PPN - Process Plant Network

PPN - Process Plant Network

PPN - Process Plant Network

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T hE COMPLE T E PACk AGE ahead of the pack<br />

AuGusT/sePTeMbeR 2010<br />

Bakery Edition<br />

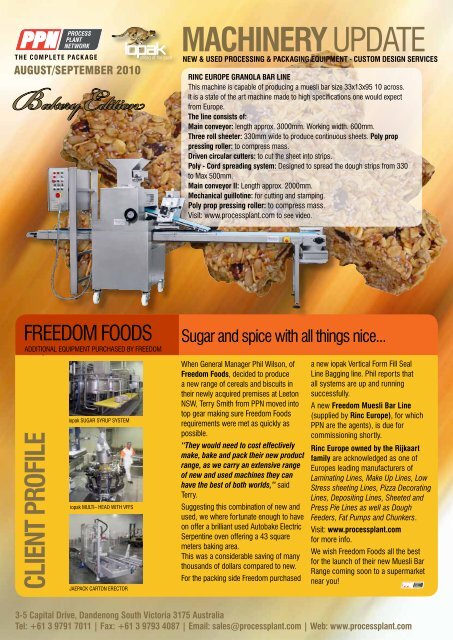

FREEDOM FOODS<br />

S Supply Group<br />

many<br />

ADDITIONAL EQUIPMENT PURCHASED BY FREEDOM<br />

CLiEnT PrOFiLE<br />

iopak SUGAR SYRUP SYSTEM<br />

iopak MULTI– HEAD WITH VFFS<br />

JAEPACK CARTON ERECTOR<br />

MAChinEry UPDATE<br />

nEW & USED PrOCESSinG & PACkAGinG EQUiPMEnT - CUSTOM DESiGn SErViCES<br />

rinC EUrOPE GrAnOLA bAr LinE<br />

This machine is capable of producing a muesli bar size 33x13x95 10 across.<br />

It is a state of the art machine made to high specifications one would expect<br />

from Europe.<br />

The line consists of:<br />

Main conveyor: length approx. 3000mm. Working width. 600mm.<br />

Three roll sheeter: 330mm wide to produce continuous sheets. Poly prop<br />

pressing roller: to compress mass.<br />

Driven circular cutters: to cut the sheet into strips.<br />

Poly - Cord spreading system: Designed to spread the dough strips from 330<br />

to Max 500mm.<br />

Main conveyor ii: Length approx. 2000mm.<br />

Mechanical guillotine: for cutting and stamping.<br />

Poly prop pressing roller: to compress mass.<br />

Visit: www.processplant.com to see video.<br />

Sugar and spice with all things nice...<br />

When General Manager Phil Wilson, of<br />

Freedom Foods, decided to produce<br />

a new range of cereals and biscuits in<br />

their newly acquired premises at Leeton<br />

NSW, Terry Smith from <strong>PPN</strong> moved into<br />

top gear making sure Freedom Foods<br />

requirements were met as quickly as<br />

possible.<br />

“They would need to cost effectively<br />

make, bake and pack their new product<br />

range, as we carry an extensive range<br />

of new and used machines they can<br />

have the best of both worlds,” said<br />

Terry.<br />

Suggesting this combination of new and<br />

used, we where fortunate enough to have<br />

on offer a brilliant used Autobake Electric<br />

Serpentine oven offering a 43 square<br />

meters baking area.<br />

This was a considerable saving of many<br />

thousands of dollars compared to new.<br />

For the packing side Freedom purchased<br />

a new iopak Vertical Form Fill Seal<br />

Line Bagging line. Phil reports that<br />

all systems are up and running<br />

successfully.<br />

A new Freedom Muesli bar Line<br />

(supplied by rinc Europe), for which<br />

<strong>PPN</strong> are the agents), is due for<br />

commissioning shortly.<br />

rinc Europe owned by the rijkaart<br />

family are acknowledged as one of<br />

Europes leading manufacturers of<br />

Laminating Lines, Make Up Lines, Low<br />

Stress sheeting Lines, Pizza Decorating<br />

Lines, Depositing Lines, Sheeted and<br />

Press Pie Lines as well as Dough<br />

Feeders, Fat Pumps and Chunkers.<br />

Visit: www.processplant.com<br />

for more info.<br />

We wish Freedom Foods all the best<br />

for the launch of their new Muesli Bar<br />

Range coming soon to a supermarket<br />

near you!<br />

3-5 Capital Drive, Dandenong South Victoria 3175 Australia<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

