Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

© Siemens AG 2007<br />

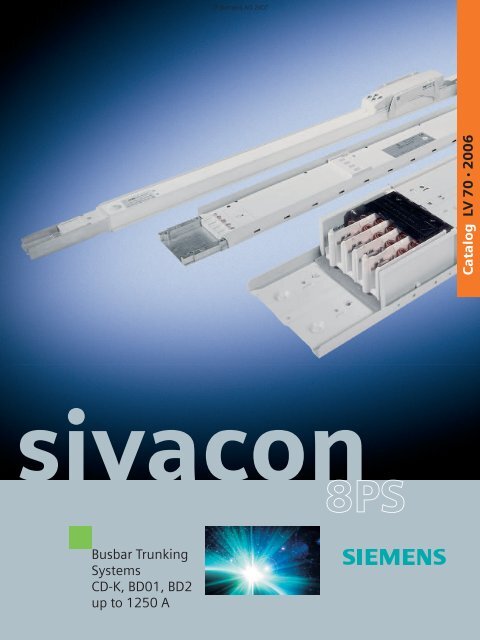

Catalog LV 70 • 2006<br />

sivacon 8PS<br />

Busbar Trunking<br />

<strong>System</strong>s<br />

CD-K, <strong>BD01</strong>, BD2<br />

up to 1250 A

© Siemens AG 2007<br />

Related catalogs<br />

Contents<br />

Low-Voltage Controls and<br />

Distribution<br />

SIRIUS · SENTRON · SIVACON<br />

Order No.:<br />

Catalog<br />

E86060-K1002-A101-A5-7600<br />

Technical Information<br />

E86060-T1002-A101-A5-7600<br />

LV 1<br />

LV 1 T<br />

<strong>System</strong>s • Controls: Contactors and contactor assemblies,<br />

solid-state switching devices • Protection equipment<br />

• Load feeders, motor starters and soft starters •<br />

Monitoring and control devices • Detecting devices •<br />

Commanding and signaling devices • Transformers •<br />

Power supplies • ALPHA FIX terminal blocks • Planning<br />

and configuration with SIRIUS • SIVACON busway and<br />

cubicle systems • SENTRON switching and protection<br />

devices for power distribution: Air circuit-breakers,<br />

molded case circuit-breakers, switch disconnectors •<br />

Planning, design and management with SIMARIS •<br />

BETA modular installation devices<br />

Industrial Communication<br />

Industrial Communication<br />

for Automation and Drives<br />

Order No.:<br />

E86060-K6710-A101-B5-7600<br />

IK PI<br />

PROFINET/Industrial Ethernet • Industrial Mobile<br />

Communicaton • PROFIBUS to IEC 61158/EN 50170 •<br />

SIMATIC ET 200 distributed I/Os • AS-Interface to<br />

EN 50295/IEC 61158 • Remote operation with SINAUT<br />

ST7 • Telecontrol • Routers • ECOFAST system<br />

SIVENT<br />

2CC and 2CQ Axial Fans<br />

Order No.:<br />

E86060-K1865-A101-A1-7600<br />

LV 65<br />

2CC low-pressure axial fans • 2CQ medium-pressure<br />

axial fans<br />

SIDAC<br />

Reactors and Filters<br />

Order No.:<br />

E86060-K2803-A101-A3-7600<br />

SIVACON 8PS<br />

Busway <strong>System</strong>s<br />

CD-K, <strong>BD01</strong>, BD2<br />

up to1250 A<br />

Order No.:<br />

E86060-K1870-A101-A2-7600<br />

Automation & Drives<br />

The A&D Offline-Mall<br />

CD-ROM:<br />

E86060-D<strong>40</strong>01-A110-C4-7600<br />

DVD:<br />

E86060-D<strong>40</strong>01-A510-C4-7600<br />

A&D Mall<br />

Internet:<br />

http://www.siemens.com/<br />

automation/mall<br />

Catalog PDF<br />

Internet:<br />

http://www.automation.<br />

siemens.com/cd<br />

LV 60<br />

LV 70<br />

CA 01<br />

Commutating reactors for converters • Mains reactors<br />

for frequency converters • Iron-core output reactors •<br />

Ferrite output reactors • Iron-core smoothing reactors •<br />

Smoothing air-core reactors • Filter reactors • Application-specific<br />

reactors • Radio interference suppression<br />

filters • dv/dt filters • Sinewave filters<br />

Busway systems, Overview • CD-K system (25 to <strong>40</strong> A) •<br />

<strong>BD01</strong> system (<strong>40</strong> to <strong>160</strong> A) • BD2 system (<strong>160</strong> to<br />

1250 A)<br />

All Automation and Drives products,<br />

including those in the catalogs listed above.<br />

All Automation and Drives products,<br />

including those in the catalogs listed above.<br />

All Low-Voltage Controls and Distribution Catalogs as<br />

PDF for download.<br />

Registered trademarks<br />

Technical Assistance<br />

All product designations may be registered trademarks<br />

or product names of Siemens AG or other supplying<br />

companies. Third parties using these trademarks or<br />

product names for their own purposes may infringe<br />

upon the rights of the trademark owners.<br />

Further information about low-voltage controls is<br />

available on the Internet at:<br />

http://www.siemens.com/lowvoltage<br />

Expert technical assistance<br />

for low-voltage controlgear,<br />

switchgear and systems as<br />

well as electrical installation.<br />

Tel.: +49 (9 11) 8 95-59 00<br />

Fax: +49 (9 11) 8 95-59 07<br />

E-Mail: technical-assistance<br />

@siemens.com

© Siemens AG 2007<br />

SIVACON 8PS<br />

Busbar trunking<br />

systems CD-K, <strong>BD01</strong>,<br />

BD2 up to 1250 A<br />

Catalog LV 70 · 2006<br />

Introduction<br />

Busbar trunking systems, Overview<br />

1<br />

Invalid:<br />

Catalog LV 70 · 2004<br />

The products contained in this<br />

catalog are also included in the<br />

Offline Mall CA 01<br />

Order No.:<br />

E86060-D<strong>40</strong>01-A110-C4-7600 (CD-ROM)<br />

E86060-D<strong>40</strong>01-A510-C4-7600(DVD)<br />

Contact your local Siemens<br />

representative for further information<br />

© Siemens AG 2006<br />

CD-K system – 25 ... <strong>40</strong> A<br />

2<br />

3<br />

<strong>BD01</strong> system – <strong>40</strong> ... <strong>160</strong> A<br />

The products and systems<br />

listed in this catalog<br />

are distributed/<br />

manufactured using a<br />

certified quality<br />

management system<br />

which complies<br />

with EN ISO 9001<br />

(Certificate Register No.<br />

1210016950 TMS).<br />

The TÜV certificate is<br />

recognized in all IQNet<br />

countries.<br />

BD2 system – <strong>160</strong> ... 1250 A<br />

4<br />

5<br />

Appendix<br />

s<br />

6

© Siemens AG 2007<br />

Explanations<br />

Useful information on catalog LV 70 · 2006<br />

The catalog LV 70 · 2006 contains the data needed<br />

for the selection and ordering of the products dated<br />

07/2006.<br />

Delivery times (DT)<br />

} Preferred type<br />

A<br />

B<br />

C<br />

D<br />

X<br />

2 working days<br />

1 week<br />

3 weeks<br />

6 weeks<br />

on request<br />

Packaging size (PS)<br />

Preferred types are available immediately from<br />

stock, i.e. are dispatched within 24 hours.<br />

Normal quantities of the products are usually delivred<br />

within the specified time following receipt of<br />

your order at our branch.<br />

In exceptional cases, the actual delivery period<br />

may differ from that specified.<br />

The delivery periods apply up to the ramp at Siemens AG (products ready for<br />

dispatch). The transport times depend on the destination and type of shipping.<br />

The standard transport time for Germany is 1 day.<br />

The delivery times specified here represent the state of 07/2006. They are permanently<br />

optimized. Up-to-date information can be found at<br />

www.siemens.com/automation/mall.<br />

Dimensions<br />

The packaging size defines the number, e.g. of<br />

units, sets or meters, for outer packaging.<br />

Only the quantity defined by the packaging size or<br />

a multiple thereof can be ordered!!<br />

All dimensions in mm.<br />

2<br />

Siemens LV 70 · 2006

© Siemens AG 2007<br />

Introduction<br />

1/2 Welcome to<br />

Automation and Drives<br />

1/3 Totally Integrated Automation –<br />

innovations for more productivity<br />

1/4 Totally Integrated Power –<br />

energy distribution and<br />

management from one source<br />

1/6 Low-voltage Controls<br />

and Distribution –<br />

The basis for progressive solutions<br />

1/8 SIVACON 8PS – Busbar trunking<br />

systems in action<br />

1/10 SIVACON 8PS Engineering Tools for<br />

precisely dimensioned, economical<br />

solutions<br />

Siemens LV 70 · 2006

© Siemens AG 2007<br />

Welcome to<br />

Automation and Drives<br />

We would like to welcome you to Automation<br />

and Drives and our comprehensive range of<br />

products, systems, solutions and services for<br />

production and process automation and<br />

building technology worldwide.<br />

With Totally Integrated Automation and<br />

Totally Integrated Power, we deliver solution<br />

platforms based on standards that offer you<br />

a considerable savings potential.<br />

Discover the world of our technology now. If<br />

you need more detailed information, please<br />

contact one of your regional Siemens partners.<br />

They will be glad to assist you.<br />

1/2 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Low-Voltage Controls and Distribution –<br />

