Living in a materiaL worLd - Minnesota Precision Manufacturing ...

Living in a materiaL worLd - Minnesota Precision Manufacturing ...

Living in a materiaL worLd - Minnesota Precision Manufacturing ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

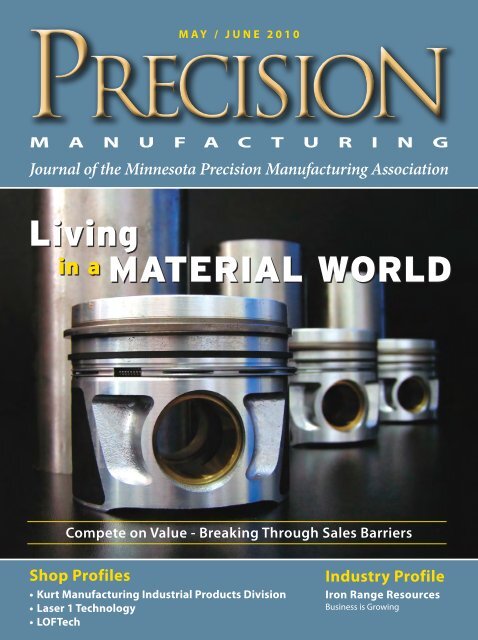

M a y / j u n e 2 0 1 0<br />

M a n u F A C T U R I N G<br />

Journal of the M<strong>in</strong>nesota <strong>Precision</strong> Manufactur<strong>in</strong>g Association<br />

<strong>Liv<strong>in</strong>g</strong><br />

<strong>in</strong> a material world<br />

Compete on Value - Break<strong>in</strong>g Through Sales Barriers<br />

Shop Profiles<br />

• Kurt Manufactur<strong>in</strong>g Industrial Products Division<br />

• Laser 1 Technology<br />

• LOFTech<br />

Industry Profile Profile<br />

Hennep<strong>in</strong> Iron Technical Range Resources College<br />

Bus<strong>in</strong>ess is Grow<strong>in</strong>g

the 2010<br />

new generation<br />

After more than 20 years of <strong>in</strong>dustry firsts, we figured 2010 would be a<br />

good year to “up the ante” aga<strong>in</strong>. So we looked at any and every way<br />

to make Haas VMCs better, and then made one last change:<br />

We added more value.<br />

IMPROVED: motion control<br />

coolant conta<strong>in</strong>ment • chip evacuation<br />

CNC <strong>in</strong>terface • ergonomics • serviceability<br />

r e l e a s e d f o r a c t i v e d u t y : 0 1 . 0 1 . 1 0<br />

Haas Factory Outlet | A Division of Productivity Inc | 763.742.1263 | www.haasproductivity.com<br />

2 | PRECISION MANUFACTURING May | June 201<br />

Specifications subject to change without notice. Not responsible for typographical errors. Mach<strong>in</strong>es shown with optional equipment.<br />

Vertical Mach<strong>in</strong><strong>in</strong>g centers

TABLE | OF CONTENTS<br />

May | June 2010<br />

w w w . p m - m n . c o m<br />

7<br />

Features<br />

12 Shop Profile:<br />

Kurt Manufactur<strong>in</strong>g Industrial Products Division<br />

Hundreds of New Kurt Workhold<strong>in</strong>g Options<br />

17 Industry Profile: Iron Range Resources<br />

Bus<strong>in</strong>ess is Grow<strong>in</strong>g<br />

21 Shop Profile: Laser 1 Technology<br />

Gett<strong>in</strong>g a Cut From M<strong>in</strong>nesota Sales Tax Refunds<br />

22 Compet<strong>in</strong>g on Value<br />

Break<strong>in</strong>g Through Sales Barriers<br />

by Terry Slattery<br />

24 Shop Profile: LOFTech<br />

F<strong>in</strong>d<strong>in</strong>g a Solid Partner <strong>in</strong> Metal Supermarkets Corporation<br />

17 24<br />

12 21<br />

Departments<br />

4 President’s Letter<br />

11 Who’s Who<br />

16 Made <strong>in</strong> MN<br />

26 Manufacturers’<br />

Marketplace<br />

29 MPMA Member<br />

Directory<br />

33 Advertisers’ Index<br />

34 MPMA Highlights<br />

34 MPMA Calendar<br />

May | June 2010 PRECISION MANUFACTURING | 3

PRESIDenT’S | LETTER<br />

Trust<br />

IN our EMPLOyEES<br />

by Mike Gramse<br />

Leav<strong>in</strong>g On A Jet Plane,” that is how<br />

the song goes. I’m do<strong>in</strong>g that tomorrow.<br />

And, though I know for many people<br />

fly<strong>in</strong>g is not uncommon, for me this is<br />

go<strong>in</strong>g to be an unusual event.<br />

I spent 4 years <strong>in</strong> the Navy aboard<br />

ship, primarily <strong>in</strong> Asia, so I have not had<br />

any desire to go on a ship aga<strong>in</strong> and be<br />

isolated at sea. But, after nearly 40 years,<br />

I have given <strong>in</strong>. Some friends had asked<br />

us to go on a cruise and, not expect<strong>in</strong>g<br />

them to f<strong>in</strong>d one, I said, if you can cruise<br />

to South East Asia we’ll go. Well, they<br />

found a cruise. We are fly<strong>in</strong>g to Bangkok,<br />

board<strong>in</strong>g a cruise ship, and spend<strong>in</strong>g 16<br />

days tour<strong>in</strong>g various ports from Bangkok<br />

to Beij<strong>in</strong>g.<br />

This may not be a big deal for many<br />

of you, but for me it is. I’m excited to<br />

get back to many of the places I visited<br />

under different circumstances dur<strong>in</strong>g the<br />

Vietnam War. Ten years ago, Eva and I<br />

were <strong>in</strong> Beij<strong>in</strong>g; I’m anxious to see how<br />

that has changed s<strong>in</strong>ce the Olympics.<br />

I thought all of this might be of some<br />

<strong>in</strong>terest because, as we have prepared for<br />

this trip—as a job shop owner with around<br />

50 employees, work<strong>in</strong>g through the<br />

recession for the past 18 months—I have<br />

been very apprehensive. I even bought trip<br />

<strong>in</strong>surance, so I could simply cancel the trip<br />

if I wasn’t comfortable go<strong>in</strong>g.<br />

When I agreed to the cruise, I expected<br />

the recession to be over by now, with<br />

everyth<strong>in</strong>g back to normal—or as normal<br />

as it can be <strong>in</strong> a job shop environment.<br />

For us that is not the case yet, as of March<br />

when I’m writ<strong>in</strong>g this letter.<br />

This really has been a challenge for me,<br />

decid<strong>in</strong>g whether or not to go ahead and<br />

take the trip. It made me realize what great<br />

people I have work<strong>in</strong>g for me, and I’m sure<br />

you have work<strong>in</strong>g for or with you.<br />

I confirmed the realization: They<br />

are the people mak<strong>in</strong>g the company<br />

successful. I had to th<strong>in</strong>k about how much<br />

I don’t th<strong>in</strong>k we give<br />

our employees all<br />

of the appreciation<br />

we should; but we<br />

need to, for their<br />

own sense of value<br />

and for our peace of<br />

m<strong>in</strong>d as owners.<br />

trust I had <strong>in</strong> my employees, which would<br />

allow me to be gone for 3 weeks. I had to<br />

trust that they would do the quotes, get<br />

the work done and meet our customers’<br />

needs. But they do that every day anyway.<br />

What did I have to worry about?<br />

In my case I have various department<br />

heads, a great adm<strong>in</strong>istrative staff and<br />

a second generation <strong>in</strong>volved. This<br />

structure provided me with peace of<br />

m<strong>in</strong>d, know<strong>in</strong>g that they will run this<br />

bus<strong>in</strong>ess while I am gone.<br />

I don’t th<strong>in</strong>k we give our employees<br />

all of the appreciation we should; but we<br />

need to, for their own sense of value and<br />

for our peace of m<strong>in</strong>d as owners.<br />

I am able to leave with a very<br />

comfortable feel<strong>in</strong>g: Our company will run<br />

well <strong>in</strong> my absence, and I will have a greater<br />

appreciation for my staff when I return.<br />

Th<strong>in</strong>k about how this relates to your<br />

company and your staff. PM<br />

MIKE GRAMSE is president<br />

of MRG Tool & Die Corp. <strong>in</strong><br />

Faribault, M<strong>in</strong>n. He can be<br />

reached at<br />

mgramse@toolanddie.net.<br />

www.pm-mn.com<br />

Support<strong>in</strong>g M<strong>in</strong>nesota <strong>in</strong> becom<strong>in</strong>g<br />

