Pneumatic Actuated - KTH Sales, Inc.

Pneumatic Actuated - KTH Sales, Inc.

Pneumatic Actuated - KTH Sales, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Pneumatic</strong> Automation<br />

Model SR / DA Actuators

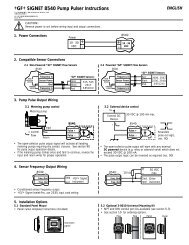

Features and Benefits<br />

2<br />

1<br />

10<br />

9<br />

8<br />

3<br />

7<br />

4<br />

6<br />

5<br />

2<br />

1. Steel Pinion<br />

Nickel plated for corrosion protection,<br />

to maximize wear resistance, and to<br />

reduce friction<br />

NAMUR slotted and threaded shaft<br />

allows for direct mounting of limit<br />

switches, positioners, and position<br />

monitors<br />

Bottom of pinion is ISO 5211<br />

2. Rotation Adjustment<br />

Adjustment ±5° in open and closed positions<br />

3. Die Cast Aluminum End Caps<br />

Standard polyester powder coated<br />

Nickel plating available<br />

4. High Tensile Steel Springs<br />

Zinc phosphate coated for corrosion resistance<br />

Spring sets easily changed to suit different air<br />

pressure/torque requirements<br />

5. Assembly Screw<br />

Stainless steel as standard<br />

6. Solenoid Valve Connection<br />

NAMUR pattern to permit direct<br />

mounting of solenoid valves<br />

7. Die Cast Aluminum Pistons<br />

Chemical nickel plating available<br />

8. Seals<br />

NBR-70 standard for temperatures<br />

ranging from -4°F to 185°F (-20°C<br />

to 85°C)<br />

Viton high temperature seals -4°F<br />

to 320°F (-20°C to 150°C)<br />

HNBR low temperature seals -40°F<br />

to 185°F (-40°C to 85°C)<br />

9. POM Piston Guides<br />

Large contact area<br />

Durable with low friction<br />

Self lubricating<br />

10. Extruded Aluminum Body<br />

UNI 6060 Aluminum<br />

Hard anodized finish to 45-50 micron<br />

for corrosion resistance and exceptional<br />

wear reduction<br />

Nickel plated or epoxy coated bodies<br />

available<br />

Top mounting pad drilled and tapped<br />

to NAMUR for direct mounting of<br />

accessories

Technical Data<br />

Type<br />

Model<br />

Cycle Time (seconds)<br />

32 52 63 75 85 100 115 125 160 200 270<br />

DA<br />

Counterclockwise<br />

Rotation<br />

0.03<br />

0.03<br />

0.06<br />

0.12<br />

0.20<br />

0.30<br />

0.53<br />

0.83<br />

1.15<br />

1.74<br />

4.50<br />

DA<br />

Clockwise Rotation<br />

0.03<br />

0.04<br />

0.08<br />

0.12<br />

0.19<br />

0.27<br />

0.47<br />

0.66<br />

1.10<br />

1.70<br />

4.50<br />

SR<br />

Counterclockwise<br />

Rotation<br />

-<br />

0.09<br />

0.14<br />

0.22<br />

0.31<br />

0.44<br />

0.83<br />

1.08<br />

1.75<br />

2.38<br />

4.50<br />

SR<br />

Clockwise Rotation<br />

-<br />

0.09<br />

0.14<br />

0.22<br />

0.33<br />

0.46<br />

0.78<br />

0.90<br />

1.34<br />

2.19<br />

6.20<br />

Approximate time per stroke (single direction) at 80 psi air supply without valve<br />

