hv 450 / 630 AP, hv 460 / 660 AP-V - Hawo

hv 450 / 630 AP, hv 460 / 660 AP-V - Hawo

hv 450 / 630 AP, hv 460 / 660 AP-V - Hawo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

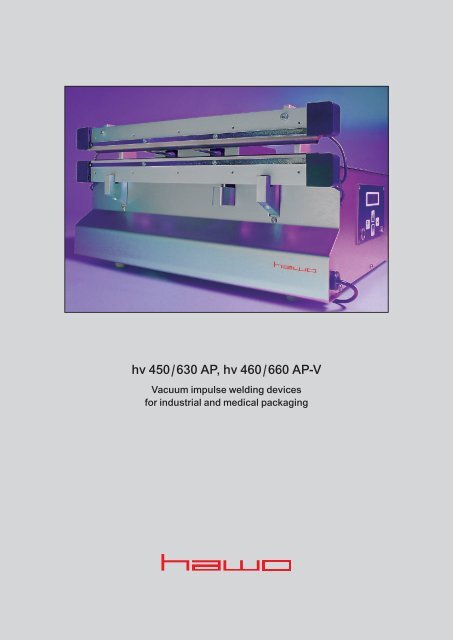

<strong>hv</strong> <strong>450</strong>/<strong>630</strong> <strong>AP</strong>, <strong>hv</strong> <strong>460</strong>/<strong>660</strong> <strong>AP</strong>-V<br />

Vacuum impulse welding devices<br />

for industrial and medical packaging

<strong>hv</strong> <strong>450</strong>/<strong>630</strong> <strong>AP</strong>, <strong>hv</strong> <strong>460</strong>/<strong>660</strong> <strong>AP</strong>-V<br />

Vacuum impulse welding devices<br />

for industrial and medical packaging<br />

The hawo vacuum impulse welding devices possess many<br />

features which makes the vacuum sealing, aeration* and welding<br />

of thermoplastic pouches user friendly, safe and simple.<br />

The following packaging materials can be used (unsuitable<br />

for gusseted pouches):<br />

• Polyethylen<br />

• Polypropylen<br />

• PVC<br />

• All types of laminates, including aluminum laminate<br />

The casing is made of stainless steel and is suitable for use in<br />

a clean room. Especially the Impulse Vacuum Welding machine<br />

<strong>hv</strong> <strong>460</strong> <strong>AP</strong>-V is suitable for use in cleanrooms fulfilling the specifications<br />

of Air Cleanliness Class ISO class 6 according to ISO<br />

14644-1 (has been awarded by Fraunhofer IPA Qualification Seal).<br />

Operation (see diagram on the following page)<br />

• The device is connected to an external compressed air supply.<br />

• The pouch (without gussers) with its product content is placed<br />

between the vacuum nozzles and weld stamp.<br />

• Pressing a foot pedal initiates the vacuum-welding<br />

process by closing the weld stamp.<br />

• After the welding process is completed, the weld stamp<br />

automatically opens and the device is again ready to start.<br />

A process that can be validated (only <strong>hv</strong> <strong>460</strong>/<strong>660</strong> AS-V)<br />

The validation of the packaging process is decisive in order to<br />

guarantee that the integrity of the packaging system is always<br />

achieved and sustained until use. The new standard EN ISO<br />

11607-2 stipulates a packaging process that can be validated<br />

and is reproducible.<br />

*only <strong>460</strong>/<strong>660</strong> <strong>AP</strong>-V<br />

It requires the critical process parameters (in this case temperature,<br />

contact pressure and welding time) are monitored and routinely<br />

documented.<br />

The warning system and machine stop must be activated in the<br />

event that critical process parameters exceed predetermined limits.<br />

EN ISO 11607-2 Conformity (only <strong>hv</strong> <strong>460</strong>/<strong>660</strong> AS-V)<br />

