MTConnect: Different Devices, Common Connection Changing ...

MTConnect: Different Devices, Common Connection Changing ...

MTConnect: Different Devices, Common Connection Changing ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

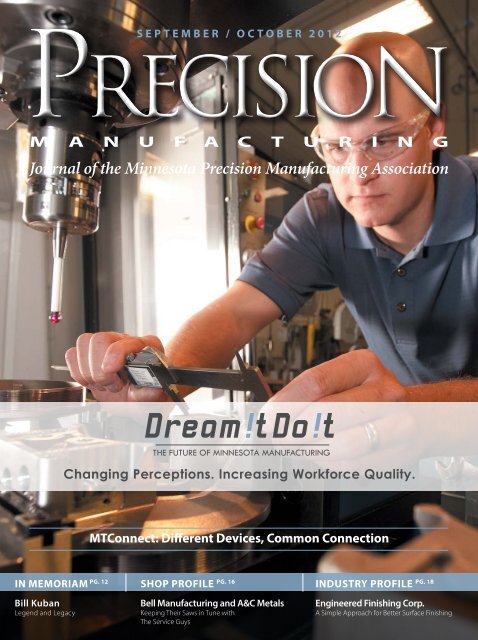

SEPTEMBER / OCTOBER 2012<br />

THE FUTURE OF MINNESOTA MANUFACTURING<br />

<strong>Changing</strong> Perceptions. Increasing Workforce Quality.<br />

<strong>MTConnect</strong>: <strong>Different</strong> <strong>Devices</strong>, <strong>Common</strong> <strong>Connection</strong><br />

PG. 12<br />

IN MEMORIAM<br />

Bill Kuban<br />

Legend and Legacy<br />

SHOP PROFILE<br />

PG. 16<br />

Bell Manufacturing and A&C Metals<br />

Keeping Their Saws in Tune with<br />

The Service Guys<br />

INDUSTRY PROFILE<br />

PG. 18<br />

Engineered Finishing Corp.<br />

A Simple Approach for Better Surface Finishing

Haas Automation<br />

Five-axis machining centers are so expensive you’d better<br />

be using them exclusively for complex five-axis work.<br />

Haas is <strong>Different</strong>.<br />

Haas 5-axis Trunnion VMCs are so affordable that many shops save tons of<br />

time using them for single-setup, multi-surface parts positioning. You can<br />

reach five sides of a part in one setup, or do simultaneous 3D work with an<br />

affordable five-axis setup. Either way, you’re way ahead of the game.<br />

Haas Factory Outlet<br />

A Division of Productivity, Inc.<br />

15200 25th Ave. North, Suite 120, Minneapolis, MN 55447<br />

Tel: 763-742-1263 • Fax: 763-476-4092<br />

430<br />

MinnesotA I 15150 25th Ave. N., Plymouth, MN 55447<br />

p: 763.742.1263 I e: hfomn@productivity.com

FEDERATED®<br />

Your Association Does!<br />

More than 400 associations representing 800,000 members<br />

exclusively recommend one or more Federated Insurance programs.<br />

Contact your local marketing representative to find out why.<br />

Visit www.federatedinsurance.com to find a representative near you.<br />

It’s Our Business<br />

to Protect Yours ®<br />

Federated Mutual Insurance Company • Federated Service Insurance Company* • Federated Life Insurance Company<br />

Home Office: 121 East Park Square • Owatonna, Minnesota 55060 • Phone: (507) 455-5200 • www.federatedinsurance.com<br />

*Federated Service Company is not licensed in the states of NH, NJ, RI, and VT.<br />

© Copyright 2012 • Federated Mutual Insurance Company

Precision<br />

Manufacturing<br />

w w w . p m - m n . c o m<br />

ISO 9001: 2008 certified<br />

CNC Milling | CNC Turning<br />

Manual Milling and Turning<br />

Surface Grinding<br />

Prototypes | Assembly<br />

Michael Yeager President<br />

mike@yeagermachine.com<br />

www.yeagermachine.com<br />

415 Tacoma Circle | Norwood Young America, MN 55368<br />

952.467.2800 office | 952.467.2880 fax<br />

Supporting Minnesota in becoming the world leader in precision<br />

contract manufacturing and related technologies.<br />

Editor & Publications Manager Amy Slettum<br />

Sales Manager<br />

Tim Crolley<br />

Designer & Art Director<br />

Severyn Skoug<br />

MINNESOTA PRECISION MANUFACTURING ASSOCIATION<br />

5353 Wayzata Blvd., Suite 350 • Minneapolis, MN 55416<br />

952.564.3041 • www.mpma.com<br />

MPMA OFFICERS<br />

President<br />

Paul Huot, Huot Manufacturing Company<br />

Vice President<br />

Treasurer<br />

Secretary<br />

Executive Director<br />

Associate Director<br />

Kimberly Arrigoni, Haberman Machine, Inc.<br />

Daniel Meyer, International Precision Machining, Inc.<br />

Jennifer Salisbury, Mack Engineering Corp.<br />

Jaime Nolan, CAE<br />

Luann Bartley<br />

EDITORIAL COMMITTEE<br />

Chair, Editor-in-Chief<br />

Brenda Kyle - blk@sppa.com<br />

Michelle Gates - mgates@bpkz.com<br />

Bill Remes - remesbill@aol.com<br />

Chuck Remillard - chuckr@kurt.com<br />

Ted Roberts - troberts@robertsautomatic.com<br />

Andrew Skoog - andrew@hexpedite.com<br />

Fred Zimmerman - zimco@visi.com<br />

Precision Manufacturing, (ISSN 0273-7523) is published six times per year by<br />

IntrinXec Management Inc., 5353 Wayzata Blvd., Suite 350, Minneapolis, MN 55416.<br />

Precision Manufacturing is the only authorized regular publication of the<br />

Minnesota Precision Manufacturing Association (MPMA). Opinions and<br />

conclusions expressed in the magazine are those of the individual writer and<br />

do not necessarily reflect the official position of the MPMA or its officers.<br />

Advertising rates provided on request. Correspondence regarding the<br />

magazine, including industry news releases, photographs and press releases<br />

relating to precision manufacturing should be sent to Precision Manufacturing,<br />

Amy Slettum, c/o IntrinXec Management, Inc., 5353 Wayzata Blvd., Suite 350,<br />

Minneapolis, MN 55416. Electronic correspondence, including attached files<br />

in Word or plain text formats, may be sent to amy@mpma.com. Unsolicited<br />

materials will not be returned.<br />

POSTMASTER: Send address changes to: Precision Manufacturing, c/o IntrinXec<br />

Management, Inc., 5353 Wayzata Blvd., Suite 350, Minneapolis, MN 55416.<br />

For editorial, advertising or membership information:<br />

Phone: (952) 564-3041<br />

Fax: (952) 252-8096<br />

Copyright ©2012 Minnesota Precision Manufacturing Association.<br />

AWARDS<br />

- Association TRENDS 2009, 2010<br />

- American Graphic Design Award 2010<br />

- MSAE Award of Excellence. 2008, 2010<br />

MEMBERS OF<br />

follow us<br />

@ twitter.com/mpmajournal<br />

4 | PRECISION MANUFACTURING September | October 2012

CONTENTS September | October 2012<br />

8<br />

DEPARTMENTS<br />

Departments<br />

7 President’s Letter<br />

7 MPMA Calendar<br />

26 Manufacturers’<br />

Marketplace<br />

28 MPMA Member<br />

Directory<br />

33 Advertisers’ Index<br />

Features<br />

FEATURES<br />

THE FUTURE OF MINNESOTA MANUFACTURING<br />

8 Dream !t Do !t Initiative<br />

<strong>Changing</strong> Perceptions. Increasing Workforce Quality.<br />

by Harrison Lloyd with contributions from Karen White<br />

12 In Memoriam<br />

Bill Kuban: Legend and Legacy<br />

by B Kyle<br />

16 Shop Profile: Bell Manufacturing and A&C Metals<br />

Keeping Their Saws in Tune with The Service Guys<br />

by Melissa DeBilzan<br />

18 Industry Profile: Engineered Finishing Corp.<br />

A Simple Approach<br />

22 Feature Story: <strong>MTConnect</strong><br />

<strong>Different</strong> <strong>Devices</strong>, <strong>Common</strong> <strong>Connection</strong><br />