Weight (pounds)<br />

Model<br />

Type<br />

32 52 63 75 85 100 115 125 160 200 270<br />

DA 1.05<br />

2.30<br />

3.30<br />

5.60<br />

7.50<br />

11.15<br />

17.60<br />

22.05<br />

43.50<br />

72.30<br />

157.50<br />

SR<br />

-<br />

2.65<br />

3.95<br />

7.05<br />

9.50<br />

14.45<br />

22.35<br />

29.50<br />

53.80<br />

111.30<br />

194.00<br />

DA &<br />

SR<br />

DA<br />

SR<br />

Type<br />

Counterclockwise<br />

Rotation<br />

Clockwise Rotation<br />

Clockwise Rotation<br />

SR<br />

Model<br />

2.3<br />

CCW<br />

CW<br />

SR<br />

-<br />

CW 1.7<br />

Air Consumption (cubic inches)<br />

6.6<br />

9.3<br />

7.7<br />

Approximate standard cubic inches of air per stroke<br />

32 52 63 75 85 100 115 125 160 200 270<br />

12.1<br />

17.2<br />

14.2<br />

16.2<br />

20.5<br />

17.2<br />

30.2<br />

39.5<br />

32.4<br />

45.3<br />

66.8<br />

54.4<br />

61.0<br />

103.7<br />

85.4<br />

106.9<br />

148.5<br />

122.0<br />

220.1<br />

290.6<br />

215.1<br />

348.1<br />

599.7<br />

462.6<br />

915.4<br />

1086.2<br />

945.9<br />

Pressure<br />

Maximum Working<br />

Pressure:<br />

Temperature<br />

Standard Range:<br />

Option High Temp:<br />

Option Low Temp:<br />

116 psi (8 bar)<br />

-4°F to 185°F, NBR<br />

(-20°C to 85°C)<br />

-4°F to 320°F, Viton<br />

(-20°C to 150°C)<br />

-40°F to 185°F, HNBR<br />

(-40°C to 85°C)<br />

Mounting Options<br />

Closed<br />

Open<br />

Counterclockwise Rotation (Standard)<br />

Clockwise Rotation<br />

3

Parts and Materials<br />

Model 32<br />

Item Description Materials Treatment DA / Qty<br />

1<br />

Body<br />

Extruded Aluminum<br />

Hard Anodized<br />

1<br />

2<br />

3<br />

Anti-blowout Pinion Steel Nickel Plated<br />

1<br />

Lower Pinion O-Ring NBR 1<br />

4<br />

5<br />

Top Pinion O-Ring<br />

Spacer Ring<br />

NBR 1<br />

POM 1<br />

6<br />

7<br />

8<br />

9<br />

Pinion Snap Ring Steel Nickel Plated<br />

1<br />

Piston Die Cast Aluminum 2<br />

Piston O-Ring NBR 2<br />

Stop Bolt Stainless Steel 2<br />

10<br />

Stop Bolt O-Ring<br />

NBR<br />

2<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

Washer Stainless Steel<br />

2<br />

Stop Bolt Retaining Nut Stainless Steel 2<br />

Left End Cap<br />

Die Cast Aluminum Painted<br />

1<br />

Right End Cap Die Cast Aluminum Painted<br />

1<br />

End Cap Seats<br />

NBR<br />

2<br />

End Cap Fixing Screw Stainless Steel<br />

8<br />

4

Parts and Materials<br />

Model 52 to 125<br />

Item Description Materials Treatment DA / Qty SR / Qty<br />

1<br />

Body<br />

Extruded Aluminum<br />

Hard Anodized<br />

1 1<br />

2<br />

Anti-blowout Pinion<br />

Steel<br />

Nickel Plated<br />

1 1<br />

3<br />

Lower Pinion O-Ring NBR 1 1<br />

4<br />

5<br />

Pinion Spacer Ring<br />

Top Pinion O-Ring<br />

POM 1 1<br />

NBR 1 1<br />

6<br />

7<br />

Cam Spacer Ring POM 1 1<br />

Cam Stainless Steel 1 1<br />

8<br />

9<br />

Position Indicator Nylon 2<br />

Pinion Washer Stainless Steel 1<br />

2<br />

1<br />

10<br />

Pinion Snap Ring<br />

Steel<br />

Nickel Plated<br />

1<br />

1<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

Piston Die Cast Aluminum<br />

2<br />

Piston O-Ring NBR 2<br />

Anti-friction Ring<br />

POM<br />

2<br />

Piston Thrust Block POM 2<br />

Stop Bolt Retaining Nut Stainless Steel<br />

2<br />

Stop Bolt<br />

Stainless Steel<br />

2<br />

External Spring<br />

Steel<br />

Zinc-Phosphate<br />

0<br />

Internal Spring<br />

Steel<br />

Zinc-Phosphate<br />

0<br />

Left End Cap<br />

Die Cast Aluminum Painted 1<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2<br />

Based on<br />

Spring<br />

Setting<br />

1<br />

20<br />

Right End Cap<br />

Die Cast Aluminum<br />

Painted<br />

1<br />

1<br />

21<br />

End Cap Seats<br />

NBR<br />

2<br />

2<br />

22<br />

End Cap Fixing Screw<br />

Stainless Steel<br />

8<br />

8<br />

5

Parts and Materials<br />

Model 160 - 200 - 270<br />

Model 270 Only<br />

Closed position adjustment<br />

upon request<br />

Item Description Materials Treatment DA / Qty SR / Qty<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

