MACHINERY UPDATE - Process Plant Network

MACHINERY UPDATE - Process Plant Network

MACHINERY UPDATE - Process Plant Network

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE COMPLE T E PACK AGE<br />

ahead of the pack<br />

<strong>MACHINERY</strong> <strong>UPDATE</strong><br />

SPECIAL EXHIBITION<br />

EDITION 2011<br />

NEW & USED PROCESSING & PACKAGING EQUIPMENT - CUSTOM DESIGN SERVICES<br />

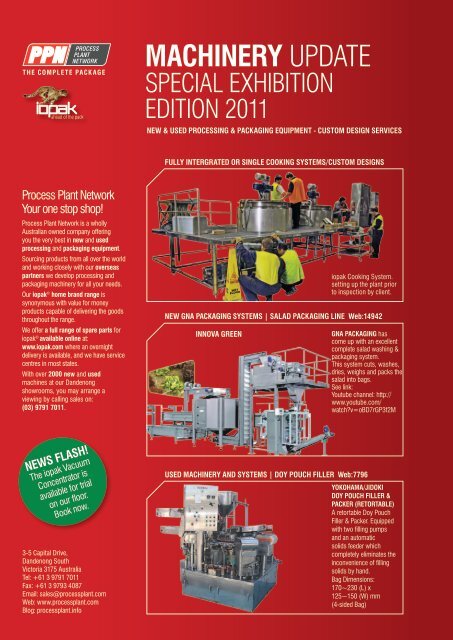

FULLY INTERGRATED OR SINGLE COOKING SYSTEMS/CUSTOM DESIGNS<br />

<strong>Process</strong> <strong>Plant</strong> <strong>Network</strong><br />

Your one stop shop!<br />

<strong>Process</strong> <strong>Plant</strong> <strong>Network</strong> is a wholly<br />

Australian owned company offering<br />

you the very best in new and used<br />

processing and packaging equipment.<br />

Sourcing products from all over the world<br />

and working closely with our overseas<br />

partners we develop processing and<br />

packaging machinery for all your needs.<br />

Our iopak © home brand range is<br />

synonymous with value for money<br />

products capable of delivering the goods<br />

throughout the range.<br />

We offer a full range of spare parts for<br />

iopak © available online at:<br />

www.iopak.com where an overnight<br />

delivery is available, and we have service<br />

centres in most states.<br />

With over 2000 new and used<br />

machines at our Dandenong<br />

showrooms, you may arrange a<br />

viewing by calling sales on:<br />

(03) 9791 7011.<br />

iopak Cooking System.<br />

setting up the plant prior<br />

to inspection by client.<br />

NEW GNA PACKAGING SYSTEMS | SALAD PACKAGING LINE Web:14942<br />

INNOVA GREEN<br />

GNA PACKAGING has<br />

come up with an excellent<br />

complete salad washing &<br />

packaging system.<br />

This system cuts, washes,<br />

dries, weighs and packs the<br />

salad into bags.<br />

See link:<br />

Youtube channel: http://<br />

www.youtube.com/<br />

watch?v=oBD7rGP3f2M<br />

NEWS FLASH!<br />

The iopak Vacuum<br />

Concentrator is<br />

available for trial<br />

on our floor.<br />

Book now.<br />

3-5 Capital Drive,<br />

Dandenong South<br />

Victoria 3175 Australia<br />

Tel: +61 3 9791 7011<br />

Fax: +61 3 9793 4087<br />

Email: sales@processplant.com<br />

Web: www.processplant.com<br />

Blog: processplant.info<br />

USED <strong>MACHINERY</strong> AND SYSTEMS | DOY POUCH FILLER Web:7796<br />

YOKOHAMA/JIDOKI<br />

Doy Pouch Filler &<br />

Packer (Retortable)<br />

A retortable Doy Pouch<br />

Filler & Packer. Equipped<br />

with two filling pumps<br />

and an automatic<br />

solids feeder which<br />

completely eliminates the<br />

inconvenience of filling<br />

solids by hand.<br />

Bag Dimensions:<br />

170~230 (L) x<br />

125~150 (W) mm<br />

(4-sided Bag)