PROCESS<br />

PLANT <strong>PPN</strong> NETWORK

iopak Sugar Syrup Preparation System is a really<br />

simple mix and match module with many uses.<br />

The plant consists of:<br />

1) 500L S/S steam jacketed contra-rotating mixing<br />

kettle or (batch dissolver) for syrup preparation<br />

2) 500L S/S steam jacketed single motion<br />

scrape-surfaced delivery tank<br />

PArT TWO MAyOnnAiSE<br />

See part one on our ‘new blog site’<br />

http://processplant.info/<br />

ahead of the pack<br />

3) 1,000L S/S steam jacketed tank for hot water<br />

preparation including<br />

hot water supply pump for product and CIP lines.<br />

4) Stainless steel skid and sub-frame<br />

5) 2” S/S jacketed product pump<br />

<strong>PPN</strong><br />

TECHNOTALK<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

6) Stainless steel piping including valves<br />

(see sketch attached)<br />

7) CIP and product Lines including valves<br />

(refer to the attached sketch)<br />

8) Steam modules for syrup preparation cooker,<br />

syrup delivery and hot water set.<br />

Web 13937<br />

the all new Qualitec FOOD TEChnOLOGy Combo & PACkAGinG packs real punch!<br />

By Bradley Wardrop-Brown<br />

www.bluoak.com.au<br />

(FirST PArT PUbLiShED APriL MAy 2010 EDiTiOn)<br />

Welcome to part two of “how do you make that” in the last edition we looked at<br />

the formation of emulsions and basic formulations. This time we will look at actually<br />

making mayonnaise on a commercial scale using the iopak EMULSyS 1000<br />

(Multi-purpose Blending Emulsifier). This unit will have you making mayonnaise<br />

like an expert in minutes, due to its compact simple yet effective design;<br />

80% Oil Formula, Vegetable oil 80%, Pasteurised Egg yolk 6%, Wine Vinegar 4%,<br />

White Manufacturers Sugar 1%, Salt 1%, Spices (e.g. mustard) 0.5%<br />

Filtered Water 7.5%<br />

We will start with the traditional recipe used as the basis for many high quality<br />

sauces and condiments. Using the <strong>PPN</strong> Emulsys 1000 system, as the name suggests,<br />

it is possible to make up to 1000 litres of Mayonnaise in a single batch as a<br />

finished product ready for filling or as a base for other products.<br />

PRocess<br />

In the main blender, add the water, vinegar, sugar, salt, spices (spices blended<br />

with salt and sugar) and finally egg yolk and mix well with scraped surface<br />

contra-rotating mixer. There are a number of methods of adding the oil to the mix<br />

to form a stable emulsion and these include;<br />

Adding oil directly to the liquid mix in a continuous stream whilst passing the full<br />

mix through the 3-stage in line emulsifier via the lobe pump,<br />

Adding oil into a hopper connected to the suction end of the lobe pump, controlling<br />

addition rate of oil through a ball valve with gravity feed.<br />

Adding oil through the optional auto oil bleed in/controlled pump rate feed at the<br />

suction end of the 3-stage in line emulsifier- This option provides the most control<br />

over finished mayonnaise viscosity and stability.<br />

It is critical that the oil is added at the right rate, too slow can cause over mixing<br />

and heating of the emulsion, to quick will cause an incomplete emulsion to form<br />

with oil later rising to the surface of the finished mayonnaise<br />

The entire mix can be recirculated with additional oil added until all of the oil has<br />

been emulsified into the product. Care should be taken to prevent over heating<br />

of the formed mayonnaise due to heat loads produced through pumps and<br />

emulsifiers and the addition of the optional cooling jacket on the Emulsys 1000<br />

2.<br />

BAKERY<br />

You may be interested in the following item<br />

can prevent this. Overheating of the mayonnaise can cause the proteins in the egg<br />

yolk to denature and coagulate and this will result in the loss of the emulsion.<br />

Additional flavours and ingredients can be added directly into the hopper utilising<br />

the efficient mixing profile of the contra-rotating stirrers in the tank or the mayonnaise<br />

can be pumped to a separate mixing tank/holding tank ready for filling.<br />

Note: Low fat mayonnaise is made in a very similar way however the water/egg<br />

and dry material blend is passed through the emulsifier to ensure complete mixing<br />

and hydration of the pre-gelatinised starches and vegetable gums prior to the<br />

addition of the oil phase.<br />

PRoducTs MAde fRoM MAyonnAise<br />

There are a number of very familiar sauces and condiments made from mayonnaise<br />

