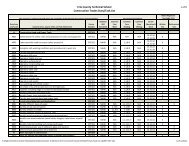

Duty & Task List - Ects.org

Duty & Task List - Ects.org

Duty & Task List - Ects.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

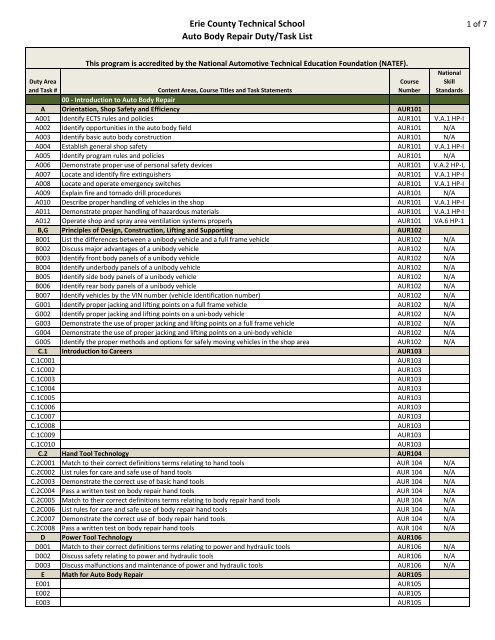

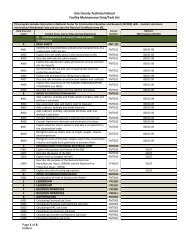

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

1 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Course<br />

Number<br />

National<br />

Skill<br />

Standards<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

00 ‐ Introduction to Auto Body Repair<br />

A Orientation, Shop Safety and Efficiency AUR101<br />

A001 Identify ECTS rules and policies AUR101 V.A.1 HP‐I<br />

A002 Identify opportunities in the auto body field AUR101 N/A<br />

A003 Identify basic auto body construction AUR101 N/A<br />

A004 Establish general shop safety AUR101 V.A.1 HP‐I<br />

A005 Identify program rules and policies AUR101 N/A<br />

A006 Demonstrate proper use of personal safety devices AUR101 V.A.2 HP‐I,<br />

A007 Locate and identify fire extinguishers AUR101 V.A.1 HP‐I<br />

A008 Locate and operate emergency switches AUR101 V.A.1 HP‐I<br />

A009 Explain fire and tornado drill procedures AUR101 N/A<br />

A010 Describe proper handling of vehicles in the shop AUR101 V.A.1 HP‐I<br />

A011 Demonstrate proper handling of hazardous materials AUR101 V.A.1 HP‐I<br />

A012 Operate shop and spray area ventilation systems properly AUR101 VA.6 HP‐1<br />

B,G Principles of Design, Construction, Lifting and Supporting AUR102<br />

B001 <strong>List</strong> the differences between a unibody vehicle and a full frame vehicle AUR102 N/A<br />

B002 Discuss major advantages of a unibody vehicle AUR102 N/A<br />

B003 Identify front body panels of a unibody vehicle AUR102 N/A<br />

B004 Identify underbody panels of a unibody vehicle AUR102 N/A<br />

B005 Identify side body panels of a unibody vehicle AUR102 N/A<br />

B006 Identify rear body panels of a unibody vehicle AUR102 N/A<br />

B007 Identify vehicles by the VIN number (vehicle identification number) AUR102 N/A<br />

G001 Identify proper jacking and lifting points on a full frame vehicle AUR102 N/A<br />

G002 Identify proper jacking and lifting points on a uni‐body vehicle AUR102 N/A<br />

G003 Demonstrate the use of proper jacking and lifting points on a full frame vehicle AUR102 N/A<br />

G004 Demonstrate the use of proper jacking and lifting points on a uni‐body vehicle AUR102 N/A<br />

G005 Identify the proper methods and options for safely moving vehicles in the shop area AUR102 N/A<br />

C.1 Introduction to Careers AUR103<br />

C.1C001<br />

AUR103<br />

C.1C002<br />

AUR103<br />

C.1C003<br />

AUR103<br />

C.1C004<br />

AUR103<br />

C.1C005<br />

AUR103<br />

C.1C006<br />

AUR103<br />

C.1C007<br />

AUR103<br />

C.1C008<br />

AUR103<br />

C.1C009<br />

AUR103<br />

C.1C010<br />

AUR103<br />

C.2 Hand Tool Technology AUR104<br />

C.2C001 Match to their correct definitions terms relating to hand tools AUR 104 N/A<br />

C.2C002 <strong>List</strong> rules for care and safe use of hand tools AUR 104 N/A<br />

C.2C003 Demonstrate the correct use of basic hand tools AUR 104 N/A<br />

C.2C004 Pass a written test on body repair hand tools AUR 104 N/A<br />

C.2C005 Match to their correct definitions terms relating to body repair hand tools AUR 104 N/A<br />

C.2C006 <strong>List</strong> rules for care and safe use of body repair hand tools AUR 104 N/A<br />

C.2C007 Demonstrate the correct use of body repair hand tools AUR 104 N/A<br />

C.2C008 Pass a written test on body repair hand tools AUR 104 N/A<br />

D Power Tool Technology AUR106<br />

D001 Match to their correct definitions terms relating to power and hydraulic tools AUR106 N/A<br />

D002 Discuss safety relating to power and hydraulic tools AUR106 N/A<br />

D003 Discuss malfunctions and maintenance of power and hydraulic tools AUR106 N/A<br />

E Math for Auto Body Repair AUR105<br />

E001<br />

AUR105<br />

E002<br />

AUR105<br />

E003<br />

AUR105

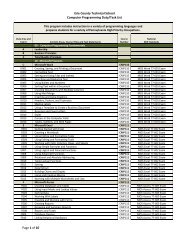

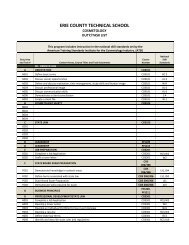

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

2 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

E004<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

Course<br />

Number<br />

AUR105<br />

National<br />

Skill<br />

Standards<br />

F Math for Auto Body Repair II AUR107<br />

F001<br />

AUR107<br />

F002<br />

AUR107<br />

F003<br />

AUR107<br />

F004<br />

AUR107<br />

AA Compressed Air System Technology AUR108<br />

AA01 Demonstrate safe and proper use of power and hydraulic tools AUR108 N/A<br />

AA02 Identify air powered tools used in body repair AUR108 N/A<br />

AA03 Discuss safety of air powered tools AUR108 N/A<br />

AA04 <strong>List</strong> rules for care and safe use of air powered tools AUR108 N/A<br />

AA05 Demonstrate safe and proper use of air powered tools AUR108 N/A<br />

AA06 Pass a written test on air powered tools AUR108 N/A<br />

G Incorporated into <strong>Duty</strong> B<br />

H Applied Math II AUR201<br />

H001<br />

AUR201<br />

H002<br />

AUR201<br />

H003<br />

AUR201<br />

H004<br />

AUR201<br />

W‐Z MIG Welding Equipment & Technology AUR202<br />

W001 Match to their correct definitions terms relating to MIG welding AUR202 N/A<br />

W002 <strong>List</strong> safety rules for MIG welding AUR202 N/A<br />

W003 Label the components of a MIG welder AUR202 N/A<br />

W004 Adjust MIG welder to weld sheet metal AUR202 N/A<br />

W005 Adjust MIG welder to weld structural steel AUR202 N/A<br />

W006 Shut down MIG welding equipment AUR202 N/A<br />

X001 Stitch weld a butt joint on sheet metal coupon‐ flat AUR202 N/A<br />

X002 Stitch weld a lap joint on sheet metal coupon ‐ flat AUR202 N/A<br />

X003 Run several continuous beads on sheet metal coupon ‐ flat AUR202 N/A<br />

X004 Plug weld a lap joint on sheet metal coupon ‐ flat AUR202 N/A<br />

X005 Pass a written test on MIG welding joints and techniques AUR202 N/A<br />

Y001 Stitch weld a butt joint on vehicle sheet metal ‐flat AUR202 N/A<br />

Y002 Stitch weld a lap joint on vehicle sheet metal ‐ flat AUR202 N/A<br />

Y003 Run several continuous beads on vehicle sheet metal ‐ flat AUR202 N/A<br />

Y004 Plug weld a lap joint on ehicle sheet metal ‐ flat AUR202 N/A<br />

Y005 Pass a written test on MIG welding joints and techniques ‐ AUR202 N/A<br />

Z001 Stitch weld a butt joint on vehicle sheet metal‐ vertical and overhead AUR202 N/A<br />

