Hot Tapping Procedure - International Paper

Hot Tapping Procedure - International Paper

Hot Tapping Procedure - International Paper

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

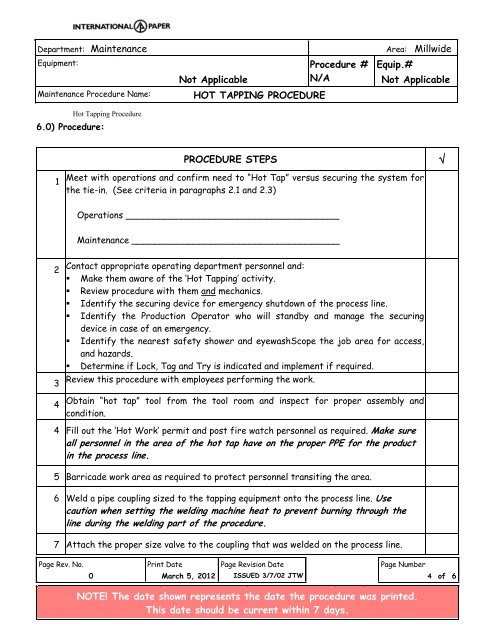

Department: Maintenance Area: Millwide<br />

Equipment:<br />

Not Applicable<br />

Maintenance <strong>Procedure</strong> Name: HOT TAPPING PROCEDURE<br />

6.0) <strong>Procedure</strong>:<br />

1<br />

2<br />

3<br />

4<br />

<strong>Hot</strong> <strong>Tapping</strong> <strong>Procedure</strong><br />

<strong>Procedure</strong> #<br />

N/A<br />

Equip.#<br />

Not Applicable<br />

PROCEDURE STEPS �<br />

Meet with operations and confirm need to “<strong>Hot</strong> Tap” versus securing the system for<br />

the tie-in. (See criteria in paragraphs 2.1 and 2.3)<br />

Operations ______________________________________<br />

Maintenance _____________________________________<br />

Contact appropriate operating department personnel and:<br />

� Make them aware of the „<strong>Hot</strong> <strong>Tapping</strong>‟ activity.<br />

� Review procedure with them and mechanics.<br />

� Identify the securing device for emergency shutdown of the process line.<br />

� Identify the Production Operator who will standby and manage the securing<br />

device in case of an emergency.<br />

� Identify the nearest safety shower and eyewashScope the job area for access,<br />

and hazards.<br />

� Determine if Lock, Tag and Try is indicated and implement if required.<br />

Review this procedure with employees performing the work.<br />

Obtain “hot tap” tool from the tool room and inspect for proper assembly and<br />

condition.<br />

4 Fill out the „<strong>Hot</strong> Work‟ permit and post fire watch personnel as required. Make sure<br />

all personnel in the area of the hot tap have on the proper PPE for the product<br />

in the process line.<br />

5 Barricade work area as required to protect personnel transiting the area.<br />

6 Weld a pipe coupling sized to the tapping equipment onto the process line. Use<br />

caution when setting the welding machine heat to prevent burning through the<br />

line during the welding part of the procedure.<br />

7 Attach the proper size valve to the coupling that was welded on the process line.<br />

Page Rev. No. Print Date Page Revision Date Page Number<br />

0 March 5, 2012 ISSUED 3/7/02 JTW 4 of 6<br />

NOTE! The date shown represents the date the procedure was printed.<br />

This date should be current within 7 days.