The basis for progressive solutions<br />

Extremely high demands are made on modern low-voltage controls and distribution:<br />

users want cost-effective solutions that are easy to integrate in control cabinets, distribution boards and distributed<br />

systems and can communicate perfectly with each other.<br />

Siemens has the answer: SIRIUS industrial controls and low-voltage power distribution with<br />

SIVACON, SENTRON and SIMARIS<br />

SIRIUS industrial controls<br />

The SIRIUS range has everything you need for switching, protecting and starting loads. Products for monitoring, control,<br />

detection, commanding, signaling and power supply round off the spectrum of industrial controls. Combined with Totally<br />

Integrated Automation, Safety Integrated and ECOFAST, our product portfolio can be bundled to create optimized<br />

systems. All in all, Siemens provides innovative controls with modern features, such as integrated communication and<br />

safety technology that work to your advantage: The basis for ground-breaking integrated solutions.<br />

Low-voltage power distribution with SIVACON, SENTRON and SIMARIS<br />

Non-residental buildings and industrial plants have one thing in common: without electricity, everything comes to a halt.<br />

The availability, safety and cost effectiveness of the power distribution system is of utmost importance – from the medium<br />

voltage supply point through to the socket outlet. And only integrated solutions can ensure maximum efficiency<br />

for planning, configuration and operation. The concept is called Totally Integrated Power from Siemens.<br />

Total integration in planning and configuration creates synergies and saves costs. Perfectly interacting products and<br />

systems provide efficient engineering and reliable operation. In the field of low-voltage power distribution, the following<br />

product ranges are available:<br />

SIVACON: From flexible busbar trunking systems through to safe power distribution boards and motor control centers.<br />

SENTRON: From well-proven switch disconnectors through to intelligent circuit-breakers.<br />

SIMARIS: The software range for the planning, design and management of power distribution.<br />

SENTRON switching devices<br />

SIRIUS modular systems<br />

SIRIUS Safety Integrated<br />

Siemens LV 70 · 2006<br />

1/3

© Siemens AG 2007<br />

Totally Integrated Automation –<br />

innovations for more productivity<br />

With thelaunchofTotally IntegratedAutomation, we were the<br />

first ones on the market to consistently implement the trend<br />

from equipment to an integrated automation solution, and<br />

have continuously improved the system ever since.<br />

Whether your industryisprocess- and production-oriented or<br />

ahybrid, Totally Integrated Automation is aunique "common<br />

solution"platformthat covers all the sectors.<br />

Totally Integrated Automation is an integrated platformfor the<br />

entireproduction line -from receiving to technical processing<br />

and production areas to shipping. Thanks tothe system-<br />

ERP<br />

Enterprise<br />

Resource<br />

Planning<br />

Ethernet<br />

MES<br />

Manufacturing<br />

Execution<br />

<strong>System</strong>s<br />

Ethernet<br />

Production<br />

Order<br />

Management<br />

Production<br />

Operations<br />

Recording<br />

Material<br />

Management<br />

Equipment<br />

Management<br />

Control<br />

SIMATIC NET<br />

Industrial<br />

Communication<br />

SINAUT Telecontrol<br />

<strong>System</strong><br />

SIMATIC<br />

Software<br />

SIMATIC Controllers/<br />

Automation <strong>System</strong><br />

SIMATIC<br />

Sensors<br />

PROFINET<br />

Industrial<br />

Ethernet<br />

Safety Integrated<br />

PROFIBUS<br />

PC-based Automation<br />

AS-Interface<br />

KNX/EIB<br />

Building<br />

Technology<br />

GAMMA inst abus<br />

Micro-Automation and<br />

Actuator-Sensor Interface Level<br />

ECOFAST IP65<br />

Distributed<br />

Automation <strong>System</strong><br />

1/4 Siemens LV70·2006

© Siemens AG 2007<br />

oriented engineering environment, integrated, open communicationsaswell<br />

asintelligent diagnostics options, your plant<br />

now benefits in every phase of the life cycle.<br />

In fact, to this dayweare the only companyworldwide that can<br />

offeracontrol systembased on an integrated platform forboth<br />

the production and process industry.<br />

SIMATIC IT Framework<br />

Production Modeler<br />

Plant<br />

Information<br />

Management<br />

Detailed<br />

Production<br />

Scheduling<br />

Product Specification<br />

Management <strong>System</strong><br />

Laboratory Information<br />

Management <strong>System</strong><br />

SENTRON<br />

Circuit<br />

Breakers<br />

SIMATIC PCS 7<br />

ProcessControl <strong>System</strong><br />

SIMATIC HMI<br />

Human Machine<br />

Interface<br />

SIMOTION<br />

Motion Control<br />

<strong>System</strong><br />

SINUMERIK<br />

Computer<br />

NumericControl<br />

Field Instrumentation/<br />

Analytics<br />

HART<br />

SIMOCODE pro<br />

MotorManagement<br />

<strong>System</strong><br />

SIMATIC<br />

Distributed<br />

I/O<br />

SIWAREX<br />

Weighing<br />

Technology<br />

PROFIBUSPA<br />

Drive<strong>System</strong>s/<br />

SINAMICS<br />

SINAMICS<br />

SIMODRIVE<br />

SINAMICS<br />

Siemens LV 70 ·2006<br />

1/5

© Siemens AG 2007<br />

Totally Integrated Power –<br />

integrated power distribution<br />

from one source<br />

Totally Integrated Power by Siemens offers integrated solutions<br />

for power distribution in commercial, institutional and<br />

industrial buildings ranging from medium voltage to the wall<br />

outlet.<br />

Totally Integrated Power is based on the integration in<br />

planning and configuration as well as on interface-optimized<br />

products and systems. In addition, it features communication<br />

and software modules for interfacing power distribution<br />

systems to industrial automation and building automation,<br />

thus offering a substantial savings potential.<br />

Communication<br />

HMI Load<br />

Graphs Prognoses<br />

management<br />

Process/production<br />

automation<br />

U<br />

I<br />

coso<br />

P<br />

W<br />

PROCESS FIELD BUS<br />

Products and systems<br />

£ 110 kV<br />

Planning and configuration<br />

1/6 Siemens LV 70 · 2006

DATE:<br />

EMPLOYEE<br />

COST CENTER<br />

PAY PERIOD BEGINNING<br />

PAY PERIOD ENDING<br />

DATE<br />

IN<br />

OUT<br />

IN<br />

OUT<br />

OVERTIME<br />

DATE<br />

IN<br />

OUT<br />

IN<br />

OUT<br />

OVERTIME<br />

DATE<br />

IN<br />

OUT<br />

IN<br />

OUT<br />

OVERTIME<br />

CODES<br />

V=VACATION<br />

H=HOLIDAY<br />

S=SICK<br />

SUN MON TUE WED THUR FRI SAT SUN TOTAL<br />

SUN MON TUE WED THUR FRI SAT SUN TOTAL<br />

SUN MON TUE WED THUR FRI SAT SUN TOTAL<br />

REGULAR HOLIDAY OTHER<br />

OVER THE HOURS<br />

TIME & ONE-HALF<br />

SICK<br />

VACATION<br />

TOTALHOURS<br />

TOTALHOURS<br />

TOTALHOURS<br />

© Siemens AG 2007<br />

Message/<br />

error<br />

management<br />

Maintenance<br />

Substation<br />

Distribution<br />

Maintenance<br />

task<br />

Selective<br />

protection<br />

Protocols<br />

Power<br />

quality<br />

Cost center<br />

Building<br />

automation<br />

Hall 1 Air conditioning system<br />

checkup<br />

Distribution 3 Replacing circuit<br />

breaker contacts<br />

Infeed II Replacing meters<br />

central ON<br />

OFF<br />

local ON<br />

OFF<br />

tripped<br />

instabus EIB<br />

Siemens LV 70 · 2006<br />

1/7

© Siemens AG 2007<br />

SIVACON 8PS –<br />

Busbar trunking systems in action<br />

Busbar trunking systems in the low-voltage<br />

range guarantee the reliable transmission and<br />

distribution of power from the transformer<br />

through the main distribution board to the load.<br />

Siemens offers a complete range of high-performance<br />

systems:<br />

• CD-K for 25 A to <strong>40</strong> A<br />

• <strong>BD01</strong> for <strong>40</strong> A to <strong>160</strong> A<br />

