JUNE 2013 - Minnesota Precision Manufacturing Association

JUNE 2013 - Minnesota Precision Manufacturing Association

JUNE 2013 - Minnesota Precision Manufacturing Association

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

E-Z setupMachine 4 sidesHorizontal EditionRepeat (max profit)the eC-400 | 4 axes with twin pallets | Affordable Haas price.Haas Factory OutletA Division of Productivity, Inc.15200 25th Ave. North, Suite 120, Minneapolis, MN 55447Tel: 763-742-1263 • Fax: 763-476-4092430MinnesotA i 15150 25th Ave. n., Plymouth, Mn 55447p: 763.742.1263 i e: hfomn@productivity.com

Study the impact ofENERGYStudy the impact ofEFFICIENCYBOTTOM on yourLINEAUDITS AND STUDIES. Xcel Energy offers auditsand in-depth studies that can help you identify exactlywhere and how much your facility can save by makingenergy efficiency upgrades. What’s more, we often can helpyou pay for these studies, then provide rebates to makeyour upgrades more affordable and your paybacks faster.Visit ResponsibleByNature.com/Business or call anenergy efficiency specialist at 1-800-481-4700.ResponsibleByNature.com/Business© <strong>2013</strong> Xcel Energy Inc.

CONTENTS May | June <strong>2013</strong>11DEPARTMENTSDepartments6 News Bytes7 MPMA Calendar9 President’s Letter35 Manufacturers’Marketplace36 MPMA MemberDirectory42 Advertisers’ IndexCOLUMNSColumnsFeaturesFEATURES18 Shop Profile: Ace Cutter GrindingCutting Costs with Lube-Techby Melissa DeBilzan22 Leadership Insights SeriesCommunication - Getting the Messageby B Kyle28 Feature Story: The ABCs of Employee Certificationand CredentialsPart 2: Employee Apprenticeshipsby Melissa DeBilzan32 Shop Profile: MINNCOR IndustriesA Positive Connection with <strong>Minnesota</strong> Wireby Melissa DeBilzanQUALITY16 Made in <strong>Minnesota</strong>Gerdau20 Who’s WhoDr. Kevin Kopischke26 Best PracticesImplementing Quality34 Educator’s CornerProviding SkilledGraduatesE-CLUSIVESE-clusivesE-clusives are online only@ www.pm-mn.com.Key Policies to Boost<strong>Manufacturing</strong>Confronting the U.S.Advanced <strong>Manufacturing</strong>Skills Gap18 22 28 32APPROVEDMay | June <strong>2013</strong> PRECISION MANUFACTURING | 5