WE HAVE COOKERS/KETTLES<br />

for every situation...<br />

PPN, iopak can assist with your entire<br />

cooker/kettle needs from 68 litre to 5000 litre.<br />

Single or contra-rotating scraper arm.<br />

Steam Jacketed Cookers<br />

For larger size kettles try the<br />

standard 500-2000 litre range.<br />

Jacketed Cooker Kettles (Contra<br />

Rotating) 316. Bigger sizes available.<br />

$26,750.00 +gst<br />

Web: 8531<br />

This 68 litre iopak electric cooker<br />

with removeable swing arm<br />

mixer, is ideal for the boutique<br />

manufacturer producing high quality<br />

low volume product.<br />

$10,500 +gst<br />

Web: 14262<br />

500 Lt<br />

2000 Lt<br />

Value add to your cooker/kettle<br />

with a dedicated pump and skid mount...<br />

$38,500 + gst<br />

Web: 12703<br />

The iopak 500 litre Cooker Module with<br />

steam jacketed cooker/kettle, contrarotating<br />

scraper mixing arm in-line lobe<br />

pump and control panel.<br />

Excellent for: sauces, purees, broth,<br />

creams etc.<br />

$49,500 +gst<br />

Web: 14038<br />

Arrange your<br />

trial now!<br />

Call sales:<br />

+61 (03) 9791 7011<br />

2.<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info

Fully Intergrated systems that add to your productivity capacity, as well as future expansion.<br />

Upgrade your cooker/kettle with a dedicated skid mounted pump, mill, de-aerator, etc.<br />

The iopak Cooksys 500 Cooking/Mixing<br />

Line can be configured many ways. As a<br />

Pre-Mix Vessel as well as a Cooker, an<br />

In-Line Colloid Mill, Pumps and Switchgear.<br />

This versatility is ideal, enabling countless<br />

combinations at a very affordable price.<br />

Call sales on:<br />

+61 (03) 9791 7011<br />

Web: 12011<br />

There are many<br />

accessories available.<br />

iopak 1/100-2.2 H In Line<br />

High Shear Dispersion<br />

Emulsifier<br />

$4,850 +gst<br />

Web 13087<br />

iopak Rotary Lobe Pumps.<br />

Many sizes and types available.<br />

Featured, 2” (50mm) handles<br />

5600-11000 litres/hr.<br />

(subject to product and head)<br />

$7,950+gst<br />

Web: 12566<br />

CHECK YOUR WEIGHT<br />

with our combos...<br />

QUALITEC Metal Detector<br />

Checkweigher Combo<br />

This highly sensitive metal detector /<br />

checkweigher combination is geared<br />

towards maintaining almost perfect<br />

accuracy as well as stringent hygenic<br />

standards.<br />

Maximum Weight: 600g<br />

Weighing Range: 6 - 600g<br />

Min Division: 0.1g<br />

Min Accuracy: ±0.2g<br />

Capacity: Max 210 units/min<br />

Conveyor Width: 150 mm<br />

Tunnel Height: Choice of Up to<br />

Approx. 130mm<br />

$22,500 +gst<br />

Web: 14587<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info<br />

3.