Body<br />

Anti-blowout Pinion<br />

Extruded Aluminum<br />

Steel<br />

1 1<br />

1 1<br />

Lower Pinion O-Ring NBR 1 1<br />

Top Pinion O-Ring NBR 1 1<br />

Pinion Spacer Ring POM 1 1<br />

Pinion Snap Ring Steel Nickel Plated<br />

1 1<br />

Piston Die Cast Aluminum 2 2<br />

Piston O-Ring NBR 2<br />

Anti-friction Ring PTFE 15% Graphite 2<br />

Piston Thrust Block<br />

POM<br />

Stop Bolt O-Ring NBR<br />

2<br />

Washer Stainless Steel 2<br />

Stop Bolt Retaining Nut<br />

Stainless Steel<br />

Stop Bolt Stainless Steel 2<br />

External Spring<br />

Central Spring<br />

Internal Spring<br />

Left End Cap<br />

Right End Cap<br />

End Cap Fixing Screw<br />

End Cap O-Ring<br />

End Cap Fixing Screw<br />

Precompressed Spring<br />

Anti-friction Ring<br />

Pinion Washer<br />

Steel<br />

Steel<br />

Steel<br />

Die Cast Aluminum<br />

Die Cast Aluminum<br />

Stainless Steel<br />

NBR<br />

NBR<br />

Steel<br />

PTFE 15% Graphite<br />

Stainless Steel<br />

Hard Anodized<br />

Nickel Plated<br />

4 (6)*<br />

Zinc-Phosphate 0<br />

Zinc-Phosphate<br />

Zinc-Phosphate<br />

Painted<br />

Painted 1<br />

Zinc-Phosphate<br />

Closed Position Adjustment Upon Request<br />

2<br />

0<br />

0<br />

1<br />

8 (12)*<br />

2<br />

2<br />

0<br />

1<br />

1<br />

2<br />

2<br />

4 (6)*<br />

2<br />

2<br />

2<br />

2<br />

Based on<br />

Spring<br />

Setting<br />

1<br />

1<br />

8 (12)*<br />

2<br />

2<br />

Based on<br />

Spring Setting<br />

1<br />

1<br />

26<br />

Plate<br />

GGG40<br />

Painted<br />

1<br />

1<br />

27<br />

Coupling<br />

Steel<br />

Nickel Plated<br />

1<br />

1<br />

28<br />

Anti-friction Ring<br />

PTFE<br />

1<br />

1<br />

29<br />

Stop Screw<br />

Steel<br />

Zinc Plated<br />

1<br />

1<br />

30<br />

Stop Bolt Retaining Nut<br />

Stainless Steel<br />

1<br />

1<br />

6<br />

31 Fixing Screws<br />

Stainless Steel<br />

* (6) and (12) Valid for Model 270 Only<br />

4<br />

4

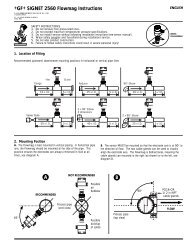

Sizing and Selection<br />

Double Acting Actuators<br />

Top View<br />

Air In<br />

Air pushes pistons outward,<br />

pinion turns counterclockwise<br />

Air In<br />

Air pushes pistons inward,<br />

pinion turns clockwise<br />

Sizing<br />

1. Determine the maximum torque of the valve to be actuated<br />

2. Add a reasonable safety factor to the valve torque to obtain the required actuator<br />

torque (safety factor = 20% to 50% based on working conditions)<br />

3. Refer to Double Acting torque chart below. Read down the Air Supply Pressure<br />