by Dave Edstrom<br />

12 16 18 22<br />

COLUMNS<br />

Columns<br />

11 Manufacturing Marvels<br />

Election Fervor in 2012<br />

15 Made In Minnesota<br />

Tower Solutions<br />

20 Who’s Who<br />

Karen White<br />

Bemidji State University<br />

24 Best Practices<br />

Environmentally<br />

Green<br />

34 Metaling Affairs<br />

Gone Fishing<br />

E-CLUSIVES<br />

E-clusives<br />

E-clusives are online only<br />

@ www.pm-mn.com.<br />

End the Uncertainty so<br />

Manufacturing Can Grow<br />

Advancing Manufacturing,<br />

Tomorrow and Today<br />

Lean from Beginning<br />

September | October 2012 PRECISION MANUFACTURING | 5

MC103<br />

POWERFUL SOLUTIONS. GLOBAL FORCE.<br />

s<br />

orea<br />

orea Ltd.<br />

hihwa Industr. Complex<br />

Dong, Shihung-Shi,<br />

Specials are Our Standard<br />

Korea 429-450<br />

4 4506<br />

4 4507<br />

ugal<br />

N, S.L.<br />

Tie Rod Cylinders<br />

Series H<br />

Series LH<br />

Series A<br />

s<br />

Arriba<br />

gium,<br />

Denmark,<br />

States<br />

E Ede<br />

de<br />

com<br />

A long<br />

Milwauk<br />

pneum<br />

certifie<br />

Our<br />

pos<br />

of<br />

p<br />

ma<br />

hydrau<br />

WORKHOLDING E214<br />

ISO 9001<br />

REGISTERED<br />

Boosters<br />

Air Oil Tanks<br />

Accumulators<br />

Alignment Couplers<br />

Design Engineer’s Guide<br />

WORKHOLDING<br />

CATALOG<br />

WORK<br />

A global resource of workholding solutions<br />

Midwest Machine Tool Supply<br />

230 Commerce Circle South, Fridley, MN 55432-3148 • 763-571-3550<br />

800-327-9523 • Fax 763-571-3790 • www.midwestmachinetool.com<br />

Fargo Operations: 4340-15th Ave. N., Fargo, ND 58102 701-356-3810 Fax 701-356-3812<br />

YOUR Milwaukee Cylinder and Enerpac Workholding DISTRIBUTOR

MPMA EVENTS:<br />

SEPTEMBER<br />

Sept. 20 - 11 a.m. registration<br />

SHOOT FOR SCHOLARSHIPS<br />

Keynote Speaker: Lawrence J. Yatch II<br />

Location: Minnesota Horse & Hunt Club<br />

OCTOBER<br />

Oct. 21-27<br />

MANUFACTURERS WEEK<br />

THE FUTURE OF MINNESOTA MANUFACTURING<br />

Oct. 21-27<br />

DREAM !T DO !T STATEWIDE TOUR OF<br />

MANUFACTURING<br />

Oct. 23<br />

MINNESOTA MANUFACTURERS SUMMIT<br />

Location: Hilton Minneapolis/St. Paul<br />

Airport<br />

Time: TBD<br />

Oct. 25 - 5:30 p.m.<br />

MPMA ANNUAL MEETING<br />

Location: Marriott Minneapolis West<br />

Oct. 30 - 6:00 p.m.<br />

MINNESOTA MANUFACTURING AWARDS<br />

Keynote Speaker: Harry Moser<br />

Location: Metropolitan Ballroom<br />

NOVEMBER<br />

Nov. 15<br />

For Members Only<br />

MANUFACTURING FACILITY TOUR<br />

Location: Mold-Tech, Inc.<br />

Time: TBD<br />

Manufacturing as a Career<br />

OUR FUTURE WORKFORCE<br />

by Paul Huot<br />

As manufacturers and business<br />

managers we are looking for the right<br />

employees to help our business succeed. Part<br />

of the current issue is that young people are<br />

not looking at manufacturing as a career.<br />

We all know the challenges. High school<br />

students are not shown all of the career<br />

opportunities possible in the manufacturing<br />

industry and are discouraged from pursuing<br />

many of the technical skills we need.<br />

In this issue the cover story is on the<br />

Dream It. Do It. initiative, educating<br />

people looking for a career about what<br />

manufacturing has to offer. I am proud<br />

to announce that the MPMA Board<br />

of Directors has approved $30,000 to<br />

support bringing the campaign statewide.<br />

Dream It. Do It. Initiative<br />

The Dream It. Do It. initiative is being<br />

sponsored by other Minnesota associations<br />

as well, including Tri-State Manufacturers’<br />

Association, West Central Initiative<br />

(WCI), MNSCU’s 360° Manufacturing,<br />

Applied Engineering Center of Excellence,<br />

Central Minnesota Manufacturers<br />

Association, and manufacturers from the<br />

Brainerd Lakes area. This is another great<br />

example of different associations working<br />

together for a common cause.<br />

We have seen programs that promote<br />

jobs in manufacturing come and go without<br />

much success. I like this program because<br />

it’s nationwide, promoting manufacturing<br />

careers to students around the country.<br />

The new Dream It. Do It. Web site<br />

will have resources for parents, teachers,<br />

school counselors, and prospective future<br />

employees. Prospective employees can find<br />

information on the types of jobs available,<br />

what they pay, and what schools offer the<br />

training someone would need to get that<br />

position. In addition, the Web site will<br />

offer success stories, with video interviews<br />

from local people in the industry telling<br />

their story and how they got started in<br />

manufacturing and the benefits.<br />

If you haven’t already noticed,<br />

billboard advertising for the Dream<br />

It. Do It. initiative has already started<br />

PRESIDENT’S LETTER<br />

around the state. More billboards are<br />

expected to be mounted around the<br />

metro area as the campaign gets into<br />

full swing during Manufacturers Week<br />

in October. In addition, you will see<br />

online radio ads and social media sites<br />

promoting the campaign.<br />

A Younger Generation<br />

As an organization, the MPMA asked<br />

the staff to look at ideas for ways to attract<br />

young people to manufacturing. Harrison<br />

Lloyd, marketing communications<br />

specialist took on the project and found<br />

the Dream It. Do It. campaign. It included<br />

everything the Board had asked him to<br />

develop, so he figured why reinvent it.<br />

Harrison contacted and collaborated<br />

with Karen White at 360° Center of<br />

Excellence who manages the campaign.<br />

The information then was presented to the<br />

Board and we unanimously voted that this<br />

was something the MPMA could work with<br />

and wanted to help bring statewide.<br />

You can help this campaign work.<br />

Find employees who are excelling in your<br />

business and talk to them about telling<br />

their story. Contact Harrison@mpma.<br />

com for more information.<br />

You or someone in your organization<br />

also can join the MPMA Workforce<br />

Development Committee. The mission<br />

of this committee is to support industry<br />

through workforce development. The<br />

goals of this committee include: identifing<br />

the educational needs of the industry;<br />

supporting current trends within industry;<br />

increasing awareness of job opportunities<br />

in the industry; and connecting with<br />

industry peers.<br />

If you would like to get involved in<br />

this committee contact me at P.Huot@<br />

huot.com or Jaime@mpma.com.<br />

PM<br />

PAUL HUOT is the president<br />

of Huot Manufacturing. He<br />

can be reached at<br />

p.huot@huot.com.<br />

September | October 2012 PRECISION MANUFACTURING | 7

THE FUTURE OF MINNESOTA MANUFACTURING<br />

Dream !t Do !t Initiative<br />

<strong>Changing</strong> Perceptions. Increasing Workforce Quality.<br />

by Harrison Lloyd with contributions from Karen White<br />

Minnesota manufacturers continually have expressed concern about their industry’s image. Despite<br />

offering over 3,300 clean, high-paying new jobs to the Minnesota market every year, parents and<br />

teachers are not encouraging young people to consider manufacturing careers. The Dream It. Do It.<br />

promotional campaign is the industry’s immediate response to manufacturers’ hiring challenges, aimed<br />

at changing perceptions and increasing the quality of Minnesota’s manufacturing workforce.<br />