7” Touch Screen<br />

We can supply in-line Weigh Scales starting from $13,250.00<br />

for an iopak Twin Head Linear Weigher progressing to an iopak<br />

24 Head Dimple or Flat Plate (or Split System).<br />

All our weighers can be used for dry or moist products<br />

such as salads. We supply full washdown Multi-Heads also!<br />

NEED TO FILL?<br />

WEIGH THESE UP!<br />

Multi Heads VFFS’s and more...<br />

The iopak all stainless steel<br />

14 Head Weigher with 7”<br />

Touch Screen is excellent for, dry<br />

and processed food, fresh food<br />

(snacks, seeds, coffee beans<br />

granules, tea, sugar, confectionery,<br />

nuts, dried fruit etc).<br />

$32,500 +gst<br />

Web: 13143<br />

this goes<br />

with that...<br />

add to your system with:<br />

iopak stainless<br />

steel and aluminium<br />

platform<br />

$12,480.00 +gst<br />

Web: 13934<br />

The iopak VFFS Stainless Steel<br />

IWS 600 (Small Footprint Servo<br />

Driven) Bag making machine with<br />

date coder and forming shoulder.<br />

$49,500+gst<br />

Web: 15190<br />

We have an extensive range<br />

of VFFS to choose to from.<br />

iopak inclined elevator<br />

$8,750 +gst<br />

Web: 12481<br />

iopak stainless steel inclined conveyor<br />

$3,450 +gst Web: 12478<br />

iopak stainless steel bucket elevator,<br />

with inbuilt vibratory feeder. 3.8M discharge<br />

$19,500 +gst Web: 15140<br />

$16,500 +gst Web: 15141<br />

Powder Coated<br />

4.<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info

BUILDING A BETTER<br />

MODULAR SYSTEM<br />

that works for you<br />

System comprises:<br />

Stainless steel bucket elevator<br />

with vibratory infeed.<br />

Web: 15140<br />

14 Head Weigher<br />

Web: 13143<br />

Stainless steel and<br />

aluminium platform<br />

Web: 13934<br />

All Stainless steel VFFS<br />

(servo driven) Bag Making<br />

Machine<br />

Web: 15190<br />

Stainless steel Rotary<br />

Pack-Off Table<br />

Inclined Off-Take Conveyor<br />

Web: 15191<br />

$110,000 +gst<br />

Confectionery/Snack Food Packaging Line<br />

Web:15173<br />

Web: 14459<br />

iopak complete packaging system with a<br />

10 Head stainless steel Weigher, VFFS,<br />

Out-Feed System, all PLC controlled<br />

$68,000 +gst<br />

iopak SACHET PACKERS<br />

If you’re a contract packer<br />

or manufacturer packing<br />

granules spices, soups,<br />

yeast, desserts, detergents,<br />

pharmaceutical, agricultural<br />

powders / granules, tea, pan<br />

masala, or coffee, you need to<br />

trial the next generation Sachet<br />

Packers from iopak. Depending<br />

on individual applications<br />

these great sachet packers<br />

will satisfy your needs for<br />

quality and performance at an<br />

affordable price.<br />

iopak Sachet Packer with<br />

Volumetric Cup Filler<br />

and Piston Pump<br />

$32,500 +gst<br />

Web: 14155<br />

iopak Sachet Packer<br />

with Auger Filler<br />

$38,000 +gst<br />

Web: 14484<br />

Web: 14146<br />

iopak Confectionery Packaging System<br />

with Inclined Conveyor Indexing System,<br />

VFFS (servo driven) and Off-Take Conveyor.<br />

All PLC controlled.<br />

$76,938 +gst<br />

Arrange your<br />

trial now!<br />

Call sales:<br />

+61 (03) 9791 7011<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info<br />

5.

