Preci-Dip Durtal SA - PRECI-DIP SA

Preci-Dip Durtal SA - PRECI-DIP SA

Preci-Dip Durtal SA - PRECI-DIP SA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WWW.<strong>PRECI</strong><strong>DIP</strong>.COM<br />

<strong>PRECI</strong>-<strong>DIP</strong> DURTAL <strong>SA</strong> · 2800 DELEMONT · SWITZERLAND<br />

PRESS- FIT TECHNOLOGY<br />

A cost effective alternative to soldering connectors to a board

COMPLIANT PRESS-FIT TECHNOLOGY<br />

BASIC TECHNOLOGY<br />

Press-fit technology, which has been<br />

around for some 20 years now, is a<br />

solderless connection method. It consists<br />

of force fitting an oversized contact<br />

pin into the plated through hole<br />

of a printed circuit board (PCB). The<br />

high radial pressure produces a deformation,<br />

resulting in a gas-tight electrical<br />

connection of high quality.<br />

This difference in pin cross section<br />

and hole diameter results in a deformation<br />

of either the PCB hole or the<br />

cross section of the pin during the<br />

insertion process of pin into PCB<br />

hole. There are two major types of<br />

press-fit sections:<br />

COMPLIANT PRESS-FIT TECHNOLOGY BY <strong>PRECI</strong>-<strong>DIP</strong><br />

We have been producing contacts, sockets and connectors with press-fit terminations for<br />

over ten years.<br />

The specific design of our compliant pin is based on a «modified eye of a needle» principle<br />

with particular attention paid to geometry, elasticity characteristics, and surface finish. Its<br />

main features are:<br />

- Elastic deformation over the total range of the hole tolerance;<br />

- High retention force, in spite of the low insertion force (much below generally admitted<br />

maximum values);<br />

- Gas-tight contact zone without any damage (chipping) to hole metallisation;<br />

- Low, constant electrical contact resistance;<br />

- Complies with IEC60352-5 standard.<br />

They are available for plated hole diameters of 0.6, 0.7, 0.9 and 1.0 mm, according to IEC<br />

standards. They are compatible with PCB finishes in tin, copper, or gold on nickel.<br />

A solid pin which does not deform<br />

in the insertion process (Fig.A):<br />

- With square or hexagonal cross<br />

section and point-to-point dimension<br />

of the polygon greater than<br />

PCB finished hole diameter;<br />

- The deformation takes place on<br />

the PCB side.<br />

A compliant pin which compresses<br />

as a result of insertion into the PCB<br />

through hole (Fig.B):<br />

- With radial elasticity in the contact<br />

zone;<br />

- The deformation takes place on<br />

the contact side.<br />

<strong>Preci</strong>-<strong>Dip</strong> compliant press-fit pin based on<br />

a «modified eye of a needle» principle.<br />

Micrograph cross section of inserted compliant<br />

pin.<br />

COMPLIANT PRESS-FIT TECHNOLOGY WITH CONNECTING PIN<br />

For applications requiring connections on both sides of the PCB, the press-fit termination<br />

is extended in the form of an additional contact pin which mates with the female contact<br />

of another PCB. This type of contact also has the modified eye of a needle to give superior<br />

quality of the press-fit connection.<br />

It is presently only available for 1 mm diameter PCB holes.<br />

Fig.A: Cross-section<br />

solid pin<br />

Fig.B: Cross-section<br />

compliant pin<br />

Over the years, the compliant pin<br />

technology for press-fit insertion<br />

gained general recognition over the<br />

solid pin.<br />

Solid press-fit pin<br />

Compliant press-fit with connecting pin

TECHNICAL SPECIFICATIONS<br />

ADVANTAGES OF PRESS-FIT<br />

OVER SOLDER-BASED TECHNOLOGY<br />

The basic advantages of press-fit<br />

technology are obvious, in particular<br />

when it comes to adding contacts<br />

or connectors to a soldered SMD<br />

board:<br />

- Efficient, reliable and quick assembly<br />

of connectors, without any<br />

mounting accessories (screws,<br />

brackets, etc.);<br />

- No soldering problems (such as<br />

thermal load on PCB and components,<br />

degassing, hole filling on<br />

multilayer, bridging, cold soldering<br />

joints...);<br />

- No residues on PCB and connector<br />

contact area, affecting reliability;<br />

- Complete reparability. Connectors<br />

can be easily exchanged.<br />

Press-fit connections are easily added<br />

to an SMD board after reflow soldering<br />

of the components, as the<br />

hole metallisation is not affected by<br />

this process.<br />

Technical specification<br />

Operating temperature range: -55 to +125 °C<br />

Pin material:<br />

Bronze CuSn4Pb4Zn4 (C54400)<br />

Pin plating:<br />

Tin over Nickel<br />

Press-fit characteristic measured acc. to IEC 60352-5 (single pin):<br />

Press-in force : 90 N max. (at min. hole diameter) / 65 N typ<br />

Push-out force : 30 N min. (at max. hole diameter) / 50 N typ.<br />

Push-out 3rd cycle : 20 N min. (at max. hole diameter)<br />

PCB hole specifications: Dimensions<br />

Nominal hole diameter Diameter finished hole Diameter drilled hole<br />

0.6 mm 0.6 +/- 0.05 mm 0.7 +/- 0.02 mm<br />

0.7 mm 0.7 +0.07 / -0.05 mm 0.8 +0.03 /- 0.02 mm<br />

0.9 mm 0.9 +0.07 / -0.05 mm 1.0 +/- 0.02 mm<br />

1.0 mm 1.0 +0.09 / -0.06 mm 1.15 +/- 0.025 mm<br />

PCB hole specifications: Plating<br />

PCB surface finish Tin Copper Gold over nickel<br />

Thickness - copper min. 25 µm min. 25 µm min. 25 µm<br />

Thickness - tin 5 - 15 µm – -<br />

Thickness - nickel – – 2.5 - 5 µm<br />

Thickness - gold – – 0.05 - 0.2 µm<br />

… FROM OUR CATALOGUE<br />

Socket and pin contacts with compliant press-fit terminations are currently available in our<br />