8 | PRECISION MANUFACTURING September | October 2012

COVER STORY<br />

Dream It. Do It. is a national effort produced by the National<br />

Association of Manufacturers (NAM) to promote manufacturing<br />

careers to students around the country. Here in Minnesota,<br />

the initiative is spearheaded by Minnesota State Colleges and<br />

Universities (MNSCU’s) 360° Manufacturing and Applied<br />

Engineering ATE Regional Center of Excellence, led by Bemidji State<br />

University. The campaign has served West Central Minnesota with<br />

Tri-State Manufacturers’ Association since 2009 and, more recently,<br />

the Brainerd Lakes area manufacturers.<br />

In a new collaborative effort with the Minnesota Precision<br />

Manufacturing Association (MPMA), the campaign plans to take<br />

its message statewide to create a brand image for the manufacturing<br />

industry. The Dream it. Do it. brand name will become the banner<br />

that unites manufacturers, technical colleges, middle and high<br />

schools, students, and parents in the statewide workforce development<br />

effort. The new launch will feature various Minnesota manufacturers<br />

and their employees by sharing stories of men and women who are<br />

passionate about their manufacturing careers. The initiative will show<br />

the public what modern manufacturing looks like every day.<br />

Over the past few months, Dream It. Do It. has been interviewing<br />

a diverse group of companies and manufacturing professionals who<br />

have high job satisfaction and break the “assembly line” stereotype. The<br />

highlighted interviewees are portrayed in clean environments where<br />

they are well paid, respected, and engaged in their work.<br />

For example, Troy Stenstrom is a lead machinist at StoneL<br />

Corporation in Fergus Falls, Minn., and is quoted on a billboard<br />

saying, “Manufacturing has come back to the states … because we<br />

do higher quality work.” In an interview, Stenstrom reported, “You<br />

see something different every day in manufacturing, and you’re<br />

constantly learning. It’s not the grunt job that it used to be. It’s a<br />

respectable position.” Stenstrom is a driven guy who is passionate<br />

about his job, and his interview will be featured in an online video at<br />

DreamitDoitMN.com.<br />

“This is the ‘Got Milk’ campaign for manufacturing …” said 360°<br />

Executive Director Karen White. “We are building a recognizable<br />

brand that represents a paradigm shift in the way people think about<br />

our industry.”<br />

This October the campaign is launching media to represent<br />

the manufacturing industry, including billboards, online videos,<br />

online radio spots, social media pages, and a robust new web site,<br />

all culminating for a dramatic explosion of media during Minnesota<br />

Manufacturers Week October 21-27, 2012. The statewide initiative is<br />

targeting specific regions for this launch including the Twin Cities,<br />

West Central, St. Cloud, Brainard Lakes, and Mankato.<br />

To track the campaign’s progress, 360° will be enlisting a research<br />

firm to conduct surveys and watch regional employment data. In<br />

addition, they will be closely monitoring trends in online activity like<br />

Web site hits and social media conversations.<br />

During April and May of this year MNSCU, along with the<br />

Minnesota Chamber of Commerce and the Department of<br />

Employment and Economic Development conducted 12 listening<br />

sessions across Minnesota to connect with manufacturers and<br />

hear their workforce concerns. In all sessions, companies voiced<br />

concerns about the industry’s image and how young people are not<br />

[ continued ]<br />

Strong, versatile and innovative,<br />

Minnesota’s manufacturing sector is the<br />

backbone of the state’s economy. From<br />

high-tech electronics to high-end food products, Minnesota<br />

manufacturers produce a wide variety of goods that are<br />

known the world over for their high quality.<br />

CAREER OUTLOOK<br />

MN manufacturing has over 3,300<br />

job openings every year<br />

and paid over......<br />

ECONOMIC IMPACT<br />

largest<br />

industry<br />

13%<br />

AVERAGE SALARY<br />

manufacturing jobs<br />

most MN jobs<br />

HERE’S WHY manufacturing<br />

is the backbone of the<br />

economy.<br />

of all MN jobs are in<br />

Manufacturing. That’s<br />

292,078 careers<br />

That’s<br />

Manufacturing<br />

Job<br />

creates 1.9 jobs<br />

in supporting<br />

industries<br />

employees<br />

MN FORTUNE 500 COMPANIES<br />

Many of the top manufacturing brands are in MN<br />

other MN<br />

Fortune 500s<br />

in wages to employees during 2010<br />

MN<br />

manufacturing<br />

Fortune 500s<br />

September | October 2012 PRECISION MANUFACTURING | 9

COVER STORY That’s<br />

employees<br />

MN FORTUNE 500 COMPANIES<br />

Many of the top manufacturing brands are in MN<br />

other MN<br />

Fortune 500s<br />

MN<br />

manufacturing<br />

Fortune 500s<br />

“The new Dream It. Do It. Web site is the central<br />

online space for manufacturing workforce<br />

development. People can share their stories,<br />

connect with training programs, and learn<br />

about the vast potential that manufacturing<br />

has to offer them.“<br />

- Jaime Nolan, executive director of the Minnesota<br />

Precision Manufacturing Association<br />

Rated one of the top<br />

20 places to work for<br />

recent grads in 2010<br />

by Experience, Inc.<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

Largest private<br />

company in the U.S.<br />

with $119.5 billion in<br />

revenue for 2011<br />

WELL EDUCATED WORKERS<br />

Manufacturing careers are great for<br />

Minnesota’s well educated population<br />

MINNESOTA<br />

STATE COLLEGES<br />

& UNIVERSITIES<br />

state for most<br />

high school<br />

diplomas<br />

of Minnesotans<br />

have a<br />

bachelors<br />

degree<br />

Minnesota State Colleges<br />

and Universities (MnSCU)<br />

works with the National<br />

Science Foundation to host<br />

two “Centers of Excellence”<br />

related to manufacturing<br />

where students can get<br />

plugged in to great careers.<br />

YOUR FUTURE IS HERE FOR THE MAKING<br />

Statistics from The MN Department of Employment and<br />

Economic Development. Original artwork by the<br />

Dream !t Do !t Campaign. DreamItDoItMN.com<br />

encouraged by their teachers or parents to find a career in<br />

manufacturing. As an immediate response to these concerns,<br />

Dream It. Do It. focuses on three target markets:<br />

1. The Youth: Both male and female in grades 6 – 12<br />

with an expressed interest in engineering, mechanics,<br />

mathematics, and tactile learning.<br />

2. The Futures: Male and female ages 18 – 34 who are<br />

unemployed or unsatisfied with current job.<br />

3. The Influencers: Educators, institutions, influential relatives<br />

of The Youth and Futures segments, and manufacturing<br />

companies that support workforce development.<br />

White comments, “Reaching these target markets will<br />

depend greatly on the effective collaboration between state<br />

and local organizations.”<br />

“We are seeing great interest in Dream It. Do It. from<br />

manufacturers and others, and believe that now is the perfect time<br />

to take this across the state. Our sponsors combine to create a vast<br />

network of manufacturers, educational influencers and students.<br />

It is a great foundation from which the campaign can start to build<br />

momentum and impact as a brand,” reported White.<br />

360°’s recent National Science Foundation Award qualifies<br />

them to become an Advanced Technological Education Regional<br />

Center for advanced manufacturing—which will bring continuity<br />

and financial support over the next 4 years to the Dream It. Do<br />

It. campaign. The campaign hopes to find more strategic regional<br />

partnerships in order to retain a steady stream of media and<br />

publish year-round promotions about manufacturing after the<br />

October launch. Dream It. Do It. is here to stay as manufacturing’s<br />

voice to the public.<br />

Want to get involved? Keep a close eye on<br />

DreamItDoItMN.com for the new Web site launch with<br />

videos, articles, and photos from the campaign. You also<br />

can help to make the campaign successful by sharing the<br />

message with your colleagues or getting involved through<br />

the “for industry” tab on the Web site.<br />

PM<br />

HARRISON LLOYD is the marketing communications<br />

specialist with the Minnesota Precision Manufacturing<br />

Association. He can be reached at Harrison@mpma.com.<br />