the world leader <strong>in</strong> precision contract<br />

manufactur<strong>in</strong>g and related technologies.<br />

EDITOR | PUBLICATIONS MANAGER<br />

Amy Slettum<br />

SALES MANAGER<br />

Tim Crolley<br />

DESIGNER | ART DIRECTOR<br />

Severyn Skoug<br />

MINNESOTA PRECISION<br />

MANUFACTURING ASSOCIATION<br />

5353 Wayzata Blvd., Suite 207<br />

M<strong>in</strong>neapolis, MN 55416<br />

952.564.3041<br />

www.mpma.com<br />

MPMA OFFICERS<br />

President<br />

Mike Gramse, MRG Tool & Die Corp.<br />

Vice President<br />

Bob Miller, Kendeco Tool Crib<br />

Treasurer<br />

Paul Huot, Huot Manufactur<strong>in</strong>g Company<br />

Secretary<br />

Kim Arrigoni, Haberman Mach<strong>in</strong>e, Inc.<br />

EXECUTIVE DIRECTOR<br />

Jaime Nolan, CAE<br />

ASSOCIATE DIRECTOR<br />

Luann Bartley<br />

EDITORIAL COMMITTEE<br />

Chair, Editor-<strong>in</strong>-Chief<br />

Brenda Kyle<br />

blk@sppa.com<br />

Michelle Gates<br />

mgates@bpkz.com<br />

Denny Nybo<br />

dennynybo@comcast.net<br />

Bill Remes<br />

billr@ameristarmfg.com<br />

Chuck Remillard<br />

chuckr@kurt.com<br />

Ted Roberts<br />

troberts@robertsautomatic.com<br />

Andrew Skoog<br />

apskoog@gmail.com<br />

Fred Zimmerman<br />

zimco@visi.com<br />

For editorial, advertis<strong>in</strong>g or<br />

membership <strong>in</strong>formation:<br />

Voice: 952.564.3041<br />

Fax: 952.252.8096<br />

<strong>Precision</strong> Manufactur<strong>in</strong>g (ISSN 0273-7523),<br />

is published six times per year by Intr<strong>in</strong>Xec<br />

Management Inc., 5353 Wayzata Blvd., Suite<br />

207, M<strong>in</strong>neapolis, MN 55416. <strong>Precision</strong><br />

Manufactur<strong>in</strong>g is the only authorized regular<br />

publication of the M<strong>in</strong>nesota <strong>Precision</strong><br />

Manufactur<strong>in</strong>g Association (MPMA). Op<strong>in</strong>ions<br />

and conclusions expressed <strong>in</strong> the magaz<strong>in</strong>e<br />

are those of the <strong>in</strong>dividual writer and do<br />

not necessarily reflect the official position<br />

of the MPMA or its officers. Advertis<strong>in</strong>g<br />

rates provided on request. Correspondence<br />

regard<strong>in</strong>g the magaz<strong>in</strong>e, <strong>in</strong>clud<strong>in</strong>g <strong>in</strong>dustry<br />

news releases, photographs and press releases<br />

relat<strong>in</strong>g to precision manufactur<strong>in</strong>g should be<br />

sent to <strong>Precision</strong> Manufactur<strong>in</strong>g, Amy Slettum,<br />

c/o Intr<strong>in</strong>Xec Management, Inc., 5353 Wayzata<br />

Blvd., Suite 207, M<strong>in</strong>neapolis, MN 55416.<br />

Electronic correspondence, <strong>in</strong>clud<strong>in</strong>g attached<br />

files <strong>in</strong> Word or pla<strong>in</strong> text formats, may be sent<br />

to amy@mpma.com. Unsolicited materials will<br />

not be returned. POSTMASTER: Send address<br />

changes to: <strong>Precision</strong> Manufactur<strong>in</strong>g, c/o<br />

Intr<strong>in</strong>Xec Management, Inc., 5353 Wayzata<br />

Blvd., Suite 207, M<strong>in</strong>neapolis, MN 55416.<br />

Copyright ©2010 M<strong>in</strong>nesota <strong>Precision</strong><br />

Manufactur<strong>in</strong>g Association.<br />

4 | PRECISION MANUFACTURING May | June 2010

Make the Right Moves Early <strong>in</strong> Your Bus<strong>in</strong>ess<br />

You worked hard to create a successful, respected bus<strong>in</strong>ess. The open<strong>in</strong>g moves of your exit strategy<br />

plan will ultimately help determ<strong>in</strong>e your f<strong>in</strong>al f<strong>in</strong>ancial victory.<br />

Many professional advisors suggest putt<strong>in</strong>g a succession plan <strong>in</strong> place at least five years before you<br />

<strong>in</strong>tend to retire…10 years may be even better. In fact, some recommend that an exit strategy be built<br />

<strong>in</strong>to the <strong>in</strong>itial bus<strong>in</strong>ess plan.<br />

Proper plann<strong>in</strong>g for your bus<strong>in</strong>ess and personal need should address:<br />

• Retirement <strong>in</strong>come<br />

• The death and disability of an owner<br />

• The departure of a bus<strong>in</strong>ess owner<br />

• Family members <strong>in</strong>volved <strong>in</strong> the bus<strong>in</strong>ess<br />

Avoid a future problem and make the first move now. To help assure f<strong>in</strong>ancial security for you, your<br />

family, and your bus<strong>in</strong>ess, contact your Federated representative or your association office for<br />

<strong>in</strong>formation on Federated’s F<strong>in</strong>ancial Protection Services. The advantage will be yours.<br />

It’s Our Bus<strong>in</strong>ess to Protect Yours ®<br />

09.04 Ed. 4-09 • The FEDERATED Insurance Companies • Home Office: 121 East Park Square • Owatonna, M<strong>in</strong>nesota 55060<br />

Phone: (507) 455-5200 • www.federated<strong>in</strong>surance.com<br />

May | June 2010 PRECISION MANUFACTURING | 5

<strong>Liv<strong>in</strong>g</strong><br />

<strong>in</strong> a material world<br />

The cost and availability of raw materials may make<br />

it harder for manufacturers to ramp up aga<strong>in</strong>.<br />

The demand for metals and other commodities plummeted <strong>in</strong><br />

late 2008 and 2009 as economies around the world suffered from a<br />

sharp downturn. Prices followed and, <strong>in</strong> some cases, bottomed out,<br />

provid<strong>in</strong>g at least some relief for manufacturers.<br />

That relief was short-lived, however. World activity, while not<br />

exactly thriv<strong>in</strong>g, is show<strong>in</strong>g signs of life. In anticipation of better<br />

economic output, many commodity prices are well above their<br />

recent lows.<br />

Manufactur<strong>in</strong>g activity now has been up for several consecutive<br />

months <strong>in</strong> a row, mean<strong>in</strong>g more and more companies are busy<br />

order<strong>in</strong>g and try<strong>in</strong>g to replenish their <strong>in</strong>ventory. Surcharges, price<br />

<strong>in</strong>creases and short supplies of even some common items seem to<br />

characterize today’s market. Will manufacturers be able to get the<br />

material they need, when they need it, at a fair price? It depends.<br />

Dur<strong>in</strong>g the recession, most manufacturers cleaned out their<br />

<strong>in</strong>ventory; the mills and service centers did the same. Although<br />

manufactur<strong>in</strong>g has been pick<strong>in</strong>g up, many of those mills and<br />

service centers are trail<strong>in</strong>g beh<strong>in</strong>d, runn<strong>in</strong>g at 50 or 60 percent<br />

capacity. Demand is outstripp<strong>in</strong>g <strong>in</strong>ventory levels.<br />

Miles Free, director of <strong>in</strong>dustry research and technology at the<br />

<strong>Precision</strong> Mach<strong>in</strong>ed Products Association (PMPA), said it this<br />

way: “Until larger <strong>in</strong>ventories of scrap build-up from <strong>in</strong>creases <strong>in</strong><br />

the production, the <strong>in</strong>dustry and its supply cha<strong>in</strong> face a paradox<br />

of no scrap from which to make steel, therefore no steel to make<br />

parts, therefore no scrap to make steel. It’s the classic chicken and<br />

the egg situation.”<br />

In addition, Ch<strong>in</strong>a and other countries are consum<strong>in</strong>g raw<br />

materials at a faster rate than the United States. PMPA estimates<br />

that Ch<strong>in</strong>a consumes about 31 percent of all the steel <strong>in</strong> the world.<br />

Other sources say that figure is closer to 50 percent—and grow<strong>in</strong>g.<br />

Prices rema<strong>in</strong> highly volatile and are based more on <strong>in</strong>vestor<br />

<strong>in</strong>terest and speculation than on true supply and demand.<br />

Of course, prices are be<strong>in</strong>g <strong>in</strong>fluenced by a surge <strong>in</strong> Ch<strong>in</strong>ese<br />

consumption as well.<br />

“The global price of metals is really more reflective of Ch<strong>in</strong>ese<br />

demand than local neighborhood demand,” Free said. “They’re the<br />

ones sett<strong>in</strong>g the price because they’re the big user.”<br />

From December of 2008 to December of 2009, the price of<br />

copper went up 112 percent. Alum<strong>in</strong>um went up 44 percent; nickel<br />

<strong>in</strong>creased by 27 percent; and steel was up by 35 percent.<br />

In a recent Wall Street Journal article, a large steelmaker<br />

advised steel consumers to brace for the onset of much higher steel<br />

prices <strong>in</strong> the com<strong>in</strong>g months—<strong>in</strong>creases of 70 percent or more.<br />