PPN can supply a range of flow wrappers, from the budget value<br />

iopak FW-320E, to the top of the range iopak IPVBOX 250<br />

PACK IT, WRAP IT! iopak, go with the flow<br />

HORIZONTAL FLOW WRAPPER (BOX MOTION) IPV BOX-250<br />

Ideal for-complete line feeding of various solid and regular products, eg.<br />

medicine, hardware, electrical products, case box or product attached with<br />

tray. Packing Speed : 15-80 bags/min. Film Width : 115-500mm Bagging<br />

size range : (L 70-999mm) (W 50-150mm) (H 5-120mm). All s/s.<br />

Web: 14322<br />

$89,990 +GST<br />

iopak Model CAPCR300<br />

Rotary Single or Multi-Head<br />

Servo-driven Capper<br />

(plastic, screw, press-on)<br />

We can offer a single head servodriven<br />

capper with touch-screen<br />

interface or a multi-head unit<br />

with all the optional extras.<br />

Speed: 20 - 80<br />

bottles/min<br />

(depending on<br />

number of heads and cap size)<br />

Cap Size: 25mm - 60mm<br />

Container Size: 25mm - 80mm<br />

Features:<br />

• Servo-Capping Head<br />

• Touch Screen Interface<br />

• Quick change-over parts<br />

• Giraffe Type Cap Elevator<br />

Web: 15174<br />

iopak IFW-503E<br />

Electronic Horizontal Flow<br />

Wrapper (Box Motion Jaw)<br />

Speed: 15-60 packs/min<br />

(Product Dependent)<br />

Bag Sizes: 220 - 440<br />

L x 220 W x 90H mm<br />

Film Width: 600mm<br />

Web: 13871<br />

$47,990 +GST<br />

NEW<br />

INNOVATIVE<br />

DESIGNS<br />

iopak IFW-502E<br />

(Electronic, Rotary Jaw).<br />

Speed: 25-150 packs/min<br />

(Product Dependent)<br />

Bag Sizes: 65 - 450 L x 140 W<br />

x 30 - 80 H mm<br />

Film Width: 400mm<br />

Packaging Material: OPP, PE,<br />

PVC, OPP/CPP, PT/PE, KOP/<br />

CPP, Aluminium<br />

Jaws: Rotary Motion<br />

Web: 14117<br />

$39,990 +GST<br />

iopak Semi Automatic<br />

Horizontal Cartoner<br />

Semi Automatic<br />

Horizontal Cartoner is very<br />

competitively priced and<br />

an ideal machine for the<br />

contract packer.<br />

Specifications<br />

Speed: Up to 56 packs/min<br />

(Product Dependent)<br />

Pack Size: 150 - 410 L x 52 -<br />

250 W x 30 - 75 H mm<br />

Sealing Type: Hot Melt<br />

Glueing System.<br />

Web: 13869<br />

$19,950 +GST<br />

6.<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info

CUSTOM<br />

DESIGN SERVICES<br />

CUSTOM<br />

DESIGNS design services.<br />

no problems...<br />

Ask about our custom<br />

iopak Multi-cooker/cooling system<br />

PPN knows that<br />

everyone works their<br />

own way. Every<br />

manufacturing system<br />

is unique. We are able<br />

to design, test and<br />

create a system to<br />

meet your needs.<br />

Here are just a few<br />

examples.<br />

iopak automatic cook and blend process<br />

line. Recipe control with operator prompt.<br />

Section of iopak custom designed<br />

filling line. Designed to carry 20 litre<br />

bottles.<br />

MATERIALS HANDLING<br />

iopak Emulsys 1000 muti-purpose<br />

blending emulsifier. Great for mayonnaise.<br />

Web: 14971 $60,000 +gst<br />

iopak Stainless Steel<br />

Bulk Bag Unloader with<br />

Electric Hoist<br />

This iopak stainless steel<br />

Bulk Bag Uloader with<br />

electric hoist is a very<br />

useful item for bag handling.<br />

Units are also available in<br />

mild steel.<br />

Specifications<br />

Unloading Weight: 2,000 Kg<br />

Max. Bag Size: 1400 L x<br />

1400 W x 1100 H mm<br />

Web: 15142<br />

$29,500 +gst<br />

iopak S/S Bulk Bag<br />

Unloader<br />

Also available in mild<br />

steel.<br />

Unloading weight:<br />

2,000 kg<br />

Max. Bag size:<br />

1400mm L x 1400mm<br />

W x 1400 H mm.<br />

Frame material: sus304<br />

Lifting via forklift.<br />

Web: 15144<br />

$16,500 +gst<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info<br />

7.