KAREN WHITE is the executive director of MNSCU’s 360°<br />

Manufacturing and Applied Engineering Center of<br />

Excellence at Bemidji State University. She can be<br />

reached at KWhite@bemidjistate.edu.<br />

10 | PRECISION MANUFACTURING September | October 2012

MANUFACTURING MARVELS<br />

Election Fervor in 2012<br />

ECONOMIC FIX LIES IN MATH, NOT POLITICS<br />

by Fred Zimmerman<br />

One of my mid-20th century history<br />

professors was fond of asserting that<br />

wars were inconsequential to the<br />

pattern of history. He argued that<br />

technology, economics, demographics,<br />

education and moral development<br />

were more influential. In addition to<br />

wars, the professor might have added<br />

elections as less meaningful events in<br />

the long term.<br />

Much of the world is embroiled<br />

in election fervor in 2012. Citizens in<br />

France, Ireland, Egypt, Greece, Russia,<br />

several German states and the United<br />

States are fervently championing one<br />

candidate or another in the hope of<br />

restoring the prosperity and comfort of<br />

past decades.<br />

Yet, given our collective abhorrence<br />

of any sort of behavior modification or<br />

sacrifice, prosperity and comfort may<br />

no longer be within our reach. As an<br />

informed friend has noted, “We have<br />

one party that will never increase any<br />

taxes and another that will never stop<br />

spending. Where will it end?”<br />

Europe, the United States, and<br />

many other countries have something<br />

in common. Many of their citizens<br />

have absolutely no personal interest in<br />

participating in either responsible fiscal<br />

policies or qualitative improvements<br />

in their own activities. Yet, they insist<br />

that greater prosperity is due to them<br />

and harbor the mistaken belief that<br />

deep societal problems such as neglect,<br />

waste, declining production, overcompensation,<br />

premature retirements<br />

and profligate spending can be reversed<br />

by elections. As we all become energized<br />

in identifying the evils of opposing<br />

political parties, we perhaps have<br />

overlooked the dysfunctional influence<br />

that we, the citizens, have played.<br />

Did Greece’s economic fortunes<br />

improve with elections? Will<br />

France fare any better if that new<br />

administration repudiates recent<br />

European initiatives to forestall<br />

financial contagion? Will U.S. citizens<br />

really support the tough remedial<br />

actions necessary to avoid similar<br />

problems in this country?<br />

It is easy to blame elected officials,<br />

and many of them do have grievous<br />

faults. But, perhaps their greatest fault is<br />

listening too much to us, the constituents.<br />

We want to retire earlier than we should<br />

and we want someone else to fund it<br />

because we don’t save anything.<br />

Collectively, we want more<br />

social programs, no taxes, and the<br />

complete freedom to conduct all of<br />

our affairs without regulation—even<br />

if that sometimes results in financial<br />

catastrophe. We want a highly technical<br />

modern society, but we don’t want<br />

to spend any money maintaining<br />

the infrastructure. Almost all of us,<br />

individually, want any economic<br />

adjustments to be borne by somebody<br />

else. We tend to deny any responsibility<br />

for ourselves.<br />

While we fight with one another<br />

about which political party is the<br />

personification of the greatest evil, we<br />

are rocketing forth to an economic<br />

situation that is unmistakably<br />

arithmetic rather than political. The<br />

debts we are accumulating are so large<br />

that they are not payable without<br />

stifling growth, scaling back needed<br />

programs, raising unemployment<br />

and neglecting further our already<br />

deteriorating infrastructure.<br />

Whether we are Republicans,<br />

Democrats or Independents, this<br />

endemic denial of responsibility is<br />

likely to end poorly for us. We forget<br />

that interest payments are part of a<br />

sovereign nation’s budget that has<br />

priority over such worthy endeavors as<br />

education, health care, construction,<br />

maintenance and national defense.<br />

Interest rates are held to artificially<br />

low levels now. But what happens if<br />

the Chinese ever need their money to<br />

address their many unsolved social<br />

problems? What will interest rates be<br />

like then?<br />

The way out of the developed<br />

world’s difficult financial quandary<br />

is unlikely to be solved by electing<br />

anybody. We need to change ourselves.<br />

Serious modifications of our own<br />

behavior are overdue. In order to avoid<br />

financial implosion we are going to<br />

have to work with more dedication and<br />

innovation, accept more reasonable<br />

compensation, retire later, stay<br />

healthier, embrace practical financial<br />

regulation, incorporate reasonable<br />

taxation, collect the taxes we have, and<br />

make meaningful investments for the<br />

future. These steps should not be that<br />

difficult or that surprising. As recently<br />

noted in the Financial Times, “Billions<br />

of people around the world would give<br />

anything for what Europeans (and<br />

Americans) call austerity.”<br />

By taking these needed and overdue<br />

steps, our country and others like<br />

it, will have reasonable chances of<br />

avoiding the long gradual descent to<br />

far more problematic and less pleasant<br />

societies. Then, whoever is elected<br />

might have a chance of succeeding.<br />

This article was orginally published in the<br />

Star Tribune on June 3, 2012. Reprinted with<br />

permisson from Dr. Fred Zimmerman.<br />

DR. FRED ZIMMERMAN<br />

is professor emeritus<br />

of Engineering and<br />

Management at the<br />

University of St. Thomas.<br />

He can be reached at<br />

zimco@visi.com.<br />

PM<br />

September | October 2012 PRECISION MANUFACTURING | 11

y B Kyle<br />

Bill Kuban<br />

Legend and Legacy<br />

“As a legend, Bill spanned the gap<br />

between our industry founders and the<br />

leaders of today. In creating a legacy,<br />

Bill stewarded his father’s company<br />

into a secure future with an excellent<br />

management team and the employees<br />

who helped build it.”<br />

- Mike Neeley, president, Technology Reps<br />

The passing of William G. (Bill)<br />

Kuban in March 2012 marks the end of<br />

an era. Kuban was something special. He<br />

combined shrewd, home-grown business<br />

acumen with the irreverent charisma of a<br />

regular guy who truly cared about people.<br />

His life and career truly personified a<br />

season within the fabric of Minnesota’s<br />

manufacturing community that has<br />

been known for tough but collegial<br />

competition, the forging of an association<br />

to promote manufacturing, a humble<br />

yet strategic flair that has mobilized this<br />

sector towards ever more sophistication,<br />

productivity, and competitive advantage.<br />

Those of us fortunate enough to have<br />

known Kuban have lost a dear friend,<br />

a father, and an inspiring mentor. Our<br />

community is better because of Kuban.<br />

He will be missed.<br />

The Curious Entrepreneur<br />

“Bill was a man of infinite possibility.<br />

He explored ideas of all kinds because<br />

they were interesting. There was no up<br />

or down, no fences, no structure. He’d<br />

go straight to the possibilities. That said,<br />

he could ground and focus himself with<br />

laser intensity when needed. He was a<br />

remarkable man.”<br />

- Steve Carlsen, president, Kurt Manufacturing<br />

Known for his trademark sessions<br />

of opining in the office, asking such<br />

questions as “I was wondering about …,”<br />

Kuban always was “working on a new<br />

idea.” He tinkered with technology as<br />

esoteric as metallurgy and as earthy as<br />

creating racquetballs with more bounce.<br />

“Kuban became intrigued with the<br />

design of a police baton, for example,”<br />

Carlsen remembered with a grin. “He<br />

spent hours tweaking the design until he<br />

came up with several designs. The designs<br />

then became tool room prototypes that<br />

would be tested by everyone who came to<br />

his office. He was like that with everything,<br />

always energizing off of new ideas, looking<br />

for that ‘better mousetrap.’ And for every<br />

success, he wrestled through 100 failures.<br />

That’s what an entrepreneurial genius<br />

looks like on the ground. In truth, for<br />

Kuban, often the creation itself was more<br />

