ESAB CUTTING SYSTEMS Productivity, Simplicity and ... - imosdg.ro

ESAB CUTTING SYSTEMS Productivity, Simplicity and ... - imosdg.ro

ESAB CUTTING SYSTEMS Productivity, Simplicity and ... - imosdg.ro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

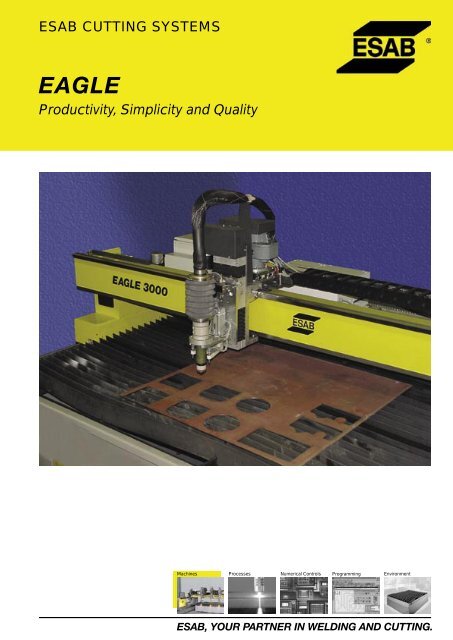

<st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>CUTTING</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>SYSTEMS</st<strong>ro</strong>ng><br />

EAGLE<br />

<st<strong>ro</strong>ng>P<strong>ro</strong>ductivity</st<strong>ro</strong>ng>, <st<strong>ro</strong>ng>Simplicity</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> Quality<br />

Machines P<strong>ro</strong>cesses Numerical Cont<strong>ro</strong>ls P<strong>ro</strong>gramming Envi<strong>ro</strong>nment<br />

<st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng>, YOUR PARTNER IN WELDING AND <st<strong>ro</strong>ng>CUTTING</st<strong>ro</strong>ng>.

<st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> EAGLE Class<br />

The EAGLE class of precision plasma cutting machines deliver exceptional<br />

unrivalled cutting accuracy, p<strong>ro</strong>ductivity <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> quality th<strong>ro</strong>ughout the plasma<br />

cutting thickness range f<strong>ro</strong>m 0.75 to 30 mm.<br />

General description<br />

User independent cut quality<br />

With the Vision PC<br />

automatic p<strong>ro</strong>grammable<br />

parameters<br />

option, <st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> p<strong>ro</strong>vides<br />

automatic setting of<br />

all the machine <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng><br />

plasma parameters<br />

including gas pressure<br />

<st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> type, by selection<br />

of the app<strong>ro</strong>priate<br />

thickness on the<br />

supplied database.<br />

The outst<st<strong>ro</strong>ng>and</st<strong>ro</strong>ng>ing EAGLE machine is specifically designed for<br />

precision plasma applications. It combines high p<strong>ro</strong>ductivity,<br />

exceptional accuracy <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> sophisticated p<strong>ro</strong>cess integration<br />

to deliver the highest cut quality parts at the most economical<br />

price.<br />

The EAGLE is simple to use giving user independent cut quality<br />

of parts in a high p<strong>ro</strong>ductivity envi<strong>ro</strong>nment. The machine<br />

can automatically change f<strong>ro</strong>m cutting to marking to further<br />

enhance its flexibility in modern workshops.<br />

The EAGLE combines speeds up to 30 m/min <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> offers exceptional<br />

plasma cutting quality using the precision plasma<br />

family. Low maintenance <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> the highest safety requirements<br />

have also been incorporated in the design.<br />

High precision mechanical design<br />

A low level precision<br />

beam supported<br />

by side<br />

carriages with optimum<br />

positioned<br />

running<br />

wheels<br />

gives a machine<br />

with a high stiffness.<br />

The twin<br />

sided<br />

synch<strong>ro</strong>nised<br />

rack <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng><br />

pinion drive together<br />

with the<br />

linear guiding system give the highest accuracy th<strong>ro</strong>ughout<br />