>>><br />

May | June 2010 PRECISION MANUFACTURING | 7

COVer | RAW MATERIALS<br />

STEEL USE AROUND THE WORLD<br />

Other Europe<br />

3%<br />

New EU<br />

2%<br />

EU<br />

14%<br />

CSI Former<br />

(USSR)<br />

13%<br />

Source: PMPA<br />

NAFTA<br />

13%<br />

Others<br />

10%<br />

OtherAsia<br />

15%<br />

Impact on Manufacturers<br />

Not all manufacturers are be<strong>in</strong>g<br />

affected by material bottlenecks and<br />

price sw<strong>in</strong>gs, however. While some are<br />

scrambl<strong>in</strong>g to fill <strong>in</strong>ventories, others have<br />

barely noticed any changes at all.<br />

Kurt Manufactur<strong>in</strong>g Company<br />

Inc., which purchases large amounts of<br />

alum<strong>in</strong>um and steel, hasn’t experienced<br />

any problems order<strong>in</strong>g raw materials —<br />

only steady price <strong>in</strong>creases. Over the last<br />

6 months, the company has been order<strong>in</strong>g<br />

quite a bit of metal to keep up with orders,<br />

and Brad Carlstrom, Kurt’s purchas<strong>in</strong>g<br />

manager, believes it’s a buyer’s market.<br />

“The supplies still seem to be strong,”<br />

he said. “I guess it depends on what type<br />

of metal you’re chas<strong>in</strong>g, but for basic<br />

alum<strong>in</strong>ums, steels and sta<strong>in</strong>less, I haven’t<br />

had any problems. On the other hand, a<br />

real uptick <strong>in</strong> demand will cause issues.<br />

There’s no question that the service<br />

centers around the Tw<strong>in</strong> Cities have been<br />

a cushion for us.”<br />

Carlstrom said he hasn’t noticed a<br />

difference <strong>in</strong> lead times, either. However,<br />

he has noticed a steady <strong>in</strong>crease <strong>in</strong> the<br />

price of alum<strong>in</strong>um, which crept up to<br />

over a dollar per pound earlier this year.<br />

“But that’s go<strong>in</strong>g to turnaround,” he said.<br />

“I’m anticipat<strong>in</strong>g that quarter by quarter,<br />

we’ll see a drop <strong>in</strong> alum<strong>in</strong>um prices.”<br />

It’s a different story at Cass Screw<br />

Mach<strong>in</strong>e Products Company, which<br />

purchases mostly carbon rounds to make<br />

screw mach<strong>in</strong>ed products.<br />

Ch<strong>in</strong>a<br />

31%<br />

Japan<br />

8%<br />

In the fall of last<br />

year, Kalei Ensead, who<br />

works <strong>in</strong> the company’s<br />

purchas<strong>in</strong>g department,<br />

began notic<strong>in</strong>g that<br />

some distribution<br />

centers couldn’t fill<br />

her orders, especially<br />

if she needed larger<br />

quantities. She said she<br />

wasn’t order<strong>in</strong>g anyth<strong>in</strong>g<br />

special, just standard<br />

grade carbon steel.<br />

“We’re gett<strong>in</strong>g busier<br />

and look<strong>in</strong>g for materials<br />

that just aren’t there,”<br />

Ensead said.<br />

Now, <strong>in</strong>stead of buy<strong>in</strong>g<br />

10,000 pounds of stock<br />

from one vendor, she is<br />

buy<strong>in</strong>g it from three.<br />

In addition, Ensead is deal<strong>in</strong>g with<br />

higher prices. “When you run <strong>in</strong>to a<br />

situation where availability is slim, you<br />

start go<strong>in</strong>g outside of your normal source<br />

and you end up pay<strong>in</strong>g more,” she said.<br />

“Sometimes it’s cheaper to pay more for<br />

a product than to have a mach<strong>in</strong>e sit for<br />

3 days.”<br />

Impact on Distribution Centers<br />

Demand seems to be pick<strong>in</strong>g up<br />

at distribution centers, although it is<br />

nowhere near the level of early 2008.<br />

The question is whether the demand is<br />

temporary or long-term. If it’s temporary,<br />

many distribution centers will cont<strong>in</strong>ue to<br />

operate at less than full capacity.<br />

EMJ Metals<br />

Orders are way up at EMJ Metals<br />

from this time last year. The company is<br />

on pace to do over $100 million <strong>in</strong> sales<br />

this year and beat last year’s revenue by<br />

20 percent.<br />

EMJ is owned by Reliance Steel &<br />

Alum<strong>in</strong>um Company, which is one of<br />

the largest metals service centers <strong>in</strong> the<br />

United States. Mike Goepfrich, general<br />

sales manager, said he doesn’t th<strong>in</strong>k most<br />

manufacturers are hav<strong>in</strong>g problems with<br />

availability, especially if they’re order<strong>in</strong>g<br />

standard grade, but it depends on where<br />

they order it.<br />

He said he’s see<strong>in</strong>g more people<br />

who are normally mill buyers turn to<br />

distribution centers for their metals<br />

because they can’t wait 6 to 12 weeks.<br />

“I’ve never had a customer call me and<br />

tell me they’re go<strong>in</strong>g to fire me because of<br />

a price,” he said. “But I have had people tell<br />

me they’re go<strong>in</strong>g to fire me because I didn’t<br />

have the stock they needed.”<br />

In the meantime, Goepfrich expects<br />

metal prices to <strong>in</strong>crease <strong>in</strong> the short-term,<br />

at least until the third quarter when they<br />

may beg<strong>in</strong> to flatten out.<br />

Spectro Alloys Corporation<br />

When the Cash for Clunkers program<br />

went <strong>in</strong>to effect, the automakers were<br />

caught off-guard and so were many of<br />

their material suppliers. Spectro Alloys<br />

Corporation, which converts secondary<br />

alum<strong>in</strong>um scrap <strong>in</strong>to a new alloy, was<br />

one of them. The company had been<br />

produc<strong>in</strong>g at 50 percent capacity when it<br />

was suddenly slammed with orders.<br />

“We were go<strong>in</strong>g to our suppliers and<br />

they weren’t able to supply fast enough,”<br />

said Alan Gergen, regional sales manager.<br />

He believes the supply cha<strong>in</strong> is still<br />

tight, result<strong>in</strong>g <strong>in</strong> longer lead times and<br />

less flexibility <strong>in</strong> pric<strong>in</strong>g. He attributes<br />