NEWSBYTESCheck out some of the latest news and events happening around MPMA and the manufacturingindustry. If you have something you would like to submit for publishing to our news section, please emailnewsbytes@pm-mn.com. For more news and events be sure to check out www.pm-mn.com.RECENTLY IN THE NEWSWilson Tool International …donated a specialty grinder worth $14,000 to AnokaTechnical College in Anoka, Minn. The donation is intendedto enhance the training opportunities for students of thecollege. The grinder is used to sharpen punch press toolingand will be used to train students in the college’s <strong>Precision</strong>Sheet Metal labs who may one day be employed bycustomers of Wilson Tool.Federated Insurance …is introducing a new risk management program titled “RiskManagement Culture: A Vision for Your Future.” Designed tohelp policyholders identify and prevent the risk exposures thatnegatively impact their bottom lines, the program was inspiredby feedback received from business owners across the country.Top Tool Company …Congratulations to Top Tool Company for being awardedQuality Magazine’s <strong>2013</strong> Plant of the Year award. Top Toolstood out for several reasons, including its advancedmanufacturing practices, investments in high-precisiontechnology, employee training and commitment to quality.Wyoming Machine …On Tuesday, April 2, <strong>2013</strong>, U.S. Sen. Al Franken (D-Minn.)visited Wyoming Machine in Stacy to discuss with localbusiness owners, educators and students the current effortto ensure workers are prepared to fill job openings in theregion. The visit included a tour of Wyoming Machine priorto the roundtable discussion.STEP UPTO THE PLATE!Anoka Technical College is coordinating a weeklong(June 24-28) summer <strong>Manufacturing</strong>Camp—ages 13-15—with the followinghands-on activities packed into an excitingweek: SolidWorks / Blueprint Reading, MedicalDevices, Welding, Metal Fabrication / Finishing /Plating / Coating.Various opportunities are available. If interested inparticipating contact Nick Graff at 763-576-4788 orngraff@anokatech.edu.150+ATTENDEES@ GRAND VIEW10 thLARGESTOver 150 manufacturers and educators gathered in Brainerd for the<strong>2013</strong> Grand View conference to discuss workforce developmentand discover new ways to collaborate. Impactful topics include thestatewide Dream it. Do it MN campaign, the eTech Program from the360 Center of Excellence, and the premier of the new Edge FactorVideo “Metal & Flesh.”Taken alone, manufacturing in the United States wouldbe the 10th largest economy in the world.Source: Bureau of Economic Analysis, Industry Economic Accounts (2011) and InternationalMonetary Fund (2011).Staying ConnectedFeaturing Ben Martin with Hegman MachineryBen Martin, applications engineer with Hegman Machinery connects with the editor of <strong>Precision</strong><strong>Manufacturing</strong> and talks about his engaging story of inspiration and passion in the manufacturingindustry. Read his story today by visiting www.pm-mn.com.Do you have a story to tell? Contact Amy Slettum at newsbytes@pm-mn.com and see your story inthe next online issue of <strong>Precision</strong> <strong>Manufacturing</strong>.6 | PRECISION MANUFACTURING May | June <strong>2013</strong>

Think You Can’t Afford Health Benefits?Contact your local Federated representative tolearn more about innovative health insuranceplan options, including high deductible plansand health savings accounts—because quality,cost-effective benefit options are key tofinancial health.Visit www.federatedinsurance.com to find arepresentative near you.Federated Mutual Insurance Company • Federated Service Insurance Company* • Federated Life Insurance CompanyOwatonna, <strong>Minnesota</strong> 55060 • Phone: (507) 455-5200 • www.federatedinsurance.com*Not licensed in the states of NH, NJ, RI, and VT. © <strong>2013</strong> Federated Mutual Insurance Company

PRESIDENT’S LETTERWorkshops for WarriorsTAKING CARE OF OUR OWNby Kimberly ArrigoniIrecently attended a National Institute for Metalworking Skills (NIMS) board meeting in San Diego,CA. During this visit, I experienced a tour of the Workshops for Warriors, a 501(c)(3) nonprofitorganization. This nonprofit organization is dedicated to training, certifying, and placing veterans inmanufacturing careers. The Navy veteran and his wife who started the nonprofit are paying it forward byproviding a facility for veterans to receive the training they need for a career in manufacturing and makethe transition into civilian life.As disheartening as this sounds, many veterans often are told that, after dedicating 4 years or evendecades of service, they are not qualified to do many jobs.KIMBERLY ARRIGONIcontrollerHaberman MachineKimA@habermanmachine.com“As we express our gratitude,we must never forget thatthe highest appreciation isnot to utter words, but to liveby them.”~ John Fitzgerald KennedyThis training for a manufacturing career is in machining, welding and programming, and it isprovided at no cost to our veterans. The wait list for this training is long, about 500 people, andgrowing. These classes are taught by industry professionals, current members of the Armed Forces,and other skilled veterans. Sometimes the instruction time is even donated by these professionals.The placement rate for these individuals is 100 percent; yet, there is no federal, state, or municipalfunding. There is a lofty goal to train over 900 veterans a year. And this is where we come in—theyneed more money and equipment. The founder has set a loftier goal: To someday replicate thisprogram throughout the country.So, here is my pitch. Currently, two challenge grants are available that mean a lot to this program:they are through the Gene Haas Foundation and the Society of <strong>Manufacturing</strong> EngineersEducation Foundation. They each have donated $100,000. For every dollar raised, those twofoundations will donate an additional dollar, up to $100,000 each, with potential for $400,000 infunding—a lot of money for a program that makes a big difference!We can help make this big difference. I realize that some of you may think that because thisprogram is in California, they are beyond an “arms distance away” and that it isn’t our problem;however, these are our veterans and they are being trained there before heading home, whether thatmeans heading home to California, Colorado or <strong>Minnesota</strong>.“If you build it they will come.” With so many veterans coming home, we can help ensure aprogram like this continues to grow. Did I mention that we need trained and skilled workers inour industry? Ok, not funny I know, but this is another way to get our future workforce trainedand employed. Those soft skills that so often are lacking in many of our recent hires are found inveterans, as they are quite disciplined. In fact, if three classes of training are missed, they are kickedout of the program. Their military disciplines make for one heck of a dedicated, drug free, and veryobvious legal-resident of the United States type employee that we all want.This is just a brief introduction into this incredible organization, as there is so much more that can andshould be mentioned, like the welding carts they have designed and are currently selling (yes, you canbuy one) to help support their training programs. Their website is www.workshopsforwarriors.org. Ifyour travels take you in that direction, I recommend taking a tour. Please consider a donation whetherit is through time, talent, or treasure. We can do this!It is an honor to have met the founder with an amazing dream. I salute you Hernan Luis y Prado!Taking care of our own and making twice the difference (Our Veterans…Our Industry)!PMMay | June <strong>2013</strong> PRECISION MANUFACTURING | 9