and these include;<br />

Tartare sauce- to mayonnaise add chopped gherkins, minced onions, minced<br />

capers, lemon juice, ground black pepper.<br />

Thousand island dressing- to mayonnaise add, Tabasco sauce, chopped green<br />

capsicum, chopped red capsicum, tomato sauce, minced onion and ground black<br />

pepper. Garlic Aioli- to mayonnaise ( made with vegetable oil and olive oil blend)-<br />

roasted garlic paste, salt, fresh garlic mince and lemon juice<br />

Dill and Mustard sauce- to mayonnaise add chopped dried or fresh dill, Dijon<br />

mustard, seeded mustard, lemon juice, ground black pepper<br />

All of the sauces developed above are subject to potential microbiological spoilage<br />

due to the addition of fresh ingredients. It is very important that the products<br />

are developed in conjunction with an experienced Food Technologist or Food<br />

Scientist to ensure the products are stable prior to release for sale and that the<br />

materials added are free from pathogens. The products described above are long<br />

shelf life refrigerated products however it is possible to produce shelf stable products<br />

with the use of preservatives, antioxidants and/or product design to prevent<br />

spoilage during ambient storage. Please contact BOI Food Tech for advice for your<br />

individual application.<br />

Bradley Wardrop-Brown<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

PROCESS<br />

PLANT <strong>PPN</strong> NETWORK

Used PERFECT PROCESSING EQUIPMENT<br />

Floor Stock<br />

ArSOPi Jacketed Mixing Tank (Food<br />

grade - never used) with agitator,<br />

spray ball etc. Tank was designed<br />

as a mixing vessel in a food factory<br />

plant.(Unused, still in its original<br />

crate).1400mm High x 950mm O/D<br />

with Agitation: Centre Inlet 100mm,<br />

M/ Hole 300mm + 50mm inlet 2 x<br />

20/32mm inlet, other end 1 x 75mm<br />

+ 1 x 50mm. - Jacket Full Length x<br />

50mm Thick insulation.<br />

Web 14665<br />

Floor Stock Floor Stock<br />

AUSMADE Jacketed Mixing Tank<br />

with agitator. A geared motor drives<br />

the agitator.<br />

Tank Dimensions (capacity)<br />

1000mm ø OD x 1500mm H OD<br />

Overall capacity: 900L<br />

Jacket: Oil or Water<br />

Tank has dished ends.<br />

Manhole at top approximately<br />

450mm<br />

Web 14576<br />

Floor Stock<br />

CONTHERM (6x9)<br />

SCrAPED SUrFACE<br />

hEAT EXChAnGErS<br />

Excellent for, viscous foods, gravy,<br />

sauces, whipped products, aerated<br />

products, and personal care products.<br />

SPECiFiCATiOnS<br />

Design Pressure : 450PSIA<br />

Max Working Pressure : 450PSIA<br />

Design Temperature 315 Deg C<br />

Media Chamber Specifications<br />

Design Pressure : 225 PSIA<br />

Max Working Pressure : 225 PSIA<br />

Web 8343<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

Floor Stock<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

hELiOS Electric Kettle(Hot Pot)<br />

with APV Lobe pump<br />

A mobile self heated cooker fitted<br />

with 3 x Helios heaters as well as<br />

a lobe pump. Overall Dimensions:<br />

830mm ID x 700mm D<br />

Possible working capacity: 250L<br />

3 X Helios Heaters. 240V ea, 12.00<br />

Watts each. Pump - APV Crepaco<br />

Model P3P. Motor Size: 0.75kW<br />

Web 13590<br />

AUSMADE Jacketed Conicalbottomed<br />

tank on platform<br />

Used as a header tank for liquids<br />

and emulsions. Conical section<br />

is dimple jacketed for heating or<br />

cooling.<br />

Volume 500 litres<br />

Dimensions: Dia 1060 mm<br />

Straight side 400 mm<br />

Cone 500 mm<br />

Height from outlet to ground: 850mm<br />

Web 14637<br />

UrSChEL Model OV<br />

A most efficient machine for<br />

crosscutting. Excellent for<br />

asparagus, bamboo shoots,<br />

bananas, carrots, celery,<br />

cucumbers, etc. 1350-2700 kgs/hr<br />

on carrots depending on diameter<br />

and method of feeding.<br />

Size of Slices: 1.6 mm to 34 mm<br />

depending on knife blades fitted.<br />

Web 12129<br />

Floor Stock<br />

ribbOn bLEnDEr<br />

Chemical <strong>Plant</strong> & Engineering<br />

500L s/s ribbon blender fitted<br />

with single shaft double helix ribbons.<br />

Approximately 400L overall<br />

Inside dimensions<br />

Depth: 620mm<br />

Length :1850mm<br />

Width : 500mm<br />

Web 14602<br />

Floor Stock<br />

3.