WHAT’S NEW... CHECK OUT THESE WINNERS!<br />

ahead of the pack<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

iopak Automatic Pneumatic<br />

Cap Tightener.<br />

This budget priced machine is easy<br />

to operate with a small footprint and<br />

is the ideal next step to increase<br />

your bottling production line.<br />

Features:<br />

Servo motor<br />

Air required for capping<br />

head Digital Input<br />

Adjustable torque setting<br />

Gating system (air required)<br />

Sensor detection<br />

Web: 14874<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

SEAL PACK Rotary Type Tub<br />

Filling and Sealing Machine<br />

(INNOVATIVE NEW DESIGN)<br />

This Cup or Tub Filling Machine has<br />

been re-designed with fantastic new<br />

innovative ideas.<br />

See http://www.youtube.com/user/<br />

D20400077#p/u/0/WpFz9znP3aU<br />

(New Design!)<br />

The Seal Pack FM-2202B rotary<br />

tub or cup filler and sealer can be<br />

used for liquids, viscous products,<br />

creams, powders or granules.<br />

depending on your specific need.<br />

Web: 14135<br />

iopak MiniDoy Pouch Machine<br />

Nice and compact design. It might be<br />

small - but it offers so many features!<br />

This mini doy pouch machine can<br />

seal pouches at a speed of up to<br />

20 pouches/min. For those who<br />

have limited space available in their<br />

factories, this machine takes up only<br />

1 pallet space (1710mm x 510mm x<br />

950mm H) Speed: Max 20 packs/min<br />

(Product & Pouch Dependent)<br />

Bag Width: 150 - 280 mm (Standard)<br />

Web: 14965<br />

NEW DIAMOND Vacuum<br />

& Gas Flush Tray Sealer<br />

J-V053A<br />

Suitable for: Powdery and granular<br />

products such as beans, coffee, tea<br />

leaves, herbs, nuts, pulses, grains<br />

etc, • Fresh meat, seafood, pickled<br />

vegetables, bakery products.<br />

Speed: Operator Dependent<br />

Max Tray Dimensions: 540 L x 330<br />

W x 110 H mm<br />

Max Sealing Temp: 150 0 C<br />

Power Supply: 3-Phase, 415V, 50Hz<br />

Web: 14940<br />

iopak EASYSEAL 3400 INDUCTION<br />

SEALER<br />

Features:<br />

Very smart induction cap sealer<br />

with many great features.<br />

- Model 3400B handles container<br />

sizes from: 60 ~ 120mm<br />

(other models also available)<br />

- Production rate : Max.50m/min<br />

( variations depending on the<br />

container size)<br />

- Input Power : AC200 ~ 230V *<br />

50/60HZ * 1P - 4KW<br />

Many optional extras available.<br />

Sensor & Ejector<br />

Conveyor extra<br />

Web: 15192<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

iopak CF-10T Case Erector<br />

Very COMPACT!<br />

Folds bottom covers of carton<br />

Can be used as platform for packing<br />

products.<br />

Air Pressure: 4kg/cm2<br />

Case Size: L200-600mm, W150-<br />

480mm,H120-480mm (the height is<br />

the standard sealing height of carton<br />

sealer machine)<br />

Outside dimension: L1500 X W900<br />

X H780mm<br />

Web: 15113<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

iopak Lobe Pump Filler<br />

with Product Hopper<br />

Capacity: Up to 20 fills/min<br />

(Product Dependent)<br />

Fill Range: 30 - 5,000 ml<br />