Open HOuseMay 14please Join us atOur Grand OpeningMay 14, <strong>2013</strong>Please RsVP to:matsuurausa.com/rsvpor scan belowMatsuura Machinery usa325 Randolph ave. • suite 100saint paul, Mn 55102SCAN MESeven machines will be on display, running demos underpower. Also, the new VX Series will be making its NorthAmerican debut.www.matsuurausa.com

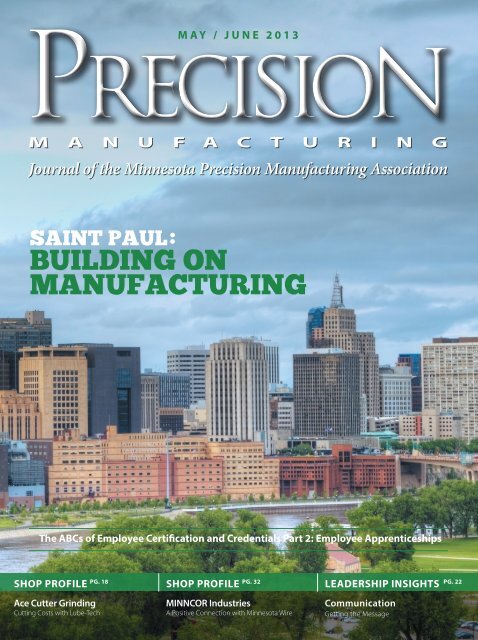

SAINT PAUL:BUILDING ONby B KyleMANUFACTURINGIt isn’t every day—indeed, it isn’t every year—that an international company establishes its U.S. headquarters in<strong>Minnesota</strong>. It is even more celebrated when said company chooses to locate along the great Mississippi River in SaintPaul, our capital city. The past few years of real estate development have been lean; so it has been especially sweetto participate in such a welcome. April 1, <strong>2013</strong>, was a big day for <strong>Minnesota</strong> as Matsuura USA opened its doors forbusiness. More celebrations are to come, with an official ribbon cutting at the new U.S. headquarters on May 14, <strong>2013</strong>.Matsuura Machinery USA (MMU)is a newly formed, wholly-ownedsubsidiary of Matsuura MachineryCorporation of Japan (MMC). Since itsinception in 1935, Matsuura Corporationhas been at the forefront of innovativedesign and development of high qualityCNC controlled machining centers fromits world headquarters in Fukui, Japan.Their line includes horizontals andverticals in all sizes, configured with 3 to5 axes, single table, twin and multi palletsystems, twin spindles and tool changers,cell systems, and their ultra-high speedlinear motor machines. Sales in 2012reached $170 million, $30 million ofwhich was done in the United States.MMC’s direct presence in theUnited States has been long in coming.For the past 40 years, MMC operatedin the United States through a masterdistributor agreement, importingmachines and providing both salesand service through Methods MachineTools, out of Boston, Mass. Based onits excellent market growth in theUnited States (almost 10,000 Matsuurainstallations), in 2012 MMC decided toexpand its presence by establishing directoperations for importing, sales, service,and technical support.WHY MINNESOTA?Although Matsuura’s Japaneseleadership was willing to consider severalstates as candidates for its new U.S.operations, <strong>Minnesota</strong> had some uniqueadvantages. John Schwartz, president ofMatsuura USA, is homegrown. The upperMidwest and <strong>Minnesota</strong> specificallyis a strong manufacturing region.Productivity Inc, Matsuura’s exclusivedistributor in this region, is among thenation’s best.So, why Saint Paul specifically?Matsuura couldn’t pass up the real estateopportunity presented by the Saint PaulPort Authority. “The Port Authority wasinstrumental in bringing us to SaintPaul,” said Schwartz. “We started lookingat sites in the metro area in early 2012.We met B Kyle at the Port Authority inearly September, pretty late in the game.Frankly, our plans already were focusingon some real estate in a couple of thefirst-ring suburbs.[ continued ]May | June <strong>2013</strong> PRECISION MANUFACTURING | 11

COVER STORYMatsuura factory in Fukui, Japan.“We were introduced to B Kylethrough our banking partner; he assuredus it would be worth our time to findout what the Port could offer. She wasnot deterred by coming late to the partybecause she knew that Saint Paul could becompetitive in delivering a building forus. And they were.