fun than the ensuing sales dollars.”<br />

Kern Walker, long time employee and<br />

friend, picked up the story with a chuckle.<br />

“Another one of Kuban’s ideas came from<br />

our days of racquetball together. We played<br />

all the time. Kuban would tell me that he<br />

couldn’t afford all the racquetballs we had<br />

to buy because we wore so many out. So<br />

he started chewing this idea, and finally<br />

12 | PRECISION MANUFACTURING September | October 2012

Bill Kuban: Legend and Legacy<br />

designed a re-pressurization chamber from<br />

a used milk can canister. He put some balls<br />

in there, re-pressurized the canister and<br />

took them to the court … we didn’t have<br />

racquetballs anymore, we had bullets!”<br />

This entrepreneurial spirit was<br />

channeled in business through Kuban’s<br />

extraordinary vision. A voracious reader,<br />

Kuban studied economics, politics and, of<br />

course, his first love—manufacturing. He<br />

was remarkably astute at deciphering the<br />

effect of economic or political activities for<br />

manufacturing and making savvy business<br />

decisions to capitalize on those anticipated<br />

leanings. He kept alert for the next good<br />

business opportunity that could contribute<br />

to the company’s growth.<br />

And he shared what he learned. “As<br />

did many others, I often called or met with<br />

Kuban, over the years, in an effort to better<br />

understand some technical concept or get<br />

his take on some public policy or economic<br />

event that might impact manufacturing,”<br />

said Fred Zimmerman, professor emeritus,<br />

University of St. Thomas. “His insights<br />

into the personalities of large corporations<br />

were profoundly instructional—insights<br />

that never would be found in any academic<br />

article or textbook. He was very much part<br />

of my own education—and that of others.”<br />

“Conversely, Kuban was deeply<br />

sentimental,” finished Carlsen. “For years<br />

we had a 1960s vintage Omnimill OM120<br />

sitting on our floor. It hasn’t turned a spindle<br />

in years. When I would broach the subject<br />

of selling the machine, Kuban would shoot<br />

back, ‘that is a good machine, but the<br />

engineers just won’t put a job on it.’ He just<br />

liked having it around. I kept the machine<br />

on the floor till Kuban passed away.”<br />

Growing the Business<br />

“Kurt’s transition to a big company<br />

is due to what I consider to be Bill’s<br />

strongest attribute as a leader. He had<br />

the ability to let others make decisions<br />

and then got out of the way, while<br />

focusing on what he did best.”<br />

- Steve Carlsen, president, Kurt Manufacturing<br />

Kuban was an entrepreneur who<br />

grew his company into so much more.<br />

He developed his leaders’ strengths<br />

and released them with authority and<br />

empowerment. This is still a people<br />

business, and Kuban knew that.<br />

In his book, The Science to Success,<br />

Charles Koch talks about “decision rights.”<br />

Leaders earn them by making good<br />

decisions. It’s a process; it happens over<br />

time. The owner ultimately can release,<br />

detach appropriately, to the point that an<br />

organization moves beyond a personal<br />

enterprise into a business. “Kuban would<br />

employ this,” said Carlsen. “At a division<br />

meeting, when I had a suggestion for<br />

something to change or employ, he’d ask<br />

me, ‘Do you have the money to do that?’ It<br />

was his company, ultimately his money, and<br />

yet he had released it—he was empowering<br />

me to make my decisions for my division.”<br />

“Kuban was very, very good at letting<br />

go,” confirmed Walker. “He led Steve<br />

as he led me. He gave us latitude, he<br />

empowered us. Even when he didn’t<br />

approve of a decision, he’d let us give it<br />

a try—he’d let us fail. That says so much<br />

about Kuban’s leadership.”<br />

A Savvy Business Person<br />

Who Cared About People<br />

“Bill was funny, hard working, loyal,<br />

charming, and outrageous. Once you<br />

were Bill’s friend, you were friends for<br />

life. And he would drop everything if<br />

you called needing help.”<br />

- Ralph Hegman, president, Hegman Machine Tool<br />

“He just cared about what you said,<br />

what you were doing, why you were<br />

doing it, and what was going on in your<br />

life,” said Walker. “It made him easy to<br />

talk to and he got along with just about<br />

everybody. And he was funny. Oh, the<br />

stories he would tell—the stories we could<br />

tell. Kuban had no problem laughing at<br />

life. He was a good man—not perfect, but<br />

very good. And he wore his success so<br />

humbly. We worked together for almost<br />

40 years and we were real friends.”<br />

“Kuban always was available to meet<br />

with fellow members of the manufacturing<br />

community to exchange ideas, to appraise<br />

the economy, or to listen and appreciate<br />

any misfortune that anyone may have been<br />

having,” said Zimmerman. “His regard for<br />

other manufacturers was genuine. ‘We are<br />

competitors, but we are not enemies,’ he<br />

would say. During less robust periods, I<br />

can remember his being deeply concerned<br />

about some of the difficulties competitors,<br />

or associates, were experiencing. Often<br />

these concerns resulted in quiet, unknown<br />

help. In addition to his technical and<br />

managerial prowess, Kuban was a true<br />

friend to many.”<br />

Chuck Hales, a friend and business<br />

colleague for over 40 years, proudly<br />

recalled their friendship. “Kuban was<br />

a soft spoken man with the highest<br />

integrity, and one of the most caring<br />

people I’ve ever had the privilege of<br />

knowing. A couple days before Kuban<br />

went to heaven, he called me at home to<br />

see how I was doing after my recent heart<br />

surgery. Not one word about himself the<br />

whole time we talked. Our conversation<br />

ended with my asking him if he could<br />

make our annual fishing trip to South<br />

Dakota. He answered, ‘we’ll see.’ Kuban<br />

and I were friends to the end.”<br />

History of Kurt Manufacturing<br />

Kuban succeeded his father as head<br />

of Kurt Manufacturing in the mid-<br />

1970s, when the company’s annual sales<br />

were at $7 million. That foundation led<br />

to decades of long term global growth<br />

and expansion for Kurt under Kuban’s<br />

direction. He was a true visionary,<br />

developing branded products, which<br />

today account for over half of Kurt’s $100<br />

million in annual sales. Among these is a<br />

broad base of products for the hydraulics,<br />

machine tool and fitness markets.<br />

Active in the business as chairman<br />

until his death, Kuban completed an<br />

Employee Stock Ownership Plan (ESOP)<br />

in 2011. The completed sale transaction<br />

provided for the continuation of Kurt<br />

Manufacturing with its present senior<br />

executive management team and<br />

employees as owners of the company.<br />

“With the employees now owning the<br />

company, we are continuing to expand<br />

with the addition of new products and<br />

services, ongoing additions of highly<br />

automated manufacturing systems, and<br />

potential acquisitions,” said president<br />

Steve Carlsen. “The ownership transition<br />

put in place by Kuban is working well and<br />

we look forward to a bright future.” PM<br />

B KYLE is the vice president of business<br />

development at the Saint Paul Port Authority<br />

in Saint Paul, Minn., and a friend to Bill Kuban.<br />

She can be reached at blk@sppa.com.<br />

September | October 2012 PRECISION MANUFACTURING | 13

your Core value:<br />

Profitability<br />

our Core values:<br />

PartnershiP // PerformanCe // ProfitaBility<br />

When price competition is tough, production cost becomes critical. Hegman Machine<br />

Tool will help you select equipment that improves your profitability in multiple ways:<br />

reliable machine tools maximize shop uptime<br />

ease of use means greater operator efficiency<br />

accurate results reduce part failures and scrap<br />

Proactive service plans minimize repair costs<br />

Hegman Machine Tool provides products, service and support to manufacturers<br />

throughout the Upper Midwest. We value partnerships and deliver performance to<br />

make our customers more profitable.<br />

Call today to disCover what we Can do for you.<br />

800.374.0367 or visit us at www.hegmanmaChine.Com<br />

Hegman macHine Tool, inc. // 8718 monTicello lane norTH maple grove, mn 55369 // 763.424.5622 // 800.374.0367 // www.HegmanmacHine.com