much of the shortage to Ch<strong>in</strong>a and India.<br />

“If the United States used its own<br />

scrap, there would be enough,” Gergen<br />

said. “But it’s all be<strong>in</strong>g exported. The<br />

U. S. government doesn’t really see that<br />

as a problem because they see this huge<br />

trade deficit and they get excited when we<br />

send th<strong>in</strong>gs overseas.”<br />

Cost has been another challenge<br />

for Spectro Alloys. At one po<strong>in</strong>t a year<br />

ago, the basic alum<strong>in</strong>um alloy that the<br />

company produces cost .65 cents per<br />

pound. Today it’s $1.03 per pound.<br />

Gergen expects to see a market, for<br />

raw materials, that is flat to up over the<br />

next year. His advice to manufacturers<br />

is to budget for the cost of the products<br />

they’re mak<strong>in</strong>g—and stick to it.<br />

“Buy accord<strong>in</strong>g to that budget <strong>in</strong>stead<br />

of try<strong>in</strong>g to beat the market,” he said.<br />

Chicago Tube & Iron<br />

Chicago Tube & Iron is one of the<br />

largest steel service centers <strong>in</strong> the United<br />

States, with 10 subsidiaries throughout the<br />

Midwest. It was hit hard by the recession.<br />

Dur<strong>in</strong>g the first 3 quarters of 2008, the<br />

price of scrap was as high as $800 per ton<br />

and the company was on track to have a<br />

record year. Dur<strong>in</strong>g the fourth quarter,<br />

however, orders came to an abrupt halt.<br />

The price of scrap dropped <strong>in</strong> half and so<br />

8 | PRECISION MANUFACTURING May | June 201

COVer | RAW MATERIALS<br />

did demand. It proved to be a very bad<br />

year for the company.<br />

After bottom<strong>in</strong>g out last July, Chicago<br />

Tube & Iron f<strong>in</strong>ally is see<strong>in</strong>g a modest<br />

<strong>in</strong>crease <strong>in</strong> demand, although it is down<br />

considerably from early 2008. Larry<br />

Soehrman, vice president of materials<br />

management, said the company is<br />

beg<strong>in</strong>n<strong>in</strong>g to keep a little more material<br />

on hand, anticipat<strong>in</strong>g demand to pick up<br />

<strong>in</strong> the second half of the year. However,<br />

he th<strong>in</strong>ks lead times are a bigger problem<br />

than supply right now.<br />

“One of the biggest problems is<br />

that most of the mills and distributors<br />

are work<strong>in</strong>g at less than full capacity,”<br />

he said. “So if there’s a slight uptick <strong>in</strong><br />

demand, it shows up fairly quickly. That’s<br />

why we’re see<strong>in</strong>g lead times <strong>in</strong>crease a<br />

bit. It’s not because there’s a problem<br />

with supply; it’s because there aren’t as<br />

many people work<strong>in</strong>g.”<br />

His advice to manufacturers is to<br />

plan ahead.<br />

“If you have any unusual items that<br />

are critical to a customer base, you’re<br />

better off gett<strong>in</strong>g those on order sooner<br />

rather than later; because, if there is a<br />

ramp up, it will be difficult for suppliers<br />

to react as quickly as they did before,<br />

because they’re runn<strong>in</strong>g on shorter hours<br />

and shorter staff,” Soehrman said.<br />

The Future of the Market<br />

Free said he can’t predict when<br />

prices will level out aga<strong>in</strong>, but he<br />

expects them to rema<strong>in</strong> highly volatile<br />

this year as the economy gets <strong>in</strong>to fits<br />

and starts with recovery.<br />

Surcharges, he believes, have become<br />

a permanent feature <strong>in</strong> the market for<br />

raw materials used <strong>in</strong> manufactur<strong>in</strong>g,<br />

and shops that offer fixed prices for their<br />

products do so at their own peril.<br />

He and other analysts will be keep<strong>in</strong>g<br />

a close eye on the hous<strong>in</strong>g and auto<br />

<strong>in</strong>dustries. Houses require large amounts<br />

of steel, and contractors drive light trucks,<br />

which also require large amounts of steel.<br />

These two <strong>in</strong>dustries are a major part of<br />

the metal ecosystem and have a significant<br />

effect on supply, demand and price.<br />

Natural disasters are another powerful<br />

<strong>in</strong>fluence on the price of metals. One<br />

day after an earthquake struck Chile, for<br />

example, copper prices went up 2 percent.<br />

Chile is the world’s largest producer<br />

of copper and, although the m<strong>in</strong>es<br />

themselves weren’t damaged, electricity<br />

was <strong>in</strong>terrupted.<br />

So how do you <strong>in</strong>telligently manage<br />

risk when the price of your raw<br />

material—which may be half your part<br />

costs—doubles?<br />

“You don’t give firm prices for a year,<br />

that’s for sure,” Free said.<br />

“The advice I would give<br />

manufacturers,” he concluded, “is that it’s<br />

probably more important to know where<br />

you can f<strong>in</strong>d material than what you<br />

ultimately will pay for it. I’m not say<strong>in</strong>g<br />

give away your product, but price for<br />

immediate delivery trumps low price for<br />

2 months out from now.”<br />

It’s a material world, <strong>in</strong>deed. PM<br />

Melissa DeBilzan is a contribut<strong>in</strong>g writer<br />

for Intr<strong>in</strong>xec Management, Inc. She can be<br />

reached at melissa@mpma.com.<br />

THE RISING COSTS OF RAW MATERIALS<br />

600<br />

550<br />

500<br />

450<br />

400<br />

Alum<strong>in</strong>um (cents per pound)<br />

Brass (cents per pound)<br />

Copper (cents per pound)<br />

Nickel Scrap (cents per pound)<br />

Steel Scrap ($ per gross ton)<br />

Ch<strong>in</strong>a Coke ($ per ton)<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Mar 09 Apr 09 May 09 June 09 July 09 Aug 09 Sep 09 Oct 09 Nov 09 Dec 09 Jan 10 Feb 10 Mar 10<br />

Source: PMPA<br />

May | June 2010 PRECISION MANUFACTURING | 9

10 | PRECISION MANUFACTURING May | June 201

who’s | WHO<br />

Lori and Traci Tapani, Wyom<strong>in</strong>g Mach<strong>in</strong>e, Inc.<br />

MORE THAN ONE BOTTOM LINE<br />

by B Kyle<br />

The theme of “possibility” is an<br />

<strong>in</strong>terest<strong>in</strong>g one. Ford, Edison, Disney,<br />

Robb<strong>in</strong>s, Nietzsche and so many others<br />

all speak of the power to be found <strong>in</strong><br />

explor<strong>in</strong>g the “what could be’s.”<br />

Lori and Traci Tapani, sisters and copresidents<br />

of Wyom<strong>in</strong>g Mach<strong>in</strong>e, Inc., a<br />

precision metal fabricator, demonstrate<br />

their ease with this concept.<br />

LT: It’s how we were raised. It was the<br />

foundation of our upbr<strong>in</strong>g<strong>in</strong>g. We had a<br />

stay-at-home mom, and a former Mar<strong>in</strong>e<br />

dad. Both are hardwork<strong>in</strong>g and really<br />

creative. On Saturday we might be mix<strong>in</strong>g<br />

cement and learn<strong>in</strong>g how to make cement<br />

stairs with our dad because he thought it<br />

was critical that we know how to do these<br />

th<strong>in</strong>gs. And then on Sunday we would<br />

cook and bake with mom.<br />

Once you get used to a life filled<br />

with “outside the box” choices, you get<br />

comfortable <strong>in</strong> that space. And you can<br />

expand that attitude to other aspects of<br />

your life.<br />

These sisters jo<strong>in</strong>ed their dad at<br />

Wyom<strong>in</strong>g Mach<strong>in</strong>e <strong>in</strong> 1994, leav<strong>in</strong>g<br />

f<strong>in</strong>ancial careers to enter a world <strong>in</strong> which<br />

they were very much the odd ones out.<br />

Q: How long did it take for you to<br />

f<strong>in</strong>d your own rhythm as leaders and<br />

women <strong>in</strong> the manufactur<strong>in</strong>g arena?<br />

TT: [Smil<strong>in</strong>g at Lori, as together<br />

they share a moment to silently reflect<br />

on the challenges they’ve shared.]<br />

Once we came to the realization that<br />

we never would really fit <strong>in</strong>, as women<br />

and mothers, when we came to grips<br />

that it wasn’t happen<strong>in</strong>g, we f<strong>in</strong>ally<br />

laughed and relaxed <strong>in</strong>to figur<strong>in</strong>g out<br />

how to do bus<strong>in</strong>ess our way. And, you<br />

know, bus<strong>in</strong>ess got better, relationships<br />

expanded, because we weren’t try<strong>in</strong>g to<br />

be someth<strong>in</strong>g we weren’t.<br />

LT: The process of fully becom<strong>in</strong>g<br />

ourselves as leaders started hitt<strong>in</strong>g<br />

home for us when our software<br />

company selected Wyom<strong>in</strong>g Mach<strong>in</strong>e as<br />

Lori and Traci Tapani, co-presidents of<br />

Wyom<strong>in</strong>g Mach<strong>in</strong>e, Inc.<br />

a beta site for their new lean schedul<strong>in</strong>g<br />

program. We were one of 15 companies<br />

<strong>in</strong> the nation selected, because we had<br />

a reputation for be<strong>in</strong>g progressive and a<br />

will<strong>in</strong>gness to try new th<strong>in</strong>gs.<br />

TT: Then other th<strong>in</strong>gs began to<br />

happen. We got an opportunity to do<br />

an onl<strong>in</strong>e Web<strong>in</strong>ar for IndustryWeek<br />

magaz<strong>in</strong>e. To be quite honest, we<br />

cont<strong>in</strong>ue to be surprised that folks are<br />

<strong>in</strong>terested <strong>in</strong> what we have to say. It’s<br />

extraord<strong>in</strong>ary.<br />

Q: You both are unique <strong>in</strong> that<br />

you seem to be keenly aware of<br />

the connectedness between your<br />

th<strong>in</strong>k<strong>in</strong>g and the results you are<br />

experienc<strong>in</strong>g <strong>in</strong> both your personal<br />

and professional lives.<br />

LT: What you might discover <strong>in</strong><br />

meet<strong>in</strong>g with us is that our formula<br />

for success is constantly chang<strong>in</strong>g.<br />

Our core is about be<strong>in</strong>g true to self,<br />

about <strong>in</strong>tegrat<strong>in</strong>g personal values with<br />

professional discipl<strong>in</strong>es. Add to that<br />

our “special sauce” of possibility and<br />

connectedness, and we th<strong>in</strong>k we’ve got a<br />

w<strong>in</strong>n<strong>in</strong>g comb<strong>in</strong>ation.<br />

Earlier this year we were <strong>in</strong>vited to<br />

speak at St. Cather<strong>in</strong>e University, to an<br />

organizational leadership class entitled<br />

Servant Leadership. At this event we<br />

met other women struggl<strong>in</strong>g with<br />

servant leadership, with the challenges<br />

of reconcil<strong>in</strong>g personal values with<br />

professional choices.<br />

It was there that we shared the<br />

concept that, to our way of th<strong>in</strong>k<strong>in</strong>g,<br />

there is more than one bottom l<strong>in</strong>e<br />

<strong>in</strong> bus<strong>in</strong>ess. Obviously, we need<br />

profitability. But if that’s at the expense<br />

of human relations and your family, then<br />

maybe the bus<strong>in</strong>ess is not so successful<br />

after all.<br />

Q: How did the women respond?<br />

TT: The audience was full of midlife,<br />

professional women, who from my<br />

perspective had remarkable careers of<br />

their own. And yet many of them spoke<br />

about be<strong>in</strong>g <strong>in</strong>spired by the simple fact<br />

that we stepped out <strong>in</strong>to the unknown<br />

when we took on this bus<strong>in</strong>ess.<br />

Q: What do you th<strong>in</strong>k is the biggest<br />

hurdle for these women—that they<br />

feel you somehow overcame?<br />

TT: There’s a difference between<br />

hav<strong>in</strong>g professional competence and<br />

hav<strong>in</strong>g an <strong>in</strong>ner belief that you actually<br />

can do whatever you want to. Lori and<br />

I were raised <strong>in</strong> such a way that, <strong>in</strong> all<br />

honesty, it would never occur to us that<br />

we could not do someth<strong>in</strong>g. This doesn’t<br />

mean you’re not afraid sometimes, but<br />

that we are open to the possibility of<br />

do<strong>in</strong>g someth<strong>in</strong>g different. It seems to<br />

me, with some people, there is a level of<br />

doubt about this.<br />

LT: As soon as we stopped try<strong>in</strong>g to<br />

fit <strong>in</strong> regard<strong>in</strong>g bus<strong>in</strong>ess, and we became<br />

open to the possibility that be<strong>in</strong>g different<br />

might not be so bad, our world expanded.<br />

We’re discover<strong>in</strong>g that your life is<br />

smaller if you’re not will<strong>in</strong>g to consider<br />

the possibility <strong>in</strong> every opportunity. PM<br />

B KyLE is the vice<br />

president of bus<strong>in</strong>ess<br />

development at the Sa<strong>in</strong>t<br />

Paul Port Authority <strong>in</strong> St.<br />

Paul, M<strong>in</strong>n. She can be<br />

reached at blk@sppa.com.<br />

May | June 2010 PRECISION MANUFACTURING | 11

shOP | PROFILE<br />

Kurt Workhold<strong>in</strong>g<br />

HuNDREDS OF NEW WORKHOLDING OPTIONS<br />

The new Kurt FMS has a total of 32 different workhold<strong>in</strong>g fixtures.<br />