catalogue as single contacts and for a multitude of sockets and connectors, in standard or<br />

customised versions, such as:<br />

ASSEMBLY WITH<br />

THE PRINTED CIRCUIT BOARD<br />

Assembly of press-fit connectors and<br />

sockets with the PCB requires only<br />

simple tooling which can be installed<br />

on a small press: a base plate with<br />

holes corresponding to the hole pattern<br />

of the PCB and an upper tool<br />

(flat rock or with slots to allow for<br />

the contact pins in the case of male<br />

contacts).<br />

DIL sockets : Pitch 2.54 mm (Series 146)<br />

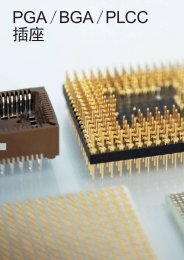

PGA sockets : Interstitial or 2.54 mm grid (Series 546)<br />

PCB connectors :<br />

- Sockets : Pitch 2 mm , standard or with polarization (Series 831-833)<br />

Pitch 2.54 mm with mating pin ø 0.47 mm (Series 346/356 and 801/803)<br />

Pitch 2.54 mm with mating pin ø 0.76 mm (Series 801/803)<br />

- Pins : Pitch 2.54 mm, connecting pin ø 0.47 mm (Series 356/456 )<br />

Pitch 2.54, connecting pin ø 0.76 mm, standard or shrouded version<br />

(Series 800/802/804)<br />

You will find all the complementary technical specifications related to the above products in<br />

our catalog.<br />

More sophisticated equipment (semiautomatic<br />

or automatic for volume<br />

production) is also available on the<br />

market.<br />

Press-fit termination are available for a multitude of sockets and connectors.

SWISS QUALITY IS NOT A LEGEND<br />

Let us prove it !<br />

A MANUFACTURER<br />

CAPABLE OF RESPONDING<br />

TO SPECIFIC REQUESTS<br />

Many years of experience<br />

<strong>PRECI</strong>-<strong>DIP</strong> DURTAL <strong>SA</strong>, established<br />

1976 in Delémont, capital of the<br />

Swiss Jura, has long experience in<br />

manufacturing screw-machined high<br />

precision contacts.<br />

Today we are one of the world leaders<br />

in manufacturing contacts and<br />

connectors. We offer a broad line of<br />

reliable, high quality interconnect<br />

components, or customised contacts<br />

available in loose conditions or assembled<br />

with insulator bodies.<br />

Take advantage of our experience in<br />

studying and quoting solutions<br />

according to your specific requirements.<br />

You will be pleasantly surprised<br />

by the rapidity of our response.<br />

Customer safety<br />

We fully guarantee the reliability and<br />

the irreproachable performance of our<br />

products. To this end, we have chosen<br />

a challenging, but efficient way:<br />

under the surveillance of a vigilant<br />

quality assurance department (ISO<br />

9001: 2000 and ISO 14001), we handle<br />

in our own manufacturing plant:<br />

Delémont<br />

(Switzerland)<br />

Layout: Publicité Rutz | www.pub-rutz.ch<br />

- The screw-machining of all parts<br />

including possible secondary operations;<br />

- The stamping and forming of the<br />

clips;<br />

- All the electroplating processes and<br />

surface treatments;<br />

- The production of our range of MIL<br />

contacts, including colour code marking,<br />

in our own production unit,<br />

also certified to MIL-STD 790;<br />

- The production of the miniature<br />

helical springs with precisely defined<br />

characteristics used on our spring<br />

loaded contacts;<br />

- The injection of the insulator bodies<br />

in materials adapted to their<br />

application;<br />

- All the assembling operations, executed<br />

on automatic equipment of<br />

our own design.<br />

In our Delémont manufacturing unit with a surface of<br />

193.500 sq.ft. (certified ISO 9001:2000; MIL-STD-790 and<br />

ISO 14001) we produce all the components required for<br />

making highly reliable contacts and connectors.<br />

Once screw-machined, the press-fit details are then produced<br />

on the home designed multi-station rotary type<br />

machines.<br />

Our high speed screw machines produce up to 130 million<br />

precision parts per week. With this volume, <strong>PRECI</strong>-<strong>DIP</strong><br />

is one of the world leaders in high precision machined contacts.<br />

After machining and plating, the contacts are either shipped<br />

in bulk or assembled into sockets and connectors.<br />

Fully integrated production...<br />

Flexibility, rapidity, know-how<br />

Mastering the entire product by an<br />

integrated production tool is one of<br />

the best trump cards one can have.<br />

Most of our special machinery is designed<br />

by our own engineering department.<br />

We are therefore totally independent<br />

from any sub-contractors.<br />

Consequently, we will be able to<br />

respond to all your enquiries with<br />

economically priced solutions, equally<br />

for small or high volume batches.<br />

info and products online : www.precidip.com<br />

CONNECT US !<br />

<strong>PRECI</strong>-<strong>DIP</strong> <strong>Durtal</strong> <strong>SA</strong><br />

Rue Saint-Maurice 34, P.O.Box 341<br />

CH-2800 Delémont / Switzerland<br />

Phone: +41 (0)32 421 04 00<br />

Fax: +41 (0)32 421 04 01<br />

E-mail: sales@precidip.com<br />

Your <strong>PRECI</strong>-<strong>DIP</strong> dealer: