You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ENGINEERING<br />

BEARING TYPES AND CAGES<br />

RADIAL SPHERICAL ROLLER BEARING TYPES AND CAGES<br />

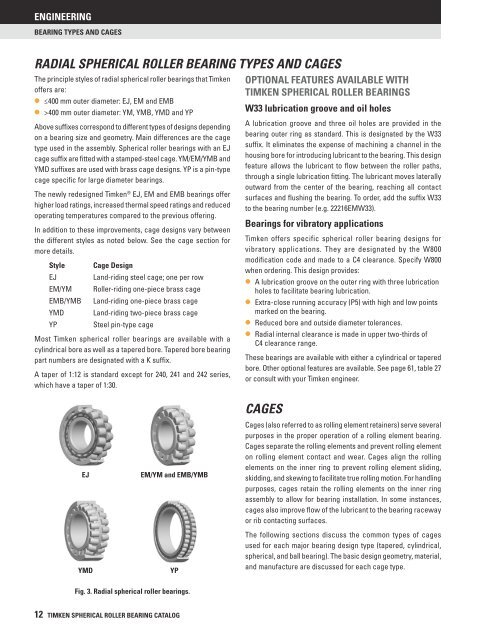

The principle styles of radial spherical roller bearings that <strong>Timken</strong><br />

offers are:<br />

• ≤400 mm outer diameter: EJ, EM and EMB<br />

• >400 mm outer diameter: YM, YMB, YMD and YP<br />

Above suffixes correspond to different types of designs depending<br />

on a bearing size and geometry. Main differences are the cage<br />

type used in the assembly. <strong>Spherical</strong> roller bearings with an EJ<br />

cage suffix are fitted with a stamped-steel cage. YM/EM/YMB and<br />

YMD suffixes are used with brass cage designs. YP is a pin-type<br />

cage specific for large diameter bearings.<br />

The newly redesigned <strong>Timken</strong> ® EJ, EM and EMB bearings offer<br />

higher load ratings, increased thermal speed ratings and reduced<br />

operating temperatures compared to the previous offering.<br />

In addition to these improvements, cage designs vary between<br />

the different styles as noted below. See the cage section for<br />

more details.<br />

Style<br />

EJ<br />

EM/YM<br />

EMB/YMB<br />

YMD<br />

YP<br />

Cage Design<br />

Land-riding steel cage; one per row<br />

<strong>Roller</strong>-riding one-piece brass cage<br />

Land-riding one-piece brass cage<br />

Land-riding two-piece brass cage<br />

Steel pin-type cage<br />

Most <strong>Timken</strong> spherical roller bearings are available with a<br />

cylindrical bore as well as a tapered bore. Tapered bore bearing<br />

part numbers are designated with a K suffix.<br />

A taper of 1:12 is standard except for 240, 241 and 242 series,<br />

which have a taper of 1:30.<br />

OPTIONAL FEATURES AVAILABLE WITH<br />

TIMKEN SPHERICAL ROLLER BEARINGS<br />

W33 lubrication groove and oil holes<br />

A lubrication groove and three oil holes are provided in the<br />

bearing outer ring as standard. This is designated by the W33<br />

suffix. It eliminates the expense of machining a channel in the<br />

housing bore for introducing lubricant to the bearing. This design<br />

feature allows the lubricant to flow between the roller paths,<br />

through a single lubrication fitting. The lubricant moves laterally<br />

outward from the center of the bearing, reaching all contact<br />

surfaces and flushing the bearing. To order, add the suffix W33<br />

to the bearing number (e.g. 22216EMW33).<br />

<strong>Bearing</strong>s for vibratory applications<br />

<strong>Timken</strong> offers specific spherical roller bearing designs for<br />

vibratory applications. They are designated by the W800<br />

modification code and made to a C4 clearance. Specify W800<br />

when ordering. This design provides:<br />

• A lubrication groove on the outer ring with three lubrication<br />

holes to facilitate bearing lubrication.<br />

• Extra-close running accuracy (P5) with high and low points<br />

marked on the bearing.<br />

• Reduced bore and outside diameter tolerances.<br />

• Radial internal clearance is made in upper two-thirds of<br />

C4 clearance range.<br />

These bearings are available with either a cylindrical or tapered<br />

bore. Other optional features are available. See page 61, table 27<br />

or consult with your <strong>Timken</strong> engineer.<br />

CAGES<br />

EJ<br />

YMD<br />

EM/YM and EMB/YMB<br />

YP<br />

Cages (also referred to as rolling element retainers) serve several<br />

purposes in the proper operation of a rolling element bearing.<br />

Cages separate the rolling elements and prevent rolling element<br />

on rolling element contact and wear. Cages align the rolling<br />

elements on the inner ring to prevent rolling element sliding,<br />

skidding, and skewing to facilitate true rolling motion. For handling<br />

purposes, cages retain the rolling elements on the inner ring<br />

assembly to allow for bearing installation. In some instances,<br />

cages also improve flow of the lubricant to the bearing raceway<br />

or rib contacting surfaces.<br />

The following sections discuss the common types of cages<br />

used for each major bearing design type (tapered, cylindrical,<br />

spherical, and ball bearing). The basic design geometry, material,<br />

and manufacture are discussed for each cage type.<br />

Fig. 3. Radial spherical roller bearings.<br />

12 TIMKEN SPHERICAL ROLLER BEARING CATALOG