In order to provide manufacturers<br />

of precision parts with more options<br />

to compete globally, Kurt Industrial<br />

Products has expanded its workhold<strong>in</strong>g<br />

to <strong>in</strong>clude an astonish<strong>in</strong>g array of<br />

products. Dozens of new workhold<strong>in</strong>g<br />

designs have been <strong>in</strong>troduced <strong>in</strong> the last<br />

year alone. With them, a new automated<br />

manufactur<strong>in</strong>g system has been <strong>in</strong>stalled<br />

at Kurt to provide very fast product<br />

turnaround with the highest quality.<br />

Users of these new Kurt products rave<br />

about the results they are experienc<strong>in</strong>g.<br />

“We wanted to manufacture Kurt<br />

workhold<strong>in</strong>g us<strong>in</strong>g as much of our<br />

own product as possible,” reported<br />

Steve Tschida, manufactur<strong>in</strong>g manager<br />

for Kurt. “We wanted customers and<br />

prospects to see how our new offer<strong>in</strong>gs<br />

could help them become much more<br />

efficient and compete better <strong>in</strong> a global<br />

economy. We utilized standard Kurt<br />

workhold<strong>in</strong>g, custom eng<strong>in</strong>eered<br />

workhold<strong>in</strong>g, the Kurt DockLock system<br />

and Kurt eng<strong>in</strong>eered systems to put this<br />

cell together. In short, we wanted to make<br />

this a showpiece of all Kurt’s abilities to<br />

present and prospective customers.”<br />

The flexible manufactur<strong>in</strong>g system<br />

(FMS) has a total of 32 different<br />

workhold<strong>in</strong>g fixtures. All of these are<br />

designed around a four-mach<strong>in</strong>e Mazak<br />

Palletech system consist<strong>in</strong>g of 36 pallet<br />

stockers and two load stations. Seven<br />

of the workhold<strong>in</strong>g fixtures have been<br />

outfitted with an automatic coupl<strong>in</strong>g<br />

device designed by Kurt eng<strong>in</strong>eers.<br />

Four of these fixtures are designed to<br />

show the programmer how to approach<br />

more sides of a part, allow<strong>in</strong>g rough<br />

mach<strong>in</strong><strong>in</strong>g operations to be completed<br />

<strong>in</strong> a s<strong>in</strong>gle operation. These fixtures<br />

have hydraulic pistons that are key to<br />

the rigidity of the mach<strong>in</strong><strong>in</strong>g process for<br />

produc<strong>in</strong>g highly precise components<br />

and a quality end product.<br />

Twenty-five of the manual fixtures <strong>in</strong><br />

the FMS l<strong>in</strong>e were designed with a similar<br />

goal—to mach<strong>in</strong>e all of the components<br />

<strong>in</strong> a s<strong>in</strong>gle operation, us<strong>in</strong>g as much<br />

standard Kurt products as possible.<br />

Customers Like Haberman Mach<strong>in</strong>e,<br />

Inc. Benefit From Kurt’s Workhold<strong>in</strong>g<br />

Expertise<br />

Kurt provided a well-known Tw<strong>in</strong><br />

City precision mach<strong>in</strong><strong>in</strong>g company,<br />

Haberman Mach<strong>in</strong>e, Inc, with modified,<br />

standard workhold<strong>in</strong>g that reduces setup<br />

time while <strong>in</strong>creas<strong>in</strong>g productivity. Two<br />

customized Kurt XL vises are mounted<br />

back-to-back and vertically. The setup<br />

elim<strong>in</strong>ates the need for a tombstone and<br />

provides center-of-gravity mach<strong>in</strong><strong>in</strong>g<br />

with vibration-free rigidity.<br />

The new workhold<strong>in</strong>g setup replaced<br />

a much slower setup process on vertical<br />

mach<strong>in</strong><strong>in</strong>g centers where parts were<br />

clamped ly<strong>in</strong>g down. In the new setup,<br />

the matched Kurt vises both have huge,<br />

21-<strong>in</strong>ch jaw open<strong>in</strong>gs for clamp<strong>in</strong>g<br />

vertical steel workblanks weigh<strong>in</strong>g well<br />

over 100 pounds. Important also, the<br />

workhold<strong>in</strong>g setup is designed for use on<br />

two different sized mach<strong>in</strong>e pallets, giv<strong>in</strong>g<br />

Haberman Mach<strong>in</strong>e maximum flexibility<br />

to mach<strong>in</strong>e a wider range of large parts.<br />

“This is really a great workhold<strong>in</strong>g<br />

setup,” reports Scott Ness of Haberman<br />

Mach<strong>in</strong>e. “We elim<strong>in</strong>ated the need for<br />

a tombstone, which saves us $5,000 to<br />

$8,000, and we’re not sacrific<strong>in</strong>g clamp<strong>in</strong>g<br />

rigidity. The fact that we can center<br />

workpieces and take advantage of gravity<br />

<strong>in</strong> the setup really prevents vibration<br />

and tool chatter when mak<strong>in</strong>g the most<br />

aggressive cuts. Our operators like it<br />

because it’s easier to setup and there are<br />

no mach<strong>in</strong><strong>in</strong>g clearance issues. We’re<br />

We elim<strong>in</strong>ated the need for a tombstone,<br />

which saves us $5,000 to $8,000, and we’re<br />

not sacrific<strong>in</strong>g clamp<strong>in</strong>g rigidity.<br />

- Scott Ness, Haberman Mach<strong>in</strong>e, Inc.<br />

12 | PRECISION MANUFACTURING May | June 201<br />

PAID SUPPLEMENT

gett<strong>in</strong>g top mach<strong>in</strong>e speeds, great f<strong>in</strong>ishes<br />

and no scrapped parts. Thanks aga<strong>in</strong> to<br />

Kurt for the workhold<strong>in</strong>g solution.”<br />

Super Torquer Systems Reduces<br />

Component Mach<strong>in</strong><strong>in</strong>g 65 Percent<br />

With Kurt Workhold<strong>in</strong>g<br />

Four Kurt HDM6AL double station<br />

vises mounted side by side on a vertical<br />

mach<strong>in</strong><strong>in</strong>g center reduced part mach<strong>in</strong><strong>in</strong>g<br />

costs by 65 percent, utiliz<strong>in</strong>g quick change<br />

jaws and some clever process plann<strong>in</strong>g.<br />

Most of the major components <strong>in</strong> this vise<br />

setup are now processed <strong>in</strong> Kurt’s FMS.<br />

Super Torquer Systems’ setup<br />

<strong>in</strong>cludes four Kurt HDM6AL vises that<br />

clamp four high carbon steel blanks,<br />

which are mach<strong>in</strong>ed <strong>in</strong>to 40 sw<strong>in</strong>g<br />

weights, used <strong>in</strong> the “Heel Clicker”<br />

clutch kit for popular snowmobile<br />

models. The mach<strong>in</strong><strong>in</strong>g process saves 65<br />

percent <strong>in</strong> mach<strong>in</strong><strong>in</strong>g costs.<br />

Initial justification for this setup was<br />

that four Kurt HD tw<strong>in</strong> station vises<br />

provided high density for hold<strong>in</strong>g four of<br />

the cam arms per vise. In addition, these<br />

vises provided a flexible platform us<strong>in</strong>g<br />

mach<strong>in</strong>ed changeable jaws for hold<strong>in</strong>g and<br />

mach<strong>in</strong><strong>in</strong>g other components <strong>in</strong> the clutch<br />

weight assemblies. That, plus the mach<strong>in</strong>ed<br />

jaws are easily changed so mach<strong>in</strong>e<br />

downtime is m<strong>in</strong>imal, part hold<strong>in</strong>g rigidity<br />

is excellent and repeatable accuracy is a<br />

given. A major additional benefit—the<br />

setup holds 10 parts per vise <strong>in</strong>stead of the<br />

orig<strong>in</strong>al four parts.<br />

C<strong>in</strong>dy Nouis, CNC programmer/<br />

co-owner of Super Torquer said, “The 65<br />

percent cost reduction should pay for the<br />

new setup three times over the first year.”<br />

Proof Is In The Orders<br />

Kurt is currently deliver<strong>in</strong>g a quarter<br />

of a million dollars <strong>in</strong> automated custom<br />

workhold<strong>in</strong>g fixtures to a Tier One<br />

automotive manufacturer. The <strong>in</strong>itial order<br />

calls for 10 custom workhold<strong>in</strong>g fixtures to<br />

be <strong>in</strong>tegrated with robot arms <strong>in</strong>to exist<strong>in</strong>g<br />

automated transfer l<strong>in</strong>es for precision<br />

mach<strong>in</strong><strong>in</strong>g automotive bear<strong>in</strong>g hous<strong>in</strong>gs.<br />

