Living in a materiaL worLd - Minnesota Precision Manufacturing ...

Living in a materiaL worLd - Minnesota Precision Manufacturing ...

Living in a materiaL worLd - Minnesota Precision Manufacturing ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Industry Profile<br />

Iron range resources<br />

Premier Plastics<br />

www.premierplasticsmn.com<br />

Attracted to the area’s dedicated workforce, Bob<br />

Menne relocated his bus<strong>in</strong>ess from Wyom<strong>in</strong>g, M<strong>in</strong>n.,<br />

to Hoyt Lakes, M<strong>in</strong>n., <strong>in</strong> 2003. He moved <strong>in</strong>to a new<br />

35,000-square-foot facility, hired nearly 20 employees the<br />

first year, and hasn’t looked back s<strong>in</strong>ce.<br />

“The workforce up here is quite a bit different,”<br />

Menne said. “There are good, hardwork<strong>in</strong>g, available<br />

employees here. We have far less turnover now.”<br />

After relocat<strong>in</strong>g to northeastern M<strong>in</strong>nesota, Premier<br />

Plastics more than doubled its sales and growth and<br />

expanded its capabilities to <strong>in</strong>clude both rotational<br />

mold<strong>in</strong>g and thermoform<strong>in</strong>g. The company makes<br />

a variety of parts for the recreational and mar<strong>in</strong>e<br />

<strong>in</strong>dustries, <strong>in</strong>clud<strong>in</strong>g seat<strong>in</strong>g, dash panels, cup holders,<br />

cargo boxes and other parts.<br />

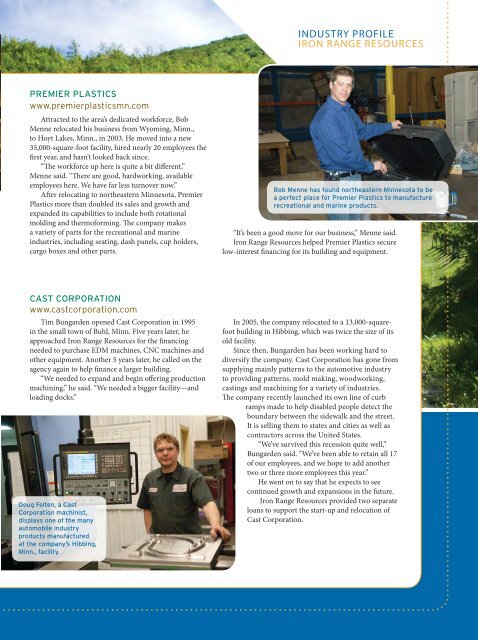

Bob Menne has found northeastern M<strong>in</strong>nesota to be<br />

a perfect place for Premier Plastics to manufacture<br />

recreational and mar<strong>in</strong>e products.<br />

“It’s been a good move for our bus<strong>in</strong>ess,” Menne said.<br />

Iron Range Resources helped Premier Plastics secure<br />

low-<strong>in</strong>terest f<strong>in</strong>anc<strong>in</strong>g for its build<strong>in</strong>g and equipment.<br />

Cast cOrporation<br />

www.castcorporation.com<br />

Tim Bungarden opened Cast Corporation <strong>in</strong> 1995<br />

<strong>in</strong> the small town of Buhl, M<strong>in</strong>n. Five years later, he<br />

approached Iron Range Resources for the f<strong>in</strong>anc<strong>in</strong>g<br />

needed to purchase EDM mach<strong>in</strong>es, CNC mach<strong>in</strong>es and<br />

other equipment. Another 5 years later, he called on the<br />

agency aga<strong>in</strong> to help f<strong>in</strong>ance a larger build<strong>in</strong>g.<br />

“We needed to expand and beg<strong>in</strong> offer<strong>in</strong>g production<br />

mach<strong>in</strong><strong>in</strong>g,” he said. “We needed a bigger facility—and<br />

load<strong>in</strong>g docks.”<br />

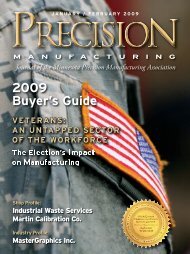

Doug Felten, a Cast<br />

Corporation mach<strong>in</strong>ist,<br />

displays one of the many<br />

automobile <strong>in</strong>dustry<br />

products manufactured<br />

at the company’s Hibb<strong>in</strong>g,<br />

M<strong>in</strong>n., facility.<br />

In 2005, the company relocated to a 13,000-squarefoot<br />

build<strong>in</strong>g <strong>in</strong> Hibb<strong>in</strong>g, which was twice the size of its<br />

old facility.<br />

S<strong>in</strong>ce then, Bungarden has been work<strong>in</strong>g hard to<br />

diversify the company. Cast Corporation has gone from<br />

supply<strong>in</strong>g ma<strong>in</strong>ly patterns to the automotive <strong>in</strong>dustry<br />

to provid<strong>in</strong>g patterns, mold mak<strong>in</strong>g, woodwork<strong>in</strong>g,<br />

cast<strong>in</strong>gs and mach<strong>in</strong><strong>in</strong>g for a variety of <strong>in</strong>dustries.<br />

The company recently launched its own l<strong>in</strong>e of curb<br />

ramps made to help disabled people detect the<br />

boundary between the sidewalk and the street.<br />

It is sell<strong>in</strong>g them to states and cities as well as<br />

contractors across the United States.<br />

“We’ve survived this recession quite well,”<br />

Bungarden said. “We’ve been able to reta<strong>in</strong> all 17<br />

of our employees, and we hope to add another<br />

two or three more employees this year.”<br />

He went on to say that he expects to see<br />

cont<strong>in</strong>ued growth and expansions <strong>in</strong> the future.<br />

Iron Range Resources provided two separate<br />

loans to support the start-up and relocation of<br />

Cast Corporation.