Layman report - Currenta

Layman report - Currenta

Layman report - Currenta

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

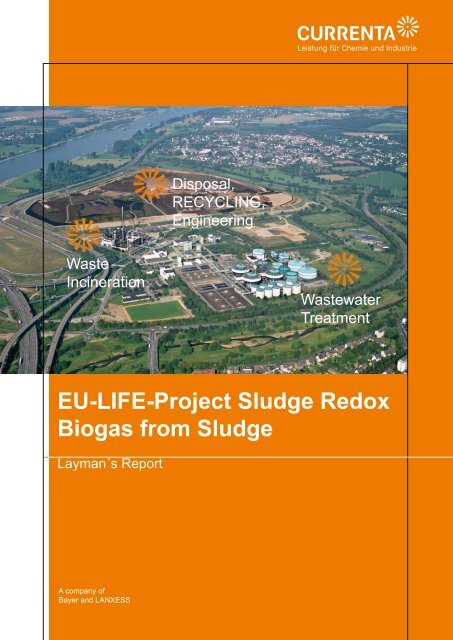

Disposal,<br />

RECYCLING,<br />

Engineering<br />

Waste<br />

Incineration<br />

Wastewater<br />

Treatment<br />

EU-LIFE-Project Sludge Redox<br />

Biogas from Sludge<br />

<strong>Layman</strong>´s Report<br />

A company of<br />

Bayer and LANXESS

Biogas from sewage sludge<br />

Final <strong>report</strong> on a demonstration project - with financial support from the EU LIFE program<br />

This <strong>report</strong> presents the results of a CURRENTA<br />

project to investigate a combination process to reduce<br />

the volume of sewage sludge from industrial sources<br />

on a pilot scale. A total of 20,000 metric tons per<br />

annum of dewatered surplus activated sludge are<br />

available for the generation of biogas at the<br />

CHEMPARK Leverkusen This is the outcome of a<br />

two-year demonstration project that received financial<br />

support from the European Union within the framework<br />

of the LIFE program.<br />

Sewage sludge is an ongoing subject<br />

Germany produces approximately 2 million metric tons<br />

(solids) of sewage sludge per annum. Around one third<br />

of this is currently used to fertilize areas in agricultural<br />

Wastewater treatment plant in the Leverkusen Waste Management Center<br />

The project “Sludge Redox” presented here is the last<br />

link to date in a long chain of research projects that<br />

have been carried out by Bayer AG, Bayer Industry<br />

Services and CURRENTA for over 20 years. The Porteous<br />

process – a thermal process for treating sewage<br />

sludge with a high organic content – was applied at the<br />

Leverkusen site in the 1980s to improve the dewatering<br />

of the sludge. The sludge was heated to 170 °C in<br />

that process. In the 1990s a process was developed<br />

for the alkaline hydrolysis of sewage sludge. Sludge<br />

digestion, a common process in municipal wastewater<br />

treatment plants, was also tested. Unfortunately, it was<br />

not possible to convert industrial sewage sludge<br />

efficiently into biogas with this method.<br />

use. Sewage sludge from industrial sources – which<br />

often contains residues e. g. heavy metals – is incinerated.<br />

This process is expensive. The search for new<br />

sewage sludge disposal processes that are less<br />

expensive and have a lower environmental impact is<br />

important because of the large quantities of industrial<br />

sewage sludge generated. The EU therefore supports<br />

research activities that are aimed at developing new<br />

processes to reduce the quantity of sewage sludge and<br />

save energy.<br />

Membrane filter press for dewatering sludge at the wastewater treatment plant<br />

Leverkusen<br />

2 <strong>Layman</strong>´s Report

Biogas from sewage sludge<br />

Industrial sewage sludge is a very special<br />

substance<br />

The challenges facing scientists in wastewater treatment<br />

plants of the chemical industry were fundamentally<br />

different to those in the communal sector. Wastewater<br />

from a Chemical Park has high concentrations of<br />

many different chemicals. Frequently it is necessary to<br />

pretreat plant effluents to make it biodegradable.<br />

Numerous chemicals are harmful to anaerobic bacteria<br />

that generate biogas from organic substances in the<br />

absence of air. For decades it proved impossible to<br />

generate biogas from chemical wastewater. But the<br />

wastewater loads have changed considerably in many<br />

Chemical Parks since the end of the 1990s as a result<br />

of new, more efficient manufacturing processes.<br />

Bacteria that could not withstand the wastewater<br />

conditions a few years ago can survive in wastewater<br />

today.<br />

Günter Müller shows the participants of the LIFE symposium lab-scale plant for sludge reduction<br />