The 65 percent cost<br />

reduction should<br />

pay for the new<br />

setup three times<br />

over the first year.<br />

- C<strong>in</strong>dy Nouis, CNC<br />

programmer / co-owner of<br />

Super Torquer Systems<br />

The customer’s old workhold<strong>in</strong>g<br />

devices were limited to a 30-micron<br />

tolerance. Kurt’s newly delivered fixtures<br />

hold parts flat, to under 12 microns, while<br />

ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g a 1.67 Cpk level. Now that’s<br />

quality… Kurt quality!<br />

PAID SUPPLEMENT<br />

May | June 2010 PRECISION MANUFACTURING | 13

Innovation and excellence<br />

create a resourceful<br />

MINNESOTA CENTER FOR ENGINEERING & MANUFACTURING EXCELLENCE<br />

PARTNERS<br />

M<strong>in</strong>nesota State University, Mankato, Lead University<br />

Alexandria Technical College, Alexandria<br />

Anoka Technical College, Anoka<br />

Hennep<strong>in</strong> Technical College, Eden Prairie and Brooklyn Park<br />

Normandale Community College, Bloom<strong>in</strong>gton<br />

Northeast Higher Education District<br />

Hibb<strong>in</strong>g Community College, Hibb<strong>in</strong>g<br />

Itasca Community College, Grand Rapids<br />

Mesabi Range Community and Technical College, Eveleth and Virg<strong>in</strong>ia<br />

Vermillion Community College, Ely<br />

Ra<strong>in</strong>y River Community College, International Falls<br />

South Central College, North Mankato and Faribault<br />

A member of the M<strong>in</strong>nesota State Colleges and Universities<br />

system. The M<strong>in</strong>nesota State Colleges and Universities system<br />

is an Equal Opportunity employer and educator.<br />

www.mnceme.org Follow us on<br />

at www.twitter.com/maximizemn<br />

14 | PRECISION MANUFACTURING May | June 201

Gun Drill<strong>in</strong>g<br />

Now is the time to take your shot!<br />

There has never been a better time to start or relocate your bus<strong>in</strong>ess <strong>in</strong> Northeastern M<strong>in</strong>nesota.<br />

Be a player <strong>in</strong> the unprecedented economic expansion poised on our horizon.<br />

It’s time to see beyond our great golf and northwoods charm, and take a serious look at<br />

the opportunities at hand:<br />

1. Unprecedented growth<br />

2. Innovation<br />

3. Home to world-class global companies<br />

4. Quality of place<br />

5. Millions available for f<strong>in</strong>anc<strong>in</strong>g<br />

Contact our Bus<strong>in</strong>ess Development Team today and f<strong>in</strong>d out how Iron Range Resources<br />

can assist you with f<strong>in</strong>anc<strong>in</strong>g, site selection and <strong>in</strong>centive packages that are way above par.<br />

877-829-3936<br />

ironrangeresources.net<br />

Your vision. Our back<strong>in</strong>g.<br />

May | June 2010 PRECISION MANUFACTURING | 15

MADE | IN MINNESOTA<br />

Bright (Solar) Ideas<br />

ENERGY EFFICIENCY<br />

by Bill Remes<br />

In 2008, the founders of tenKsolar,<br />

Inc. founded their company with an<br />

idea—an idea to design and build a<br />

better solar panel. Identify<strong>in</strong>g the<br />

problems with solar panels as they<br />

currently existed, tenKsolar knew it<br />

had better ideas for a design that would<br />

produce more energy, more safety and<br />

with less cost. As the old say<strong>in</strong>g goes,<br />

they could “build a better mousetrap.”<br />

Located <strong>in</strong> Burnsville, M<strong>in</strong>n.,<br />

tenKsolar now has launched their new<br />

l<strong>in</strong>e of RAIS modules, which stands for<br />

redundant array of <strong>in</strong>tegrated solar.<br />

The current design of most solar<br />

panels <strong>in</strong>volves each one of the cells<br />

be<strong>in</strong>g wired or l<strong>in</strong>ked together <strong>in</strong> a<br />

series. So, when one or several of the<br />

cells is blocked and not work<strong>in</strong>g, large<br />

portions, if not all, of the solar panel<br />

fail to work—not generat<strong>in</strong>g power.<br />

[Remember the old str<strong>in</strong>gs of Christmas<br />

tree lights? When one of the lights went<br />

out—all of the lights went out. Solar<br />

panels, when l<strong>in</strong>ked <strong>in</strong> series, almost are<br />

that bad.]<br />

tenKsolar’s RAIS modules utilize a<br />

cell matrix architecture design <strong>in</strong> their<br />

coupl<strong>in</strong>g and output. One portion of<br />

a solar panel may be blocked, or fail,<br />

and a majority of the power still will<br />

be generated by that panel. And each<br />

module can stand alone—generat<strong>in</strong>g<br />

power when other modules for whatever<br />

reason may not be operat<strong>in</strong>g. The<br />

modules are designed so that energy<br />

literally f<strong>in</strong>ds an alternative path toward<br />

the output coupler.<br />

The National Renewable Energy<br />

Laboratory (NREL) has established<br />

an <strong>in</strong>dustry standard for the efficiency<br />

rat<strong>in</strong>g of solar panels, which are<br />

measured <strong>in</strong> photovoltaic (PV) watts.<br />

NREL rates other currently available<br />

solar panels as hav<strong>in</strong>g generally a 77 to<br />

82 percent efficiency rat<strong>in</strong>g, with only a<br />

72 to 74 percent efficiency rat<strong>in</strong>g after<br />

10 years of operation.<br />

Due to the<br />

efficiency of their<br />

design, the tenKsolar<br />

panels are show<strong>in</strong>g<br />

test results with an<br />

<strong>in</strong>itial efficiency of<br />

91 to 92 percent,<br />

with an efficiency<br />

of approximately 87<br />

percent even after 10<br />

years of operation.<br />

To boost the<br />

efficiency even<br />

further, the solar<br />

panel design also<br />

takes advantage of<br />

reflected light. Most<br />

solar panels only<br />

use direct sunlight.<br />

Whereas, mount<strong>in</strong>g of highly reflective<br />

panels, adjacent to a tenKsolar panel,<br />

adds a significant amount to the total<br />

energy output.<br />

Due to the fact that light can be<br />

reflected onto the panels, the optimal<br />

mount<strong>in</strong>g angle of each solar panel—<br />

which generally is equal to the latitude<br />

at which the panels are <strong>in</strong>stalled (45<br />

degrees latitude for M<strong>in</strong>nesota)—is not<br />

quite as important for tenKsolar panels.<br />

Two other important features that<br />

tenKsolar has designed <strong>in</strong>to their<br />

product offer<strong>in</strong>g <strong>in</strong>clude:<br />

▶▶Product Safety. Each panel<br />

operates at 48 volts—a voltage that<br />

is more safe for anyone who may<br />

come <strong>in</strong> contact with the panel.<br />

Conventional panels operate on as<br />

much as 600 volts—a lethal dose of<br />

electricity if you come <strong>in</strong> contact<br />

<strong>in</strong>advertently.<br />

▶▶Lightweight. tenKsolar panels<br />

are all made with an alum<strong>in</strong>um<br />

backplane, ensur<strong>in</strong>g a good silicone<br />

seal, which also keeps humidity<br />

This tenKsolar solar panel module, even with partial snow<br />

coverage, will still produce 82 percent of full area power; whereas a<br />

conventional solar panel might only produce less than 10 percent.<br />

out. The <strong>in</strong>stallations are virtually<br />

all alum<strong>in</strong>um structures, which is<br />

far less costly and far less weight<br />

than steel. This weight reduction<br />

means that many solar modules,<br />

particularly large solar modules, will<br />

not overburden the weight bear<strong>in</strong>g<br />

capacity of the structure <strong>in</strong> which<br />

they are mounted. In most <strong>in</strong>stances,<br />

the modules can be attached with no<br />

roof penetration (less opportunity<br />

for a roof to leak). tenKsolar claims<br />

to have the lowest pounds per square<br />

foot (with the highest kW rat<strong>in</strong>g)<br />

available today.<br />

There are many bright ideas<br />

designed <strong>in</strong>to these new state-of-the-art<br />

solar panels, conceived and produced<br />

right here <strong>in</strong> M<strong>in</strong>nesota. PM<br />

BILL REMES is the director<br />

of sales & market<strong>in</strong>g for<br />

AmeriStar Manufactur<strong>in</strong>g<br />

Inc. <strong>in</strong> Mankato, M<strong>in</strong>n. He<br />

can be reached at<br />

billr@ameristarmfg.com.<br />

sponsored by | HEGMAN MACHINE TOOL INC.<br />

16 | PRECISION MANUFACTURING May | June 201

Industry Profile<br />

Iron range resources<br />

Your vision. Our back<strong>in</strong>g.<br />

<br />

Bus<strong>in</strong>ess is<br />

GROW<br />

NG<br />

As the only region <strong>in</strong> M<strong>in</strong>nesota with its own state development agency, northeastern M<strong>in</strong>nesota has a<br />

crop of grants, loans and venture capital available for companies that choose to relocate or expand <strong>in</strong><br />

the area. Today, the region is home to many grow<strong>in</strong>g bus<strong>in</strong>esses and $6.4 billion worth of development.<br />