Z002 Stitch weld a lap joint on vehicle sheet metal‐ vertical and overhead AUR202 N/A<br />

Z003 Run several continuous beads on vehicle sheet metal‐ vertical and overhead AUR202 N/A<br />

Z004 Plug weld a lap joint on vehicle sheet metal‐ vertical and overhead AUR202 N/A<br />

Z005 Pass a written test on MIG welding joints and techniques AUR202 N/A<br />

M Service Info Specs and Measurements AUR203<br />

M001<br />

AUR203<br />

M002<br />

AUR203<br />

M003<br />

AUR203<br />

M004<br />

AUR203<br />

M005<br />

AUR203<br />

M006<br />

AUR203<br />

M007<br />

AUR203<br />

M008<br />

AUR203<br />

I Applied Math III AUR301<br />

I001<br />

AUR301<br />

I002<br />

AUR301<br />

I003<br />

AUR301<br />

I004<br />

AUR301

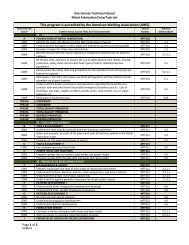

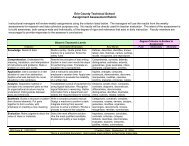

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

3 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Course<br />

Number<br />

National<br />

Skill<br />

Standards<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

J Leadership PFS109<br />

K Business Principles PFS209<br />

L Total Quality Management PFS309<br />

10 ‐ Estimating<br />

YY Damage Appraisal AUR211<br />

YY001 Estimate Auto Body Repair Work AUR211<br />

20 ‐ Minor Repairs<br />

EE Working Sheet Metal AUR121<br />

EE01 Analyze damaged sheet metal AUR121 N/A<br />

EE02 Clean the exterior surface AUR121 N/A<br />

EE03 Rough‐out damaged sheet metal AUR121 N/A<br />

EE04 Shrink stretched sheet metal AUR121 N/A<br />

EE05 Prepare surface for body filler AUR121 N/A<br />

FF Using Body Fillers AUR122<br />

FF01 Mix and apply body filler AUR122 N/A<br />

FF02 Shape body filler AUR122 N/A<br />

FF03 Utilize stud gun to repair damaged sheet metal AUR122 N/A<br />

GG Hood, Bumper, Fender, Lid and Trim Service AUR221<br />

GG01<br />

AUR221<br />

GG02<br />

AUR221<br />

GG03<br />

AUR221<br />

GG04<br />

AUR221<br />

GG05<br />

AUR221<br />

GG06<br />

AUR221<br />

GG07<br />

AUR221<br />

MM Door, Roof and Glass Service AUR222<br />

MM01 Identify vehicle glass and replacement procedures AUR222 N/A<br />

MM02 Remove and replace a gasket type window or back glass AUR222 N/A<br />

MM03 Remove and replace a glass with urethane sealants AUR222 N/A<br />

MM04 Install bonded mirror brackets to windshield AUR222 N/A<br />

MM05 Remove and replace a door handle AUR222 N/A<br />

MM06 Remove and replace a door trim panel AUR222 N/A<br />

MM07 Remove and replace a door glass AUR222 N/A<br />

MM08 Remove and replace a door glass regulator AUR222 N/A<br />

MM09 Inspect power windows AUR222 N/A<br />

O Repairing Plastics AUR321<br />

O001<br />

AUR321<br />

O002 AUR321<br />

O003<br />

AUR321<br />

O004<br />

AUR321<br />

O005<br />

AUR321<br />

O006<br />

AUR321<br />

P Passenger Compartment Service AUR322<br />

P001<br />

AUR322<br />

P002<br />

AUR322<br />

P003<br />

AUR322<br />

P004<br />

AUR322<br />

P005<br />

AUR322<br />

P006<br />

AUR322<br />

P007<br />

AUR322<br />

30 ‐ Major Body Frame Repairs<br />

HH Welded Panel Replacement AUR231<br />

HH01 Identify different types of sheet metal damage AUR231 N/A<br />

HH02 Develop a repair plan to remove different types of dents/creases AUR231 N/A<br />

