE EARTH MOVING<br />

MACHINERY MARKET<br />

Bauma, now in its 29th edition, took<br />

place in Munich from <strong>the</strong> 15th to <strong>the</strong><br />

25th of April.<br />

With an exhibition area of 555,000<br />

sq.m and <strong>the</strong> proportion of international<br />

exhibitors at 60%, <strong>the</strong> event has set<br />

<strong>new</strong> records for number of exhibitors,<br />

international participation and surface<br />

area covered.<br />

There was a significant increase in <strong>the</strong><br />

number of exhibitors from China, India<br />

and Turkey.<br />

The negative economic situation in <strong>the</strong><br />

months leading up to Bauma and <strong>the</strong><br />

sudden halt to air traffic caused by <strong>the</strong><br />

eruption of <strong>the</strong> Icelandic volcano<br />

Eyjafjallajokull did, however, have an<br />

impact on <strong>the</strong> total number of visitors.<br />

Bauma 2010 had about 415,000 visitors,<br />

17% less than <strong>the</strong> 2007 edition.<br />

There were 3,150 exhibitors from 53<br />

countries.<br />

“Despite <strong>the</strong> immediate counter-measures<br />

taken by Messe München (…), in <strong>the</strong><br />

second half of <strong>the</strong> week as well, when<br />

attendance is usually higher, it was not<br />

possible to bring <strong>the</strong> number of operators<br />

expected from Asia, India and America<br />

to Munich. Never<strong>the</strong>less, in <strong>the</strong> light<br />

of <strong>the</strong> trend reversal before Bauma<br />

2010, we are very optimistic about <strong>the</strong><br />

forthcoming edition of Bauma China<br />

2010 in Shanghai, which is already<br />

fully booked” stresses Klaus Dittrich,<br />

Chairman of Messe München GmbH.<br />

conjunction with <strong>the</strong> German branch,<br />

<strong>Berco</strong> Deutschland, now in its 50th<br />

year of activity, an important anniversary<br />

that was celebrated by both <strong>the</strong> German<br />

branch and <strong>Berco</strong> SpA, toge<strong>the</strong>r with our<br />

customers, on <strong>the</strong> afternoon of <strong>the</strong><br />

22nd of April, during <strong>the</strong> fair.<br />

The festivities were opened by Pier<br />

Hahn and Kurt Jonas, <strong>the</strong> Directors of<br />

<strong>Berco</strong> Deutschland, and <strong>the</strong> <strong>Berco</strong> SpA<br />

Managing Director, Bruno Saturni, who,<br />

in <strong>the</strong>ir speeches, discussed <strong>the</strong> salient<br />

points in <strong>the</strong> history of <strong>the</strong> branch and<br />

thanked all those who contribute to<br />

<strong>the</strong> company's success on a daily basis:<br />

<strong>the</strong> customers, for <strong>the</strong>ir loyalty to <strong>the</strong><br />

brand, and <strong>the</strong> employees for <strong>the</strong>ir<br />

efforts and devotion to <strong>the</strong>ir work in <strong>the</strong><br />

company.<br />

THE NEW DESIGNS ON DISPLAY<br />

The most significant <strong>new</strong>comer to <strong>the</strong><br />

stand was definitely <strong>the</strong> Robustus, <strong>the</strong><br />

<strong>new</strong> <strong>rotating</strong> pin and <strong>bushing</strong> <strong>system</strong><br />

patented by <strong>Berco</strong>, previewed in public<br />

for <strong>the</strong> very first time.<br />

The Robustus is a <strong>track</strong> <strong>system</strong> that<br />

benefits from all <strong>the</strong> advantages of<br />

<strong>rotating</strong> <strong>bushing</strong>s without having to<br />

revert to complex, costly and not very<br />

versatile dedicated <strong>system</strong>s.<br />

Of exceptional interest in <strong>the</strong> complete<br />

<strong>system</strong>s area were a number of <strong>new</strong><br />

designs for CTL machines, a sector in<br />

which <strong>Berco</strong> has won a big slice of <strong>the</strong><br />

OEM market thanks above all to its<br />

patented “Sliding Frame” <strong>system</strong>.<br />

Also worthy of note amongst <strong>the</strong> many<br />

<strong>new</strong> designs in complete <strong>system</strong>s was<br />

one of <strong>Berco</strong>'s latest projects, a paver<br />

undercarriage designed in close<br />

cooperation with a road construction<br />

equipment manufacturer.<br />

The undercarriage is designed for<br />

one of <strong>the</strong> most powerful and<br />

high-performance pavers of its kind,<br />

with a laying width of up to 16 m.<br />

Ano<strong>the</strong>r feature on show was a PC450<br />

frame.<br />

These extendable undercarriages are<br />

currently assembled at <strong>Berco</strong> UK,<br />

<strong>the</strong> British branch, and supplied<br />

just-in-time directly to <strong>the</strong> manufacturer<br />

in Britain.<br />

In <strong>the</strong> components area, particular<br />

emphasis was given to <strong>the</strong> mining<br />

products range and to <strong>the</strong> Chinese<br />

branch, highlighting <strong>the</strong> company<br />

strategy of guaranteeing <strong>Berco</strong> quality<br />

standards on products destined for<br />

Asiatic markets - products such as <strong>track</strong><br />

chains and rollers, which are actually<br />

assembled locally from a mixture of<br />

locally manufactured components and<br />

components forged in <strong>the</strong> Italian<br />

factories.<br />

During <strong>the</strong> event, despite <strong>the</strong> absences<br />

caused by <strong>the</strong> flight cancellations, many<br />

fruitful meetings took place and<br />

important contracts were signed; let's<br />

hope that <strong>the</strong>se are real signs of <strong>the</strong> start<br />