the entire cutting area.<br />

Powerful drive motors <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> the rigid beam construction ensure<br />

rapid response to direction change required for high quality<br />

plasma cutting.<br />

The precise longitudinal guiding track is mounted separate<br />

<st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> below the height of the cutting table ensuring the high<br />

precision is not affected by the constant loading <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> offloading<br />

of plate on the table.<br />

This unique system enables the customer to achieve consistent<br />

cut quality without regard to the operators skills or experience.<br />

Set up times between different thicknesses <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> different materials<br />

are dramatically reduced ensuring consistently high<br />

cutting quality with better p<strong>ro</strong>ductivity.<br />

High efficiency <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> p<strong>ro</strong>ductivity<br />

High efficiency <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> p<strong>ro</strong>ductivity are p<strong>ro</strong>vided by many unique<br />

features <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> include:<br />

High speed torch raise <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> lower<br />

Patented pre-flow <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> pre-switch of plasma gases<br />

Cutting, contouring <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> positioning speed<br />

of up to 30 m/min<br />

Minimised set up time between different<br />

materials <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> thicknesses<br />

Multiple pre-defined cutting areas<br />

Pentium based p<strong>ro</strong>cessing power of CNC cont<strong>ro</strong>l<br />

Ability to fit two plasma systems to the machine

Advanced plasma torch carriage<br />

The plasma carriage is designed to incorporate all the latest<br />

enhancements in plasma cutting to give a sophisticated fully<br />

automatic torch height cont<strong>ro</strong>l together with design imp<strong>ro</strong>vements<br />

in collision p<strong>ro</strong>tection <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> operator convenience:<br />

Plasma marking<br />

With precision plasma a<br />

marking option can be offered<br />

using the same plasma<br />

cutting torch without a separate<br />

marking station. This<br />

gives the following benefits:<br />

Increased accuracy<br />

of the marking<br />

Maximisation of the<br />

cutting area<br />

Reduced changeover time<br />

Lower overall costs<br />

CNC cont<strong>ro</strong>l<br />

The machine can be supplied with either the Vision PC or NCE<br />

290 CNC cont<strong>ro</strong>l. On the Vision PC, several options could be<br />

integrated such as :<br />

Initial Torch Height Setting via SRIHSS (Super Rapid<br />

Initial Height Setting System) - positioning the height<br />

of the plasma torch within less than 2 seconds,<br />

reducing tremendously the non cutting time.<br />

Cutting height sensing via responsive arc voltage<br />

Unique <st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> anti-collision system, offering the<br />

following unique advantages:<br />

+ Immediate stop of the machine<br />

whatever the collision<br />

+ Complete removing of the torch in case<br />

of big collision to avoid damage<br />

+ Easy consumable change, by removing<br />

the torch f<strong>ro</strong>m its support<br />

+ Highly accurate alignment sensor which always<br />

guarantees a correct alignment of the torch<br />

Oil Moisture Spraying System assists Hole Piercing,<br />

better plasma start <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> consumable lifetime (option).<br />

Plasma counter, with definition of warning values to<br />

inform the operator about the life time, number of<br />

piercing etc.<br />

<st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> Plasmarc systems<br />

The EAGLE uses plasma cutting systems that deliver:<br />

Pinpoint accuracy<br />

Nar<strong>ro</strong>w kerf width <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> high quality cutting<br />

