INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

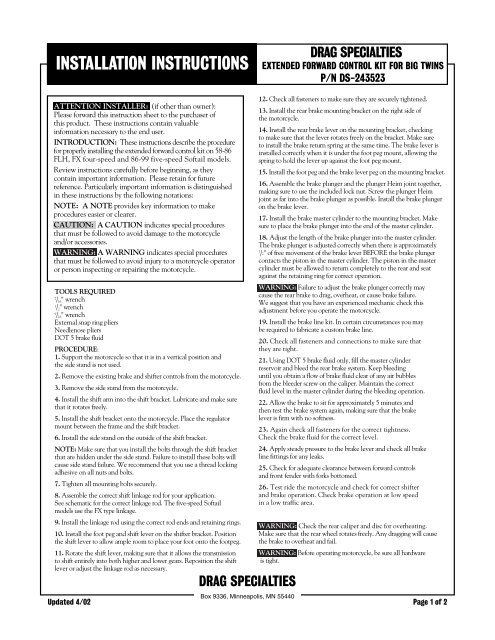

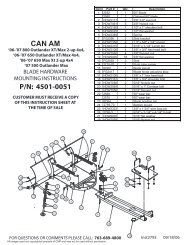

<strong>INSTALLATION</strong> <strong>INSTRUCTIONS</strong><br />

DRAG SPECIALTIES<br />

EXTENDED FORWARD CONTROL KIT FOR BIG TWINS<br />

P/N DS-243523<br />

ATTENTION INSTALLER: (if other than owner):<br />

Please forward this instruction sheet to the purchaser of<br />

this product. These instructions contain valuable<br />

information necessary to the end user.<br />

INTRODUCTION: These instructions describe the procedure<br />

for properly installing the extended forward control kit on 58-86<br />

FLH, FX four-speed and 86-99 five-speed Softail models.<br />

Review instructions carefully before beginning, as they<br />

contain important information. Please retain for future<br />

reference. Particularly important information is distinguished<br />

in these instructions by the following notations:<br />

NOTE: A NOTE provides key information to make<br />

procedures easier or clearer.<br />

CAUTION: A CAUTION indicates special procedures<br />

that must be followed to avoid damage to the motorcycle<br />

and/or accessories.<br />

WARNING: A WARNING indicates special procedures<br />

that must be followed to avoid injury to a motorcycle operator<br />

or person inspecting or repairing the motorcycle.<br />

TOOLS REQUIRED<br />

7<br />

/ 16 " wrench<br />

1<br />

/ 2 " wrench<br />

9<br />

/ 16 " wrench<br />

External snap ring pliers<br />

Needlenose pliers<br />

DOT 5 brake fluid<br />

PROCEDURE:<br />

1. Support the motorcycle so that it is in a vertical position and<br />

the side stand is not used.<br />

2. Remove the existing brake and shifter controls from the motorcycle.<br />

3. Remove the side stand from the motorcycle.<br />

4. Install the shift arm into the shift bracket. Lubricate and make sure<br />

that it rotates freely.<br />

5. Install the shift bracket onto the motorcycle. Place the regulator<br />

mount between the frame and the shift bracket.<br />

6. Install the side stand on the outside of the shift bracket.<br />

NOTE: Make sure that you install the bolts through the shift bracket<br />

that are hidden under the side stand. Failure to install these bolts will<br />

cause side stand failure. We recommend that you use a thread locking<br />

adhesive on all nuts and bolts.<br />

7. Tighten all mounting bolts securely.<br />

8. Assemble the correct shift linkage rod for your application.<br />

See schematic for the correct linkage rod. The five-speed Softail<br />

models use the FX type linkage.<br />

9. Install the linkage rod using the correct rod ends and retaining rings.<br />

10. Install the foot peg and shift lever on the shifter bracket. Position<br />

the shift lever to allow ample room to place your foot onto the footpeg.<br />

11. Rotate the shift lever, making sure that it allows the transmission<br />

to shift entirely into both higher and lower gears. Reposition the shift<br />

lever or adjust the linkage rod as necessary.<br />

DRAG SPECIALTIES<br />

12. Check all fasteners to make sure they are securely tightened.<br />

13. Install the rear brake mounting bracket on the right side of<br />

the motorcycle.<br />

14. Install the rear brake lever on the mounting bracket, checking<br />

to make sure that the lever rotates freely on the bracket. Make sure<br />

to install the brake return spring at the same time. The brake lever is<br />

installed correctly when it is under the foot peg mount, allowing the<br />

spring to hold the lever up against the foot peg mount.<br />

15. Install the foot peg and the brake lever peg on the mounting bracket.<br />

16. Assemble the brake plunger and the plunger Heim joint together,<br />

making sure to use the included lock nut. Screw the plunger Heim<br />

joint as far into the brake plunger as possible. Install the brake plunger<br />

on the brake lever.<br />