HH03 Properly prepare metal for application of filler AUR231 N/A

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

4 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Course<br />

Number<br />

National<br />

Skill<br />

Standards<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

HH04 Apply/shape body filler AUR231 N/A<br />

HH05 Remove and replace sections of non‐structural panels, welded on AUR231 N/A<br />

HH06 Section non‐structural panels, welded on AUR231 N/A<br />

HH07 Remove and replace cosmetic panels, bolted on AUR231 N/A<br />

HH08 Replace bonded door panels AUR231 N/A<br />

Q Restoring Corrosion Protection AUR232<br />

Q001<br />

AUR232<br />

Q002<br />

AUR232<br />

Q003<br />

AUR232<br />

Q004<br />

AUR232<br />

R Uni‐Body Frame Realignment AUR331<br />

R001<br />

AUR331<br />

R002<br />

AUR331<br />

R003<br />

AUR331<br />

R004<br />

AUR331<br />

RR Body/Frame Damage Measurement AUR332<br />

RR01<br />

AUR332<br />

RR02<br />

AUR332<br />

RR03<br />

AUR332<br />

RR04<br />

AUR332<br />

RR05<br />

AUR332<br />

40 ‐ Mechanical and Electrical Repairs<br />

T Chassis Service and Wheel Alignment AUR341<br />

T001<br />

AUR341<br />

T002<br />

AUR341<br />

T003<br />

AUR341<br />

T004<br />

AUR341<br />

T005<br />

AUR341<br />

T006<br />

AUR341<br />

T007<br />

AUR341<br />

U Electrical/Electronic System Operation and Service AUR342<br />

U001<br />

AUR342<br />

U002<br />

AUR342<br />

U003<br />

AUR342<br />

U004<br />

AUR342<br />

U005<br />

AUR342<br />

U006<br />

AUR342<br />

U007<br />

AUR342<br />

U008<br />

AUR342<br />

U009<br />

AUR342<br />

V Restraint System Operation and Service AUR343<br />

V001<br />

AUR343<br />

V002<br />

AUR343<br />

V003<br />

AUR343<br />

V004<br />

AUR343<br />

V005<br />

AUR343<br />

V006<br />

AUR343<br />

V007<br />

AUR343<br />

V008<br />

AUR343<br />

80 ‐ Refinishing<br />

NN, OO Vehicle Surface Prep and Masking AUR181<br />

NN01 Match to their correct definitions terms relating to surface prep AUR181 V.B.2. HP‐I<br />

NN02 Remove surface contaminants using soap and water AUR181 V.B.2. HP‐I<br />

NN03 Remove surface contaminants using wax and grease remover AUR181 V.B.2. HP‐I<br />

NN04 Open the repair area AUR181 V.B.4. HP‐I

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

5 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Course<br />

Number<br />

National<br />

Skill<br />

Standards<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

NN05 Perform various sanding techniques on existing finishes AUR181 V.B.5. HP‐I<br />

NN06 Apply metal conditioner to bare metal AUR181 V.B.7. HP‐I<br />

NN07 Remove stripes, decals or trim in repair area AUR181 V.B.1. HP‐I<br />

OO01 Level paint and/or primer with the block sanding technique AUR181 V.B.12. HP‐I<br />

OO02 Provide for adhesion with proper thorough sanding techniques AUR181 V.B.5. HP‐I<br />

OO03 Provide for adhesion with proper scuff sanding techniques AUR181 V.B.5. HP‐I<br />

OO04 Determine amount and calculate a mixing ratio AUR181 V.D.2. HP‐I<br />

OO05 Mix and apply a single stage paint system AUR181 V.D.5. HP‐I<br />

OO06 Mix and apply a base coat/clear coat paint system AUR181 V.B.6. HP‐I<br />

PP Refinish Equipment Technology AUR281<br />

PP01 Utilize safe painting practices including the use of protective clothing and equipment AUR281 V.A.6. HP‐I<br />