Iron Range Resources, a state agency funded by taconite<br />

production taxes, is focused exclusively on the success of<br />

bus<strong>in</strong>esses <strong>in</strong> northeastern M<strong>in</strong>nesota, provid<strong>in</strong>g them<br />

with vital fund<strong>in</strong>g and support.<br />

GROw<strong>in</strong>g bus<strong>in</strong>esses<br />

Access to capital is critical for new and grow<strong>in</strong>g<br />

companies, especially <strong>in</strong> a tight credit market. The<br />

f<strong>in</strong>anc<strong>in</strong>g programs available through Iron Range<br />

Resources are among the most wide-rang<strong>in</strong>g and creative<br />

<strong>in</strong> the country.<br />

Iron Range Resources can provide low or no <strong>in</strong>terest<br />

loans, revenue bonds, tra<strong>in</strong><strong>in</strong>g assistance and grants <strong>in</strong><br />

some cases. Sometimes it’s possible to structure debt<br />

forgiveness <strong>in</strong>to certa<strong>in</strong> projects if they meet criteria tied<br />

to job creation and retention.<br />

GROw<strong>in</strong>g communities<br />

In addition to assist<strong>in</strong>g bus<strong>in</strong>esses, Iron Range<br />

Resources is strengthen<strong>in</strong>g surround<strong>in</strong>g communities.<br />

By provid<strong>in</strong>g grants to local governments for bus<strong>in</strong>ess<br />

and residential <strong>in</strong>frastructure development, the agency is<br />

pav<strong>in</strong>g the way for community growth.<br />

GROw<strong>in</strong>g workforce<br />

Iron Range Resources is help<strong>in</strong>g to grow the region’s<br />

workforce through an educational model called The<br />

Applied Learn<strong>in</strong>g Institute. This is a partnership of<br />

school districts and colleges ensur<strong>in</strong>g high school<br />

students are able to earn college credit for technical<br />

education classes, not just liberal arts classes.<br />

Iron Range Resources is advanc<strong>in</strong>g the region’s<br />

workforce through the Arrowhead Institute of<br />

Technology, which allows students to earn bachelor’s<br />

and master’s degrees without leav<strong>in</strong>g the region. S<strong>in</strong>ce<br />

the program is completely project-based, students<br />

spend the majority of their time learn<strong>in</strong>g <strong>in</strong> <strong>in</strong>dustry,<br />

not the classroom.<br />

>>><br />

Over the last 3 years,<br />

enrollment <strong>in</strong> the<br />

Applied Learn<strong>in</strong>g<br />

Institute has grown by<br />

271 percent. In addition,<br />

enrollment <strong>in</strong> postsecondary<br />

technical<br />

programs <strong>in</strong>creased by<br />

73.2 percent.<br />

Over the last 6 years,<br />

Iron Range Resources<br />

has <strong>in</strong>vested $65.6<br />

million <strong>in</strong> loans to new<br />

and exist<strong>in</strong>g bus<strong>in</strong>esses<br />

<strong>in</strong> the region. Those<br />

loans were leveraged an<br />

average of nearly 4.5<br />

times, creat<strong>in</strong>g a total<br />

bus<strong>in</strong>ess <strong>in</strong>vestment<br />

impact of $294.2<br />

million and creat<strong>in</strong>g and<br />

reta<strong>in</strong><strong>in</strong>g 4,193 jobs.<br />

Over the last 6 years,<br />

Iron Range Resources<br />

has provided more than<br />

$90 million <strong>in</strong> grants<br />

to fund community and<br />

economic development,<br />

<strong>in</strong>clud<strong>in</strong>g over $5<br />

million for renewable<br />

energy <strong>in</strong>itiatives.<br />

S<strong>in</strong>ce 1990, the agency<br />

has helped fund the<br />

development of 2,200<br />

hous<strong>in</strong>g units and 25<br />

<strong>in</strong>dustrial parks.<br />

www.ironrangeresources.com

Industry Profile<br />

Iron range resources<br />

Magnetation, Incorporated<br />

www.magnetation.com<br />

Shortly after open<strong>in</strong>g its doors <strong>in</strong> February of<br />

2009, Magnetation knew it was time to expand.<br />

Based <strong>in</strong> Nashwauk, M<strong>in</strong>n., Magnetation has<br />

developed a proprietary—and highly profitable—<br />

process that converts natural ore waste <strong>in</strong>to iron.<br />

Magnetation sets up shop near old tail<strong>in</strong>gs<br />

bas<strong>in</strong>s. Scattered across the region, these bas<strong>in</strong>s<br />

store the waste from iron ore m<strong>in</strong><strong>in</strong>g. The waste<br />

is processed through Magnetation’s equipment<br />

and iron concentrate is drawn out and sold to<br />

iron makers and steel mills.<br />

When Magnetation is f<strong>in</strong>ished with the tail<strong>in</strong>gs<br />

bas<strong>in</strong>s, it converts these wastelands <strong>in</strong>to ecologically<br />

function<strong>in</strong>g wetlands. The company then moves onto the<br />

next tail<strong>in</strong>gs bas<strong>in</strong> site.<br />

“Northeastern M<strong>in</strong>nesota is a great place for an<br />

entrepreneurial effort like ours because of the f<strong>in</strong>anc<strong>in</strong>g<br />

that’s available through Iron Range Resources, which is<br />

not someth<strong>in</strong>g you can get just anywhere,” said Larry<br />

Leht<strong>in</strong>en, CEO and majority owner. “They’ve allowed a<br />

bus<strong>in</strong>ess like ours to come <strong>in</strong>to existence that otherwise<br />

Wide Open cOMpany<br />

www.wideopenco.com<br />

Kirk Davis has been <strong>in</strong> the power sports bus<strong>in</strong>ess<br />

for decades and is<br />

a motorcycle, ATV<br />

and snowmobile<br />

enthusiast. But he’s<br />

never seen as much<br />

excitement around a<br />

power sports product<br />

as he’s see<strong>in</strong>g with<br />

utility terra<strong>in</strong> vehicles<br />

(UTVs), he said.<br />

About 10 years<br />

ago, Davis decided<br />

to get out of the boat<br />

bus<strong>in</strong>ess and jump<br />

<strong>in</strong>to the UTV market.<br />

After launch<strong>in</strong>g Wide<br />

Open Company<br />

<strong>in</strong> Grand Rapids,<br />

M<strong>in</strong>nesota <strong>in</strong> 1998,<br />

he and a handful of<br />

employees began design<strong>in</strong>g and build<strong>in</strong>g hoods for<br />

crawler vehicles. In 2001 his company began design<strong>in</strong>g<br />

Based <strong>in</strong> Grand Rapids, M<strong>in</strong>n.,<br />

Kirk Davis’ Wide Open Company is<br />

recognized with<strong>in</strong> the power sports<br />

<strong>in</strong>dustry as a high quality manufacturer<br />

of utility terra<strong>in</strong> vehicle accessories.<br />

A proprietary process developed by Magnetation,<br />

Incorporated extracts iron units from natural iron ore<br />

tail<strong>in</strong>gs and then turns the tail<strong>in</strong>gs bas<strong>in</strong>s <strong>in</strong>to wetlands.<br />

may not have.”<br />

Magnetation’s first plant was built <strong>in</strong> 2009 with the<br />

capacity of produc<strong>in</strong>g 125,000 tons of product per year.<br />

Soon after, the company expanded, <strong>in</strong>creas<strong>in</strong>g capacity to<br />

250,000 tons per year.<br />

“We hope to put up another four or five plants <strong>in</strong> the<br />

next 10 years,” Leht<strong>in</strong>en said.<br />

Iron Range Resources provided much of the orig<strong>in</strong>al<br />

f<strong>in</strong>anc<strong>in</strong>g to build Magnetation’s facility. The agency also<br />

provided low-<strong>in</strong>terest loans to allow the company to<br />

grow shortly after open<strong>in</strong>g.<br />

cab enclosures for the Polaris Ranger vehicle. That, he<br />

said, is when bus<strong>in</strong>ess really started to take off.<br />

“We’re out of warehous<strong>in</strong>g space as I speak,” Davis<br />

said. “We hired 12 employees last year and we’ll hire<br />

potentially another 12 this year.”<br />

UTVs have become popular among consumers,<br />

particularly baby boomers, due to the fact that they can<br />

be used year-round, carry multiple passengers and haul<br />

heavy loads. They’ve also become useful for the m<strong>in</strong><strong>in</strong>g<br />

and construction <strong>in</strong>dustries as well as the military.<br />

Today, Wide Open Company employs 35 people and<br />

manufactures 2,500 UTV enclosures per year <strong>in</strong> addition<br />

to thousands of heaters and accessories.<br />

Davis decided to start Wide Open Company <strong>in</strong><br />

northeastern M<strong>in</strong>nesota for a number of reasons: “First,<br />

there’s a strong <strong>in</strong>dustrial <strong>in</strong>frastructure here to support<br />

us,” he said. “Second, there are a number of talented<br />

crafts people <strong>in</strong> this area who have the ability to develop<br />

some of the prototypes and tools we need. Beyond that,<br />

it’s just a great place to live and raise a family.”<br />

Iron Range Resources provided loans to Wide Open<br />

Company for equipment and expansion.