• BD2 for <strong>160</strong> A to 1250 A<br />

• LR for <strong>40</strong>0 A to 6300 A<br />

• LD for 1100 A to 5000 A<br />

• LX for 800 A to 6300 A<br />

All busbar trunking systems are "Type-tested<br />

low-voltage controlgear assemblies" (TTA)<br />

according to IEC/EN 60439-1 and -2. They thus<br />

provide a safety standard which meets the high<br />

demands of automated production facilities and<br />

building management systems.<br />

The <strong>BD01</strong> system is quickly mounted and ideal<br />

for power distribution in craft businesses and the<br />

skilled trades, e.g. in photographic studios.<br />

Other advantages:<br />

• Well-arranged network topology<br />

• Unproblematic retrofitting in the event of load<br />

changes<br />

• Low operating costs thanks to high availability<br />

• Easy planning and mounting<br />

Area-wide solutions for lighting systems and<br />

small loads<br />

Be it in furniture stores, supermarkets or greenhouses<br />

– with the CD-K system (up to <strong>40</strong> A) you<br />

can easily mount and supply power to lighting<br />

systems over large areas. The attractive design<br />

of the busbar trunking systems is very suitable<br />

for sales rooms open to the public. On the other<br />

hand, its high degree of protection allows the<br />

CD system to be used even in harsh environments.<br />

The ideal system for production lines<br />

needing a great deal of power is the<br />

LD system up to 5000 A.<br />

Power for loads with no fixed location<br />

The <strong>BD01</strong> system is ideal for power distribution<br />

(up to <strong>160</strong> A) in craft businesses and the skilled<br />

trades. The busbar enclosures can be easily<br />

and quickly connected. An anti-rotation element<br />

in the tap-off units prevents incorrect mounting<br />

and guarantees easy conversion.<br />

Other advantages: Minimum keeping of stocks<br />

and straightforward planning thanks to one<br />

standard size for five different levels of current.<br />

In the petrochemical industry, it is the LR system that provides<br />

reliable and fault-free power supply.<br />

1/8 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Universal power distribution<br />

The BD2 system (up to 1250 A) supplies power<br />

to medium-size loads in buildings and all<br />

sectors of industry. Pre-assembled tap-off units<br />

with the most diverse equipment enable universal<br />

use. Two standard frame sizes covering all<br />

current ratings simplify stock keeping and<br />

planning.<br />

Siemens offers modular ancillary equipment units for indication, control and monitoring<br />

of the flow of power through busbar trunking systems. These units are equipped with bus<br />

interfaces, control circuit devices and power meters.<br />

The LX busbar trunking system is the perfect equipment for multi-storey buildings where<br />

large quantities of power need to be transported, uninfluenced by the mounting position<br />

of the system.<br />

High availability in production<br />

The louvred LD busbar trunking system, up to<br />

5000 A, is the system for transporting current in<br />

production lines with a large energy requirement,<br />

such as in the automotive industry. A<br />

separate PE bar enables the assured response<br />

of the protective device over long conducting<br />

paths. The high short-circuit resistance permits<br />

protection by medium-voltage circuit-breakers<br />

for the conveyance of power between the<br />

transformer and the main infeed. Tap-off units<br />

up to 1250 A can be plugged in without causing<br />

any problems.<br />

Flexible power distribution for multi-storey<br />

buildings<br />

The LX sandwich-style system, up to 6300 A, is<br />

used where large quantities of power need to be<br />

transported, uninfluenced by the mounting position<br />

of the system. Be it for radio broadcasting<br />

stations, computer centers or Internet providers<br />

– conductor configurations with an insulated<br />

PE/ground conductor and double neutral conductor<br />

cross-section guarantee an interferencefree<br />

power supply. Tap-off units up to 1250 A<br />

are available as standard.<br />

Safe power conveyance for petrochemicals<br />

The encapsulated LR system (up to 6300 A) is<br />

extremely resistant to external interference<br />

thanks to its high degree of protection. This<br />

ensures safe and reliable transport of power<br />

even in rough weather or in highly dust and dirt<br />

and corrosion polluted industrial environments.<br />

Typical applications of this system is the petrochemical<br />

industry, waste incinerators and power<br />

stations.<br />

Siemens LV 70 · 2006<br />

1/9

© Siemens AG 2007<br />

SIVACON 8PS Engineering Tools for<br />

precisely dimensioned, economical solutions<br />

SIVACON Engineering Tools from Siemens help<br />

generate precisely dimensioned and efficient<br />

planning and design solutions, You are in full<br />

control of even complex tasks at all times:<br />

Selection aid for busbar trunking systems<br />

(MobileSpice)<br />

The selection aid enables you to order busbar<br />

trunking systems up to 1250 A and is available<br />

in the Mall. The same selection aid can also be<br />

found in Catalog CA 01 on CD-ROM.<br />

The following configurators are available:<br />

• SIVACON 8PS <strong>System</strong> CD-K, 25 ... <strong>40</strong> A<br />

• SIVACON 8PS <strong>System</strong> <strong>BD01</strong>, <strong>40</strong> ... <strong>160</strong> A<br />

• SIVACON 8PS <strong>System</strong> BD2, <strong>160</strong> ... 1250 A<br />

In MobileSpice, you select the trunking units for your system from a menu,<br />

and then transfer them into an order list.<br />

Should you have any queries concerning<br />

installation, functionality or application options –<br />

please mail us at<br />

sbts.tool_support@siemens.com<br />

We will be pleased to assist you.<br />

1/10 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s,<br />

Overview<br />

2/2 Contents<br />

2/4 <strong>System</strong> overview<br />

2/6 Technical overview<br />

2/8 Principles of busbar trunking<br />

planning<br />

2/9 Communication-capable busbar<br />

trunking for industry and buildings<br />

2/11 Busbars instead of cables<br />

Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Contents<br />

■ Overview<br />

2<br />

Trunking unit with tap-off unit<br />

Feeder unit<br />

2/2 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Contents<br />

CD-K system – 25 A ... <strong>40</strong> A<br />

BD2 system – <strong>160</strong> A ... 1250 A<br />

NSV0_00201<br />

NSV0_00421<br />

Page<br />

<strong>System</strong> overview of busbar trunking systems 2/4<br />

Technical overview of busbar trunking systems 2/6<br />

Contents: CD-K system 3/1<br />

Overview 3/2<br />

Design 3/4<br />

Technical specifications 3/7<br />

Selection and ordering data 3/9<br />

Engineering 3/15<br />

Dimensional drawings 3/22<br />

Page<br />

<strong>System</strong> overview of busbar trunking systems 2/4<br />

Technical overview of busbar trunking systems 2/6<br />

Contents: BD2 system 5/1<br />

Overview 5/2<br />

Design 5/4<br />

Technical specifications 5/14<br />

Selection and ordering data 5/22<br />

Engineering 5/73<br />

Fire barriers 5/94<br />

Dimensional drawings 5/102<br />

2<br />

<strong>BD01</strong> system – <strong>40</strong> A ... <strong>160</strong> A<br />