MADE IN MINNESOTA<br />

Tower Solutions<br />

SECURITY, INTELLIGENCE, AND LIFE SAVING<br />

by Bill Remes<br />

Tower Solutions’ fully extended tower.<br />

Photo courtesy of Tower Solutions.<br />

Imagine yourself a member of the<br />

United States military, deployed in a<br />

hostile area, in a forward position and<br />

being assigned to conduct reconnaissance<br />

and surveillance regarding the enemy. Or<br />

imagine yourself as a member of the United<br />

States border patrol, responsible for finding<br />

and intercepting any illegal immigrants.<br />

Envision the ability to rapidly deploy your<br />

equipment—cameras, thermal imaging<br />

equipment, motion detectors, etc.—to an<br />

elevation of 20 to 80 feet at the push of a<br />

button. And, more importantly, be able to<br />

retrieve that equipment very rapidly and to<br />

depart from your forward, exposed area.<br />

That can be the difference between success<br />

and failure, and even life and death.<br />

Lift Payloads<br />

Tower Solutions, in Pine City, Minn.,<br />

is providing the most portable, high speed,<br />

stable, tower equipment available on the<br />

market today. Their systems are capable<br />

of lifting payloads up to 2,000 pounds,<br />

reaching heights up to 80 feet. They have<br />

some of the most capable and highly<br />

sought-after systems around the world, in<br />

use by our own military, the Department<br />

of Homeland Security, and police and<br />

sherriff ’s departments across the nation.<br />

The multi-patented design is unique<br />

in the world of portable erectable towers.<br />

Prior to the first Tower Solutions models,<br />

the U.S. Military used only “telescoping”<br />

tower models which could take up to three<br />

people up to a full day to erect. The Tower<br />

Solutions units can be erected by one<br />

person in as little as 5 minutes.<br />

Unique Mechanism<br />

At the heart of the design is the<br />

completely unique hooking mechanism<br />

that locks the three-sided tower together,<br />

creating a rigid structure. Each side of<br />

the tower consists of sections hinged<br />

together, which are stowed in three<br />

rolls. When the patented lift system<br />

is activated each section hooks to the<br />

adjacent sections—the sections essentially<br />

are zipped together as they are raised,<br />

creating a rigid structure. Once extended,<br />

the tower requires no power to keep it up<br />

and is capable of supporting a 2,000 pound<br />

payload and resists winds over 65 mph.<br />

One of the strengths of the system is the<br />

design of the maintenance-free drive. The<br />

tower is erected to full height by means of<br />

gears and is powered by an electric motor.<br />

Other competitive towers rely on<br />

hydraulics, pneumatics, and cabling systems<br />

to erect and retract their towers. In harsh<br />

environments, the hydraulic and pneumatic<br />

systems are viewed, particularly by the<br />

U.S. Military, as being unreliable and easily<br />

compromised in critical applications.<br />

Numerous Applications<br />

Applications for the towers are not<br />

limited to military and security and/<br />

or police applications—they have many<br />

commercial uses as well. John Norris,<br />

co-owner of Tower Solutions, showed me<br />

some of the applications during my visit. In<br />

one instance, a company developing a new<br />

wind turbine generator design purchased<br />

one of the 80-foot towers for testing and<br />

fine-tuning the performance of their<br />

unique electric generator. Tower Solutions<br />

was selected for this task because it could<br />

quickly and easily elevate the turbine<br />

up into the wind to take performance<br />

measurements and retract the turbine<br />

to make engineering adjustments. This<br />

capability significantly accelerated the<br />

research and development progress of the<br />

turbine. It provided the added benefit of<br />

having their employees working on the unit<br />

at ground level, rather than while elevated.<br />

Recently, Tower Solutions developed<br />

a scaled down tower unit that is in the<br />

pre-production stage of development.<br />

This small, tabletop unit is capable of<br />

elevations up to 20 feet, which makes it<br />

highly effective for mobile surveillance and<br />

reconnaissance. It deploys any payload up<br />

to 100 pounds in less than 60 seconds and<br />

offers excellent wind resistance for steady<br />

monitoring of surveillance.<br />

But the story that Norris related that<br />

I enjoyed the most was of the experience<br />

by co-owner Steve Kensinger, while at<br />

a trade show over in Europe. A U.S.<br />

Marine attending the trade show told<br />

Kensinger that he, recently, had been<br />

serving in the Middle East working in a<br />

forward reconnaissance position using<br />

their tower. The soldier said that once an<br />

80-foot structure is extended into the sky,<br />

everyone knows your position. The speed<br />

of retracting the tower allowed them to get<br />

out of the area before local mortar units<br />

could aim their weapons and launch an<br />

attack. This tower, without doubt, in his<br />

opinion saved U.S. lives.<br />

Tower Solutions is truly a “Made in<br />

Minnesota” success story of which we all<br />

can be proud.<br />

PM<br />

BILL REMES is a Sales &<br />

Marketing Consultant in<br />

Manufacturing and Capital<br />

Equipment and can be<br />

reached at<br />

remesbill@aol.com<br />

sponsored by HEGMAN MACHINE TOOL INC.<br />

September | October 2012 PRECISION MANUFACTURING | 15

Bell Manufacturing and A&C Metals<br />

KEEPING THEIR SAWS IN TUNE WITH<br />

THE SERVICE GUYS<br />

To keep up with increased demand<br />

for its products, Bell Manufacturing,<br />

a custom metal fabricator located in<br />

Golden Valley, feeds its band saws<br />

almost continuously. Business is up<br />

15 percent this year over last year and,<br />

if one machine breaks down, it could<br />

lead to days or weeks of backlog. For<br />

that reason, the company relies on The<br />

Service Guys for emergency repairs and<br />

routine maintenance.<br />

A family-owned business since 1965,<br />

Bell Manufacturing works with all types<br />

of metal to make a variety of products,<br />

from industrial shelving to store fixtures.<br />

The majority of its business, however, is<br />

making steel furniture and accessories,<br />

such as loft beds, table bases, and outdoor<br />

furniture. Currently, it is a major supplier<br />

to Room and Board, one of the largest<br />

furniture retailers in the United States.<br />

Last year, however, a portion of Bell<br />

Manufacturing’s business nearly came<br />

to a screeching halt. One of its two band<br />

saws stopped working and needed to be<br />

fixed immediately. It appeared there was<br />

a problem with the wiring that controlled<br />

the machine’s backstop. Steve Buckman,<br />

maintenance supervisor, called the<br />

machine’s manufacturer in Germany and<br />

was shocked to learn that a replacement<br />

system would cost $10,000 and take 2 to 3<br />

months to arrive.<br />

Buckman’s next call was to The<br />

Service Guys, a local metalworking<br />

machine repair company. He had been<br />

doing business with founders Chris<br />

Tarvestad and Dave Meyer for more<br />

than a decade, even before he was hired<br />

Chris Tarvestad (left) and<br />

Dave Meyer (right) at IMTS.<br />

at Bell Manufacturing, and wanted a<br />

second opinion. Tarvestad recommended<br />

a product called a Tigerstop, which was<br />

retrofitted to the machine and performed<br />

as well as the replacement system at a<br />

fraction of the cost. Within a week, the<br />

band saw was up and running.<br />

The Tigerstop has been in use for<br />

nearly a year without any problems. In<br />

fact, Bell Manufacturing installed another<br />

Tigerstop on its second band saw a few<br />

months later.<br />

“It has been a lifesaver,” Buckman<br />

said. “Essentially, we got a brand new<br />

machine for $8,000 installed and under<br />

warranty. Plus it’s a lot easier to use. The<br />

old system was a moveable backstop or<br />

link stop, which was very complicated for<br />

the average person to use. Now anyone<br />

with 5 minutes of training can walk right<br />

up to these machines and use them.<br />

The controls are as simple to use as a<br />

handheld calculator.”<br />

Over the years, The Service Guys<br />

have worked on at least a dozen other<br />

“There have been several times when<br />

The Service Guys were able to repair<br />

or debug a machine faster than the<br />

manufacturers of those machines …”<br />

- Jeff Jensen, plant manager, A&C Metals<br />

machines at Bell Manufacturing, from<br />

CNC mills to cold saws to band saws.<br />

Often times The Service Guys are able<br />

to walk Buckman through repair and<br />

maintenance right over the phone.<br />

“I would highly recommend them to<br />

other companies,” he said. “They have a<br />

wide knowledge base and have always<br />

been able to get our machines up and<br />

running quickly.”<br />

A&C Metals<br />

A&C Metals, another longtime<br />

customer, agrees. This metal service<br />

center, located in Blaine, relies on The<br />

Service Guys to repair all of its metal<br />

cutting machines in order to keep up<br />

with local demand for next-day delivery<br />

on pre-cut metals. A&C Metal’s band<br />

saws, cold saws, precision plate saws and<br />

contour saws run 24 hours a day, 6 days a<br />

week, resulting in at least one breakdown<br />

every few weeks. But nothing has been<br />

beyond repair for The Service Guys,<br />

according to Jeff Jensen, plant manager.<br />

“There have been several times<br />

when The Service Guys were able to<br />

repair or debug a machine faster than<br />

the manufacturers of those machines,”<br />

he said. “Several years ago, for example,<br />

one of our plate saws broke down, so<br />

the machine’s manufacturer sent out a<br />

technician. The technician spent 3 days<br />

working on the machine but couldn’t<br />

figure out what was wrong. I called Chris<br />

and he was able to repair it in 1 hour.”<br />

“Another time there was a problem<br />

with one of our cold saws,” added Jon<br />

Degnan, foreman. “Dave stopped by on<br />

his way up to the cabin and spent 3 hours<br />

fixing the machine, with his wife waiting<br />

patiently in the parking lot—all so the<br />

machine would be ready for the first shift<br />

on Monday morning. That’s the kind of<br />

service they provide.”<br />

In addition to routine maintenance<br />

and emergency repairs, A&C Metals relies<br />

on The Service Guys for machine parts as<br />

well. It recently began purchasing a new<br />

16 | PRECISION MANUFACTURING September | October 2012<br />

PAID SUPPLEMENT

SHOP PROFILE<br />

“If you schedule regular maintenance a few times per year,<br />

we can catch 90 percent or more of all the failures you’ll<br />

potentially see within the next few months, especially with<br />

regard to bearings and blades …”<br />

- Chris Tarvestad, founder, The Service Guys<br />

line of band saw blades and discovered<br />

that they perform just as well as the topend<br />

blades, for less money.<br />

“We just feel there’s nothing they can’t<br />

do,” Jensen said, “whether it’s solving<br />

a tough problem with a machine or<br />

knowing which parts we don’t have to<br />

order from the manufacturer.”<br />

About The Service Guys<br />

Tarvestad and Meyer started The<br />

Service Guys as a “service only” company<br />

in 2004, after working for several years<br />

as field service engineers for a local<br />

distributor. Today, they sell and service a<br />

full line of production machinery for small<br />

manufacturers as well as large OEMs.<br />

They also handle special applications<br />

and integration in-house. Most of their<br />

customers are in the Midwest area but,<br />

since they receive referrals from many<br />

machine manufacturers, they get calls<br />

from people all over the country.<br />

The most common problems they see<br />

on band saws, according to Tarvestad, are<br />

parts coming off the machines that are<br />

not cut straight and true, and saw blades<br />

that may last only a fraction of the time<br />

they should. To avoid these issues, he<br />

offers manufacturers two words of advice:<br />

scheduled maintenance.<br />

“If you schedule regular maintenance a<br />

few times per year, we can catch 90 percent<br />

or more of all the failures you’ll potentially<br />

see within the next few months, especially<br />

with regard to bearings and blades,” he<br />

said. “This is so much easier to deal with<br />

than an emergency downtime situation,<br />

because we can schedule downtime for<br />

inspection inside your work schedule, not<br />

in an emergency case when the machine<br />

stops working.”<br />

Recently, The Service Guys began<br />

refurbishing and selling used machines<br />

to complement their offering of new<br />

machinery. However, service has and<br />

always will be the focus of the business.<br />

“We service first and sell by accident,”<br />

Tarvestad said. “I think our customers<br />

appreciate that approach.”<br />

PM<br />

For more information about The Service Guys, visit www.theserviceguys.net or contact Chris<br />

Tarvestad at 763.234.9810 or chris@theserviceguys.net.<br />

Above: Two Tigerstop linear measurement rails operate back-to-back as installed on Bell’s Kaltenback saws.<br />

