62 Robam-Väizene-Anepaio-Kolats-Valgma 2008

62 Robam-Väizene-Anepaio-Kolats-Valgma 2008

62 Robam-Väizene-Anepaio-Kolats-Valgma 2008

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5 th International Symposium<br />

„Topical Problems in the Field of Electrical and Power Engineering”,<br />

Doctoral School of Energy and Geotechnology<br />

Kuressaare, Estonia, January 14 – 19, <strong>2008</strong><br />

Measuring mining influence in the form of students practice in<br />

opposition to the emotional environmental impact assessment<br />

Karin <strong>Robam</strong>, Vivika Väizene, Ain <strong>Anepaio</strong>, Margit <strong>Kolats</strong>, Ingo <strong>Valgma</strong><br />

Department of Mining, Tallinn University of Technology<br />

karin.robam@ttu.ee<br />

Abstract<br />

Environmental impact assessment of mining<br />

influence is a procedure that involves an analysis<br />

of vibration, noise and drainage water effects on<br />

the environment and effects that attends if<br />

drainage water has been pumped out of mines.<br />

Data for environmental impact assessment,<br />

geotechnological research and teaching comes<br />

mainly from fieldwork measurements, laboratory<br />

analysis and modelling. Measuring is useless<br />

without laboratory analysing and modelling or<br />

processing of the data with modern software. In<br />

addition to analysing and taking into account the<br />

comments new results and conclusions have to be<br />

produced. The purpose of the analysis is to find out<br />

and appraise the positive or negative impact of<br />

mining influence.<br />

Keywords<br />

Fieldwork, environmental impact of mining,<br />

geotechnology, experiments, testing, modelling,<br />

visualisation.<br />

Introduction<br />

Environmental impact assessment base on available<br />

data, which is gathered from fieldwork or laboratory.<br />

In this article is handled environmental impact<br />

assessment through noise, ground vibration, water<br />

velocity, flow and discharge from the mines.<br />

Data is gathered from measurements in the course of<br />

science club fieldworks. The science club of mining<br />

and geology was started in the spring semester of<br />

2006, where the excursions to the phosphorite<br />

grounds in Maardu and to the limestone deposit in<br />

Harku took place to assess the effects of mining<br />

(http://mi.ttu.ee/teadusklubi) [2].<br />

Students are included in fieldworks to make studies<br />

more attractive and interesting. During the<br />

fieldworks students adjust better to the speciality and<br />

it expands the knowledge about using modern<br />

equipment, which increases the quality of student’s<br />

work.<br />

Measuring water velocity, flow and<br />

discharge from the mines<br />

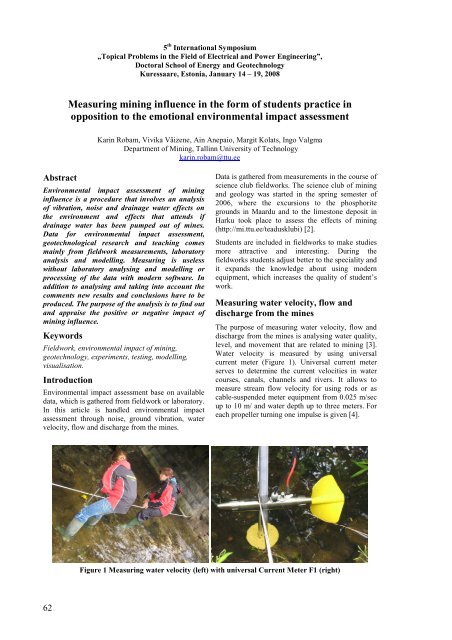

The purpose of measuring water velocity, flow and<br />

discharge from the mines is analysing water quality,<br />

level, and movement that are related to mining [3].<br />

Water velocity is measured by using universal<br />

current meter (Figure 1). Universal current meter<br />

serves to determine the current velocities in water<br />

courses, canals, channels and rivers. It allows to<br />

measure stream flow velocity for using rods or as<br />

cable-suspended meter equipment from 0.025 m/sec<br />

up to 10 m/ and water depth up to three meters. For<br />

each propeller turning one impulse is given [4].<br />

Figure 1 Measuring water velocity (left) with universal Current Meter F1 (right)<br />