NSV0_00241<br />

Page<br />

<strong>System</strong> overview of busbar trunking systems 2/4<br />

Technical overview of busbar trunking systems 2/6<br />

Contents: <strong>BD01</strong> system 4/1<br />

Overview 4/2<br />

Design 4/3<br />

Technical specifications 4/8<br />

Selection and ordering data 4/10<br />

Engineering 4/28<br />

Dimensional drawings 4/33<br />

Siemens LV 70 · 2006<br />

2/3

D 0 1 -K<br />

B<br />

0 1 D<br />

D 0 1 -K<br />

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

<strong>System</strong> overview<br />

■ Overview<br />

6<br />

2<br />

3<br />

6<br />

B B<br />

2<br />

4<br />

6<br />

1<br />

B B<br />

5<br />

6<br />

NSV0_00682<br />

2/4 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

<strong>System</strong> overview<br />

■ Benefits<br />

$ CD-K system up to <strong>40</strong> A<br />

The versatile busbar trunking system for area-wide power<br />

supply to lighting systems:<br />

• Versatile thanks to high degree of protection up to IP55<br />

• Lower planning costs through simple configuration<br />

• Time-saving mounting through plug-in quick connector<br />

• Tap-off points on both sides for optimized utilization of the<br />

busbar<br />

• Uniform current loading of the conductors through splitting of<br />

the tap-off plugs among the individual phases<br />

• Tap-off plugs allow fast, flexible load relocation<br />

% <strong>BD01</strong> system up to <strong>160</strong> A<br />

The busbar trunking system for power distribution in craft<br />

business and the skilled trades:<br />

• High degree of protection up to IP55<br />

• Flexible power supply<br />

• Easy and quick planning<br />

• Time-saving mounting<br />

• Reliable mechanical and electrical connection<br />

• High stability, low weight<br />

• Few basic modules required<br />

• Storage-friendly system<br />

• Variable changes of direction<br />

• Versatile tap-off units<br />

• Positive opening and closing of tap-off points<br />

& BD2 system up to 1250 A<br />

The busbar trunking system for operation in the harsh industrial<br />

world.<br />

• High degree of protection up to IP55<br />

• Easy and quick planning<br />

• Time-saving and economical mounting<br />

• Reliable and safe operation<br />

• Flexible modular system with simple solutions for every<br />

application<br />

• Early planning of the power distribution system without exact<br />

knowledge of load locations<br />

• Early readiness for operation thanks to fast and simple<br />

mounting<br />

• Innovative design: No more compensation boxes to<br />

compensate elongation<br />

• Codable outgoing enclosures and outgoing points<br />

• Sealable throughout<br />

( LD system up to 5000 A<br />

The busbar trunking system for optimized power distribution in<br />

industry:<br />

• High degree of protection IP54<br />

• Quick and easy mounting<br />

• Reliable and safe operation<br />

• Space-saving, compact design up to 5000 A in one enclosure<br />

• Load outgoing feeders up to 1250 A<br />

• Type-tested connection to distribution boards and<br />

transformers<br />

) LX system up to 6300 A<br />

The busbar trunking system for power transmission and distribution<br />

in buildings:<br />

• High degree of protection up to IP55<br />

• Quick and easy mounting<br />

• Reliable and safe operation<br />

• Load outgoing feeders up to 1250 A<br />

• Type-tested connection to distribution boards and transformers<br />

LR system<br />

The busbar trunking system for power conveyance under<br />

extreme ambient conditions (IP68).<br />

Detailed information about this system is available from the<br />

Siemens branch located close to you.<br />

* Communication-capable busbar trunking systems<br />

Communication-capable function expansions for combination<br />

with known outgoing enclosures:<br />

• Can be used with the systems <strong>BD01</strong>, BD2, LD and LX<br />

• Applications:<br />

- Control of lighting for large areas<br />

- Remote switching and signaling in the industrial sector<br />

- Load monitoring of decentral power tap-offs<br />

• Connection to the bus systems EIB, AS-Interface and<br />

PROFIBUS<br />

• Easy contacting of the bus cable by insulation displacement<br />

method<br />

• Easy and quick planning<br />

• Flexible expansions and modifications<br />

• Module system<br />

• Retrofitting of existing installations<br />

■ More information<br />

Selection aid for busbar trunking systems (MobileSpice)<br />

The selection aid enables you to order busbar trunking systems<br />

up to 1250 A.<br />

The following configurators are available:<br />

• SIVACON 8PS <strong>System</strong> CD-K, 25 ... <strong>40</strong> A<br />

• SIVACON 8PS <strong>System</strong> <strong>BD01</strong>, <strong>40</strong> ... <strong>160</strong> A<br />

• SIVACON 8PS <strong>System</strong> BD2, <strong>160</strong> .... 1250 A<br />

This selection aid is available in the A&D Mall and in the<br />

Catalog CA 01 on CD-ROM. This CD-ROM is available free of<br />

charge from your Siemens branch.<br />

Manual<br />

Planning with SIVACON 8PS – Busbar trunking systems up to<br />

6300 A<br />

(available soon)<br />

Leaflet<br />

Busbar trunking for safe and flexible power distribution up to<br />

6300 A<br />

(Order No. E20001-A220-P309-V1-7600)<br />

2<br />

Siemens LV 70 · 2006<br />

2/5

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Technical overview<br />

■ Overview<br />

2<br />

Busbar trunking systems Rated current Rated operational<br />

voltage<br />

CD-K 30<br />

<strong>40</strong><br />

2 3 25<br />

2 3 <strong>40</strong><br />

NSV0_00201<br />

Frequency<br />

Number of<br />

active<br />

conductors<br />

Degree of<br />

protection<br />

A V AC Hz °C<br />

Ambient<br />

temperature,<br />

min./max.<br />

<strong>40</strong>0 50 ... 60 2, 3, 4, 2 3 4 Up to IP55 -5/+<strong>40</strong><br />

(PE = enclosure)<br />

<strong>BD01</strong> <strong>40</strong><br />

63<br />

100<br />

125<br />

<strong>160</strong><br />

NSV0_00241<br />

<strong>40</strong>0 50 ... 60 4<br />

Up to IP55 -5/+<strong>40</strong><br />

(PE = enclosure)<br />

BD2A<br />

BD2C<br />

<strong>160</strong> ... <strong>40</strong>0,<br />

500 ... 1250<br />

690 50 ... 60 5 Up to IP55 -5/+<strong>40</strong><br />

NSV0_00421<br />

LDA1 ... LDA8<br />

LDC2 ... LDC8<br />

1100 ... <strong>40</strong>00,<br />

2000 ... 5000<br />

1000 50 ... 60 4 or 5 Up to IP54 -5/+<strong>40</strong><br />

NSV0_00681<br />

LXA01 ... LXA10<br />

LXC01 ... LXC10<br />

800 ... 4500,<br />

1000.... 6300<br />

690 50 ... 60 3, 4, 5, 6 Up to IP55 -5/+<strong>40</strong><br />

(PE = enclosure)<br />

NSV0_00321<br />

LRC01 ... LRC29 630.... 6300 1000 50 ... 60 4, 5 IP68 -5/+<strong>40</strong><br />

NSV0_01451<br />

2/6 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Technical overview<br />

Mounting<br />

position<br />

Length Tap-off points Tap-off units Material Fire load Can be combined with communication-capable<br />

tap-off units for<br />

m<br />

kWh/m<br />

Edgewise 2<br />

3<br />

On one side<br />

every 0.5 or 1 m<br />

On two sides<br />

every 0.5 or 1 m<br />

Up to 16 A<br />

Insulated<br />

Cu conductors,<br />

painted sheetsteel<br />

enclosure<br />

0.1 ... 0.48 --<br />

2<br />

Edgewise,<br />

flat<br />

(tap-off points<br />

downwards)<br />

2<br />

3<br />

On one side<br />

every 0.5 or 1 m<br />

Up to 63 A<br />

Insulated<br />

Al or Cu<br />

conductors,<br />

painted sheetsteel<br />

enclosure<br />

0.76 Lighting control<br />

Edgewise;<br />

flat and vertical<br />

0.5 ... 3.25 None<br />

On two sides<br />

offset every 0.25<br />

or 0.5 m<br />

Up to 630 A<br />

Al or Cu busbars,<br />

painted sheetsteel<br />

enclosure<br />

0.6 ... 0.67<br />

(without tap-off<br />

points)<br />

Lighting control,<br />

remote switching, signaling and<br />

consumption measurement<br />

Horizontal,<br />

edgewise<br />

and vertical<br />

0.5 ... 3.2 None<br />

On one side<br />

every 1 m<br />

On two sides<br />

every 1 m<br />

Up to 1250 A<br />

Insulated<br />

Al or Cu busbars,<br />

painted sheetsteel<br />

enclosure<br />

4.16 ... 8.83<br />

(without tap-off<br />

points)<br />

Remote switching and signaling<br />

and consumption measurement<br />

Horizontal,<br />

edgewise<br />

and vertical<br />

0.35 ... 3 None<br />

On one side<br />

every 0.5 m<br />

On two sides<br />

every 0.5 m<br />

Up to 1250 A<br />

Insulated 1.95 ... 11.07<br />

Al or Cu busbars, (without tap-off<br />

painted aluminum<br />

points)<br />

enclosure<br />

Remote switching and signaling<br />

and consumption measurement<br />

Horizontal,<br />

edgewise<br />

and vertical<br />

0.5 ... 3 None<br />

On one side<br />

selectable<br />

Up to 630 A<br />

Epoxy resin<br />

system,<br />

Cu busbars<br />

-- --<br />

Siemens LV 70 · 2006<br />

2/7

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Principles of busbar trunking planning<br />