4.<br />

Used<br />

Manufactured in the Netherlands,<br />

in pristine condition.<br />

The line consists of the following items:<br />

1) 3 Roll sheeter (up to 0,5mm adjustment)<br />

2) Mechanical guillotine (this moves up and down)<br />

stroke length: 60mm<br />

Number of strokes: adjustable<br />

Hack width: 600mm<br />

Drive: abm motor<br />

Used<br />

RADEMAKER BV Shortbread Forming System<br />

Application: the mechanical guillotine is designed<br />

to cut a continuous sheet of dough in desired<br />

lengths. The unit is generally mounted on a<br />

retractable belt.<br />

3) Gauging rolls<br />

4) Slitting rolls with comb<br />

5) Indexing/diverger/spreader system for trays.<br />

Web 12797<br />

Used<br />

BLUM + CO 800mm W Chocolate Enrober<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

Used<br />

Priced to clear! Call sales<br />

now (03) 9791 7011<br />

This Enrober is designed to process all<br />

fluid chocolate & cocoa masses involved<br />

in coating of candies and biscuits.<br />

Width of Enrober: 800mm<br />

Bottomer chocolate applicator is a feature.<br />

b)The infeed conveyor is included<br />

c) Stringer: Not included<br />

Web 14643<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

Priced to clear! Call sales<br />

now (03) 9791 7011

Used<br />

Floor Stock<br />

Floor Stock<br />

Floor Stock<br />

Floor Stock<br />

COME AND INSPECT OUR INSPECTION EQUIPMENT<br />

bAyLiSS was used in a biscuit plant.<br />

Tested and calibrated and is running<br />

well on biscuits and chocolates.<br />

Sensitivity: 1.5fe and 2.00mm s/s<br />

Belt Width: 50mm H x 800mm W<br />

Belt Length: 2000mm<br />

Electrics: 415V, 50Hz<br />

Height above floor: 1000mm<br />

(adjustable)<br />

Overall Dimensions: 2000mm L x<br />

1200mm W x 1140mm L<br />

Web 14202<br />

nikkA Metal Detector (Belt type)<br />

Aperture Size: 200 H mm x 480 W<br />

YOM: 2000<br />

Web 14503<br />

iShiDA/SAFELinE<br />

Metal Detector (Belt Size 350mm)<br />

In excellent condition.<br />

Aperture:<br />

Approx 85mm H x 400 W<br />

(belt size 350mm)<br />

This unit is a ferrocheck<br />

for use with metalised<br />

film.<br />

Detects 1.2fe and 3.0 s/s<br />

Web 13716<br />

locK PiPELinE METAL DETECTOr<br />

(all s/s with touchscreen)<br />

Designed for contaminant detection<br />

in products transported by pipeline, eg.<br />

meat, vegetables, preserves, soups,<br />

pet foods, dairy products, powders<br />

and pastes.<br />

Web 14647<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

A perfect combination<br />

Floor Stock<br />

Floor Stock<br />

Floor Stock<br />

Floor Stock<br />

AnriTSU/iShiDA Metal Detector/<br />

Checkweigher Combo<br />

Model KD802 AW<br />

Pass Height: 95mm<br />

Belt Width - 350mm<br />

Pass Width: 450mm<br />

Belt Speed: 10 - 73 metres/min<br />

(speed variable)<br />

Max Product weight: 5kg<br />

Classification: IP 65<br />

Web 14688<br />

iShiDA Checkweigher<br />

Weight: Max 18kg<br />

Conveyor Speed: 21m/min<br />

Note: Belt stops and an alarm<br />

sounds for incorrect weight<br />

Weighing belt 550 mm long<br />

Web 14688<br />

GOrinG kErr<br />

Metal Detector (Belt Type)<br />

Metal Detector Opening:<br />

550mm W x 55mm H<br />

Belt Dimensions: 2350mm L x<br />

500mm W<br />

Single Phase, 10 Amp, 50Hz<br />

Touch panel control<br />

Belt stop + Buzzer Reject System<br />

L: 2350 W: 1050 H:1070<br />

Web 14696<br />

yAMATO Checkweigher<br />

Weigh Range : 5g - 300g<br />

Accuracy: 0.5g<br />

Detecting Device: Load Cell.<br />

Checking Method: 3 Categories 2<br />

Directions [Over, Under, Accept]<br />

Web 5845<br />

LOMA iQ² Series Metal Detector<br />

was used in the<br />

confectionery industry.<br />

Aperture:75mm H x 450mm W<br />

Sensitivity: 1.0 Fe, 1.5 S/S<br />

Web 13587<br />

Used<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

Priced to clear! Call sales<br />

now (03) 9791 7011<br />

5.