of a gradual, but steady, recovery.<br />

4<br />

BERCO AT THE FAIR<br />

Despite <strong>the</strong> uncertainty of <strong>the</strong> market<br />

situation, <strong>Berco</strong> was back in its usual<br />

stand location at Bauma.<br />

This fair is still <strong>the</strong> most important<br />

international event in <strong>the</strong> in <strong>the</strong> industry<br />

and it is not by chance that it was<br />

chosen as <strong>the</strong> place to confirm <strong>Berco</strong>'s<br />

image as a leading company on <strong>the</strong><br />

world stage.<br />

<strong>Berco</strong>'s participation was organised in<br />

BN59 > july 2010

Product & Services<br />

<strong>ROBUSTUS</strong>: THE NEW<br />

ROTATING BUSHING TRACK SYSTEM<br />

At Bauma 2010 <strong>Berco</strong><br />

officially presented <strong>ROBUSTUS</strong>,<br />

acronym for its brand<br />

<strong>new</strong> ROtating BUShing<br />

Track Undercarriage System.<br />

According to common<br />

experience, 50% or more of<br />

<strong>the</strong> maintenance costs<br />

during <strong>the</strong> life of a crawler<br />

dozer or loader belongs to<br />

undercarriage maintenance<br />

and repairs.<br />

Increasing <strong>the</strong> life of<br />

undercarriage components is<br />

<strong>the</strong> winning strategy to reduce<br />

ownership and operating costs.<br />

CHARACTERISTICS<br />

The core feature of <strong>the</strong> <strong>new</strong> <strong>system</strong> is <strong>the</strong><br />

<strong>rotating</strong> <strong>bushing</strong>.<br />

In a machine fitted out with traditional<br />

undercarriage <strong>the</strong> sprocket slides on <strong>the</strong><br />

external surface of <strong>the</strong> <strong>bushing</strong> during<br />

normal operation, causing <strong>bushing</strong> and<br />

sprocket wear.<br />

In <strong>the</strong> <strong>new</strong> <strong>system</strong> <strong>the</strong> <strong>bushing</strong> rotates<br />

when in contact with <strong>the</strong> sprocket,<br />

reducing <strong>the</strong> <strong>bushing</strong> and sprocket friction<br />

and wear and thus enabling longer life.<br />

As a consequence, it is not necessary<br />

to turn <strong>bushing</strong>s and pins and replace<br />

sprocket segments during <strong>the</strong> whole life<br />

of <strong>the</strong> undercarriage.<br />

A wider <strong>track</strong> link rail (“big footprint” <strong>track</strong><br />

link) provides an extended running<br />

surface area, balancing <strong>the</strong> wear of all<br />

components and eliminating scalloping<br />

wear in <strong>the</strong> contact between chain and<br />

roller and between chain and idler.<br />

The reinforced hardware improves joint<br />

stability. The resulting dampening of<br />

vibrations and noise assures more<br />

comfortable ride and maximum control<br />

of <strong>the</strong> machine during <strong>the</strong> operations.<br />

<strong>Berco</strong> Pin Retention (BPR) and an<br />

improved seal design produce a lasting<br />

seal capacity and assure long life to <strong>the</strong><br />

complete <strong>system</strong>.<br />

COMPATIBILITY<br />

The <strong>new</strong> <strong>system</strong> is fully compatible with<br />

existing frames and standard components:<br />

older machines can be easily upgraded<br />

to increase <strong>the</strong>ir productivity and <strong>the</strong><br />

life of <strong>the</strong> undercarriage.<br />

In <strong>the</strong> same way <strong>ROBUSTUS</strong> is forwardcompatible<br />

with <strong>the</strong> <strong>new</strong> generation<br />

undercarriages equipped with parallel<br />

or twin links.<br />

The innovative <strong>rotating</strong> <strong>bushing</strong> <strong>track</strong>s<br />

<strong>system</strong> can be easily installed on any<br />

machine at any time. With a simple<br />

operation and no extra work you can<br />

extend <strong>the</strong> life of your undercarriage,<br />

improving reliability and reducing costs.<br />

<strong>Berco</strong> field tests proved that <strong>the</strong> <strong>new</strong><br />