2<br />

■ Overview<br />

Trunking units for currents from <strong>40</strong> to 6300 A<br />

When it comes to developing a power distribution concept,<br />

including the configuring of systems and devices, it is necessary<br />

to coordinate the requirements and possibilities of the end-user<br />

with those of the manufacturer.<br />

With this in mind, the individual systems are described along<br />

with their technical features and applications. Another element is<br />

the graphic representation of the various busbar trunking<br />

elements. All details of importance for the planning work are<br />

specially emphasized and explained.<br />

In "More Information" you will find ideas for a ready-to-use<br />

planning solution. For example, dimensioning principles are<br />

presented and in-depth information given on subjects such as<br />

fire protection through compartmentalization or functional<br />

endurance.<br />

Services and engineering tools are available from Siemens to<br />

simplify the drawing up of customer specifications.<br />

General information<br />

When developing the planning concept of a power supply system<br />

it is necessary not only to consider the standards and<br />

specifications in force but also to clarify the correlations between<br />

economy and technology. Electrical equipment such as distribution<br />

boards and transformers must be dimensioned and<br />

selected so that they represent an optimum in their entirety and<br />

not just individually.<br />

All components must be sufficiently dimensioned for the loads<br />

which arise in the event of a fault as well as during operation at<br />

rated values. Other decisive points to be considered when<br />

drawing up the power concept are:<br />

• The type, utilization and shape of building<br />

(e.g. high-rise, flat-roof and number of storeys)<br />

• Determination of load centers and fixing of possible supply<br />

routes and locations for transformers and main distribution<br />

boards<br />

• Fixing of building-related rating values according to specific<br />

area loads depending on the building's use<br />

• Specifications and requirements imposed by the building<br />

authorities<br />

• Requirements imposed by the power supply companies<br />

The result will never be a single solution but several versions<br />

which must be assessed with regard to their technical and<br />

economic implications. The following requirements are paramount<br />

in this connection:<br />

• Easy and clear-cut planning<br />

• Long life<br />

• High availability<br />

• Low fire load<br />

• Flexible adaptation to alterations in the building<br />

In most applications these requirements are easily met by the<br />

use of suitable busbar. For this reason, busbar rather than the<br />

cable installation method is being used more and more often by<br />

engineering offices for the conveyance and distribution of<br />

power. Siemens offers busbar trunking systems from 25 to<br />

6300 A:<br />

• The CD-K busbar system from 25 to <strong>40</strong> A for supplying power<br />

to lights and miniature loads<br />

• The <strong>BD01</strong> busbar system from <strong>40</strong> to <strong>160</strong> A for supplying<br />

power to workshops with outgoing feeders up to 63 A<br />

• The BD2 system from <strong>160</strong> to 1250 A for supplying power to<br />

medium-size loads in buildings and in industry<br />

• The LD system for supplying power to loads with medium<br />

power consumption and in industry<br />

• The LX sandwich system for the distribution of large amounts<br />

of power in buildings<br />

• The LR encapsulated system for the conveyance of power in<br />

extreme ambient conditions (IP68)<br />

2/8 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Communication-capable busbar trunking<br />

for industry and buildings<br />

■ Overview<br />

Busbar trunking systems<br />

The strengths of busbar trunking systems lie in the conveyance<br />

and distribution and the switching and contacting of electrical<br />

power.<br />

The integration of automation and building management systems<br />

in the Siemens busbar trunking systems results in additional<br />

benefits and at the same time increases the flexibility of the<br />

busbar trunking.<br />

The combination of standard tap-off units with standard ancillary<br />

equipment units ensures efficiency particularly in planning,<br />

installation and operation.<br />

Advantages of the system solution during planning:<br />

• Modular system<br />

• Tested standard components<br />

• Free choice of bus system<br />

• Use of common bus systems<br />

Advantages of the system solution during start-up:<br />

• Easy and quick installation<br />

• Start-up in steps possible<br />

• Flexible in case of expansions and modifications<br />

Advantages of the system solution during operation:<br />

• Transparency of switching states<br />

• Central recording of power costs<br />

• Increase in plant availability as a result of immediate detection<br />

of the type of fault and its location<br />

• Preventive maintenance through recording of hours in operation<br />

and operating cycles<br />

<strong>System</strong> concept of communication-capable busbar trunking<br />

Switching and reporting with the BD2 system<br />

The standardized tap-off units of the busbar trunking systems<br />

can be combined with standard types of ancillary equipment<br />

unit to form a system solution of communication-capable busbar<br />

trunking.<br />

The standard applications are assembled at the factory from a<br />

combination of tap-off unit and ancillary equipment unit. The bus<br />

cable for transmitting the data signals is laid in a cable duct<br />

which must be mounted on the busbar enclosure.<br />

2<br />

Siemens LV 70 · 2006<br />

2/9

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Communication-capable busbar trunking<br />

for industry and buildings<br />

2<br />

Standard application: lighting control<br />

The lighting control application enables the efficient and lowcost<br />

implementation of lighting control systems for large areas<br />

such as are used, for example, in supermarkets, furniture stores<br />

or DIY centers.<br />

The power bus is formed by <strong>BD01</strong> or BD2 busbar trunking from<br />

Siemens, depending on the current requirement.<br />

The standard tap-off units, equipped with miniature circuitbreakers<br />

or fuses, feed CD-K busbar systems which act simultaneously<br />

as the support system for the lighting elements. The<br />

economical and efficient control of extensive lighting systems is<br />

thus possible.<br />

The EIB (European Installation Bus) or AS-Interface bus systems<br />

are suitable for standard applications. On live busbar systems<br />

the tap-off point for power and bus can be adapted to the<br />

operational requirements.<br />

Possible functions of the lighting control<br />

• Three times single-pole switching (L1, L2, L3) or 1/3, 2/3, 3/3<br />

control<br />

• Checkback of switching states<br />

•Lamp test<br />

• Recording of hours in operation and operating cycles<br />

Standard application for consumption recording<br />

The consumption recording function enables the central<br />

recording of distributed power meters.<br />

The time-consuming reading of local meters is no longer necessary.<br />

Integration of the consumption recording in a visualization<br />

or I&C system by means of the data bus creates maximum transparency<br />

in the power distribution board. If recorded continuously,<br />

the measured values collected can be assigned to cost<br />

centers at a central point. The evaluation of trends and histories<br />

enables the data acquired to be analyzed.<br />

The combinations of tap-off unit and ancillary equipment unit<br />

can be equipped with either calibrated or non-calibrated power<br />

meters and enable the quick and transparent presentation of<br />

power consumption levels at the power tap-off points.<br />

The power bus is formed by BD2, LD or LX busbar trunking from<br />

Siemens, depending on the current requirement. Transformer<br />

sets (non-calibrated and calibrated) are available for the various<br />

tap-off units and levels of current.<br />

Possible functions for consumption recording<br />

• Recording of consumption data<br />

• Resetting of meter total<br />

• Indication of a group fault<br />

• Reporting in the event of meter overflow, calling up of<br />

historical data<br />

Standard application for switching and reporting<br />

The application for switching and reporting enables the remote<br />

switching and remote monitoring of power or motor feeders.<br />

The power supply becomes highly transparent through the central<br />

recording of switching and operating states. In the event of<br />

a fault, the type of fault, e.g. short-circuit or overload tripping,<br />

and its location are detected quickly and efficiently so that the<br />

availability of the power supply system is effectively increased.<br />

The power bus is formed by BD2, LD or LX busbar trunking<br />

systems from Siemens, depending on the current requirement.<br />

The combinations of standard tap-off unit and standard device<br />

unit are equipped with corresponding switching devices and<br />

enable the centrally controlled switching and monitoring of the<br />

circuit-breakers.<br />

The AS-Interface or PROFIBUS bus systems are suitable for<br />

standard applications.<br />

Possible functions for switching and reporting<br />

• Central recording of switching and operating states<br />

• Local and central switching<br />

• Switching on is monitored by means of an integrated run-time<br />

monitor<br />

• Fault signal inputs<br />

• Group fault signal<br />

• Short-circuit signal<br />

• Overload signal<br />

• Recording of hours in operation and operating cycles<br />

• Limit value signals<br />

2/10 Siemens LV 70 · 2006

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Busbars instead of cables<br />