6.<br />

Used<br />

PAcKMATic Shrink Tunnel and<br />

Sleeve wrapper with stacking device.<br />

Tunnel aperture 460 x 240 high.<br />

Web 13743<br />

Floor Stock<br />

LOOKING FOR SHRINK WRAPPERS?<br />

yU-XUAn PACkAGinG<br />

TEChnOLOGy LTD<br />

Shrink Tunnel and Sleeve wrapper<br />

with stacking device. Tunnel aperture<br />

460 x 240 high. XU-YUAN is a<br />

convective heat shrink tunnel that<br />

processed tamper-evident bands and<br />

sleeve/label applications.<br />

Tunnel is suitable for PVC, PET, OPS<br />

shrink packaging materials use.<br />

Suitable for shrink wrapping a wide<br />

variety of bottle shapes etc.<br />

- Accurate temperature control to<br />

+/- 5 degree.<br />

Web 14687<br />

Floor Stock<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

MPi Shrink TUnnEL<br />

(s/s - used on tamper evident<br />

bands) This is a convective heat<br />

shrink tunnel that processes<br />

tamper-evident bands<br />

and sleeve/label applications.<br />

Tunnel Dimensions:<br />

1,500 L x 150mm H x 180mm W<br />

Web 14570<br />

Floor Stock<br />

MPi Shrink MASTEr<br />

Multi stack collator fully digital<br />

infeed and out feed speed<br />

Dimensions: 670mm w x 330mm h<br />

Maximum film width and sealing<br />

element: 800mm wide<br />

Electrics: 3 phase, 415 volt, 50 hz<br />

Web 14682<br />

Floor Stock

HERE’S EIGHT OF THE BEST!<br />

FUJi<br />

Automatic Shrink Flow Wrapper<br />

(high speed) with shrink tunnel.<br />

Operating Speed: 10 - 40pcs/min.<br />

product dependent.<br />

Packaging Material:<br />

Heat Shrinkable Film.<br />

Bag Dimensions:<br />

Length: 100mm - 250mm L<br />

Width: 80mm 240mm W<br />

Height: 14 - 80mm H<br />

NB. Complete with shrink tunnel.<br />

Web 12713<br />

Floor Stock<br />

WE HAVE OVER 2000 NEW AND USED MACHINES ON OFFER<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

MiniPACk<br />

L- Bar Shrink Wrap Machine<br />

enables a package to be sealed and<br />

shrunk in one operation. Features:<br />

Shrink timer, sealing timer, and<br />

adjustable temperature control.<br />

Max dimension of Seal Area:<br />

420mm x 550mm Max dimension<br />

of pack: 350 x 500 x 200 H. Voltage:<br />

Single phase<br />

Max power starting up: 3.3kW<br />

Web 13692<br />

Floor Stock<br />

PACkMATiC CLEArPACk<br />

Sleeve Wrapper (Collator & Tunnel<br />

- all s/s) Model: 50ASW25 (Sleeve)<br />

50ST30 (tunnel)<br />

The Packmatic 50 ASW Automatic<br />

Sleeve Wrapper makes distribution<br />

packs in LDPE / PVC shrink<br />

films that will help you to lower<br />

your packaging costs and increase<br />

sales.<br />

Web 14447<br />

Floor Stock<br />

hEATShrink AUSTrALiA<br />

Envelope Former<br />

It simultaneously feeds 480mm Max<br />

width films to both the bottom and the<br />

top of the product.<br />

Footprint - 2380mm L x 1250mm W x<br />

1420mm H.<br />

heat Shrink Tunnel :-<br />

Tunnel Internal Dimensions 1225mm L<br />

x 185mm H x 465mm W.<br />

Footprint - L 2000mm x W 780mm x<br />

H 1550mm.<br />

Web 8251<br />

Floor Stock<br />

7.

