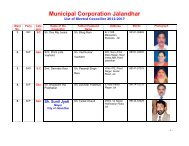

MUNICIPAL CORPORATION JALANDHAR

MUNICIPAL CORPORATION JALANDHAR

MUNICIPAL CORPORATION JALANDHAR

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10<br />

The tank shall be mounted on a auxiliary frame of ISMC 150 section and shall be adequately strength<br />

need to render it torque resistant. The auxiliary frame shall be manufactured to the size of the vehicle’s<br />

chassis and shall be of an all electrically welded construction.<br />

1.3 THE HIGH PRESSURE JETTING PUMP<br />

The high pressure Triplex Plunger Pump shall be a fully variable unit with a heavy duty, positive<br />

displacement, reciprocating triplex plunger and having a discharge capacity of 226 LPM @ 130 bar<br />

pressure to perform the jetting function with a high degree of efficiency and reliability.<br />

The pump should be of Myers USA or Pratisolli Italy make with proven performance.<br />

The pump shall be suitably located on the chassis with provision for stopping the jetting pump without<br />

stopping the prime mover.<br />

The pump shall be equipped with pressure relief valve for protection and life extension of jetting pump.<br />

High pressure jetting system works on the principle of Hydro dynamic cleaning by water pressure suitable<br />

for cleaning, sewer lines of diameter ranging from 350 mm to 800 mm. The high pressure jetting system<br />

will be adequately protected by incorporating suction filter, relief valve and un-loader valves. Mounting<br />

of jetting pump shall be on the side of the auxiliary frame with the pump head facing upwards.<br />

1.4 JETTING HOSE AND HOSE REAL.<br />

The hose reel drum should be of sturdy design and should be design to take a minimum 120 Mtrs. of 25<br />

mm. internal diameter high pressure jetting hose. The hose reel drum should be given through a hydraulic<br />

motor. The rotation of the hose reel about its axis should be through a rotation of 180 Deg. The hose reel<br />

should be of the pivoted type inner core of hose should be constructed of special water grease resistance<br />

material.<br />

Thermoplastic Electrometric material core tube fiber braided reinforcement & should have abrasion<br />

resistant. Urethanes core the inner are should be water grease resistant material. Minimum Bend radius of<br />

hose should be 150 mm working pressure should be 172 bar and minimum burst pressure should be of<br />

425 bar. The Jetting Hose should be Parker Only.<br />

1.5 VACUUM PUMP<br />

The Equipment shall be fitted with a rotary sliding vanes type, positive displacement type<br />

Exhauster/Compressor known for its unmatched performance and for its trouble free and cost effective<br />

service through out the life of the equipment. The pump shall be fitted with high temperature resistant,<br />

asbestos free vanes, shall have a minimum free airflow displacement capacity of 13850 LPM<br />

The exhauster/blower shall be of an imported origin preferable of Jurop, Italy or MASPORT (USA) or<br />

MANNESMANN-DEMAG (GERMANY)