■ Overview<br />

Easier when it comes to planning<br />

Easy to plan, quick to install and flexible to use: Siemens busbar<br />

trunking systems are the economical answer for conveying<br />

power into any building. The power distribution system can be<br />

precisely planned from the total load rating and the type and<br />

number of loads. Clarity is assured by the line-shaped network<br />

topology with regularly arranged load feeders. All applications<br />

can be implemented in less time and space with standardized<br />

sizes.<br />

Quicker when it comes to installing<br />

Benefits during installation: busbar trunking systems can be installed<br />

by two persons, saving time and money compared to the<br />

costly cable installation method. Installation errors are practically<br />

ruled out by the safe and user-guided connection technology.<br />

No special tools are required. Another benefit for quick installation:<br />

Siemens busbar trunking systems are easy to fasten<br />

and have large intervals between supports (busbars up to 4 m,<br />

cables every 1.5 m).<br />

Siemens busbar trunking systems are an economical alternative<br />

to the cable installation method.<br />

High short-circuit resistance and<br />

minimum fire load result in greater safety<br />

A step-ahead in terms of safety – be it short-circuit resistance or<br />

fire load. For example, the BD2A-250 busbar trunking systems<br />

have a fire load of only 1.32 kWh/m; comparable cables (NYY<br />

4× 95/50mm 2 ) have 5.19 kWh/m by contrast. And the busbars<br />

are halogen-free. Siemens busbar trunking systems have a high<br />

short-circuit resistance. Also, the near-load protection against<br />

short-circuiting simplifies troubleshooting.<br />

2<br />

High fire load with cables<br />

With cable installation, new loads are connected by way of an additional<br />

sub-distribution board, which is costly and time-consuming<br />

Tap-off units near the loads make local arrangements more transparent<br />

Low fire load with busbar trunking<br />

More flexible in case of expansions and modifications<br />

If the power distribution system has to be adapted to new<br />

requirements, the busbar will take you quicker to your goal.<br />

For example, new tap-off units can simply be mounted on the<br />

tap-off points. The system can be expanded and modified without<br />

difficulty. Tap-off units and system parts increase the flexibility.<br />

Cost-intensive downtimes are eliminated or minimized. The<br />

power distribution system enables faultless operation with high<br />

user-friendliness and safety.<br />

Siemens LV 70 · 2006<br />

2/11

© Siemens AG 2007<br />

Busbar Trunking <strong>System</strong>s, Overview<br />

Notes<br />

2<br />

2/12 Siemens LV 70 · 2006

© Siemens AG 2007<br />

CD-K <strong>System</strong> – 25 ... <strong>40</strong> A<br />

3/2 Introduction<br />

3/7 General data<br />

3/9 Trunking units<br />

3/11 Feeder units<br />

3/12 Tap-off plugs<br />

3/13 Accessories<br />

3/15 Engineering information<br />

3/22 Configuring aids<br />

Siemens LV 70 · 2006

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

© Siemens AG 2007<br />

Introduction<br />

■ Overview<br />

5<br />

4<br />

1<br />

2<br />

2<br />

3<br />

5<br />

5<br />

3<br />

4<br />

3<br />

3<br />

2<br />

NSV0_00035a<br />

5<br />

5<br />

1<br />

4<br />

1 Trunking unit<br />

2 Feeder unit<br />

3 Tap-off plug<br />

4 End flange<br />

5 Optional equipment<br />

3/2 Siemens LV 70 · 2006

© Siemens AG 2007<br />

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

Introduction<br />

Version<br />

Type-tested low-voltage controlgear assembly (TTA)<br />

according to<br />

• IEC/EN 60439-1<br />

• IEC/EN 60439-2<br />

Degree of protection<br />

• High degree of protection to IP54 of the standard version<br />

• Increase to IP55 with accessories<br />

Components<br />

■ Design<br />

Trunking units<br />

3 2 1<br />

NSV0_00001<br />

Trunking units<br />

• 3-, 4-, 5- and 3/5-conductor system<br />

• Equipment on one side:<br />

- 2 or 3 outgoing feeders spaced 1 m apart<br />

- 5 outgoing feeders spaced 0.5 m apart<br />

• Equipment on two sides:<br />

- 2, 3 or 5 outgoing feeders spaced 1 m apart<br />

- 2, 3 or 5 outgoing feeders spaced 0.5 m apart<br />

• Lengths of 2 m and 3 m<br />

• Plug-in connection<br />

• Codable tap-off points<br />

Feeder units<br />

• Entry feeder units<br />

• End feeder units<br />

Tap-off plugs<br />

• 3-pole, 10 A and 16 A, Lx (phase can be plugged over<br />

optionally to L1, L2, L3 ), N and PE<br />

• 5-pole, 10 A and 16 A, L1, L2, L3, N, PE<br />

Accessories<br />

•End flange<br />

• Fixing bracket<br />

• Suspension hook<br />

• Suspension bracket<br />

• Cable fixture<br />

•Coding set<br />

• Degree of protection IP55<br />

1 Locating section<br />

2 Connection terminal<br />

3 Tap-off point<br />

The trunking units are available in lengths of 2 m and 3 m. They<br />

consist of a rectangular, galvanized metal enclosure with a<br />

white-gray paint finish.<br />

They are equipped on one side or two sides with current leads:<br />

• 2 leads for L1 + N (PE = enclosure)<br />

• 3 leads for L1 + L2 + N (PE = enclosure)<br />

• 4 leads for L1 + L2 + L3 + N (PE = enclosure)<br />

Single conductor run:<br />

tap-off points at intervals<br />

of 0,5 or 1 m<br />

The tap-off points are spaced at regular intervals of 0.5 or 1 m on<br />

the trunking unit.<br />

The trunking unit enclosure acts as the PE conductor. Three<br />

current ratings are available: 2 × 25 A, 30 A, <strong>40</strong> A and 2 × <strong>40</strong> A.<br />

All trunking units have finger-safe tap-off points, that can be<br />

coded by the user.<br />

Connections<br />

NSV0_00002<br />

Two conductor runs:<br />

tap-off points at intervals<br />

of 0,5 or 1 m<br />

3<br />

■ Benefits<br />

7 Lower planning costs through simple configuration<br />

7 Quick-release plug-in connection for fast assembly<br />

7 Tap-off points on both sides for optimized utilization of the<br />

busbar<br />

7 Uniform current loading of the conductors through splitting of<br />

the tap-off plugs among the individual phases<br />

7 Tap-off plugs allow fast and flexible load relocation<br />

7 Accessories for increasing the degree of protection to IP55 for<br />

extreme environmental conditions<br />

NSV0_00003<br />

The trunking units, including those with feeder units and flanges,<br />

are assembled without tools by straightforward plug-in connection.<br />

The PE path is established automatically when the enclosures<br />

are connected.<br />

An interlock mechanism with two fixings prevents a loosening of<br />

the connections between the trunking units, Two fixtures prevent<br />

self-disconnection of the connection. No expansion compensation<br />

is required.<br />

Siemens LV 70 · 2006<br />

3/3

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

© Siemens AG 2007<br />

Introduction<br />

End flanges<br />

The phase tap-off can therefore be changed by simply changing<br />

the contacts to another terminal.<br />

NSV0_00004<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00007<br />

These flanges provide protection against direct contact at the<br />

ends of the busbar run. They are suitable for use with all<br />

systems.<br />

Feeder units<br />

L1 + N + PE L2 + N + PE L3 + N + PE<br />

3<br />

Two versions are available:<br />

• as an entry feeder unit for 2 × 25 A, 30 A, <strong>40</strong> A and 2 × <strong>40</strong> A,<br />

• as a end feeder unit for 2 × 25 A, 30 A, <strong>40</strong> A and 2 × <strong>40</strong> A.<br />