PP02 Use the paint gun with proper technique AUR281 V.C.2 HP‐I<br />

PP03 Service and maintain a spray gun AUR281 V.C.1 HP‐I<br />

PP04 Service and maintain the paint room AUR281 V.C.2 HP‐I<br />

PP05 Identify HVLP equipment AUR281 V.C.2 HP‐I<br />

PP06 Demonstrate appropriate masking techniques AUR281 V.B.8. HP‐I<br />

PP07 Match masking Terms to masking definitions AUR281 V.B.8. HP‐I<br />

PP08 Pass a written test on masking procedures AUR281 V.B.8. HP‐I<br />

PP09 Pass a performance test on masking procedures AUR281 V.B.8. HP‐I<br />

QQ Refinishing Procedures AUR282<br />

QQ01 Identify refinishing equipment AUR282 V.C.1 HP‐I<br />

QQ02 Utilize safe painting practices including the use of protective clothing and equipment AUR282 V.A.2 HP‐I<br />

QQ03 Use the paint gun with proper technique AUR282 V.C.2 HP‐I<br />

QQ04 Service and maintain a spray gun AUR282 V.C.1 HP‐I<br />

QQ05 Service and maintain the paint room AUR282 V.A.2 HP‐I<br />

QQ06 Identify HVLP equipment AUR282 V.C.1 HP‐I<br />

QQ07 Strip painted surface using Chemical Strippers AUR282 V.B.4 HP‐I<br />

QQ08 Prepare surface of a new panel AUR282 V.B.5 HP‐I<br />

QQ09 Prepare surface of a damaged panel AUR282 V.B.5 HP‐I<br />

QQ10 Demonstrate appropriate sanding techniques AUR282 V.B.3 HP‐I<br />

QQ11 Select and apply appropriate /primer surface /sealer AUR282 VB10 HP‐I<br />

QQ12 Apply Guide coat and block sand to desired contour AUR282 V.B. 13 HP‐I<br />

QQ13 Identify topcoats and topcoat application procedures AUR282 V.D.1 HP‐I<br />

UU‐XX Paint Problems and Final Detailing AUR381<br />

UU01 Determine color then tint/blend color coat AUR381<br />

V.D. 13‐16<br />

HP‐G<br />

UU02 Mix and apply flexible paint system AUR381<br />

V.D.<br />

9,10,11, HP‐<br />

G<br />

UU03 Perform clear coat repair without painting AUR381 V.F. 2 HP‐I<br />

UU04 Determine sanding procedure necessary to de‐nib fresh paint job AUR381 V.E. 19 HP‐I<br />

UU05 Choose the proper buffing technique for various conditions AUR381 V.F. 2 HP‐I<br />

UU06 Perform paint detailing after refinishing AUR381 V.F. 2‐5 HP‐I<br />

VV01<br />

VV02<br />

VV03<br />

Choose the proper equipment for the application of primers and undercoats then, spray on vehicle surfaces<br />

Locate and identify the proper mixing ratio for primers and undercoats then, spray on vehicle surfaces<br />

Locate and identify the proper application techniques for primers and undercoats then, spray on vehicle<br />

surfaces<br />

AUR381 V.B. 9,10,11<br />

HP‐I<br />

V.B. 9,10 HP‐<br />

AUR381<br />

I<br />

AUR381 V.B. 9,10,11<br />

HP‐I

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

6 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

VV04<br />

VV05<br />

WW01<br />

WW02<br />

WW03<br />

WW04<br />

WW05<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

Follow the approved procedures and use the proper protection for personal safety during the application of<br />

primers and undercoats then, spray on vehicle surfaces<br />

Spray vehicle surfaces then, identify defects during the application of primers and undercoats and determine<br />

the best correction method<br />

Choose the proper equipment for the application of single stage finishes then, spray on vehicle surfaces<br />

Locate and identify the proper mixing ratio for single stage finishes then, spray on vehicle surfaces<br />

Locate and identify the proper application techniques for single stage finishes then, spray on vehicle surfaces<br />