column to the first torque that exceeds the determined required torque, then left<br />

to find appropriate actuator size<br />

Example:<br />

Valve breakaway torque is 100 in.lbs. x 20% safety factor = 120 in.lbs.<br />

Available air supply is 70 psi. Reading down the 70 psi column, the<br />

first torque exceeding the requirement is 156 in.lbs. Selected actuator<br />

is DA52<br />

Torque Output - Double Acting<br />

MOD<br />

DA 32<br />

DA 52<br />

DA 63<br />

DA 75<br />

DA 85<br />

DA 100<br />

DA 115<br />

DA 125<br />

DA 160<br />

DA 200<br />

DA 270<br />

Air Supply Pressure (PSI)<br />

40 50 60 70 80 90 100 115<br />

Torque Output Double Acting Actuators (in.lbs.)<br />

34 43 55 64 71 82 87 101<br />

86 110 133 156 179 203 226 261<br />

154 196 238 280 321 363 405 468<br />

284 360 435 511 586 661 737 850<br />

408 518 629 740 851 962 1072 1238<br />

646<br />

1070<br />

1409<br />

2930<br />

818<br />

1355<br />

1783<br />

3662<br />

991<br />

1640<br />

2157<br />

4394<br />

1163<br />

1925<br />

2532<br />

5127<br />

1336<br />

2210<br />

2906<br />

5859<br />

1508<br />

2495<br />

3280<br />

6591<br />

1681<br />

2780<br />

3654<br />

7324<br />

1939<br />

3208<br />

4216<br />

8422<br />

5488 6866 8239 9612 10981 12359 13732 15792<br />

12734 15919 19097 22284 25469 28654 31832 36611<br />

7

Sizing and Selection<br />

Spring Return Actuators<br />

Top View<br />

Sizing<br />

Air In<br />

Air pushes pistons outward<br />

and compresses springs,<br />

pinion turns counterclockwise<br />

Air exhausted causes springs<br />

to push pistons inward,<br />

pinion turns clockwise<br />

1. Determine the maximum torque of the valve to be actuated<br />

2. Add a reasonable safety factor to the valve torque to obtain the required actuator<br />

torque (safety factor = 20% to 50% based on working conditions)<br />

3. Refer to the Spring Return torque chart. Read down the Spring Torque End<br />

column to the first value that equals or exceeds the determined required torque.<br />

Read right to the column that matches the available Air Supply Pressure, check<br />

that the Air Torque End also equals or exceeds the required torque. If so, read<br />

left to find appropriate actuator size and spring set<br />

Example:<br />

Valve breakaway torque is 120 in.lbs. x 20% safety factor = 144 in.lbs.<br />

Available air supply is 70 psi. Reading down the Spring Torque End column,<br />

the first value exceeding requirement is 162 in.lbs. Reading right to 70 psi<br />