Accuracy: +/- 1-2%<br />

Hopper Overall Capacity: Approx. 40L<br />

Web: 15161<br />

iopak weighmetric servo<br />

driven auger filler<br />

(with loadcell) is weight based.<br />

Used where weight- not volume is<br />

of paramount importance.<br />

Fitted with a microprocessor based<br />

electronic controller which is load<br />

cell based making it highly<br />

accurate, utilizing a load cell not<br />

relying solely on the auger.<br />

The 3 speed auger filler runs<br />

as fast, medium and trickle/fill.<br />

An great choice at a excellent price.<br />

Web: 14936<br />

✔<br />

PPN Quality<br />

approved<br />

2011<br />

8.<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info

USED EQUIPMENT OFFERS<br />

USED<br />

The hand picked<br />

encomical alternative.<br />

great value for money in brand names<br />

KAJIWARA Gas<br />

Cooker (Tilting)<br />

with agitator<br />

Detatchable mixer/scraper<br />

arm, simple to unclip.<br />

Capacity: 200l (working<br />

capacity 130l) Bowl i.D.:<br />

850 Diameter x 430 mm.<br />

Cooker dimensions:<br />

2,100 (w) x 1,000 (d) x<br />

1,700 (h) mm.<br />

Web: 12103<br />

AUSMADE Jacketed<br />

Conical-bottomed<br />

tank on platform<br />

Used as a header tank for<br />

liquids and emulsions.<br />

The angle of the cone<br />

is steep, ensuring easy<br />

drainage.The conical<br />

section is dimple<br />

jacketed for heating or<br />

cooling.<br />

Web: 14637<br />

APEX-comminuting<br />

mill with spare<br />

screens.<br />

All stainless steel wetted<br />

parts. Mounted on a cast<br />

frame on tubular legs<br />

on substantial lockable<br />

castors. Mill type: Knife<br />

Blade. Screen area (cm2)<br />

290.00<br />

Motor size:3HP<br />

Web: 14967<br />

PESTER S/S Shrink- Stretch Wrapper<br />

Bundler for Cartons<br />

Wrapper/Bundler/Collator for cartons never used in<br />

production. Suitable for pharmaceutical and food<br />

packaging.<br />

Max. film width 450 mm<br />

Min Film Width: 50mm<br />

Film Thickness:<br />

Min 0.025mm - Max 0.1mm<br />

Roll Dia. 300mm<br />

Web: 15091<br />

AUSMADE<br />

Jacketed Cooker with<br />

Scraper Mixing Arm.<br />

Used in a food factory<br />

making dips.It is fitted<br />

with a gate type scraper<br />

arm. Dimensions:<br />

700mm OD x 750mm D<br />

(approximately 280L)<br />

Web: 15001<br />

URSCHEL Dicer,<br />

Slicer, Strip Cutter<br />

Excellent for small to<br />

intermediate range of<br />

dices. Output: 1 - 5 ton/<br />

hr. Cut size dependant.<br />

From 1/16” x 1/8” x<br />

1/16’ [1.6mm x 3.2mm<br />

x 1.6mm] to 3/8” x 1/2”<br />

x 3/4” [9.5mm x 13mm<br />

x 19mm] can be made.<br />

Web: 14818<br />

Contech 180º bend<br />

Was used in a food<br />

manufacturing plant.<br />

Belt width - 800mm w<br />

Radius - 600mm<br />

Diameter: 3300mm<br />

Height: above floor 1300mm<br />

It features heavy duty pvc belt<br />

with tensioning springs or cleats<br />

for adjusting the belt.<br />

Powered by 1.1 Kw, 415v ac,<br />

1400rpm reduced by a sew<br />

gearbox to 130rpm three phase,<br />

tefc motor.<br />

Web: 15135<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info<br />

9.