Follow the approved procedures and use the proper protection for personal safety during the application of<br />

single stage finishes then, spray on vehicle surfaces<br />

Spray vehicle surfaces then, identify defects during the application of single stage finishes and determine the<br />

best correction method<br />

Course<br />

Number<br />

AUR381<br />

AUR381<br />

AUR381<br />

AUR381<br />

AUR381<br />

AUR381<br />

AUR381<br />

National<br />

Skill<br />

Standards<br />

V.A. 1‐6 HP‐<br />

I<br />

V.B.16,17,<br />

18 HP‐I<br />

V.D.5 HP‐I<br />

V.D.5, 13 HP‐<br />

I<br />

V.D.5, 13 HP‐<br />

I<br />

V.A.6 HP‐I<br />

V.E.1‐13 HP‐<br />

G<br />

XX01<br />

Choose the proper equipment for the application of base coat/clear coat finishes then, spray on vehicle<br />

surfaces<br />

AUR381<br />

V.C. 2 HP‐I<br />

V.D, 6 HP‐I<br />

XX02<br />

Locate and identify the proper mixing ratio for base coat/clear coat finishes then, spray on vehicle surfaces<br />

AUR381<br />

V.D.2 HP‐I<br />

XX03<br />

XX04<br />

XX05<br />

Locate and identify the proper application techniques for base coat/clear coat finishes then, spray on vehicle<br />

surfaces<br />

AUR381 V.D.6 HP‐I<br />

V.D.7 HP‐G<br />

Follow the approved procedures and use the proper protection for personal safety during the application of<br />

AUR381<br />

base coat/clear coat finishes then, spray on vehicle surfaces<br />

V.A.6 HP‐I<br />

Spray vehicle surfaces then, identify defects during the application of base coat/clear coat finishes and<br />

AUR381<br />

determine the best correction method<br />

V.E.2.‐13,<br />

90 ‐ Collision Repair Professionalism 28 HP‐G<br />

YY Job Success & ASE Certification AUR191 V.E. 29. HP‐I<br />

YY01<br />

YY02<br />

YY03<br />

YY04<br />

YY05<br />

YY06<br />

YY07<br />

N<br />

N001<br />

N002<br />

N003<br />

N004<br />

N005<br />

N006<br />

N007<br />

N008<br />

LII Lab Practices I, II, III, IV<br />

Apply body filler<br />

Shape body filler<br />

Apply undercoats<br />

Apply topcoats<br />

Apply clearcoats<br />

Rough out sheet metal<br />

Perform MIG welding techniques<br />

Align sheet metal<br />

AUR191<br />

AUR191<br />

AUR191<br />

AUR191<br />

AUR191<br />

AUR191<br />

AUR191<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

N/A<br />

N/A<br />

VB10 HP‐I<br />

VD 5 HP‐I<br />

VD 6 HP‐I<br />

N/A<br />

N/A<br />

N/A

Erie County Technical School<br />

Auto Body Repair <strong>Duty</strong>/<strong>Task</strong> <strong>List</strong><br />

7 of 7<br />

<strong>Duty</strong> Area<br />

and <strong>Task</strong> #<br />

N009<br />

N010<br />

N011<br />

N012<br />

N013<br />

S<br />

S001<br />

S002<br />

S003<br />

S004<br />

S005<br />

S006<br />

S007<br />

S008<br />

S009<br />

S010<br />

S011<br />

S012<br />

S013<br />

This program is accredited by the National Automotive Technical Education Foundation (NATEF).<br />

Identify and classify abrasives<br />

Assess damage<br />

Write work orders<br />

Identify personal safety and health protection<br />

Estimate repair costs<br />

LIII Lab Practices I, II, III, IV<br />

Apply body filler<br />

Shape body filler<br />

Apply undercoats<br />

Apply topcoats<br />

Apply clearcoats<br />

Rough out sheet metal<br />

Perform MIG welding techniques<br />

Align sheet metal<br />

Identify and classify Abrasives<br />

Assess damage<br />

Write work orders<br />

Identify personal safety and health protection<br />

Estimate repair costs<br />

Content Areas, Course Titles and <strong>Task</strong> Statements<br />

Course<br />

Number<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR291‐<br />

AUR294<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

AUR392‐<br />

AUR394<br />

National<br />

Skill<br />

Standards<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

VB10 HP‐I<br />

VD 5 HP‐I<br />

VD 6 HP‐I<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A<br />

N/A