8.<br />

Used<br />

We have over 2000 machines at our warehouses.<br />

Call sales on (03) 9791 7011 to find the machine for you.<br />

rEXPOrT<br />

Split roller extendable<br />

(telescopic) conveyor<br />

slit rollers 200mm w (450mm<br />

overall width) 2,630mm<br />

closed expands and contracts.<br />

Web 13154<br />

Floor Stock<br />

AUSMADE<br />

Cap Elevator S/S<br />

1600mm 1400mm hopper<br />

mouth opening set at<br />

1400mm above floor level.<br />

The discharge point is<br />

1780mm above floor level and<br />

the belt cleat pitch is 100mm.<br />

Web 9001<br />

Floor Stock<br />

Used<br />

Used<br />

ALFA LAVAL<br />

Clarifier Centrifuge<br />

Worm Wheel Shaft:<br />

1700-1800r/m<br />

Tachometer:1700-1800r/m<br />

Revolution Counter:<br />

142-150r/m motors18.5kw<br />

60Hz1765rpm<br />

Web 14691<br />

Floor Stock<br />

<strong>PPN</strong><br />

TETRA LAVAL<br />

ALFA LAVAL<br />

PROCESS<br />

PLANT<br />

NETWORK<br />

DOnALDSOn TOriT<br />

The reverse pulse stainless<br />

steel conical cylindrical dust<br />

filter or collector is fitted with<br />

a pleated cartridge held in<br />

a stainless steel cartridge<br />

holder.<br />

Web 13485<br />

Floor Stock<br />

GODFrEy hOWDEn<br />

Bulk Systems Blower<br />

Suitable for use in a particle/<br />

granular pneumatic conveying<br />

system. It is fitted with a 2”<br />

inlet to the filter chamber and<br />

has a 3” outlet.<br />

The system is built on a mild<br />

steel base frame.<br />

Web 9052<br />

Floor Stock<br />

TETrA LAVAL<br />

Separator Centrifuge<br />

<strong>Process</strong> <strong>Plant</strong> has this<br />

magnificent separator<br />

available.<br />

It was previously<br />

used in the<br />

dairy industry.<br />

Web 14690<br />

Floor Stock<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com

Used MATERIALS HANDLING<br />

SAFETECh SCiSSOr LiFT<br />

WiTh TUrnTAbLE<br />

Lift capacity: 1000kg<br />

Platform dimensions:<br />

1050mm w x 1500mm l<br />

Accessories included:<br />

Chequerplate platform<br />

Safety skirts<br />

Turntables on the deck<br />

Web 14574<br />

Floor Stock<br />

iShiDA<br />

Electromagnetic Vibratory<br />

Feeder. 500mm W x 630mm<br />

L hopper depth 295mm.<br />

Web 13771<br />

Floor Stock<br />

AUSMADE<br />

Soft dough declustering/chunking<br />

hopper with incline conveyor.<br />

Chunking/ Fitted with a rotating<br />

shaft with paddles. The intralox<br />

incline conveyor is cleated.<br />

Hopper Dimensions:<br />

Width : 856mm<br />

Length : 1045mm<br />

Depth : 830mm<br />

1.2A)<br />

Web 14631<br />

Floor Stock<br />

AUSMADE<br />

Fitted with stainless steel side tables<br />

on each side measuring the length<br />

of the conveyor.The belt is edged by<br />

adjustable s/s guide rails.<br />

Belt Dimensions: 80mm W x 2150mm<br />

L x 900mm above ground<br />

Side tables (s/s) on each side: 450mm<br />

W x 2150mm L<br />

Web 13534<br />

Floor Stock<br />

biLWinCO<br />

Mobile Multihead Weigher Lifter<br />

The multihead weigher is mounted on<br />

the support frame, which is equipped<br />

with wheels and a lifting/lowering<br />

device allowing you to adjust the height<br />

of the weigher to different package<br />

sizes. Size capacity:approx 500kg<br />

Web 14468<br />

Floor Stock<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

AUSMADE bOWL TiPPEr<br />

LiFTEr - hyDrAULiC<br />

Set up for bowl diameter of 1060mm.<br />

L:1450 W:1500 H:1295<br />

Fully s/S bpwl lifter/tipper used on<br />

mixing bowls in bakery plant.<br />

Web 14409<br />

Floor Stock<br />

LiFTEr TrOLLEy (STAinLESS STEEL)<br />

Very versatile back saving lifter table<br />

which is highly manoeuvrable on four<br />

swivel castors.<br />

Larger than normal lifter table:<br />

1070mml x 700mm with raised sides.<br />

Height of lift: approximately 750mm h<br />

Lift weight capacity: 150 kg<br />

Web 14250<br />

Floor Stock<br />

MArUyASU kikAi<br />

Belt conveyor with side guide rails<br />

conveyor is fitted with adjustable<br />

aluminium guide rails.<br />

Dimensions: 790mm W x 1000mm L<br />

x 800mm H<br />

Variable speed control<br />

Frame: aluminium<br />

Adjustable height<br />

Web 13790<br />

Floor Stock<br />

kAWASAki<br />

Usable belt width approx 1000mm w<br />

Overall width: 1500mm<br />

Height above ground: 1100mm<br />

(adjustable screw feet)<br />

Electrics: 0.75Kw,50hhz, 1430 rpm<br />

Complete with stop/start button<br />

Yom: 97<br />

Web 14612<br />

Floor Stock<br />

COMbinA<br />

Side Labeller Combina Classic.<br />

Suitable for all labelling tasks<br />