<strong>system</strong> increases <strong>the</strong> <strong>track</strong> life of 35<br />

percent with a maximum of 6,000 hours<br />

of operation, reducing operating costs by<br />

15 to 25 percent.<br />

Stefano Salatini<br />

Key Account Manager, OEM America<br />

NEW MINING<br />

UNDERCARRIAGES:<br />

EX1800-3, EX1900-5<br />

With <strong>the</strong> aim of extending its market<br />

share in mining by broadening its<br />

product range, <strong>Berco</strong> will be<br />

introducing <strong>the</strong> first EX1800-3 and<br />

EX1900-5 undercarriages on to <strong>the</strong><br />

market in July.<br />

We decided to focus on Hitachi<br />

excavators, amongst <strong>the</strong> most<br />

longstanding and popular machines<br />

in and around <strong>the</strong> 200-ton class, in<br />

<strong>the</strong> certainty of targeting a more<br />

extensive and receptive market than<br />

those of <strong>the</strong> o<strong>the</strong>r models in <strong>the</strong><br />

same category.<br />

Most of <strong>the</strong> first batch, due to be<br />

ready at <strong>the</strong> end of July, has already<br />

been sold on <strong>the</strong> North American,<br />

Canadian and Australian markets.<br />

Please contact a <strong>Berco</strong> dealer for<br />

fur<strong>the</strong>r information.<br />

BN59 > july 2010<br />

5

From <strong>the</strong> Subsidiaries<br />

6<br />

OPERATIONAL AT LAST<br />

THE BERCO BRANCH IN INDIA<br />

FIRST IMPRESSIONS<br />

As usual, <strong>the</strong> flight to India lands deep<br />

in <strong>the</strong> night and after a few tiring<br />

minutes we find ourselves in <strong>the</strong> long<br />

queue for customs checks.<br />

As soon as we are out of <strong>the</strong> air<br />

conditioned terminal buildings we are<br />

hit with <strong>the</strong> intense and unmistakeable<br />

scent of India, common to all regions,<br />

both north and south.<br />

The night-time journey from <strong>the</strong> <strong>new</strong> and<br />

beautiful Rajiv Ghandi airport to <strong>the</strong><br />

hotel is beyond all expectations: a long<br />

motorway link with neat flower beds<br />

in <strong>the</strong> central reservation. The first<br />

impression is that of an orderly, pleasant<br />

city.<br />

Hyderabad, toge<strong>the</strong>r with Secunderabad,<br />

forms a big urban conglomerate with a<br />

population of about seven million.<br />

The two cities stand right next to each<br />

o<strong>the</strong>r and are in fact known as <strong>the</strong><br />

“twin cities”.<br />

The car journey in <strong>the</strong> morning from<br />

Hyderabad to Cherlapally (<strong>the</strong> town to<br />

<strong>the</strong> north-east where <strong>Berco</strong><br />

Undercarriages Pvt. Ltd. is situated) is<br />

pleasant, despite <strong>the</strong> heat outside,<br />

which is already rising and will reach a<br />

temperature of 43°C by around<br />

BN59 > july 2010<br />

lunchtime.<br />

After <strong>the</strong> last few bends in <strong>the</strong> country<br />

road we get our first glimpse of <strong>the</strong><br />

<strong>Berco</strong> factory, which is a real surprise.<br />

An industrial structure, but with a<br />

definite touch of architectural style<br />

and design. The colours are strictly<br />

white and red, with a building of 8,000<br />

sq.m and a total surface area of 35,000<br />

sq.m.<br />

The factory strikes you as being<br />

considerably above <strong>the</strong> average for <strong>the</strong><br />

country.<br />

It has an aspect and a functionality<br />

which, at first sight, are decidedly<br />

'Western', a combination of European<br />

style and rigour and <strong>the</strong> great constancy<br />

and technology of India.<br />

PRESENT AND FUTURE<br />

At <strong>the</strong> entrance we were met by <strong>the</strong><br />

entire <strong>Berco</strong> India staff who paid homage<br />

to us with <strong>the</strong> usual Indian welcome<br />

for <strong>new</strong> arrivals - a garland of dried<br />

flowers placed around our necks.<br />

The operational personnel, efficiently<br />

headed by COO-General Manager<br />

S. Shakti Kumar, showed us <strong>the</strong> progress<br />

made from <strong>the</strong> very beginning, when<br />

<strong>the</strong> land was still part of <strong>the</strong> jungle,<br />

right up to <strong>the</strong> present-day factory. The<br />

civil building works and <strong>the</strong> installation<br />

of all <strong>the</strong> industrial <strong>system</strong>s was<br />

completed in about two years, managed<br />

by Orazio Astolfi, head of <strong>the</strong> Foreign<br />

Branches Service.<br />

The actual production area is vast.<br />

So far, <strong>the</strong> first two assembly lines have<br />

been installed, one for rollers and <strong>the</strong><br />

o<strong>the</strong>r for <strong>track</strong> chains, toge<strong>the</strong>r with<br />