SELECT FROM<br />

USED<br />

The hand picked<br />

encomical alternative.<br />

over 2000 new & used machines<br />

IZUMI FOOD<br />

MACHINE CO.<br />

Jacketed Mixing/Melting<br />

Tank (skid mounted /<br />

mobile). Was used in<br />

the food industry to melt<br />

chocolate. Fitted with<br />

an impeller with a wide<br />

base. Tank Dimensions:<br />

525mm OD x 700mm H<br />

Capacity: 90L<br />

Web: 14996<br />

AUSMADE<br />

Mayonnaise System<br />

Consists of :<br />

1) A header tank<br />

measuring 600mm OD x<br />

600mm D (approx 150L)<br />

2) A mixing tank<br />

measuring 1000mm<br />

OD x 600mm D (approx<br />

400L) fitted with a<br />

clamp-on agitator driven<br />

by a direct drive motor.<br />

c) Pump<br />

Web: 14993<br />

Z ARM<br />

MIXER<br />

KREBS ENGINEERING<br />

s/s Z Arm Mixer<br />

This stainless steel<br />

Krebs Z-Arm Mixer was<br />

used in a bakery plant,<br />

probably on biscuit<br />

dough. It is mounted on<br />

a s/s frame and is fitted<br />

with a hydraulic tilt as<br />

well as variable speed<br />

mixing arms.<br />

Working capacity,<br />

approximately 1000L<br />

Overall Capacity:<br />

Approximately 1400L<br />

Trough Dimensions:<br />

1070mm H x 1120mm D<br />

x 1200mm L<br />

SEW Inverter LE7-100-<br />

1753 400V<br />

Motor Size: 40kW<br />

Web: 15139<br />

PPN PICK OF THE<br />

MONTH!<br />

URSCHEL<br />

Comitrol <strong>Process</strong>or / Mill<br />

(chopping, flake cutting,<br />

granulating, pureeing,<br />

emulsifying). used in a<br />

confectionery plant.Great<br />

for small volume<br />

production. A wide<br />

selection of cutting heads<br />

and impellers available.<br />

Footprint : 550mm L x<br />

602mm W x 1050mm H<br />

Web: 15019<br />

AUSMADE<br />

Steam Blanching<br />

Trough/Tank (removable<br />

mesh baskets). Steam<br />

blanching trough is<br />

supplied with a with a<br />

stainless steel removable<br />

basket, fitted with<br />

holding lugs. Basket size:<br />

1100mm L x 400mm W<br />

x 410mm D.<br />

Web: 14999<br />

FURPHY Fat or<br />

Chocolate Melting<br />

Tank (jacketed with<br />

heating bars)<br />

Designed for chocolate<br />

or fat block melting tank.<br />

Sloping tank facilitates<br />

gravity flow. Outlet,<br />

35mm butterfly valve<br />

Heating area of tubes:<br />

2.88m 2 . Overall capacity<br />

of tank 650L.<br />

Web: 15096<br />

BRAVO GEL-MATIC Ice<br />

Cream Machine<br />

suitable for ice cream<br />

shops and hotels. Its<br />

freezing capabilities<br />

are similar to larger<br />

professional machines.<br />

Output: 30L.<br />

Web: 14737<br />

10<br />

.<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info

ARRANGE A TRIAL NOW...<br />

USED<br />

The hand picked<br />

encomical alternative.<br />

Call sales, +61 (03) 9791 7011<br />

Cheese or meat declumper<br />

Cheese or meat layer<br />

thickness spreader<br />

Return product conveyor<br />

CFS WOLFKING<br />

Meat Pump. Vane<br />

Pump is a positive<br />

displacement pump with<br />

radially moving vanes.<br />

Designed for all-round<br />

pumping applications<br />

eg. ground meat and<br />

trimmings, emulsions<br />

and pre-blends, dairy<br />

products, dough and<br />

vegetables.<br />

Web: 15074<br />

MONO Helical<br />

Rotary Pump /<br />

Progressive Cavity<br />

(2”- 50mm, mobile)<br />

Was used in the food<br />

industry. It features a<br />

stainless steel casing and<br />

baseplate and is direct<br />

driven by a 415V AC,<br />

Three Phase, 0.55kW -<br />

TEFC, Gear motor. IP55,<br />

50Hz<br />

Web: 15050<br />

SOMIC<br />

Somic Dough Sheeter or<br />

extruder is used on pie<br />

crusts, pizza, pita etc.<br />

Has own platform!<br />

Roll type: Fluted stainless<br />