Industry Profile<br />

Iron range resources<br />

Premier Plastics<br />

www.premierplasticsmn.com<br />

Attracted to the area’s dedicated workforce, Bob<br />

Menne relocated his bus<strong>in</strong>ess from Wyom<strong>in</strong>g, M<strong>in</strong>n.,<br />

to Hoyt Lakes, M<strong>in</strong>n., <strong>in</strong> 2003. He moved <strong>in</strong>to a new<br />

35,000-square-foot facility, hired nearly 20 employees the<br />

first year, and hasn’t looked back s<strong>in</strong>ce.<br />

“The workforce up here is quite a bit different,”<br />

Menne said. “There are good, hardwork<strong>in</strong>g, available<br />

employees here. We have far less turnover now.”<br />

After relocat<strong>in</strong>g to northeastern M<strong>in</strong>nesota, Premier<br />

Plastics more than doubled its sales and growth and<br />

expanded its capabilities to <strong>in</strong>clude both rotational<br />

mold<strong>in</strong>g and thermoform<strong>in</strong>g. The company makes<br />

a variety of parts for the recreational and mar<strong>in</strong>e<br />

<strong>in</strong>dustries, <strong>in</strong>clud<strong>in</strong>g seat<strong>in</strong>g, dash panels, cup holders,<br />

cargo boxes and other parts.<br />

Bob Menne has found northeastern M<strong>in</strong>nesota to be<br />

a perfect place for Premier Plastics to manufacture<br />

recreational and mar<strong>in</strong>e products.<br />

“It’s been a good move for our bus<strong>in</strong>ess,” Menne said.<br />

Iron Range Resources helped Premier Plastics secure<br />

low-<strong>in</strong>terest f<strong>in</strong>anc<strong>in</strong>g for its build<strong>in</strong>g and equipment.<br />

Cast cOrporation<br />

www.castcorporation.com<br />

Tim Bungarden opened Cast Corporation <strong>in</strong> 1995<br />

<strong>in</strong> the small town of Buhl, M<strong>in</strong>n. Five years later, he<br />

approached Iron Range Resources for the f<strong>in</strong>anc<strong>in</strong>g<br />

needed to purchase EDM mach<strong>in</strong>es, CNC mach<strong>in</strong>es and<br />

other equipment. Another 5 years later, he called on the<br />

agency aga<strong>in</strong> to help f<strong>in</strong>ance a larger build<strong>in</strong>g.<br />

“We needed to expand and beg<strong>in</strong> offer<strong>in</strong>g production<br />

mach<strong>in</strong><strong>in</strong>g,” he said. “We needed a bigger facility—and<br />

load<strong>in</strong>g docks.”<br />

Doug Felten, a Cast<br />

Corporation mach<strong>in</strong>ist,<br />

displays one of the many<br />

automobile <strong>in</strong>dustry<br />

products manufactured<br />

at the company’s Hibb<strong>in</strong>g,<br />

M<strong>in</strong>n., facility.<br />

In 2005, the company relocated to a 13,000-squarefoot<br />

build<strong>in</strong>g <strong>in</strong> Hibb<strong>in</strong>g, which was twice the size of its<br />

old facility.<br />

S<strong>in</strong>ce then, Bungarden has been work<strong>in</strong>g hard to<br />

diversify the company. Cast Corporation has gone from<br />

supply<strong>in</strong>g ma<strong>in</strong>ly patterns to the automotive <strong>in</strong>dustry<br />

to provid<strong>in</strong>g patterns, mold mak<strong>in</strong>g, woodwork<strong>in</strong>g,<br />

cast<strong>in</strong>gs and mach<strong>in</strong><strong>in</strong>g for a variety of <strong>in</strong>dustries.<br />

The company recently launched its own l<strong>in</strong>e of curb<br />

ramps made to help disabled people detect the<br />

boundary between the sidewalk and the street.<br />

It is sell<strong>in</strong>g them to states and cities as well as<br />

contractors across the United States.<br />

“We’ve survived this recession quite well,”<br />

Bungarden said. “We’ve been able to reta<strong>in</strong> all 17<br />

of our employees, and we hope to add another<br />

two or three more employees this year.”<br />

He went on to say that he expects to see<br />

cont<strong>in</strong>ued growth and expansions <strong>in</strong> the future.<br />

Iron Range Resources provided two separate<br />

loans to support the start-up and relocation of<br />

Cast Corporation.

Industry Profile<br />

Iron range resources<br />

Your vision. Our back<strong>in</strong>g.<br />

<br />

Top Reasons to Locate or Expand <strong>in</strong> Northeastern M<strong>in</strong>nesota<br />

1. LowER cOSTS<br />

The costs for land and commercial real estate are significantly lower <strong>in</strong> northeastern M<strong>in</strong>nesota.<br />

• Average cost of office build<strong>in</strong>gs is 78 percent less than national average<br />

• Average cost per acre for commercial/<strong>in</strong>dustrial real estate is 98 percent less than national average<br />

2. GREATER accESS TO capITAL<br />

Northeastern M<strong>in</strong>nesota is the only region <strong>in</strong> M<strong>in</strong>nesota with its own state development agency. As a result,<br />

bus<strong>in</strong>esses <strong>in</strong> the area have access to abundant resources for grants, loans and venture capital.<br />

• Low <strong>in</strong>terest loans as low as one to 3 percent<br />

• Loan guaranties<br />

• Equity <strong>in</strong>vestment<br />

3. EducATEd and pROducTIve wORkfORce<br />

Northeastern M<strong>in</strong>nesota is known for its skilled, educated, highly motivated and dedicated workforce.<br />

• Five out of seven counties <strong>in</strong> northeastern M<strong>in</strong>nesota were ranked among<br />

the top 25 most productive counties <strong>in</strong> M<strong>in</strong>nesota accord<strong>in</strong>g to a<br />

study conducted by the University of M<strong>in</strong>nesota Duluth.<br />

• Accord<strong>in</strong>g to the M<strong>in</strong>nesota State Plann<strong>in</strong>g Agency, northeastern HOW can we help you?<br />

M<strong>in</strong>nesota’s turnover ratio is significantly lower than any other<br />

region <strong>in</strong> M<strong>in</strong>nesota or the nation.<br />

• Despite a perception of heavy unionization, northeastern<br />

M<strong>in</strong>nesota’s workforce is just 17 percent organized—the same<br />

average as the rest of the state.<br />

• Skilled workers are more readily available <strong>in</strong> northeastern<br />

M<strong>in</strong>nesota as compared to the rest of the state accord<strong>in</strong>g to a study<br />

by the University of M<strong>in</strong>nesota Duluth.<br />

• Seventy four percent of employers <strong>in</strong> northeastern M<strong>in</strong>nesota are<br />

satisfied with their workers’ technical skills, compared to 58 percent<br />

<strong>in</strong> the metro area and 66 percent statewide.<br />

• Student ACT scores <strong>in</strong> northeastern M<strong>in</strong>nesota are among the<br />

highest <strong>in</strong> the country.<br />

If your company needs assistance <strong>in</strong> grow<strong>in</strong>g its<br />

bus<strong>in</strong>ess, help is readily available. From f<strong>in</strong>anc<strong>in</strong>g<br />

to facilities and beyond, the welcome mat is out for<br />

bus<strong>in</strong>esses of all types and sizes that would like to<br />

call northeastern M<strong>in</strong>nesota home.<br />

Contact our<br />

Bus<strong>in</strong>ess Development Team<br />

1.877.829.3936<br />

www.IronRangeResources.com<br />

4. ExcELLEnt quALITy of LIfe<br />

People tend to live and work <strong>in</strong> northeastern M<strong>in</strong>nesota because that’s where they want to be. The region’s small<br />

cities, towns and rural areas provide “big-city” amenities with low crime rates and virtually no traffic jams.<br />

Communities provide education, health care, and hous<strong>in</strong>g that are second to none. With a beautiful natural<br />

environment featur<strong>in</strong>g clean air, lush forests and sky-blue lakes, the area offers world-class, year-round outdoor<br />

recreation. A wide variety of cultural attractions <strong>in</strong>cludes visual and perform<strong>in</strong>g arts, and historic sites which<br />

preserve and showcase the rich heritage of the region.<br />

Northeastern M<strong>in</strong>nesota has long been known as a vacation dest<strong>in</strong>ation. Local residents believe it is better to live and<br />

work where you like to play.<br />

www.ironrangeresources.com

shOP | PROFILE<br />

Laser 1 Technology<br />

GETTING a Cut FROM<br />

MINNESOTA SALES TAX REFuNDS<br />

It isn’t every day companies receive a<br />

$16,000 check <strong>in</strong> the mail. But that’s exactly<br />

what happened to Laser 1 Technology, a<br />

laser mach<strong>in</strong><strong>in</strong>g shop <strong>in</strong> St. Paul, M<strong>in</strong>n.,<br />

after learn<strong>in</strong>g it had overpaid sales taxes on<br />

various items by that much.<br />

Like most shops, Laser 1 Technology<br />

spent the better part of 2008 and 2009<br />

focus<strong>in</strong>g on sales and day-to-day<br />