<strong>the</strong> paint booth and a functional<br />

materials warehouse capable of housing<br />

1000 pallets and expandable to<br />

accommodate a fur<strong>the</strong>r 1000 in <strong>the</strong><br />

future. The washing process line is<br />

currently being installed.<br />

The production area is big enough to<br />

house ano<strong>the</strong>r 5 assembly lines: 3 for<br />

rollers, 2 for <strong>track</strong> chains and 1 for<br />

front idlers, toge<strong>the</strong>r with 2 painting<br />

lines.<br />

There is also a currently unoccupied<br />

area of about 2,000 sq.m where, in <strong>the</strong><br />

near future, a machining line is to be<br />

installed for on-site components<br />

manufacture.<br />

The total order portfolio in <strong>the</strong> country<br />

in 2010 will reach about 15 million<br />

euros, and this will grow sharply over<br />

<strong>the</strong> next three years. The main OEM<br />

customers to be served initially by <strong>the</strong><br />

<strong>new</strong> factory will include L&T Komatsu,<br />

Telcon Hitachi and JCB, to be joined in<br />

<strong>the</strong> future by Kobelco and Volvo and<br />

many o<strong>the</strong>r aftermarket customers.<br />

Finally, at <strong>the</strong> end of <strong>the</strong> visit, we are<br />

proud to report that on <strong>the</strong> 25th of<br />

May 2010, thanks to <strong>the</strong> precious and<br />

indispensable work of <strong>the</strong> two specialist<br />

Italian engineers, <strong>the</strong> production line<br />

was started up. With all <strong>the</strong> personnel<br />

in attendance, toge<strong>the</strong>r with Managing<br />

Director Bruno Saturni, Orazio Astolfi,<br />

S. Shakti Kumar and <strong>the</strong> undersigned,<br />

<strong>the</strong> manufacture of <strong>the</strong> first “made in<br />

India” <strong>track</strong> chain was begun and<br />

completed.<br />

In conclusion, I would like to give<br />

special thanks to <strong>the</strong> ThyssenKrupp<br />

India staff, represented by Mr. D.<br />

Damania, for all <strong>the</strong> support <strong>the</strong>y gave<br />

us in <strong>the</strong> building of our factory.<br />

Namaskar Namaste.<br />

Federico Maurilli<br />

General Manager<br />

<strong>Berco</strong> Undercarriages (India)

BERCO QUALITY FOR THE CHINESE MARKET<br />

Producing competitive components locally without foregoing <strong>Berco</strong> quality.<br />

This is <strong>the</strong> task of <strong>the</strong> <strong>new</strong> factory in <strong>the</strong> Chinese branch, inaugurated in October<br />

Work is beginning in <strong>the</strong> Chinese branch<br />

on a <strong>new</strong> range of products for <strong>the</strong><br />

Asiatic market.<br />

The manufacturing activities are based<br />

on products made from a combination<br />

of locally purchased components whose<br />

technical characteristics are checked<br />

with rigorous quality control procedures<br />

and forged components made in <strong>the</strong><br />

<strong>Berco</strong> factories in Italy.<br />

A PRODUCTION RANGE AIMED AT<br />

ASIATIC MARKETS<br />

Last Autumn, <strong>the</strong> Chinese branch opened<br />

a <strong>new</strong> factory in <strong>the</strong> Lingag Industrial<br />

Park, near <strong>the</strong> port where <strong>Berco</strong>'s customs<br />

warehouse is situated.<br />

In October 2009, <strong>the</strong> first cast sprockets<br />

were machined in <strong>the</strong> factory, and in<br />

March 2010 work began on <strong>the</strong> assembly<br />

of <strong>track</strong> chains and rollers.<br />

The factory, which has a total surface<br />

area of 25,000 sq.m - 13,000 of which<br />

are covered - is divided into four<br />

workshops and is designed to<br />

accommodate all <strong>the</strong> planned production<br />

and commercial activities: machining,<br />

heat treatment, assembly, quality control,<br />

procurement, distribution of <strong>Berco</strong><br />

products on <strong>the</strong> Chinese market and<br />

services for both OEM and aftermarket<br />

customers.<br />

The <strong>new</strong> project, based on <strong>the</strong> <strong>the</strong> 4M1E<br />