Air Supply Pressure, the Air Torque End value is 158 in.lbs. exceeding<br />

requirement. The selected actuator is SR75-04<br />

Spring Setting Charts - Spring Return<br />

SR52 to SR125<br />

SR160 and SR200<br />

SR270<br />

Pretensioned Spring<br />

#<br />

03<br />

04<br />

05<br />

External Internal<br />

Spring Spring<br />

1 2<br />

2<br />

2<br />

1<br />

2<br />

#<br />

03<br />

04<br />

05<br />

06<br />

External<br />

Spring<br />

Central<br />

Spring<br />

1 2 -<br />

Internal<br />

Spring<br />

2 - 2<br />

2 2 -<br />

2 2 2<br />

#<br />

05<br />

06<br />

07<br />

08<br />

No. of Springs for<br />

Each Side<br />

4/5<br />

5/5<br />

5/6<br />

6/6<br />

8

Sizing and Selection<br />

Torque Output - Spring Return<br />

MOD<br />

SR52<br />

SR63<br />

SR75<br />

SR85<br />

SR100<br />

SR115<br />

SR125<br />

SR160<br />

SR200<br />

SR270<br />

SET<br />

03<br />

04<br />

05*<br />

03<br />

04<br />

05*<br />

03<br />

04<br />

05*<br />

03<br />

04<br />

05*<br />

03<br />

04<br />

05*<br />

03<br />

04<br />

05*<br />

03<br />

04<br />

05*<br />

04<br />

05*<br />

06<br />

03<br />

04<br />

05*<br />

06<br />

05<br />

06<br />

07<br />

08*<br />

Spring<br />

Torque<br />

(in.lbs)<br />

Start<br />

66<br />

82<br />

105<br />

128<br />

152<br />

196<br />

249<br />

303<br />

380<br />

361<br />

417<br />

536<br />

564<br />

691<br />

860<br />

* Standard Spring Set<br />

Spring Start<br />

Spring End<br />

Air Start<br />

Air End<br />

End<br />

46<br />

57<br />

72<br />

71<br />

85<br />

111<br />

133<br />

162<br />

205<br />

215<br />

248<br />

321<br />

318<br />

389<br />

489<br />

538<br />

625<br />

800<br />

Air Supply Pressure (PSI)<br />

60 70 80 90 100 115<br />

Torque Output Spring Return Actuators (in.lbs.)<br />

Start End Start<br />

End<br />

80 47 104 70 127 94 150 117<br />

70 31 93<br />

78<br />

55<br />

32<br />

116<br />

101<br />

78<br />

55<br />

140<br />

125<br />

101<br />

78<br />

149 79 191 121 233 162 275 204<br />

136 54 177 96 219 138 261 180<br />

151 53 193 95 235 136<br />

275 137<br />

247 83<br />

Start End Start End Start End Start End<br />

163<br />

148<br />

303<br />

276<br />

125<br />

102 183 137<br />

222<br />

178 339 241<br />

351 212 426 288 502 363<br />

322 158 398 234 473 309 549 385<br />

279 81 354 157 430 232 505 308 618 421<br />

387 211 498 322 609 432 720 543<br />

354 155 465 265 576 376 687 487 797 633<br />

392 146 503 257 614 368 725 478 891 645<br />

628 329 801 502 973 674 1146 847<br />

558 203 730 375 903 548 1075 720 1248 893<br />

630 206 802 378 975 551 1147 723 1406 982<br />

957 1044 541 1329 827 1615 1112 1900 1397<br />

1133 958 365 1243 650 1528 935 1813 1220 2098 1505<br />

1432<br />

1067 352 1352 637 1638 922 1923 1207 2350 1635<br />

1313 718 1351 640 1725 1015 2099 1389 2474 1763<br />

1477 808 1261 477 1636 851 2010 1226 2384 1600 2758 1974<br />