• Monitoring of the critical process parameters temperature,<br />

contact pressure and welding time<br />

• Warning and shutdown systems in case critical process<br />

parameters exceed predetermined limits<br />

• Connection to an external documentation system<br />

Documentation of critical process parameters<br />

(only <strong>hv</strong> <strong>460</strong>/<strong>660</strong> AS-V)<br />

For long-term documentation, the devices are compatible with<br />

various documentation systems:<br />

1. ht 180 PT-USB<br />

The new hawotest ht 180 PT-USB device is a mobile process documentation<br />

system. It automatically receives the critical process<br />

parameters as well as further relevant protocol data (machine<br />

number and personnel number, etc.). The data is then saved on<br />

an USB stick and transferred to a PC. The data is archived by<br />

means of a digitally coded PDF document directly on the PC.<br />

2. hm 455 C 3-channel curve tracer<br />

For the visual representation and documentation of critical welding<br />

parameters (temperature, contact pressure and welding time).<br />

<strong>hv</strong> <strong>450</strong>/<strong>630</strong> <strong>AP</strong>,<br />

<strong>hv</strong> <strong>460</strong>/<strong>660</strong> <strong>AP</strong>-V

Norm conformity<br />

• Quality management system according to ISO 9001:2000<br />

(QM certificate)<br />

• Fulfillment of the requirements of the DGSV Guideline for the<br />

Validation of the Sealing Process<br />

• Declaration of conformity:<br />

- CE<br />

- EN ISO 11607-2:2006 (only <strong>hv</strong> <strong>460</strong>/<strong>660</strong> AS-V)<br />

Security<br />

• Autosave: Parameter settings remain even after a power failure<br />

• Proven Safety: GS–certified safety by German test laboratory<br />

Additional functions <strong>hv</strong> <strong>450</strong>/<strong>630</strong> <strong>AP</strong><br />

• Selection of various process cycles<br />

• Easy adjustment of welding and cooling period<br />

• Automatic welding time control<br />

• Constant contact pressure<br />

Additional functions <strong>hv</strong> <strong>460</strong>/<strong>660</strong> <strong>AP</strong>-V<br />

• 2-line back-lit LCD-display<br />

• Individual adjustment of welding temperature, welding time, cooling<br />

temperature as well as vacuum time and aeration<br />

• Selection of various process cycles<br />

• Integrated clock<br />

• Multiple language menu navigation<br />

• RS 232 interface for bi-directional communication (USB optional)<br />

• Operating time<br />

• Piece counter (absolute and with reset function)<br />

• Two step foot switch for determination of vacuum period<br />

• Storage of data input with password<br />

Service<br />

• Issuance of a calibration certificate for the process decisive<br />

parameters (optional)<br />

• Seal seam resistance test in the context of validation (optional)<br />

ht 180 PT-USB System for the documentaion of the sealing<br />

process by USB-Stick (EN ISO 11607-2)

<strong>hv</strong> <strong>450</strong>/<strong>630</strong> <strong>AP</strong>, <strong>hv</strong> <strong>460</strong>/<strong>660</strong> <strong>AP</strong>-V<br />

Vacuum welding with nozzle<br />

The bag is placed over the nozzle and positioned<br />

between both weld stamps. The rubber on the weld<br />

stamps guarantees that the bag is airtight.<br />

The vacuum pump switches on and sucks<br />

the air from around the product.<br />

As soon as the vacuum time is over, the nozzles are<br />

withdrawn, the weld stamps are completely closed and<br />

the seal is created.

Sealing devices and accessories for sterile goods packaging in clinics, central sterilization<br />

departments (CSSD) and the medical industry<br />

Testing systems for the validation (Operational and Performance Qualification) of heat sealing processes<br />

Sealing devices and accessories for sterile goods packaging in dentists’ and doctors’ surgeries<br />

See also: www.generationeasy.com<br />

Plastic film welding devices for industrial packaging<br />

Vacuum impulse sealers for industrial and medical packaging<br />

Packaging machines for clothes and linen for laundries, dry cleaners and the fashion industry<br />

Subject to technical alterations<br />

July 2009 9.346.002 Printed in Germany<br />

07/09 / 0 / WRB / ST<br />

hawo GmbH · Obere Au 2–4 · 74847 Obrigheim/Germany<br />

T +49 (0)6261 9770-0 · F +49 (0)6261 9770-69<br />

info@hawo.com · www.hawo.com