PAID SUPPLEMENT<br />

September | October 2012 PRECISION MANUFACTURING | 17

10044 Goodhue St. NE<br />

Blaine, MN 55449<br />

Phone: 763.785.9278<br />

Email: bertb@engfinish.com<br />

A SIMPLE APPROACH<br />

FOR BETTER SURFACE FINISHING<br />

In the race to compete and stay<br />

ahead on a global scale, manufacturing<br />

firms constantly must look to improve<br />

equipment utilization and throughput. A<br />

big part of staying ahead is the reduction<br />

and/or elimination of non-value added<br />

activities or waste through continuous<br />

improvement of the entire value chain.<br />

Over-processing is waste when it occurs<br />

anytime more work is done on a piece<br />

than is required by the customer. This<br />

also includes using tools that are more<br />

precise, complex, or expensive than<br />

absolutely required and includes using<br />

milling centers for surface finishing.<br />

The term “surface finish” refers<br />

to the surface, including the texture,<br />

the flaws, the material, and/or any<br />

applied coatings. We generally describe<br />

the surface topography in terms of<br />

texture. Surface texture is most often<br />

characterized by four parameters:<br />

roughness, waviness, lay, and flaws.<br />

Surface roughness consists of fine<br />

irregularities in the surface texture,<br />

usually those resulting from the inherent<br />

action of a production process, such as<br />

feed marks produced during machining.<br />

Waviness is a more widely spaced<br />

component of surface texture and can<br />

result from such factors as machine or<br />

work deflections, vibration, or chatter.<br />

Lay is the direction of the predominant<br />

surface pattern. This typically would be<br />

in the length direction for tubes. Profiles<br />

almost always are made in a direction<br />

perpendicular to the lay of the surface.<br />

Tubing profiles usually are parallel to the<br />

lay direction.<br />

Flaws are unintentional, unexpected,<br />

and unwanted interruptions in the<br />

surface such as cracks, nicks, scratches,<br />

burrs, hangers, and ridges.<br />

Figure 1<br />

As shown in Figure 1 (above),<br />

surfaces produced with a milling<br />

process can have a strong lay pattern,<br />

i.e., they are unidirectional. The<br />

generation of a lay pattern is accepted<br />

and understood when you consider<br />

that milling technology is a production<br />

process where a rotating cutter is moved<br />

sequentially along prescribed tool paths.<br />

The final surface roughness from milling<br />

might be considered as the sum of two<br />

independent effects: 1) the surface<br />

roughness is a result of the geometry<br />

of tool and feed rate; and 2) the natural<br />

surface roughness is a result of the<br />

irregularities in the cutting operation<br />

(tool path/motion).<br />

The desired surface finish/roughness<br />

usually is specified by a design engineer<br />

and the appropriate processes are<br />

selected by a manufacturing and/or a<br />

process engineer. Most specifications<br />

call out a surface finish roughness<br />

described and measured as a Ra value<br />

with Ra being calculated per the ANSI<br />

B46.1 standard.<br />

Illustrated in Figure 2 (below) is a<br />

surface roughness profile along with the<br />

formula for calculating Ra. Producing<br />

the part to the Ra specification,<br />

including how rough the surface is,<br />

for many reasons, directly impacts the<br />

functional attributes of parts, including<br />

surface friction, wear, light reflection,<br />

heat transmission, ability of distributing<br />

and holding a lubricant, and fatigue, etc.<br />

The two primary objectives in<br />

machining are the production of parts<br />

with low cost and high quality. To<br />

achieve these objectives, maximum and<br />

minimum feed rates and cutting speeds,<br />

depths of cut as well as tool life, cutting<br />

force, surface roughness, and cutting<br />

power consumption are considered.<br />

Figure 2<br />

18 18 | | PRECISION MANUFACTURING September | | October 2012 2012

INDUSTRY PROFILE: ENGINEERED FINISHING CORP.<br />

The first step for minimizing is<br />

to reduce the costs for individual<br />

finishing and roughing passes for the<br />

various depths of the cut. Considered<br />

in the next step is the combination of<br />

depths of the cut for the finishing and<br />

roughing passes. Depth of cuts, along<br />

with an optimal number of passes,<br />

are combined with the stepover path<br />

distance to minimize run times and<br />

cost. The stepover value determines<br />

whether the surface finish on a<br />

component is rough or smooth.<br />

For example, when using a<br />

flatbottomed tool such as an end<br />

mill, the stepover value is normally<br />

around 70 percent of the cutter<br />

diameter in combination with depth,<br />

feed, and speed rates. Raster passes,<br />

radial passes, spiral passes, morph<br />

passes, and boundary passes are the<br />

methods of choice for true surface<br />

machining. Allocating expensive CNC<br />

machine time for cleanup and surface<br />

finishing should be considered overprocessing<br />

and costly when measured<br />

in machine time (throughput dollars)<br />

and the achieved results. Abrasive Flow<br />

Grinding (also known as abrasive flow<br />

machining) is a cost effective machining<br />

process for finishing and polishing a<br />

surface, including difficult-to-reach<br />

surfaces and internal passages.<br />

The Abrasive Flow Grinding process<br />

involves three principle elements: a<br />

tooling fixture, the machine, and the<br />

abrasive. The typical Abrasive Flow<br />

Grinding process uses two opposing<br />

cylinders to push the media in two<br />

directions, i.e., back and forth with a<br />

controlled flow pressure. Tooling is<br />

used to direct the media flow across the<br />

surface of the part and through internal<br />

passages and intersecting passages. Flow<br />

grinding action occurs wherever the<br />

media comes in contact with a surface.<br />

The flow pressure as well as the number<br />

of finishing cycles (back and forth media<br />

grinding/flow) are controlled.<br />

A workpiece fixture is used to hold<br />

a part or multiple parts for processing.<br />

The fixture directs and controls the<br />

volume and pressure of media flow<br />

across surfaces and through internal<br />

passages. Lightweight fixtures are placed<br />

on and removed from the lower media<br />

Figure 3<br />

cylinder by the machine operator. The<br />

lower media cylinder (the processing<br />

station) is located in the center of the<br />

worktable. Higher production and/<br />

or heavier fixtures can be positioned<br />

automatically from the loading station to<br />

the processing station by a hydraulically<br />

actuated dual fixture rotary table. In the<br />

way of increasing throughput dollars,<br />

flow grinding reduces other costs by<br />

reducing and/or eliminating handwork<br />

that may not be as uniform, repeatable,<br />

or predictable.<br />

The flow grinding media is made of<br />

a flowable polymer carrier mixed with<br />

one or more sizes of abrasive grain. The<br />

media viscosity range is from a soft,<br />

almost grease-like consistency, to a firm,<br />

putty-like material consistency. With<br />

a pure grinding and polishing backand-forth<br />

type of action, the grinding/<br />

abrasive media flows across surfaces<br />

or through internal passages to refine<br />

surfaces and edges.<br />

The most commonly used abrasives<br />

are silicon carbide and aluminum oxide.<br />

These provide a good balance between<br />

high performance and moderate cost.<br />

Typically, the particle sizes of abrasives<br />

used range from a coarse 20 mesh<br />