1913 1055<br />

1388 415 1762 789 2136 1164 2511 1538 3072 2099<br />

2841 1770 2447 1350 3162 2074 3886 2779<br />

3327 2230<br />

2737 1507 3452 2240 4175 2963<br />

4186 2655<br />

2983 1443 3715 2167 4421 2828 5475 3865<br />

3752 2637 5301 4035 6639 5400<br />

4699 3124 4788 3080 6126 4445 7486 5795<br />

5327 3726<br />

5453 3613 6822 5008 8182 6385<br />

6867 4664<br />

5893 3539 7288 4925 8591 6175 10562 8137<br />

12549 8044 11495 6884 1492110310 1822113619<br />

2153016920<br />

13947 8938 10539 5415 13965 8850 1727412150<br />

20574 15459<br />

15336 9832 9584 3955 13009 7381 1631910681<br />

19619 13990 2305317416<br />

1673510735 8637 2486 12063 5912 15363 9221 186721252122098 1594727115 20965<br />

- at the beginning of the spring cycle the springs are fully compressed; the stored energy<br />

and torque output of the spring is at the maximum<br />

- at the end of the spring cycle the springs are uncompressed and the torque output of the<br />

spring is at the minimum<br />

- at the beginning of the air cycle the springs are uncompressed and the air torque output<br />

is at the maximum<br />

- at the end of the air cycle the springs are fully compressed and the air torque output is at<br />

the minimum, due to increasing energy required to compress springs<br />

9

Dimensions<br />

UPON REQUEST<br />

Model 32, 160, 200, 270<br />

No 6 HOLES M5<br />

DEPTH X<br />

DETAIL<br />

*0.79 FOR MOD. 32<br />

SEE DETAIL<br />

VALID FOR MOD. 32<br />

VALID FOR MOD. 200 AND 270<br />

VALID FOR MOD. 160<br />

No 4 HOLES M5<br />

No 2 HOLES M5 x 0.23"<br />

HOLES 10/24 UNC 2B x 0.23"<br />

CCW ROTATION<br />

CW ROTATION<br />

Mod<br />

270<br />

A B C D E F G H I L M N O P Q R S T U V W Z Y X CH Drilling<br />

ISO 5211<br />

32 4.33 1.77 0.89 0.89 2.56 1.77 0.39 1.97 - 1.42<br />

10-24 UNC<br />

2Bx0.29"<br />

- - 0.47 0.46 - 1/8" - - - - 0.47 0.35 0.63 0.35 F03<br />

160 20.55 7.36 3.43 3.94 8.58 7.40 1.18 3.15 5.12 4.92<br />

1/2-13 UNC 3/8-16 UNC<br />

2Bx0.71" 2Bx0.59"<br />

4.72 1.26 1.38 3.21 1/4" 6.29 1.77 2.20 2.50 1.42 1.06 1.89 1.06 F10/F12<br />

200 22.64 8.58 4.29 4.29 10.59 9.41 1.42 3.15 5.12 5.51<br />

5/8-11 UNC<br />

2Bx0.98"<br />

- - 1.54 1.97 3.46 1/4" 7.48 2.03 2.52 3.11 1.90 1.41 1.52 1.42 F14<br />

26.46 11.42 5.71 5.71 14.21 13.03 1.42 3.15 5.12 6.50<br />

* only with square connection at 45°<br />

3/4-10 UNC<br />

2Bx1.18"<br />

-<br />

2.05 1.97 4.76 1/4" 9.05 2.68 3.11 4.37 2.37 1.81 3.23 1.81<br />

*<br />

Kit for Closed Position Adjustment Optional Model 160, 200, 270<br />

-<br />

NPT<br />

F16<br />

10

Dimensions Model 52 to 125<br />

UPON REQUEST<br />

DEPTH X<br />

DETAIL<br />

FOR MOD. 115 and 125<br />

SEE DETAIL<br />

No 4 HOLES M5<br />

*FOR MOD. 52 to 100<br />

No 4 HOLES 10/24 UNC 2B<br />

CCW ROTATION<br />

CW ROTATION<br />

Mod<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H I L M N<br />

O P Q R S T<br />

52 5.49 2.80 1.18 1.61 2.74 0.79 3.52 0.47 1.73 3.15 1.18 0.47 1.04 1.42 1.97<br />