steel working width of<br />

Roller: Approx 340mm<br />

Web: 15072<br />

PIZZA DECORATOR TOPPER<br />

(streusel machine shredded<br />

cheese etc)<br />

Dimensions:<br />

980 mm Wide x 2200 mm<br />

Long, which is controlled by<br />

a touchscreen with digital<br />

display. All s/s.<br />

Web: 15071<br />

LINX Ink Jet Printer<br />

designed especially<br />

for basic coding<br />

appliocations.<br />

Print Speed - 325m/<br />

minute •Number of lines<br />

- up to 4 •Maximum<br />

Print Height - Up to<br />

10mm.<br />

Web: 15039<br />

ANRITSU<br />

Checkweigher with<br />

Rejector. Capacity:<br />

0.5gmin & 60g max<br />

d= 0.005g<br />

Speed: 150 pcs/<br />

min (max - product<br />

dependent)<br />

Web: 14622<br />

VOLPAK<br />

Side Load RSC Case<br />

Packer (small<br />

footprint<br />

(fully auto)<br />

Ideal for the automatic<br />

casing of rigid products<br />

such as carton boxes.<br />

Min Format (w x h x l; mm.)<br />

< 200 x 150 x 120<br />

Max. Format (w x h x l;mm)<br />

> 600 x 400 x 400.<br />

Web: 14902<br />

AUSMADE<br />

Mesh Cooling Belt (s/s)<br />

S/S mesh cooling belt or<br />

conveyor used with a refrigerated<br />

cooling tunnel<br />

in the bakery industry.<br />

Dimensions: 950mm W x<br />

5mtrs long x 900mm H<br />

Fitted with a variable<br />

speed geared motor.<br />

Web: 14278<br />

Stainless steel<br />

jacketed rectangular<br />

bath ot tank. Used for<br />

warming or cooling. Fitted<br />

with a hot water jacket for<br />

heating/cooling.<br />

Trough /Bath Dimensions:<br />

2000mm L x 1300mm W<br />

x 600mm D<br />

Capacity:1500L<br />

Fitted with a 60mm outlet<br />

Web: 15051<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE C O MPLE T E PACK AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com Blog: processplant.info<br />

11.

Visit: www.process.info the PPN blog site for lastest products, tech talk, weekly specials and more!<br />

iopak spares, we’ve got plenty<br />

Don’t get caught with your plants down, stock up on your spare parts now. Order online: www.iopak.com<br />

ahead of the pack<br />

We have a complete range of spare<br />

parts and stainless steel fittings<br />

available for all the iopak machines<br />

we sell.<br />

Order online now at:<br />

www.iopak.com<br />

See the part you need, order online, and<br />

we’ll send it to you overnight.<br />

Payment:<br />

We accept Visa, Mastercard or<br />

American Express through Securepay.<br />

No card details are revealed.<br />

Tax Invoice:<br />

A tax invoice is issued when order is<br />

placed.<br />

Delivery:<br />

Spare parts are delivered by overnight<br />

express post. A standard postage<br />

and handling fee of $15, except for<br />

heavy items will be charged. Overseas<br />

delivery is $50.<br />

We service most capital cities in Australia<br />

Due to the thousands of new and used machines sold throughout Australia<br />

and New Zealand we have national service agents to look after your needs.<br />

You’ll find agents in Perth, Adelaide, Sydney and Brisbane. PPN’s head office is<br />

in Melbourne. We standby and support all our new machines and used machines<br />

(when prior arrangements have been made).<br />

At PPN our customers needs come first and we will make every effort to ensure<br />

customer satisfaction.<br />

Please note all prices are exclusive of GST<br />

All details are correct at the time of printing<br />

but subject to change without notice.<br />

O&E 2011<br />

PPN<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T HE COMPLE T E PACK AGE<br />

3-5 Capital Drive, Dandenong South Victoria 3175 Australia<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com<br />

Web: www.processplant.com | Blog: processplant.info