One end flange is included as standard with each unit.<br />

Cable entry from three sides. Use metric M25 or M32 plastic<br />

cable glands with strain relief (not included as standard).<br />

Tap-off plugs<br />

Molded plastic-enclosed tap-off plugs are used for taking current<br />

from the tap-off points on the trunking units. They can be<br />

mounted and removed by hand. This is even possible with live<br />

busbars.<br />

The following versions are available:<br />

• 3-pole and 5-pole versions without fuse base with halogenfree,<br />

flame-retardant cable.<br />

• 3-pole and 5-pole version without fuse base with terminal and<br />

plastic M20 cable grommet.<br />

• 3-pole version with fuse base for 8.5 mm × 31.5 mm cylindrical<br />

fuses; type gG (IEC) and type gL (VDE) (quick), with halogen-free,<br />

flame-retardant cable.<br />

• 3-pole and 5-pole versions with fuse bases for one or<br />

three 8.5 mm × 31.5 mm cylindrical fuses; type gG (IEC) and<br />

type gL (VDE) (quick), with terminal and plastic M20 cable<br />

grommet.<br />

NSV0_00005<br />

On the 5-pole tap-off plugs, the phase tap-off can not be<br />

changed.<br />

The phase assignment of the tap-off plugs is visible from the<br />

outside.<br />

NSV0_00037<br />

Tap-off plugs with terminals accept cables up to 2.5 mm 2 . The<br />

connection cables should be supported separately if necessary.<br />

L3<br />

L1<br />

L2<br />

N<br />

L2 L3<br />

L1<br />

N<br />

NSV0_00009<br />

L3<br />

L2<br />

L1<br />

N<br />

NSV0_00010<br />

NSV0_00036<br />

The 3-pole tap-off plugs have a variable phase tap-off, i.e. they<br />

can be plugged over (optionally to L1, L2 or L3).<br />

3/4 Siemens LV 70 · 2006

© Siemens AG 2007<br />

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

Introduction<br />

■ Accessories<br />

Underfloor mounting<br />

Fixing bracket for underfloor mounting<br />

Suspension<br />

The trunking unit profile allows attachment of the suspension<br />

and fixing brackets at any point of the trunking unit.<br />

• Fixing bracket for trunking units and suspension bracket for<br />

luminaires up to max. 20 kg (5-fold safety to DIN 49980).<br />

For more accurate centering, the CD-GP threaded plate can<br />

be used.<br />

NSV0_00011<br />

Coding<br />

Coding can be used for various frequencies and voltages. It can<br />

be retrofitted to the CD-K-... trunking units and the CD-K-A...<br />

tap-off plugs. Three code settings are possible: CD-K1, -K2, -K3.<br />

NSV0_00014<br />

Fixing bracket<br />

• Suspension bracket for suspending trunking units and for<br />

increased mechanical rigidity at the trunking unit connection<br />

points.<br />

3<br />

NSV0_00012<br />

NSV0_00015<br />

Suspension bracket<br />

• Snap-on fixing bracket for suspension from the trunking unit<br />

and for mounting luminaires (for luminaires up to max. 20 kg<br />

at 5-fold safety to DIN 49980). Also allows cables to be routed<br />

alongside the system at a later stage. Snap-on fixing brackets<br />

must be used only for balanced loads, not for concentrated<br />

loads.<br />

NSV0_00038<br />

Fixing bracket, snap-on<br />

• Cables routed with the trunking unit can be secured using the<br />

cable clip.<br />

NSV0_00017<br />

NSV0_00016<br />

Cable clip<br />

Siemens LV 70 · 2006<br />

3/5

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

© Siemens AG 2007<br />

Introduction<br />

Accessories for IP55<br />

Trunking units<br />

The higher degree of protection IP55 is achieved by fitting an<br />

additional seal and a flange at the tap-off point and by sticking<br />

pads over the connection fixtures.<br />

Tap-off plugs<br />

The degree of protection IP55 is achieved by fitting additional<br />

seals at the tap-off point.<br />

NSV0_00987<br />

N<br />

NSV0_00986<br />

Tap-off plug<br />

3<br />

Tap-off point<br />

NSV0_00988<br />

NSV0_00989<br />

Connection point between end flange and trunking unit<br />

Tap-off plug for cylindrical fuses<br />

NSV0_00990<br />

Connection between trunking units<br />

NSV0_00991<br />

Connection between trunking unit and feeder unit<br />

3/6 Siemens LV 70 · 2006

© Siemens AG 2007<br />

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

General data<br />

■ Technical specifications<br />

General technical specifications<br />

Type<br />

Trunking units<br />

CD-K-...<br />

Standards and specifications IEC/EN 60439-1 and -2<br />

Rated insulation voltage U i V AC/DC <strong>40</strong>0/<strong>40</strong>0<br />

Overvoltage category/pollution degree<br />

Rated operational voltage U e V AC <strong>40</strong>0<br />

Frequency Hz 50 ... 60<br />

Resistance to climate Damp heat, constant, according to IEC 60068-2-78<br />

Damp heat, cyclic, according to IEC 60068-2-30<br />

Ambient temperature °C -5 ... +<strong>40</strong><br />

Degree of protection according to IEC/EN 60529<br />

IP54, increase to IP55 with accessories<br />

Material<br />

•Trunking units<br />

Galvanized, painted sheet steel<br />

•Busbars<br />

Tinned and insulated round-section copper wires<br />

Mounting position<br />

Edgewise; tap-off points at the side<br />

Weigth<br />

See "Selection and Ordering Data"<br />

III/3<br />

Type CD-K-1302 CD-K-1303 CD-K-1304 CD-K-2254 (/2)<br />

Conductors<br />

Rated insulation voltage U i V AC/DC <strong>40</strong>0/<strong>40</strong>0 <strong>40</strong>0/<strong>40</strong>0 <strong>40</strong>0/<strong>40</strong>0 <strong>40</strong>0/<strong>40</strong>0<br />

Overvoltage category/pollution degree III/3 III/3 III/3 III/3<br />

Rated operational voltage U e V AC <strong>40</strong>0 <strong>40</strong>0 <strong>40</strong>0 <strong>40</strong>0<br />

Frequency Hz 50 ... 60 50 ... 60 50 ... 60 50 ... 60<br />

Rated current I e = conventional thermal current<br />

A 30 30 30 2 × 25<br />

at max. <strong>40</strong> °C and 35 °C on a 24 h average<br />

Impedance of conductors at 50 Hz<br />

and 20 °C<br />

•Resistance R 20 mΩ/m 5.79 5.79 5.79 4.56<br />

• Reactance X 20 mΩ/m 0.26 0.26 0.26 0.15<br />

• Impedance Z 20 mΩ/m 5.80 5.80 5.80 4.56<br />

Impedance of conductors<br />

under fault conditions<br />

• AC resistance R F mΩ/m 8.24 8.24 8.24 7.50<br />

• Reactance X F mΩ/m 0.44 0.44 0.44 0.32<br />

• Impedance Z F mΩ/m 8.25 8.25 8.25 7.51<br />

Zero impedance according to IEC/EN 60909 (VDE 0102)<br />

•Resistance R 0 Phase to N mΩ/m 24.24 24.24 24.24 18.59<br />

• Reactance X 0 Phase to N mΩ/m 1.77 1.77 1.77 0.82<br />

• Impedance Z 0 Phase to N mΩ/m 24.30 24.30 24.30 18.61<br />

•Resistance R 0 Phase to PE mΩ/m 12.00 12.00 12.00 13.49<br />

• Reactance X 0 Phase to PE mΩ/m 1.80 1.80 1.80 0.82<br />

• Impedance Z 0 Phase to PE mΩ/m 12.13 12.13 12.13 13.52<br />

Short-circuit strength<br />

Rated impulse withstand current I pk kA 2.4 2.4 2.4 3.0<br />

Rated short-time withstand current I cw (t = 1 s) kA 0.56 0.56 0.56 0.69<br />

Rated short-time withstand current I cw (t = 0.1 s) kA 1.6 1.6 1.6 2.0<br />

Conductors<br />

Number of active conductors 2 3 4 2 × 4 (1 × 4, 1 × 2)<br />

Conductor cross-section<br />

• L1, L2, L3 mm 2 3.2 3.2 3.2 4.0<br />

•N mm 2 3.2 3.2 3.2 4.0<br />

• PE (enclosure) = Cu mm 2 11 11 11 11<br />

Conductor material Cu Cu Cu Cu<br />

Fire load kWh/m 0.1 0.15 0.201 0.48<br />

Max. thermal load , I 2 t value A 2 s × 10 3 310 310 310 470<br />

Fixing intervals<br />

m 3 3 3 3<br />

at normal mechanical load<br />

Position of tap-off points<br />

depending on the type: on one side at 0.5 m or 1 m intervals, on both sides at 0.5 m<br />

intervals or alternating from side to side and offset at 0.5 m intervals<br />

3<br />

Siemens LV 70 · 2006<br />

3/7

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

© Siemens AG 2007<br />

General data<br />

3<br />

Type CD-K-1<strong>40</strong>2 CD-K-1<strong>40</strong>3 CD-K-1<strong>40</strong>4 CD-K-2<strong>40</strong>4 (/2)<br />

Conductors<br />

Rated insulation voltage U i V AC/DC <strong>40</strong>0/<strong>40</strong>0 <strong>40</strong>0/<strong>40</strong>0 <strong>40</strong>0/<strong>40</strong>0 <strong>40</strong>0/<strong>40</strong>0<br />

Overvoltage category/pollution degree III/3 III/3 III/3 III/3<br />

Rated operational voltage U e V AC <strong>40</strong>0 <strong>40</strong>0 <strong>40</strong>0 <strong>40</strong>0<br />

Frequency Hz 50 ... 60 50 ... 60 50 ... 60 50 ... 60<br />

Rated current I e = conventional thermal current<br />

at max. <strong>40</strong> °C and 35 °C on a 24 h average<br />

Feeder units, conductor cross-sections<br />

A <strong>40</strong> <strong>40</strong> <strong>40</strong> 2 × <strong>40</strong><br />

Impedance of conductors at 50 Hz<br />

and 20 °C<br />

•Resistance R 20 mΩ/m 3.55 3.55 3.55 3.69<br />

• Reactance X 20 mΩ/m 0.<strong>40</strong> 0.<strong>40</strong> 0.<strong>40</strong> 0.13<br />

• Impedance Z 20 mΩ/m 3.57 3.57 3.57 3.69<br />

Impedance of conductors<br />

under fault conditions<br />

• AC resistance R F mΩ/m 5.61 5.61 5.61 4.17<br />

• Reactance X F mΩ/m 0.80 0.80 0.80 0.<strong>40</strong><br />

• Impedance Z F mΩ/m 5.67 5.67 5.67 4.18<br />

Zero impedance according to IEC/EN 60909 (VDE 0102)<br />

•Resistance R 0 Phase to N mΩ/m 14.85 14.85 14.85 14.33<br />

• Reactance X 0 Phase to N mΩ/m 0.99 0.99 0.99 0.78<br />

• Impedance Z 0 Phase to N mΩ/m 14.88 14.88 14.88 14.33<br />

•Resistance R 0 Phase to PE mΩ/m 9.87 9.87 9.87 5.15<br />

• Reactance X 0 Phase to PE mΩ/m 1.02 1.02 1.02 0.74<br />

• Impedance Z 0 Phase to PE mΩ/m 9.92 9.92 9.92 5.21<br />

Short-circuit strength<br />

Rated impulse withstand current I pk kA 3.6 3.6 3.6 3.6<br />

Rated short-time withstand current I cw (t = 1 s) kA 0.85 0.85 0.85 0.85<br />

Rated short-time withstand current I cw (t = 0.1 s) kA 2.4 2.4 2.4 2.4<br />

Conductors<br />

Number of active conductors 2 3 4 2 × 4 (1 × 4, 1 × 2)<br />

Conductor cross-section<br />

• L1, L2, L3 mm 2 5.0 5.0 5.0 5.0<br />

•N mm 2 5.0 5.0 5.0 5.0<br />

• PE (enclosure) = Cu mm 2 11 11 11 11<br />

Conductor material Cu Cu Cu Cu<br />

Fire load kWh/m 0.12 0.18 0.24 0.48<br />

Max. thermal load, I 2 t value A 2 s × 10 3 720 720 720 720<br />

Fixing intervals<br />

m 3 3 3 3<br />

at normal mechanical load<br />

Position of tap-off points<br />

depending on the type: on one side at 0.5 m or 1 m intervals, on both sides at 0.5 m<br />