10-24 UNC 1/4-20 UNC<br />

2Bx0.29" 2Bx0.35"<br />

1/8" 0.32 1.49 0.55 0.43 0.47 0.43<br />

63 6.38 3.17 1.40 1.77 3.17 0.79 3.96 0.58 1.97 3.15 1.18 0.63 1.08 1.97 2.76<br />

1/4-20 UNC 5/16-18 UNC<br />

2Bx0.31" 2Bx0.47"<br />

1/8" 0.32 1.61 0.71 0.55 0.63 0.55<br />

75 8.15 3.72 1.65 2.07 3.82 0.79 4.61 0.71 2.48 3.15 1.18 0.75 1.38 1.97 2.76<br />

1/4-20 UNC 5/16-18 UNC<br />

2Bx0.31" 2Bx0.47"<br />

1/8" 0.35 1.97 0.87 0.67 0.75 0.67<br />

85 9.35 4.17 1.87 2.30 4.27 0.79 5.06 0.79 2.48 3.15 1.18 0.75 1.65 1.97 2.76<br />

1/4-20 UNC 5/16-18 UNC<br />

2Bx0.31" 2Bx0.47"<br />

1/8" 0.35 1.97 0.87 0.67 1.18 0.67<br />

100 10.69 4.84 2.17 2.68 4.78 0.79 5.57 0.79 2.48 3.15 1.18 0.81 1.97 2.76 4.02<br />

5/16-18 UNC 3/8-16 UNC<br />

2Bx0.31" 2Bx0.55"<br />

1/4" 0.35 1.97 0.87 0.67 1.18 0.67<br />

115 12.91 5.39 2.52 2.87 5.57 1.18 6.75 1.26 3.39 5.12 1.18 0.94 1.97 2.76 4.02<br />

5/16-18 UNC 3/8-16 UNC<br />

2Bx0.47" 2Bx0.59"<br />

1/4" 0.57 0.86 1.11 0.86 1.53 0.87<br />

125 14.41 5.83 2.68 3.15 6.04 1.18 7.22 1.26 3.39 5.12 1.18 0.94 2.40 2.76 4.02<br />

5/16-18 UNC 3/8-16 UNC<br />

2Bx0.47" 2Bx0.59"<br />

1/4" 0.57 0.86 1.11 0.86 1.53 0.87<br />

* F04 available upon request<br />

U<br />

V<br />

Z<br />

Y<br />

X<br />

CH<br />

Drilling<br />

ISO 5211<br />

F03/F05*<br />

F05/F07<br />

F05/F07<br />

F05/F07<br />

F07/F10<br />

F07/F10<br />

F07/F10<br />

11

Ordering Information<br />

AP SR 63 03<br />

FC<br />

V<br />

Series Model Size Spring Set Mode<br />

Option<br />

AP - Actuator <strong>Pneumatic</strong> SR -<br />

DA -<br />

Spring Return<br />

Double Acting<br />

32<br />

52<br />

63<br />

75<br />

85<br />

100<br />

115<br />

125<br />

160<br />

200<br />

270<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08<br />

FC - Fail Close V -<br />

FO - Fail Open H -<br />

Viton Seals<br />

HNBR Seals<br />

Due to continuous product development, information may change without notice.<br />