method (man, material, method,<br />

machine, environment), was implemented<br />

according to a precise program drawn<br />

up by <strong>Berco</strong> SpA management:<br />

- <strong>the</strong> necessary personnel were recruited<br />

and <strong>the</strong> heads of departments were sent<br />

to <strong>the</strong> <strong>Berco</strong> factories in Italy for<br />

specific training in heat treatment<br />

and CNC machining processes<br />

- standard work and production cycles<br />

were set up and, with <strong>the</strong> help<br />

of external consultants, a “lean<br />

production” <strong>system</strong> was created<br />

- pin and <strong>bushing</strong> production lines with<br />

heat treatment furnaces are currently<br />

being installed, along with an induction<br />

hardening line; <strong>the</strong> production tests<br />

are scheduled for <strong>the</strong> beginning of<br />

August<br />

- production tooling sets have been<br />

prepared for <strong>the</strong> various production<br />

programs<br />

- with <strong>the</strong> help of personnel from<br />

Copparo, local raw material suppliers<br />

have been selected and qualified and<br />

supplies have been scheduled for <strong>the</strong><br />

production tests<br />

- all <strong>the</strong> lines have been installed in<br />

direct collaboration with <strong>the</strong> factories<br />

in Italy and with Italian engineers<br />

on site<br />

- Navision MPR management training<br />

programs are being devised for<br />

personnel.<br />

All <strong>the</strong>se activities are expected to be<br />

completed and launched by <strong>the</strong> start<br />

of <strong>the</strong> <strong>new</strong> financial year.<br />

When fully operational, <strong>the</strong> following<br />

assembly and manufacturing processes<br />

will take place in <strong>the</strong> Chinese branch:<br />

- cast sprockets and <strong>track</strong> adjusters<br />

- pins and <strong>bushing</strong>s for medium class<br />

machines<br />

- support assembly<br />

- <strong>track</strong> chain assembly and painting<br />

- assembly of complete undercarriages,<br />

including <strong>the</strong> frames and drive <strong>system</strong>s<br />

- assembly of rollers for small and<br />

medium class machines.<br />

Half of <strong>the</strong> current world production<br />

of excavators now takes place in China.<br />

<strong>Berco</strong>'s business expansion goals in<br />

this area will be achieved thanks to<br />

<strong>the</strong> crucial contribution of local<br />

production activities in <strong>the</strong> <strong>new</strong> <strong>Berco</strong><br />

Shanghai factory.<br />

Given <strong>the</strong> fundamental importance of<br />

this project, both <strong>Berco</strong> SpA and<br />

Thyssenkrupp have dedicated special<br />

attention to it and have been highly<br />

supportive in all <strong>the</strong> stages of its<br />

implementation.<br />

We are convinced that, after an initial<br />

start-up period, <strong>the</strong> local production<br />

will bring great results to <strong>the</strong> entire<br />

group.<br />

Yi Zeng,<br />

General Manager <strong>Berco</strong> Shanghai<br />

Visit by <strong>Berco</strong> SpA and ThyssenKrupp China top management to <strong>the</strong> <strong>new</strong> factory in China. From<br />

left to right: Michael Wang, General Manager of ThyssenKrupp Shanghai, Yi Zeng, General Manager<br />

of <strong>Berco</strong> Shanghai, Wolfhart Schmitz-Meimbresse, General Director of <strong>Berco</strong> SpA Foreign Branches,<br />

Chairman of <strong>Berco</strong> Shanghai, Alfred Wewers, Chairman and Managing Director of ThyssenKrupp<br />

China, Sven Arend, Director of Sales of <strong>Berco</strong> SpA, Bruno Saturni, Managing Director of <strong>Berco</strong> SpA<br />

BN59 > july 2010<br />

7

Products & Services<br />

MUCH MORE THAN<br />

JUST SUPPLIERS OF MINING PRODUCTS<br />

<strong>Berco</strong> commits itself not just to <strong>the</strong> design and construction of superior quality components for<br />

demanding environments such as mines, but to <strong>the</strong> provision of a complete consultancy service, offering<br />

<strong>the</strong> end customer a level of support on a par with that of OEM dealers.<br />

It is well known that mining<br />

machines are subject to <strong>the</strong><br />

most extreme and tough<br />

operating conditions, ranging<br />

from iron-rich Australian<br />

deserts to <strong>the</strong> bituminous<br />

sands of Canada.<br />

<strong>Berco</strong> has always made great<br />

headway with <strong>the</strong>se products,<br />

dedicating time and skilled<br />

resources to laboratory<br />

testing and field trials.<br />

Up to 2008, <strong>the</strong> mining<br />

industry was in a state of<br />

continuous growth,<br />

generating a vast market<br />

conducive to <strong>the</strong> conquest<br />

of <strong>new</strong> shares.<br />

Since 2008, however, <strong>the</strong> drop in prices<br />

and <strong>the</strong> subsequent volatility of <strong>the</strong><br />

main raw materials have forced many<br />

mining companies ei<strong>the</strong>r to close down<br />

or cease developing many of <strong>the</strong>ir<br />

activities due to a sharp contraction in<br />

<strong>the</strong> market.<br />

The main priority for mining companies<br />

has been to reduce fleet running and<br />

maintenance costs whilst constantly<br />

increasing <strong>the</strong> reliability of <strong>the</strong> machines.<br />