(wraparound, top, bottom, front/back<br />

etc). D.C. drive motor with clutch-brake<br />

combination. Hot foil print, debossing<br />

unit and rotary print unit are possible<br />

as options. Label web passages: 100<br />

mm, 165 mm, 230 mm, 310 mm<br />

Made of rust resistant materials<br />

Web 14625<br />

Floor Stock<br />

9.

10.<br />

For the best in bakery go RINC...<br />

MULTi CrOSS rOLLEr<br />

A look inside the Multi-Cross Roller allows us to see the<br />

two sets of rollers gently pressing the dough outwards to<br />

the edge of the conveyor. The use of multiple rollers greatly<br />

reduces the tension which would be placed on the dough<br />

by a standard cross pinner. There are no chains or bearings<br />

running above the dough sheet therefore eliminating<br />

the risk of metal and lubrication contamination<br />

and making the unit practically<br />

maintenance free.<br />

DirECT DriVE<br />

Rinc Europe’s “direct drive” sheeting heads eliminate<br />

the need for chains and sprockets. Conveniently accessed<br />

through a hinged interlocked door, the drives are no longer<br />

‘underneath’ the machine. A central greasing system makes<br />

maintenance easy and the bolt on standard bearings allow<br />

for quick and easy replacement.<br />

Applied Food Technology S Y S T E M<br />

EASy OPErATiOn<br />

The Compact Laminator comes standard with a touch<br />

screen control panel. This allows the operator to<br />

visualise the line, while changing the settings.<br />

The PLC behind the panel stores up to 99 different<br />

programs and stores all the required settings to<br />

make this machine user friendly.<br />

LAMinATinG<br />

The compact laminator is unique in the<br />

world of laminators. In just a fraction of<br />

the floor space normally required by a<br />

laminator, it provides the same capabilities<br />

as a full size laminator without compromising<br />

the quality of the final product.<br />

The dough is supported by the servo<br />

driven laminating rollers to ensure the fat<br />

layer remains intact inside the dough.<br />

Mixing it with the best, the pressur<br />

Looking for the right mix?<br />

Check out the details from unimixer and Gorreri, you’ll be really impressed.<br />

The PlanetMixer range (120, 200, 300, 400 and 600) is extraordinary in its capabilities.<br />

The PlanetMixer achieves remarkable results for any type of soft mixtures such as wire<br />

cut biscuits, dosed and injected products, all types of creams, raw and cooked ones (by<br />

utilizing a double walled basin thermo-regulated with steam, bain-marie, or diathermic oil);<br />

fresh whipped cream, meringues, pâte à chou, as well as hard doughs as rotative biscuits,<br />

pie short bread, etc. But we are only touching the surface of this amazing machine.<br />

Call sales on: 9791 7011<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com

The Rinc Compact Laminator does it better ahead<br />

DOUGh QUALiTy<br />

The main focus of Rinc Europe is to produce<br />

machines that make the best possible<br />

dough products for its customers.<br />

The use of Teflon coated, large multi rollers<br />

guarantees the ultimate end result. The<br />

Large Multi Roller has reduction capacity of<br />

10 to 1. The twelve top rollers have a total<br />

diameter of 400mm.<br />

FAT PUMP<br />

A view inside the Rinc Fat Pump reveals three horizontal<br />

augers and three vertical augers. These augers will take<br />

full blocks of fat and feed them consistently into the mono<br />

pump which in turn provides the sheet of dough with a<br />

perfect layer of fat.<br />

WAnT The VeRy besT?<br />

This is the ultimate in<br />

compact laminators with<br />

an amazing range of options<br />

available.<br />

Made to the highest possible<br />

standards this is the best<br />

the netherlands has to offer.<br />

you may purchase the<br />

whole system or individual<br />

modules to suit.<br />

if you produce the best, you<br />

need the best machine to<br />

do the job.<br />

call Terry at sales on<br />

(03) 9791 7011<br />

Web 14049<br />

able unimixer PlanetMixer and Turbomixer from Gorreri.<br />

Web 14091<br />

PRe-MixeR + conTinuous AeRAToR + TuRbo eMulsifieR<br />

The storage tank and the vertical continous mixing head “Vertimix® Technology” are housed in a<br />

single structure, constructed entirely in stainless steel AISI 304. The head’s vertical position permits<br />

improved product homogenisation. It’s possible to obtain lower density, with the mixing head in<br />

horizontal position, and a better distribution of the air inside the product.<br />