<strong>62</strong>

That portion of the channel cross section in which<br />

flow occurs is called active portion and a cross<br />

section where the flow velocity is nonexistent is<br />

called off-channel storage or dead storage. The area<br />

of a channel has to divide into shares according to<br />

profile of channel width. Firstly have to measure the<br />

distance from shore and water depth at various<br />

points across the stream flow to construct a channel<br />

profile. The current velocity meter may be used to<br />

determine a vertical axis of water velocity at several<br />

points across a stream channel.<br />

As a result of surveying distance from the bank,<br />

water depth, current meter depth to water level and<br />

number of propeller rotations are measured and<br />

scheme of the flow is constructed (Figure 2). The<br />

stream flow for the profile is the sum of the average<br />

velocities of each subsection of stream flow times its<br />

cross-sectional area.<br />

0<br />

Streambed width, m<br />

0 0,5 1 1,5 2 2,5 3 3,5 4 4,5<br />

-0,05<br />

Streambed depth, m<br />

-0,1<br />

-0,15<br />

-0,2<br />

-0,25<br />

-0,3<br />

-0,35<br />

Water surface<br />

Universal current meter depth to water level<br />

Streambed<br />

Stream vertical axis<br />

Figure 2 Streambed cross section<br />

Test pumping for evaluating hydraulic<br />

conductivity of the rocks<br />

Submersible pump MP1 (Figure 4) is used for test<br />

pumping. It is specially designed for the purging and<br />

sampling groundwater in boreholes with an internal<br />

diameter of at least 50 mm and the dynamic water<br />

level must not exceed 80 metres. Pumping water out<br />

of boreholes is used to determine the coefficient of<br />

hydraulic conductivity. Pump has to be performed in<br />

several wells where water level will be surveyed. As<br />

the result of pumping water level decreases around<br />

the borehole and depression cone will be developed.<br />

As pumping continues, a cone of depression with its<br />

centre at the pumped well spreads out from well in<br />

all directions. The dimensions of the cone of<br />

depression depend upon the rate of recharge, the<br />

water-bearing properties and extend of the aquifer,<br />

the rate and duration pumping.<br />

If borehole passes through sort of unvaried soil level<br />

the coefficient of hydraulic conductivity (Figure 3)<br />

is calculated with the next formula:<br />

k<br />

2,303Q<br />

1<br />

= log [5]<br />

2 2<br />

π(h 1 + h 2)<br />

r2<br />

r<br />

Figure 3 Determining the coefficient of hydraulic<br />

conductivity<br />

63

Figure 4 Testpumping in the abandoned spoils of a strip mine<br />

Monitoring ground and air vibration<br />

Vibration can cause negative effects to the human<br />

health and to the reliability of mining machines.<br />

That is why it is important to keep vibration level<br />

under limited value and control it by carrying out<br />

measuring with vibration monitors. In order to get<br />

most accurate results device should be attached<br />

directly to the object under study. For measuring<br />

vibrations of soil and rock ground under the<br />

vibration monitor should be cleaned and monitor<br />

itself fixed with bolts (Figure 6).<br />

Log shows the results as 4 channels: 3 geophone<br />

channels, 1 microphone channel [6].<br />

According to the graphic of results of vibration<br />

analysis (Figure 5) it is possible to assess vibration<br />

influence.<br />

Figure 6 Positioning monitor towards vibration<br />

source<br />

Figure 5 Results of vibration analysis near<br />

Surface miner milling cutter<br />

Noise measurement<br />

Noise measurement are performed with device TES<br />

1352A. It is used for measuring machine influence<br />

on the environment also noise influence on sanitary<br />

conditions in populated areas and is necessary for<br />

valuating working conditions on mechanical<br />

processing.<br />

Noise is advised to measure from certain distance<br />

like 1m, 5m, 10m etc. Measuring results are store on<br />

the machine memory what can be drawn into the<br />

computer with program called Sound Meter and<br />

processed in appropriate software (Figure 7).<br />

64

110<br />

105<br />

Sound level (dB, A)<br />

100<br />

95<br />

90<br />

85<br />

Sound intensity<br />

80<br />

9:59:02 10:01:55 10:04:48 10:07:41 10:10:34 10:13:26 10:16:19<br />

Time<br />

Figure 7 Measuring noise of a hydraulic hammer (left), Noise chart of a surface miner milling (right)<br />

Acknowledgements<br />

Field works and this paper is related to the Estonian<br />

Science Foundation study- Grant No. 6558.<br />

References:<br />

Figure 8 Measuring mining benches, angles and<br />

elevations for understanding the technology<br />

Conclusions<br />

Modern testing equipment and software allows to<br />

produce and evaluate environmental impact of<br />

mining.<br />

Due to measuring water velocity, flow and discharge<br />

from the mines, test pumping for evaluating<br />

hydraulic conductivity of the rocks, monitoring<br />

ground and air vibration it is possible to analyse<br />

mining impact to environment.<br />

The most easy and useful way is to perform the<br />

measurement in the form of science club that has<br />

been successfully started in Mining department of<br />

Tallinn University of Technology.<br />

1. Karu, V. Science club of Mining and<br />

Geology. EU legislation as it affects mining. INFRA<br />

22944 TAIEX workshop. 2006.<br />

2. Karu, V; Pärnasalu, R; Õnnis, A. Science<br />

Club of Mining and Geology as it Affects Higher<br />

Education. Doctoral school of energy and<br />

geotechnology. Tallinn University of Technology<br />

2007<br />

3. Reinsalu Enno, Lind Helena, <strong>Valgma</strong> Ingo,<br />

Technogenic water body in closed oil shale mines,<br />

Oil Shale, Estonian Academy Publishers, Tallinn,<br />

2006, -<br />

4. Equpiment for water pumping Eijkelkamp.<br />

http://www.eijkelkamp.com [30.10.2007]<br />

5. Jaaniso, V. Soil Mechanics and<br />

Engineering Geology<br />

http://www.tud.ttu.ee/material/epi/Valdo_Jaaniso/Ge<br />

otehnika%20alused/PinmehA.doc [30.10.2007]<br />

6. Vibration monitor<br />

http://www.abem.se/products/vibraloc/Vibraloc.pdf<br />

[31.10.2007]<br />

65