17. Install the brake master cylinder to the mounting bracket. Make<br />

sure to place the brake plunger into the end of the master cylinder.<br />

18. Adjust the length of the brake plunger into the master cylinder.<br />

The brake plunger is adjusted correctly when there is approximately<br />

1<br />

/2" of free movement of the brake lever BEFORE the brake plunger<br />

contacts the piston in the master cylinder. The piston in the master<br />

cylinder must be allowed to return completely to the rear and seat<br />

against the retaining ring for correct operation.<br />

WARNING: Failure to adjust the brake plunger correctly may<br />

cause the rear brake to drag, overheat, or cause brake failure.<br />

We suggest that you have an experienced mechanic check this<br />

adjustment before you operate the motorcycle.<br />

19. Install the brake line kit. In certain circumstances you may<br />

be required to fabricate a custom brake line.<br />

20. Check all fasteners and connections to make sure that<br />

they are tight.<br />

21. Using DOT 5 brake fluid only, fill the master cylinder<br />

reservoir and bleed the rear brake system. Keep bleeding<br />

until you obtain a flow of brake fluid clear of any air bubbles<br />

from the bleeder screw on the caliper. Maintain the correct<br />

fluid level in the master cylinder during the bleeding operation.<br />

22. Allow the brake to sit for approximately 5 minutes and<br />

then test the brake system again, making sure that the brake<br />

lever is firm with no softness.<br />

23. Again check all fasteners for the correct tightness.<br />

Check the brake fluid for the correct level.<br />

24. Apply steady pressure to the brake lever and check all brake<br />

line fittings for any leaks.<br />

25. Check for adequate clearance between forward controls<br />

and front fender with forks bottomed.<br />

26. Test ride the motorcycle and check for correct shifter<br />

and brake operation. Check brake operation at low speed<br />

in a low traffic area.<br />

WARNING: Check the rear caliper and disc for overheating.<br />

Make sure that the rear wheel rotates freely. Any dragging will cause<br />

the brake to overheat and fail.<br />

WARNING: Before operating motorcycle, be sure all hardware<br />

is tight.<br />

Box 9336, Minneapolis, MN 55440<br />

Updated 4/02 Page 1 of 2

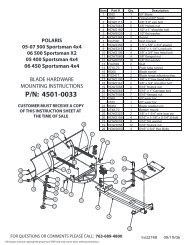

<strong>INSTALLATION</strong> <strong>INSTRUCTIONS</strong><br />

DRAG SPECIALTIES<br />

EXTENDED FORWARD CONTROL KIT FOR BIG TWINS<br />

P/N DS-243523<br />

OPTIONAL MASTER CYLINDER FOR<br />

DRUM BRAKE APPKICATION<br />

79 THRU 86 TRANSMISSIONS FX MODELS<br />

79 THRU 86 TRANSMISSIONS<br />

FL AND FXWG MODELS<br />

DRAG SPECIALTIES<br />

NO. QTY. DESCRIPTION<br />

1 1 Plate, brake lever<br />

2 1 Brake lever<br />

3 1 Plunger Heim joint<br />

4 1 Master cylinder<br />

5 1 Brake return spring<br />

6 1 Master cylinder plunger<br />

7 2 Foot peg<br />

8 2 Foot peg mounting kit<br />

9 1 Brake line kit<br />

10 1 Shifter bracket<br />

11 1 Shift arm<br />

12 1 Shift lever<br />

13 1 Shifter rod, FX type<br />

14 1 Shifter rod Heim joint, FX type<br />

15 1 Shifter rod Heim joint, FL type<br />

16 1 Shifter rod, FL type<br />

17 2 Peg, shifter and brake<br />

18 1 3/ 4" nylock nut<br />

19 1 3/ 8" - 16 x 4" bolt<br />

20 4 3/ 8" - 16 x 1" bolt<br />

21 2 5/ 16" - 24 x 2 1 / 4" bolt<br />

22 4 5/ 16" - 24 x 1 1 / 4" bolt<br />

23 1 1/ 4" - 28 x 5 / 16" set screw<br />

24 9 5/ 16" - 24 acorn nut<br />

25 3 3/ 8" int. tooth lockwasher<br />

26 1 5/ 16" - 24 x 1" bolt<br />

27 2 3/ 8" lockwasher<br />

28 8 5/ 16" lockwasher<br />

29 1 3/ 8" flatwasher (1 3 / 8" o.d.)<br />

30 1 Retaining ring<br />

31 3 Cable tie, black 7"<br />

32 1 1/ 4" - 28 UNF nut<br />

33 1 1/ 4" - 20 x 1" bolt<br />

34 1 1/ 4" flatwasher<br />

35 4 5/ 16" flatwasher<br />

36 1 Clevis pin kit<br />

Box 9336, Minneapolis, MN 55440<br />

Updated 4/02 Page 2 of 2