intervals or alternating from side to side and offset at 0.5 m intervals<br />

Version Type L1, L2, L3 N PE<br />

Tap-off plugs<br />

min.<br />

mm 2<br />

max.<br />

mm 2<br />

Entry feeder unit CD-K-...-EA 2.5 6 (f)<br />

10 (e, m)<br />

End feeder unit CD-K-...-EE 2.5 6 (f)<br />

10 (e, m)<br />

min.<br />

mm 2<br />

max.<br />

mm 2<br />

2.5 6 (f)<br />

10 (e, m)<br />

2.5 6 (f)<br />

10 (e, m)<br />

f = flexible with end sleeve, so = solid, st = stranded<br />

min.<br />

mm 2<br />

max.<br />

mm 2<br />

2.5 6 (f)<br />

10 (e, m)<br />

2.5 6 (f)<br />

10 (e, m)<br />

Type<br />

CD-K-A...<br />

Version<br />

3- or 5-pole<br />

Rated current I e A 10 or 16<br />

Switching capacity according to IEC/EN 60947-3<br />

• Utilization category<br />

AC-20B<br />

Connection<br />

without or with permanently attached cable;<br />

the PE operates as a leading contact during connection and as a delayed contact<br />

during removal<br />

Fuses<br />

without or with fuse holder for cylindrical fuses 8.5 mm × 31.5 mm,<br />

type gG (IEC) or type gL (VDE) (quick)<br />

3/8 Siemens LV 70 · 2006

© Siemens AG 2007<br />

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

Trunking units<br />

■ Selection and ordering data<br />

Version Length Conductor Tap-off points DT Type Order No. PS* Weight<br />

Number Distance<br />

per unit<br />

approx.<br />

m m kg<br />

Rated current I e = 30 A, tap-off points on one side<br />

Trunking units<br />

sheet steel enclosure,<br />

3 3-pole 3 1 A CD-K-1302-3 BVP:211151 6 units 2.450<br />

color similar to RAL 9002 (white-gray),<br />

L1<br />

codable tap-off points<br />

N<br />

PE<br />

NSV0_00236<br />

3 4-pole 3 1 A CD-K-1303-3 BVP:211152 6 units 2.550<br />

NSV0_00201<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00237<br />

2 5-pole 2 1 A CD-K-1304-2 BVP:211153 6 units 1.850<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

3 5-pole 3 1 A CD-K-1304-3 BVP:211154 6 units 2.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

3 5-pole 5 0.5 A CD-K-1304-3-05 BVP:211155 6 units 2.650<br />

3<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

Rated current I e = <strong>40</strong> A, tap-off points on one side<br />

Trunking units<br />

sheet steel enclosure,<br />

3 3-pole 3 1 A CD-K-1<strong>40</strong>2-3 BVP:211156 6 units 2.450<br />

color similar to RAL 9002 (white-gray),<br />

L1<br />

codable tap-off points<br />

N<br />

PE<br />

NSV0_00236<br />

3 4-pole 3 1 A CD-K-1<strong>40</strong>3-3 BVP:211157 6 units 2.550<br />

NSV0_00201<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00237<br />

2 5-pole 2 1 A CD-K-1<strong>40</strong>4-2 BVP:211158 6 units 1.850<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

3 5-pole 3 1 A CD-K-1<strong>40</strong>4-3 BVP:211159 6 units 2.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

3 5-pole 5 0.5 A CD-K-1<strong>40</strong>4-3-05 BVP:211<strong>160</strong> 6 units 2.850<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

* You can order this quantity or a multiple thereof.<br />

Siemens LV 70 · 2006<br />

3/9

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

© Siemens AG 2007<br />

Trunking units<br />

Version Length Conductor Tap-off points DT Type Order No. PS* Weight<br />

Number Distance<br />

per unit<br />

approx.<br />

m m kg<br />

Rated current I e = 2 × 25 A, tap-off points on two sides<br />

Trunking units<br />

sheet steel enclosure,<br />

2 2 × 5-pole 2; 1 1 A CD-K-2254-2 BVP:211161 6 units 2.350<br />

L3<br />

color similar to RAL 9002 (white-gray),<br />

L2<br />

codable tap-off points<br />

L1<br />

N<br />

PE<br />

NSV0_00239<br />

3 2 × 5-pole 3; 2 1 A CD-K-2254-3 BVP:211162 6 units 3.650<br />

NSV0_00201<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00239<br />

3 2 × 5-pole 5; 5 0.5 A CD-K-2254-3-05 BVP:211163 6 units 3.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00239<br />

2 5- + 3-pole 2; 1 1 A CD-K-2254/2-2 BVP:610352 6 units 2.350<br />

3<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L1<br />

N<br />

NSV0 002<strong>40</strong><br />

3 5- + 3-pole 3; 2 1 A CD-K-2254/2-3 BVP:610353 6 units 3.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L1<br />

N<br />

NSV0 002<strong>40</strong><br />

3 5- + 3-pole 5; 5 0.5 A CD-K-2254/2-3-05 BVP:610354 6 units 3.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L1<br />

N<br />

NSV0 002<strong>40</strong><br />

Rated current I e = 2 × <strong>40</strong> A, tap-off points on two sides<br />

Trunking units<br />

sheet steel enclosure ,<br />

2 2 × 5-pole 2; 1 1 A CD-K-2<strong>40</strong>4-2 BVP:610001 6 units 2.350<br />

L3<br />

color similar to RAL 9002 (white-gray),<br />

L2<br />

codable tap-off points<br />

L1<br />

N<br />

PE<br />

NSV0_00239<br />

3 2 × 5-pole 3; 2 1 A CD-K-2<strong>40</strong>4-3 BVP:610002 6 units 3.650<br />

NSV0_00201<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00239<br />

3 2 × 5-pole 5; 5 0.5 A CD-K-2<strong>40</strong>4-3-05 BVP:610003 6 units 3.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00239<br />

2 5- + 3-pole 2; 1 1 A CD-K-2<strong>40</strong>4/2-2 BVP:610357 6 units 2.350<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L1<br />

N<br />

NSV0 002<strong>40</strong><br />

3 5- + 3-pole 3; 2 1 A CD-K-2<strong>40</strong>4/2-3 BVP:610358 6 units 3.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L1<br />

N<br />

NSV0 002<strong>40</strong><br />

3 5- + 3-pole 5; 5 0.5 A CD-K-2<strong>40</strong>4/2-3-05 BVP:610359 6 units 3.650<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L1<br />

N<br />

NSV0 002<strong>40</strong><br />

3/10 Siemens LV 70 · 2006<br />

* You can order this quantity or a multiple thereof.

© Siemens AG 2007<br />

CD-K <strong>System</strong> — 25 ... <strong>40</strong> A<br />

Feeder units<br />

■ Selection and ordering data<br />

Version Length Conductor DT Type Order No. PS* Weight<br />

per unit<br />

approx.<br />

m<br />

kg<br />

Feeder unit, incl. CD-EF end flange<br />

Molded-plastic enclosure,<br />

terminals for 2.5 to 10 mm 2 cables,<br />

cable entry from 3 sides,<br />

suitable for plastic cable glands with strain relief,<br />

M25 or M32 (not included as standard)<br />

Rated current I e = 30 A, tap-off points on one side<br />

Entry feeder units 0.23 5-pole A CD-K-1304-EA BVP:211164 1 unit 0.320<br />

NSV0_00202<br />

End feeder units 0.23 5-pole A CD-K-1304-EE BVP:211165 1 unit 0.450<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

NSV0_00203<br />

Rated current I e = <strong>40</strong> A, tap-off points on one side<br />

Entry feeder units 0.23 5-pole A CD-K-1<strong>40</strong>4-EA BVP:211166 1 unit 0.320<br />

NSV0_00202<br />

End feeder units 0.23 5-pole A CD-K-1<strong>40</strong>4-EE BVP:211167 1 unit 0.450<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

L3<br />

L2<br />

L1<br />

N<br />

PE<br />

NSV0_00238<br />

NSV0_00238<br />

3<br />

NSV0_00203<br />