“Together with WellingtonManagement, the Port’s joint venturepartner, and Phil Simonet of ParamountReal Estate, we walked through a specbuilding that was completed in 2011.Clearly, the Port understands howmanufacturers operate, and they knowhow to develop buildings that work forus. Had we not been able to walk Mr.Matsuura through this shell, go throughthe visioning process, I don’t believe wewould be in Saint Paul today. Our timeframe being what it was, we didn’t have thetime to build new,” continued Schwartz.Port Authority President, LouisJambois, is delighted that Schwartz andhis team took the time to consider SaintPaul. “We are honored that Matsuurachose Saint Paul for its U.S. headquarters.When a company with the global prestigeand unlimited options of Matsuurachooses Saint Paul, it sends a messageto the rest of the world that Saint Paulis a great place to do business. We trulycouldn’t be happier.”Saint Paul’s Mayor Chris Coleman,is keenly aware of the need for net newbusiness growth. “Saint Paul warmlywelcomes Matsuura Machinery USAto our business community. The PortAuthority does great work preparingdevelopment sites for strong companieslike Matsuura, and we know the impactof this new headquarters facility will befelt at a national level. Matsuura’s highestquality product, well-paid technicalstaff, and long term commitment toour community represent the kind ofpartnership we celebrate. Welcome toSaint Paul, <strong>Minnesota</strong>.”Truly, Matsuura locating here in<strong>Minnesota</strong> is being lauded at all levels.Department of Employment andEconomic Development CommissionerKatie Clark Sieben has stressed theimportance of promoting internationaltrade and foreign direct investment as themost important work towards positioning<strong>Minnesota</strong> to be globally competitive.“We are proud that Matsuura haschosen to call <strong>Minnesota</strong> home,” saidCommissioner Sieben. “Their investmentin <strong>Minnesota</strong> will help grow our economyand have a positive impact for their supplychain partners here in the region andcustomers throughout the United States.”Productivity Inc, located in Plymouth,Minn., has been selling Matsuuramachining centers in our six state regionsince 1976. “Matsuura’s machines areamong the most accurate and reliable inthe world,” said Productivity’s president,Greg Buck. “Though it was a surprisethat they chose to settle here rather thana more typical machine tool location likeChicago, having their U.S. headquarterslocated in Saint Paul will be an extrabenefit for our customers. Besides ourlocal support, this new facility willprovide even faster turnaround for parts,and spindle repair likely will be availablethe same day.“Beyond the machine quality,”continued Buck, “is the tenor of thecompany as a whole. The Matsuurafamily are wonderful people. Hopefully,more customers in our extendedmanufacturing community will have anopportunity to get acquainted with theCEO, Katsu Matsuura, and the presidentof Matsuura USA, John Schwartz.”THE PROCESSIt was in 2011, that Matsuura’sleadership first began exploring the idea ofestablishing a direct presence in the UnitedStates. The number of customers continuesto grow, as does the need for directtechnical support for their machine base.The United States is the fourth suchexpansion plan. “Our facilities in the U.K.and Germany are similarly structured,as wholly-owned subsidiaries,” explainedSchwartz. “Our location in Canada,though also a subsidiary, represents otherproduct lines as well. Our U.S. facility willbe exclusive to the Matsuura line.“I was hired in mid-2011, initiallycharged to site and staff this facility,”continued Schwartz. “We chose tolocate in <strong>Minnesota</strong> for several reasons,not the least of which being our strongrelationship with Productivity. We thinkvery highly of them as a partner, andthey have helped us tremendously—fromfacility design ideas to marketplaceintelligence. No formality, just realcommunication. And we listen to them.We look forward to continuing thatspecial relationship.”“Once we chose a community, we hadto drill down to building requirements.We figured we’d need about 35,000 squarefeet, giving us room for a showroomand a spindle rebuild. We also neededeasy access to the airport. Our real estateagent, Marty Fisher, Premier CommercialProperties, Inc., helped us identify somefirst round building options.”[ continued ]12 | PRECISION MANUFACTURING May | June <strong>2013</strong>