Combined treatment process for industrial<br />

sewage sludge<br />

However, despite all of the process improvements the<br />

industrial sewage sludge generated today can still not<br />

be digested that readily. Chemists, biologists, engineers<br />

and technologists of CURRENTA have now<br />

shown how this is possible: The key to the process is<br />

the judicious combination of treatment steps that are<br />

already known. In the first step all water-soluble<br />

substances are removed using large volumes of water.<br />

Sulfate is also removed in this step as this would<br />

otherwise be converted by bacteria to foul-smelling<br />

hydrogen sulfide which is toxic to bacteria. The<br />

washing step is necessary to avoid subsequent<br />

adverse effects on digestion. The sludge floccules<br />

(which form surplus activated sludge) are then<br />

destroyed with sodium hydroxide at temperatures<br />

above 90 °C.<br />

Organic components, especially proteins, lipids and<br />

carbohydrates are very largely converted into watersoluble<br />

substances. By this step the solid concentration<br />

can be reduced significantly. Before anaerobic<br />

treatment neutralization of the hydrolysate is necessary.<br />

The neutralized hydrolysate is treated in an anaerobic<br />

bioreactor at 35 °C. In anaerobic treatment first longchain<br />

carboxylic acids are formed; these are further<br />

converted to short-chain carboxylic acids. In the final<br />

step anaerobic bacteria use this compounds to generate<br />

biogas (approx. 60 % methane and 40 % carbon<br />

dioxide). Biogas can be used for heating, electricity<br />

generation or after purification in compressed natural<br />

gas vehicles.<br />

<strong>Layman</strong>´s Report 3

Biogas from sewage sludge<br />

SLUDGE REDOX Method<br />

Water<br />

Alkaline solution<br />

Biogas<br />

Surplus<br />

activated sludge<br />

Washing<br />

step<br />

Alkaline<br />

hydrolysis<br />

Anaerobic<br />

treatment<br />

Residual<br />

sludge<br />

Watersoluble<br />

components<br />

Alkaline hydrolysis system<br />

Anaerobic treatment system<br />

4 <strong>Layman</strong>´s Report

Biogas from sewage sludge<br />

Activated sludge, untreated<br />

Activated sludge after alkaline hydrolysis<br />

Sludge after anaerobic treatment<br />

The photomicrographs of sewage sludge bacteria<br />

below show that the sludge floccules are very largely<br />

dissolved after hydrolysis with sodium hydroxide. The<br />

subsequent anaerobic treatment converts the remaining<br />

floccules partially into biogas. All that remains are<br />

fragments of the previously numerous sludge<br />

floccules. The remaining sludge will be dewatered and<br />

incinerated. The sulphate containing washing water<br />

and the effluent of the anaerobic bioreactor are treated<br />

in the wastewater treatment plant.<br />

Surplus activated<br />

sludge<br />

Washed surplus<br />

activated sludge<br />

Balance of the solids after<br />

hydrolysis and anaerobic<br />

treatment<br />

Biogas<br />

13 %<br />

100 % 98 % 30 %<br />

Solids in<br />

residual<br />

sludge<br />

2 %<br />

55 %<br />

Solubilised solids to<br />

wastewater treatment plant<br />

Solubilised solids to<br />

wastewater treatment plant<br />

<strong>Layman</strong>´s Report 5

Biogas from sewage sludge<br />

Use of sewage sludge for energy production<br />

At the industrial wastewater treatment plant (wwtp) in<br />

Leverkusen sewage sludge is first thickened before<br />

adding lime and iron salts for conditioning. Afterwards<br />

the sludge is dewatered in a membrane filter press.<br />

the calorific value is low (3,000 to 4,000 kJ/kg).<br />

Therefore it is necessary to add substances with high<br />

calorific value for sludge combustion.<br />

The Sludge Redox process generates biogas with a<br />

calorific value of 22,000 kJ/Nm 3 from. Each day 2,000<br />

to 3,000 Nm 3 biogas can be generated at the wwtp<br />

Leverkusen. More than 50 % of the energy in the<br />

surplus activated sludge can be recovered in the<br />

biogas. In the same way the amount of waste from<br />

surplus activated sludge is reduced by 70 %. The<br />

remaining sludge is reduced in organic substances and<br />

therefore the calorific value is also reduced.<br />

Karl-Heinz Stürznickel shows a component of the pilot plant for sludge reduction.<br />

After this treatment the filter cake still has a water<br />

content of about 60 %. Because of the water content<br />

and high content of inorganic substances in the sludge<br />

LIFE symposion<br />

The results of the LIFE Project “SLUDGE REDOX”<br />

were presented at 17 th September 2007 in the<br />

Leverkusen Waste Management Center. Operators of<br />

industrial and municipal wastewater treatment plants<br />

and scientists from universities and research institutes<br />

participated the symposion.<br />

Presentation of Hartmut Mayer (Emschergenossenschaft, Essen) at the LIFE symposium.<br />

6 <strong>Layman</strong>´s Report

Biogas from sewage sludge<br />

Cost-effectiveness of the combination<br />

process<br />

Although pilot-scale studies were successful, further<br />

studies will be necessary to make the new process<br />

economically viable. The large amount of sodium<br />

hydroxide solution needed to dissolve the sludge<br />

floccules means that the entire process costs €120 –<br />

140 per metric ton of sewage sludge and is therefore<br />

markedly more expensive than conventional sewage<br />

sludge incineration which costs €50 – 100 per metric<br />

ton of sludge. Even if the savings made through the<br />

use of biogas for electricity generation are included in<br />

the calculation, the process still does not reach the<br />

point of being viable economically. Further work should<br />

focus on improving the economic viability of the<br />

process in a larger pilot plant.<br />

The process can be further improved by:<br />

- application of low-cost alkaline waste<br />

- reduction of the energy consumption in<br />

the process<br />

- increase of the biogas output<br />

Sludge digestion in the future<br />

Future work will focus on the utilization of the energy<br />

present in the sewage sludge. The use of sewage<br />

sludges to yield renewable energy is an important step<br />

to improve the energy efficiency of wastewater treatment<br />

plants and to reduce carbon dioxide emissions.<br />

Dr. Fritz Bremer explained the participants of the symposion the control room of the wastewater treatment plant and the process engineering unit at the Waste Management Center.<br />

For further information on the project please<br />

contact: Dr. Guenter Mueller, <strong>Currenta</strong>, Geb. 4242,<br />

51368 Leverkusen , phone +49-214-3066227,<br />

e-mail: guenter.mueller@currenta.de<br />

<strong>Layman</strong>´s Report 7