Accessories<br />

Direct Mount NAMUR Solenoid<br />

NAMUR 4x & 7 available in<br />

various voltages<br />

Limit Switch<br />

NAMUR 4x & 7 mechanical<br />

SPDT and DPDT<br />

12<br />

Direct Mount Proximity Switch<br />

Excellent for wash down or<br />

corrosive environments<br />

Positioner<br />

4 - 20 MA or 3 - 15 PSI<br />

where control is critical

Direct Mount Valves<br />

334F<br />

304F<br />

204F<br />

337F<br />

Inline's Direct Mount Automation<br />

337T<br />

• Eliminates the need for costly mounting brackets<br />

and drive couplings<br />

514F<br />

• Creates a very low profile valve package<br />

• Utilizes a direct drive which improves actuator<br />

positioning and eliminates play, thereby preventing<br />

side-loading of the stem seal<br />

• Eliminates exposed moving parts<br />

• All Inline direct mount valves come standard with<br />

a high-cycle stem seal kit<br />

13

Need An Electric Actuator<br />

To meet the many needs of industry, Inline offers a family of electric actuators for<br />

applications when the required air supply is not available, inconsistent, weather<br />

prohibitive, or where electric actuators are preferred. Electric actuators provide<br />

consistent torques with slower cycle times in a low profile package. Ideal for many<br />

industrial applications, our electric actuators are cast from heavy-duty aluminum alloy<br />

steel and dry-powder coated for protection; and alloy steel gears are lubricated for a<br />

lifetime of service. Thermal protection prevents the motor from overheating, and a<br />

manual override engages when loss of power occurs. Available options include 25% or<br />

75% duty cycle motors, 180-degree operation, and Nema 4 enclosures, among others.<br />

14

Quality and Reliability Every Time<br />

Inline Industries is a manufacturer of high performance corrosion resistant ball valves. When<br />

paired with our sole source pneumatic or electric actuators and accessories, Inline delivers<br />

exceptional value in its automated systems.<br />

Inline offers a complete line<br />

of stainless and carbon-bystainless<br />

ball valves with<br />

threaded, socket weld, butt<br />

weld, or flanged end<br />

connections. Inline is highly<br />

regarded for its series of<br />

ISO 5211 direct mount,<br />

high-cycle valves, which<br />

eliminate the need for brackets<br />

and drive couplings. Utilizing<br />

a direct drive also improves<br />

actuator positioning, thereby<br />

preventing side-loading of the stem seal. Inline provides CAD drawings to aid in the engineering<br />

of actuation packages, and MTRs for complete traceability back to the foundry.<br />

Our pneumatic actuators are designed for high-cycle applications, providing a long life of troublefree<br />

service. They are available as Double Acting or Spring Return with bodies built of sturdy,<br />

hard anodized extruded aluminum, and steel internal components, nickel-plated for corrosion<br />

resistance. The twin rack and pinion design provides for a compact size, balanced internal force,<br />

and constant torque output. All pneumatic actuator mounting pads are drilled and tapped to<br />

NAMUR to allow direct mounting of Inline's solenoids, limit switches, and other accessories.<br />

Optional seals are available to accommodate temperature requirements.<br />

Inline also offers a compact, easy-to-set electric actuator with an ISO 5211 mounting pad. Built<br />

of sturdy, die cast aluminum, the housing and cover are weather proof and corrosion resistant.<br />

Heavy duty coated gears, thermal protectors, manual overrides, and other options or accessories<br />

are just some of the features Inline has to offer.<br />

Inline maintains an extensive and complete inventory of valves, actuators, and accessories in its<br />

California warehouse to support our network of distributors. Our knowledgeable sales staff<br />

provides real-time factory support to address technical questions, and assist in the selection and<br />

sizing of actuated systems.<br />

ISO 9001<br />

15

Distributed by:<br />

INLINE INDUSTRIES, INC.<br />

4701-A Littlejohn Street<br />

Baldwin Park, CA 91706<br />

Tel: (626) 813-6188<br />

Fax: (626) 813-6186<br />

www.ballvalve.com<br />

info@ballvalve.com<br />

© 2005 Inline Industries. All rights reserved.<br />

0501.1