expression of interest for prime - Cochin Shipyard

expression of interest for prime - Cochin Shipyard

expression of interest for prime - Cochin Shipyard

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

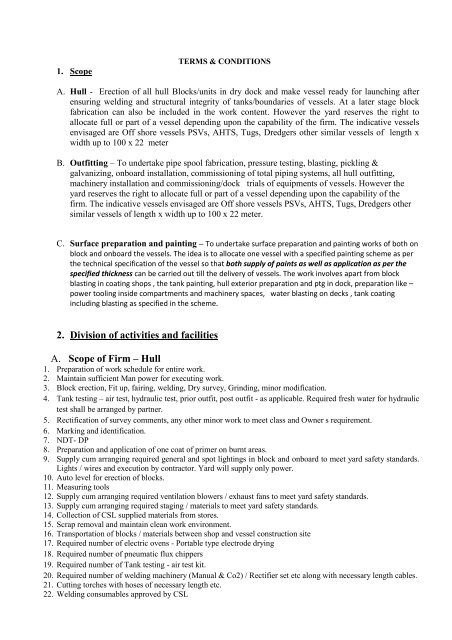

1. Scope<br />

TERMS & CONDITIONS<br />

A. Hull - Erection <strong>of</strong> all hull Blocks/units in dry dock and make vessel ready <strong>for</strong> launching after<br />

ensuring welding and structural integrity <strong>of</strong> tanks/boundaries <strong>of</strong> vessels. At a later stage block<br />

fabrication can also be included in the work content. However the yard reserves the right to<br />

allocate full or part <strong>of</strong> a vessel depending upon the capability <strong>of</strong> the firm. The indicative vessels<br />

envisaged are Off shore vessels PSVs, AHTS, Tugs, Dredgers other similar vessels <strong>of</strong> length x<br />

width up to 100 x 22 meter<br />

B. Outfitting – To undertake pipe spool fabrication, pressure testing, blasting, pickling &<br />

galvanizing, onboard installation, commissioning <strong>of</strong> total piping systems, all hull outfitting,<br />

machinery installation and commissioning/dock trials <strong>of</strong> equipments <strong>of</strong> vessels. However the<br />

yard reserves the right to allocate full or part <strong>of</strong> a vessel depending upon the capability <strong>of</strong> the<br />

firm. The indicative vessels envisaged are Off shore vessels PSVs, AHTS, Tugs, Dredgers other<br />

similar vessels <strong>of</strong> length x width up to 100 x 22 meter.<br />

C. Surface preparation and painting – To undertake surface preparation and painting works <strong>of</strong> both on<br />

block and onboard the vessels. The idea is to allocate one vessel with a specified painting scheme as per<br />

the technical specification <strong>of</strong> the vessel so that both supply <strong>of</strong> paints as well as application as per the<br />

specified thickness can be carried out till the delivery <strong>of</strong> vessels. The work involves apart from block<br />

blasting in coating shops , the tank painting, hull exterior preparation and ptg in dock, preparation like –<br />

power tooling inside compartments and machinery spaces, water blasting on decks , tank coating<br />

including blasting as specified in the scheme.<br />

2. Division <strong>of</strong> activities and facilities<br />

A. Scope <strong>of</strong> Firm – Hull<br />

1. Preparation <strong>of</strong> work schedule <strong>for</strong> entire work.<br />

2. Maintain sufficient Man power <strong>for</strong> executing work.<br />

3. Block erection, Fit up, fairing, welding, Dry survey, Grinding, minor modification.<br />

4. Tank testing – air test, hydraulic test, prior outfit, post outfit - as applicable. Required fresh water <strong>for</strong> hydraulic<br />

test shall be arranged by partner.<br />

5. Rectification <strong>of</strong> survey comments, any other minor work to meet class and Owner s requirement.<br />

6. Marking and identification.<br />

7. NDT- DP<br />

8. Preparation and application <strong>of</strong> one coat <strong>of</strong> <strong>prime</strong>r on burnt areas.<br />

9. Supply cum arranging required general and spot lightings in block and onboard to meet yard safety standards.<br />

Lights / wires and execution by contractor. Yard will supply only power.<br />

10. Auto level <strong>for</strong> erection <strong>of</strong> blocks.<br />

11. Measuring tools<br />

12. Supply cum arranging required ventilation blowers / exhaust fans to meet yard safety standards.<br />

13. Supply cum arranging required staging / materials to meet yard safety standards.<br />

14. Collection <strong>of</strong> CSL supplied materials from stores.<br />

15. Scrap removal and maintain clean work environment.<br />

16. Transportation <strong>of</strong> blocks / materials between shop and vessel construction site<br />

17. Required number <strong>of</strong> electric ovens - Portable type electrode drying<br />

18. Required number <strong>of</strong> pneumatic flux chippers<br />

19. Required number <strong>of</strong> Tank testing - air test kit.<br />

20. Required number <strong>of</strong> welding machinery (Manual & Co2) / Rectifier set etc along with necessary length cables.<br />

21. Cutting torches with hoses <strong>of</strong> necessary length etc.<br />

22. Welding consumables approved by CSL