Low bevel angle<br />

Low d<strong>ro</strong>ss<br />

Smooth cut surface<br />

Nar<strong>ro</strong>w heat affected zone<br />

Minimum plate distortion<br />

Low number of consumables to cover thickness<br />

range<br />

Cut thickness up to 30 mm mild steel, stainless steel<br />

<st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> aluminium<br />

On-Screen Timer & Counters<br />

Track consumable life,<br />

pierces, arc on time, cutting<br />

time or other data for<br />

shop management<br />

(Vision PC / NT)<br />

Up to 24 counters<br />

<st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> timers<br />

Each display can<br />

be reset to ze<strong>ro</strong><br />

Each display has a<br />

threshold value, which<br />

triggers an alarm message for the operator.<br />

P<strong>ro</strong>grammable Cutting Parameters<br />

Simplify <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> automate<br />

cutting setup<br />

Saves time<br />

No more memorizing<br />

cutting charts<br />

No more forgetting to set<br />

the right parameters<br />

Get the same cut quality<br />

every shift, every operator<br />

Plasma pre-stop<br />

Patented CNC feature<br />

Imp<strong>ro</strong>ves plasma torch consumable life<br />

Shuts down the plasma arc just as<br />

the torch reaches the end of cut<br />

Preventing arc w<st<strong>ro</strong>ng>and</st<strong>ro</strong>ng>er at the end of the cut<br />

Elect<strong>ro</strong>de <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> nozzle wear are reduced<br />

Plasma marked lines are enhanced<br />

(with precision plasma) <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> many other features.<br />

High accuracy repeatability<br />

The EAGLE guarantees unbeatable<br />

cutting repeatability for its whole operation<br />

period. The first cut will be like<br />

the last cut.

VISION PC<br />

D<br />

A<br />

B<br />

C<br />

EAGLE<br />

Machine specification<br />

Technical data<br />

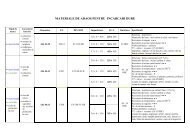

Machine sizes [mm] (B) 2,000 2,500 3,000 3,500<br />

Machine length [mm] 1,600<br />

Machine height [mm] (D) 1,700<br />

Machine width [mm] (C)<br />

Easy service <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> maintenance<br />

The machine is designed with a high build quality to give you<br />

many years of cutting life. The high reliability <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> low maintenance<br />

is assisted by:<br />

Comprehensive machine diagnostics<br />

Ability to link machine to modem service doctor<br />

Plug <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> play replacement parts<br />

Easy access to major components<br />

Comprehensive documentation <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> instruction<br />

manuals<br />

(B)+800<br />

Torch lifting height [mm] 100<br />

Table height [mm] 700<br />

Track height [mm] 600<br />

Main voltage<br />

Power input<br />

50 Hz/230 V<br />

2,000 VA<br />

Positioning speed [mm/min] 30,000<br />

Number of single torches 1 2 2 2<br />

Cutting width with 1 or 2 single torches [mm] (A) 1,500 2,000 2,500 3,000<br />

Parallel cut with 2 equal single torches [mm] (A) -- 2 x 1,000 2 x 1,250 2 x 1,500<br />

Cutting thickness<br />

Marking, Arc Marker<br />

About <st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng><br />

up to 30 mm depending on plasma power source<br />

possible<br />

Sixty years’ experience of cutting <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> responding to customers needs have resulted in an extensive range of p<strong>ro</strong>ducts<br />

to meet most p<strong>ro</strong>file cutting applications. Based a<strong>ro</strong>und the four methods of oxy-fuel cutting, plasma cutting,<br />

laser cutting <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> water jet cutting, <st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> has developed a range of machines that deliver better cut quality, higher<br />

cutting speeds, lower operating costs <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> integration into automated p<strong>ro</strong>duction methods.<br />

The right to make technical modifications <st<strong>ro</strong>ng>and</st<strong>ro</strong>ng> imp<strong>ro</strong>vements is reserved.<br />

200210 [03]<br />

<st<strong>ro</strong>ng>ESAB</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>CUTTING</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>SYSTEMS</st<strong>ro</strong>ng> GmbH<br />

Robert-Bosch-Straße 20<br />

D-61184 Karben<br />

Phone: +49 60 39 40-0<br />

Fax: +49 60 39 40-301<br />

Internet: www.esab-cutting.de<br />

E-mail: info@esab-cutting.de