To achieve this, mining companies and<br />

contractors have been compiling ever<br />

more detailed and consistent data on <strong>the</strong><br />

machines in <strong>the</strong> field and translating<br />

<strong>the</strong>m into statistics on <strong>the</strong> average life<br />

of components, making it possible to<br />

calculate a detailed “hourly cost” factor<br />

and compare <strong>the</strong> performance of different<br />

products for evaluating <strong>new</strong> suppliers.<br />

8<br />

AN ALL-ROUND SERVICE<br />

In light of this, <strong>Berco</strong> and its dealers have<br />

adopted a <strong>new</strong> approach, aimed at<br />

offering <strong>the</strong> customer a valid alternative<br />

to OEM dealers, in order to win over<br />

<strong>new</strong> shares of <strong>the</strong> aftermarket.<br />

The first step ei<strong>the</strong>r requested by <strong>the</strong><br />

customer or proposed by <strong>Berco</strong> itself is<br />

to prove <strong>the</strong> quality of our products in<br />

BN59 > july 2010<br />

field trials by measuring <strong>the</strong> life of a<br />

component in a specific application on<br />

a specific machine.<br />

Thanks to <strong>the</strong> staff training provided<br />

by <strong>Berco</strong>, our network of dealers is now<br />

able to assist customers with <strong>the</strong>se<br />

trials, by monitoring machines (sometimes<br />

in quite remote regions) at preset<br />

intervals and collecting data on<br />

undercarriage wear.<br />

This allows <strong>Berco</strong> Product Support<br />

engineers and dealers, working as a<br />

team, to set time schedules for <strong>the</strong>ir<br />

personal inspections of undercarriages<br />

- usually when specific duration targets<br />

are reached, or at <strong>the</strong> end of a trial - in<br />

order to draw conclusions toge<strong>the</strong>r with<br />

<strong>the</strong> customer.<br />

Ano<strong>the</strong>r initiative we have taken is<br />

to offer major customers specially targeted<br />

courses for <strong>the</strong>ir operators and mechanics,<br />

held directly on <strong>the</strong> mining sites, to<br />

train <strong>the</strong>m in undercarriage maintenance<br />

component inspection.<br />

All this has transformed <strong>Berco</strong> from a<br />

simple supplier of components into a<br />

bona fide consultancy service<br />

provider, bringing benefits to all parties<br />

concerned.<br />

The dealer, in fact, becomes a<br />

key player in <strong>the</strong><br />

management of<br />

<strong>the</strong> customer's stock,<br />

guaranteeing not<br />

only prompt delivery<br />

on <strong>the</strong> basis of a<br />

maintenance plan<br />

but also component<br />

reconditioning and<br />

on-site services.<br />

The end customer, on<br />

<strong>the</strong> o<strong>the</strong>r hand, not<br />

only gets a valid<br />

alternative supply to<br />

<strong>the</strong><br />

OEM,<br />

but also receives<br />

specially tailored staff<br />

training from <strong>Berco</strong><br />

with suggestions on how to improve<br />

checking and preventive maintenance<br />

procedures on <strong>the</strong> undercarriages, thus<br />

leading to consistent reductions in<br />

downtime and costs.<br />

IMPROVING OUR PRODUCT<br />

<strong>Berco</strong> itself also benefits from this<br />

process, by establishing a dialogue with<br />

operators and mechanics as <strong>the</strong>y cope<br />

with a vast variety of situations and<br />

conditions on a daily basis, thus collecting<br />

important data from <strong>the</strong> field in order<br />

to be able to improve its products.<br />

Currently, <strong>Berco</strong> is listed as a qualified<br />

supplier in a number of mines in South<br />

America, thanks to <strong>the</strong> dealer Agro<br />

Costa, in South East Asia thanks to <strong>the</strong><br />

support of USG, in Canada thanks to<br />

ESS and Union Tractor and in several<br />

mines in <strong>the</strong> former Soviet Union.<br />

These successes tell us that <strong>the</strong> approach<br />

is right, and <strong>the</strong> presence of our branches<br />

all over <strong>the</strong> world, toge<strong>the</strong>r with a dense<br />

network of dealers, allows us to extend<br />

this initiative rapidly to an ever growing<br />

number of customers.<br />

Matteo Seghieri<br />

Area Manager, Asia Pacific

From <strong>the</strong> Subsidiaries<br />

BERCO DEUTSCHLAND:<br />

50 YEARS OF SUCCESSES<br />

<strong>Berco</strong> Deutschland has grown from a small-scale distributor<br />

of spare parts to an established supplier of undercarriage<br />

<strong>system</strong>s to all <strong>the</strong> major European manufacturers<br />

THE BEGINNINGS<br />

This year, <strong>Berco</strong> Deutschland celebrates<br />

a special anniversary: 50 years of <strong>the</strong><br />

<strong>Berco</strong> trademark in Germany.<br />

<strong>Berco</strong>'s story in Germany began in 1960<br />

with <strong>the</strong> founding of Traktor Ersatzteil<br />

GmbH (TEG) by Dieter Curland, who,<br />

with 20,000 Deutschmarks of capital, set<br />

up a business for marketing earth moving<br />

machinery spare parts.<br />

These beginnings were right in <strong>the</strong><br />

middle of <strong>the</strong> so-called German<br />

“Wirtschaftswunder” (economic miracle),<br />

a period of rapid reconstruction and<br />

economic development in West Germany<br />

and Austria starting from <strong>the</strong> years<br />

immediately after <strong>the</strong> second world war.<br />

This term, coined by<br />

<strong>the</strong> American “Time” magazine in 1950,<br />

refers to this flourishing period in <strong>the</strong><br />

German economy, characterised in<br />

particular by <strong>the</strong> change from <strong>the</strong> existing<br />

currency to <strong>the</strong> <strong>new</strong> German mark and<br />

by <strong>the</strong> funding established in <strong>the</strong> Marshall<br />

plan from 1948 to 1952.<br />

TEG BECOMES<br />

EXCLUSIVE SELLER<br />

The contract with <strong>Berco</strong> was a crucial step<br />

in <strong>the</strong> company's success story. It was<br />

signed on <strong>the</strong> 8th of January 1964 and<br />

gave TEG <strong>the</strong> role of official distributor<br />

for <strong>the</strong> <strong>Berco</strong> trade mark in<br />

Germany.<br />

In <strong>the</strong> same year, <strong>the</strong><br />

company's headquarters were<br />

transferred from Hagen to<br />

Ennepetal, about thirty<br />

kilometres from Essen, where<br />

<strong>the</strong>y have remained to this<br />

day.<br />

At <strong>the</strong> end of <strong>the</strong> 70s TEG became part<br />

of Hoesch AG, just as <strong>Berco</strong> SpA came<br />

under <strong>the</strong> partial control of <strong>the</strong> same<br />

German group.<br />

On <strong>the</strong> 10th of August 1998, after <strong>the</strong><br />

purchase of <strong>the</strong> remaining <strong>Berco</strong> SpA<br />

shares by Hoesch AG in 1986 and <strong>the</strong><br />

subsequent merger between Krupp and<br />

Hoesch, <strong>the</strong> company changed its name<br />

to Krupp <strong>Berco</strong> Deutschland.<br />

Initially, TEG was active only on <strong>the</strong><br />

aftermarket, concentrating exclusively<br />

on <strong>the</strong> sale of spare parts, but later<br />

managed to establish a solid position<br />

on <strong>the</strong> OEM market as well.<br />

BERCO DEUTSCHLAND NOW<br />

Currently, <strong>Berco</strong> Deutschland, headed<br />

by its two directors Pier Hahn and Kurt<br />

Jonas in a factory of 18,000 sq.m, is<br />

capable of handling 10,000 tonnes of<br />

finished product, guaranteeing its<br />

customers a just-in-time delivery service.<br />

The <strong>Berco</strong> Deutschland staff (almost) all toge<strong>the</strong>r. Above, <strong>the</strong> Ennepetal headquarters<br />

Its 60 experienced and skilled employees<br />

meet <strong>the</strong> demands of <strong>the</strong> OEM and<br />

aftermarket customers not only with<br />

normal selling activities, but also with<br />

<strong>the</strong> development and production of<br />

specifically made-to-measure components<br />

on request.<br />

For a long time now, <strong>the</strong> company has also<br />

been specialising in building undercarriages<br />

(frames) and providing OEM customers with<br />

complete <strong>system</strong>s for <strong>track</strong>ed vehicles.<br />

The vast range of articles sold includes<br />

standard components for earth moving<br />

machines (<strong>track</strong> links, <strong>track</strong> shoes, carrier<br />

and <strong>track</strong> rollers, sprockets and <strong>track</strong><br />

adjusters) and complete sets of equipment<br />

for <strong>the</strong> machines made by all <strong>the</strong> major<br />

domestic and international manufacturers,<br />

such as Liebherr, Bucyrus, Volvo, Atlas<br />

Copco and <strong>the</strong> Wirtgen group.<br />

<strong>Berco</strong> Deutschland is <strong>the</strong> distributor for<br />

<strong>the</strong> <strong>Berco</strong> trade mark in all German<br />

speaking markets and, since 2008, in<br />

Scandinavia and all <strong>the</strong><br />

Eastern European<br />

regions, including <strong>the</strong><br />

Ukraine and Georgia.<br />

BN59 > july 2010<br />

9

Environment & Safety<br />

OBJECTIVE:<br />

“ZERO ACCIDENTS”<br />

10<br />

THYSSENKRUPP<br />

SAFETY AT WORK INITIATIVE<br />

In 2005 <strong>the</strong> ThyssenKrupp AG Executive Board<br />

launched a group-wide “Zero Accidents” initiative<br />

which, starting from Germany, was <strong>the</strong>n to be<br />

extended to all ThyssenKrupp sites throughout <strong>the</strong><br />

world.<br />

Ten occupational safety guidelines were drawn up<br />

by <strong>the</strong> ThyssenKrupp AG Executive Board in agreement<br />

with <strong>the</strong> European Group Works Council.<br />

The aim of <strong>the</strong> project is to make safety a group value<br />

and to develop a “safety culture”, by creating a set<br />

of shared values that regulate ways of behaving,<br />

making decisions and acting within an organisation.<br />

This “safety culture” must start from <strong>the</strong> top levels<br />

of <strong>the</strong> company and permeate <strong>the</strong> entire<br />

organisational structure. In fact, one of <strong>the</strong> salient<br />

points of <strong>the</strong> guidelines is <strong>the</strong> principle that<br />

workplace safety must be of <strong>the</strong> same importance<br />

to <strong>the</strong> company as economic success and product<br />

quality.<br />

The safety culture can be disseminated convincingly<br />

only if followed up directly and consistently by<br />

BN59 > july 2010<br />

<strong>the</strong> managerial staff “in<br />

person”. Managers, in fact, must be a role model for<br />

employees and must carry out <strong>the</strong>ir occupational<br />

health and safety duties with absolute rigour.<br />

Following this, a managerial level training scheme<br />

was drawn up for ThyssenKrupp companies in<br />

Germany, involving about 5,000 managers from<br />

<strong>the</strong> group's German-based companies. The first<br />

campaign outside Germany is now taking place in<br />

Italy.<br />

THE “ZERO ACCIDENTS” CAMPAIGN IN ITALY<br />

The opening conference was held on <strong>the</strong> 28th of<br />

May 2009 in Rome, attended by <strong>the</strong> Managing<br />

Directors of <strong>the</strong> ItalianThyssenKrupp companies<br />

toge<strong>the</strong>r with Ralph Labonte, <strong>the</strong> AG Executive<br />

Board member responsible for Italy.<br />

In <strong>the</strong> conference, <strong>the</strong> aims of <strong>the</strong> campaign were<br />

clearly stated: to illustrate <strong>the</strong> ThyssenKrupp safety<br />

standards to managerial<br />

personnel in relation to<br />

binding legislation and<br />

heighten awareness with<br />

regard to specific obligations<br />

and responsibilities.<br />

The target participants were<br />

defined as all personnel<br />

in charge of <strong>the</strong>ir sectors,<br />

and not just operational<br />

personnel, but also those<br />

in areas normally considered<br />

as low-risk, such as<br />

administration.<br />

Italian legislation, applied<br />

on <strong>the</strong> basis of specific<br />

responsibilities and functions,<br />

breaks <strong>the</strong> managerial level<br />

down into two categories:<br />

“managers”, with managerial<br />

functions (i.e. <strong>the</strong> organisation<br />

of work activities), and<br />

“supervisors”, with functions<br />

and responsibilities that are<br />

more operational, such as<br />

supervising actual work<br />

activities and guaranteeing<br />

<strong>the</strong> implementation of<br />

directives. Prevention and

Protection Service Managers and Delegates<br />

(RSPP/ASPP) and Workers' Safety<br />

Representatives (RLS) are also attending<br />

<strong>the</strong> courses.<br />

The program for <strong>the</strong> training course in<br />

Italy has been drawn up in collaboration<br />

with ISPESL (<strong>the</strong> Occupational Health<br />

and Safety governing body, recently<br />

incorporated into <strong>the</strong> INAIL National<br />

Insurance organisation), based on <strong>the</strong><br />

scheme tested out in Germany. The<br />

seminars are divided into eight modules<br />

(see diagram, top right).<br />

In <strong>the</strong> seminars, <strong>the</strong><br />

legal aspects - i.e. basic occupational<br />

safety legislation, managerial role and<br />

<strong>the</strong> organisation of <strong>the</strong> safety <strong>system</strong><br />

in Italy - are dealt with by ISPESL.<br />

The illustration of <strong>the</strong> concepts of “safety<br />

rules and culture in <strong>the</strong> Italian<br />

companies”, accidents analysis” and<br />

“best practices” of <strong>the</strong> group, etc., on <strong>the</strong><br />

o<strong>the</strong>r hand, is done by ThyssenKrupp<br />

tutors (from <strong>the</strong> prevention and protection<br />

services of <strong>the</strong> most representative TK<br />

companies in <strong>the</strong> country, including<br />

<strong>Berco</strong>'s Saverio Salvi, who is also <strong>the</strong><br />

group's National Coordinator for safety,<br />

and S. Di Mauro).<br />

The participants are involved actively<br />

in <strong>the</strong> seminars and an interchange of<br />

experiences is encouraged between<br />

people from different sectors and<br />

companies.<br />

The number of participants set for each<br />

seminar is not more than 30.<br />

The managerial seminars organised in<br />

2009 took place in Rome, Ferrara, Terni<br />

and Milan and were well attended (more<br />

than 88% of <strong>the</strong> managers took part in<br />

<strong>the</strong> scheme).<br />

The feedback from <strong>the</strong> seminars was<br />

positive, as evidenced by <strong>the</strong> forms<br />

completed by <strong>the</strong> participants, which<br />

confirm <strong>the</strong> high level of teaching,<br />

content and methods.<br />

The training of <strong>the</strong> supervisors, RSPP,<br />

ASPP and RLS personnel is currently<br />

taking place in all <strong>the</strong> ThyssenKrupp<br />

companies in Italy (about 630<br />

participants). 18 seminars are planned,<br />

up to 2012.<br />

Saverio Salvi<br />

Head of Prevention and Protection Services<br />

BN59 > july 2010<br />

11