abrasive (average particle size ~0.9<br />

mm) to a very fine 600 mesh abrasive<br />

(average particle size ~0.9 microns).<br />

Abrasive media will contain around 25<br />

percent up to around 67 percent, by<br />

weight of the abrasive grain.<br />

Abrasive Flow Grinding has helped<br />

us achieve polished and lapped external<br />

and internal passages characterized by<br />

their measured Ra values. Tools that are<br />

used together can help to reduce waste<br />

as measured in throughput dollars and<br />

over processing. All production practices<br />

promote the reduction of waste,<br />

reduction of over-processing, and the<br />

control of flow for increasing throughput<br />

dollars. The benefits of milling a finished<br />

surface probably are not worth the cost.<br />

Several examples of surface finishes we<br />

have accomplished with abrasive flow<br />

grinding are shown below.<br />

September | October | 2012 2012 PRECISION MANUFACTURING | 19| 19

WHO’S WHO<br />

Karen White, Bemidji State University<br />

DREAMING IT. DOING IT.<br />

by Stephani Simon<br />

There could not be a more appropriate<br />

personality affiliated with the Dream<br />

It. Do It. campaign than Karen White.<br />

She embodies the motto at home as<br />

well as in her role as executive director<br />

of MNSCU’s 360° Manufacturing and<br />

Applied Engineering Center of Excellence<br />

at Bemidji State University.<br />

The Dream<br />

Born and raised in Moorhead, Minn.,<br />

White’s life seems to have been based<br />

on a series of focused dreams that she<br />

has accomplished over time. In high<br />

school, White had a strong desire to<br />

compete, and naturally gravitated toward<br />

sports—namely tennis and cheerleading.<br />

She also began to discover a passion for<br />

engineering, taking male-dominated shop<br />

courses like automotive mechanics. It<br />

was then that White began to dream of a<br />

career in engineering.<br />

Setting out to make her dream a<br />

reality, White enrolled in the engineering<br />

program at the University of Minnesota-<br />

Duluth. She graduated with a bachelor’s<br />

degree in chemical engineering and<br />

went on to obtain a Master of Science in<br />

Chemical Engineering at the University<br />

of Kentucky.<br />

Turning Dreams into Reality<br />

It was after graduation that White’s<br />

degree introduced her to the world of<br />

manufacturing, when she accepted an<br />

engineering job at Imation in Wahpeton,<br />

North Dakota, a diskette manufacturing<br />

plant. It was at Imation that she came<br />

to understand how products are made.<br />

White credits Imation for her biggest<br />

learning moments, including being part<br />

of a 13-member plant management<br />

team responsible for meeting corporate<br />

objectives. She also came to love the fast<br />

pace of the manufacturing industry and<br />

the diverse aspects that the industry had<br />

to offer, whether it was focusing on safety,<br />

quality, cost, or capacity.<br />

After 5 years of being in engineering<br />

and management roles at Imation, White<br />

Karen White, executive director, 360° with<br />

kids left to right: Justin, Lauren and Alec.<br />

ventured back into the world of higher<br />

education, taking on an engineering<br />

operations role at North Dakota State<br />

University (NDSU) in the Center for<br />

Nanoscale Science and Engineering. At<br />

NDSU, she gained an understanding and<br />

passion for how businesses, universities,<br />

and governments form partnerships.<br />

Ultimately, the role became a natural segue<br />

into her career at Bemidji State, where she<br />

helps train workers for the manufacturing<br />

industry and has become involved with<br />

the Dream It. Do It. campaign.<br />

The Initiative<br />

It was in early 2007 that a lack<br />

of skilled workers in manufacturing<br />

prompted White to seek out support<br />

from the Minnesota Department of<br />

Employment and Economic Development.<br />

This is when she first was introduced to<br />

the concept of Dream It. Do It. Because<br />

of her passion around the campaign,<br />

White now works with the Minnesota<br />

Precision Manufacturing Association,<br />

Tri-State Manufacturers’ Association,<br />

West Central Initiative, Central Minnesota<br />

Manufacturers Association, and<br />

manufacturers from the Brainerd Lakes<br />

area to further the campaign’s initiatives,<br />

promoting a clear understanding of<br />

advanced, high-tech manufacturing.<br />

White carries this same dream it,<br />

do it philosophy into her home life.<br />

Having met her husband Jim in college,<br />

a Minnesota native from Cook (a small<br />

community north of the Iron Range), the<br />

pair is determined to teach their three<br />

kids about the diverse lifestyle Minnesota<br />

has to offer. The family, including Alec<br />

(13), Justin (9) and Lauren (4), often<br />

travels around the state taking advantage<br />

of rural and city living.<br />

One favorite White always looks<br />

forward to is visiting the farmstead of<br />

Jim’s grandfather that was established<br />

more than 80 years ago just north of<br />

Cook. They also can be found enjoying<br />

cabin life near their home in Bemidji.<br />

In addition to waterskiing and fishing,<br />

the family enjoys downhill skiing and<br />

hunting. Indeed, rarely a week goes by<br />

without playing sports of some kind.<br />

For White, that includes exercising her<br />

competitive nature by playing on a tennis<br />

league. The family also frequently travels<br />

to the Twin Cities, taking in sporting<br />

events, attending cultural exhibits, and<br />

visiting family.<br />

Open to Experiences<br />

“We want our kids to grow up<br />

knowing that hard work has rewards: to<br />

enjoy life, and to be open to experiences,”<br />

White said during the interview.<br />

This also means getting them to<br />

think about their futures. White works<br />

to involve the family in technology,<br />

robotics, and Camp Invention activities.<br />

She wants them to know what the inside<br />

of manufacturing facilities look like and<br />

how product development happens.<br />

White’s ultimate dream is for youth to<br />

be accepted when they say, “I want to be a<br />

welder.” Until then, she intends to continue<br />

to highlight the impact that manufacturing<br />

has to the state’s and nation’s economic<br />

PM<br />

health and to live her dreams.<br />

STEPHANI SIMON is<br />

the president of Orange<br />

Communications in<br />

Minneapolis, Minnesota.<br />

She can be reached at<br />

ssimon@orange77.com.<br />

20 | PRECISION MANUFACTURING September | October 2012

WHEN NUMBERS<br />

MATTER:<br />

6 NEW JOBS.<br />

2 MONTHS TO<br />

FULFILL.<br />

1 a51nx HMC.<br />

Making the parts that really<br />

matter takes a horizontal<br />

machining center that<br />

delivers what matters most:<br />

faster cycle times, greater<br />

reliability and higher-quality<br />

results. Which is why a<br />

Makino HMC is the only real<br />

choice for the production<br />

parts that matter most.<br />

It’s the speed you need to<br />

handle the jobs that matter.<br />

The Makino a51nx and a61nx.<br />

makino.com<br />

Your local distributor for MN, NE,<br />

IA, SD, ND and western WI is:<br />

© 2012 Makino<br />

Productivity Inc.<br />

15150 25th Avenue North<br />

Plymouth, MN 55447<br />

763.476.8600<br />

www.productivity.com

<strong>MTConnect</strong>:<br />

by Dave Edstrom<br />

<strong>Different</strong> <strong>Devices</strong>, <strong>Common</strong> <strong>Connection</strong><br />

In 2008, Paul Warndorf,<br />

vice president of manufacturing<br />

technology for the Association for<br />

Manufacturing Technology (AMT),<br />