The special head design allows a better chilling effect and counter flow of the cooling solution with<br />

an improvement of 25% of the cooling effect compared with a traditional mixing head.<br />

TURBOMIXER indicates when is necessary to foam, dairy creams 100% animal fat or when the<br />

products to foam contain low up to 25% due to the high speeds achieveable by the mixing head,<br />

over 1.000 rpm.<br />

For "High risk" products you may use the Clean in Place (CIP) and Steam in Place (SIP) system<br />

which complies with FDA rules. The model GTM 300 is able to foam products from 0 up to 400 l.<br />

per hour.<br />

TuRboMixeR GTM5xx & GTM7xx TuRbo eMulsifieR<br />

The storage tank and the vertical headed turbo emulsifier patented “Vertimix® Technology” are<br />

lodged in a single structure, constructed entirely in stainless steel AISI 304. The head’s vertical<br />

disposition permits to improve the product’s homogenisation and to obtain easily low density<br />

values with different types of dough, as well.<br />

<strong>PPN</strong><br />

PROCESS<br />

PLANT<br />

NETWORK<br />

T hE C O MPLE T E PACk AGE<br />

Tel: +61 3 9791 7011 | Fax: +61 3 9793 4087 | Email: sales@processplant.com | Web: www.processplant.com<br />

of the pack<br />

11.

12.<br />

New SMART FILLING/DEPOSITING SYSTEMS<br />

ACE PUMP CO LTD<br />

Multipurpose depositor / trigger<br />

nozzle filler (mobile, with hopper).<br />

It uses a helical rotor system with<br />

a servo drive. Used to fill or deposit<br />

high viscosity liquids, high density<br />

liquids, semi-solids, low concentration<br />

liquid containing granules<br />

filling.<br />

Web 14683<br />

Floor Stock<br />

iopak s/s double helix Ribbon blendeR<br />

with platform & access ladder.<br />

Much used in the food (and chemical) industries.<br />

Extremely robust& able to blend difficult products.<br />

Effective Volume: 2000L, Total Volume: 2500+<br />

Trough Dimensions: 2424mm L x 1000mm W X 1300mmD<br />

Motor Size: 22kW geared to 29Rpm.<br />

Mounted with outlet 1000mm above ground.<br />

Web:14464<br />

nEW<br />

iopak GEAr PUMP FiLLEr<br />

(Benchtop)<br />

Volume range: 50ml-4000ml<br />

Web 14138<br />

Floor Stock<br />

CHECKWEIGHER/METAL DETECTORS<br />

QUALiTEC METAL DETECTOr<br />

ChECkWEiGhEr COMbO<br />

Features almost perfect accuracy.<br />

Maximum Capacity: 1500g<br />

Division & Accuracy Min. 0.1g / Max.<br />

±0.2g<br />

Max. <strong>Process</strong>ing Speed (pcs/min) 240ppm<br />

/min (Variable Speed Control )<br />

Metal Detection Level: Fe (0.7mm) / N.Fe<br />

(0.8mm) / Sus (1.1mm)<br />

Flow Direction Left to Right (Standard)<br />

Web 14601<br />

iopak MD175X350<br />

METAL DETECTOr<br />

Aperture: 175 H x 350 W mm.<br />

Sensitivity: 1.5 mm Fe,<br />

2.0mm SUS.<br />

Conveyor Belt Speed:<br />

10 - 45 m/min<br />

(Product Dependent)<br />

Web:14511<br />

GOrrEri<br />

Volumetric Depositing Machine<br />

(decorating etc)Gear Pump Filler<br />

(Benchtop) Volume range: 50ml-<br />

4000ml<br />

Web 14382<br />

iopak LOW PrOFiLE PACkAGinG SySTEM<br />

WiTh MULTihEAD (10) VFF<br />

This system has been designed for low profile installations.<br />

It comes complete with a multihead weigher, platform, vffs<br />

bagmaking machine and a reseal bag labelling system.<br />

(a really compact little s/s machine) plus an offtake conveyor.<br />

Web:14459<br />

Height of VFFS: 1150mm<br />

Overall height: 2950 mm<br />

(Includes weigher & hopper)<br />

nEW