COVER STORYBe sure to join Matsuura at their GrandOpening celebration on May 14.Light lunch and self-guided tours will beprovided.Time: 11:00 a.m.Location: 325 Randolph Ave, Saint PaulPlease register @www.matsuurausa.com/rsvp“We met the folks at the PortAuthority about 8 months into thisprocess. We already had spent a lot oftime looking at buildings, even had acouple we were seriously considering.The size and weight of our machinesmeans we had some pretty specificrequirements around clear height, floorstrength, dock doors, so it was takingsome time to find a great building fit.The Port and Wellington delivered to usa beautiful spec building, 38,000 squarefeet, 24 foot clear height, ample parkingfor customers, and very convenient accessto the airport.“I can’t emphasize enough,” Schwartzfinished, “that this facility representsMatsuura’s fundamental commitment todelivering a best-in-class experience forour customers. To support that effort, weare being staffed with eight techniciansdirectly from Fukui, Japan, to ensure ourlaunch is flawless. We will have the rightparts, the right information, providingthe right services.”THE HISTORYMatsuura Machinery was foundedin 1935, in Fukui City (pronouncedfoo-KOO-ee), Japan. Production anddistribution first began with their latheproduct line. Milling machines were notintroduced until 1957. In 1974, then,the product line expanded to includevertical machining centers, designed forexport to the U.S. market. It was duringthe promotion of this new line that thenownerToshio Matsuura, the currentowner’s grandfather, met Clem McIver“This facility represents Matsuura’sfundamental commitment todelivering a best-in-class experiencefor our customers.”- John Schwartz, president, Matsuura USASr., founder of Methods Machine Tool, ata trade show in Japan. Though they couldnot really speak to one another, theycommunicated well enough to decidethey liked one another.Toshio Matsuura subsequently sent hisson, Masanori Matsuura, to Boston wherehe structured a professional relationshipwith Methods Machine Tool to provideimporting representation for Matsuura.That original agreement developed into amaster distributor relationship coveringthe entire United States and engaging17 to 20 distributors nationwide. ClemMcIver and Toshio Matsuura developed afriendship of mutual trust and admirationthat lasted until McIver’s death in 1995.The Matsuura Machinery Corporationand Methods Machine Tool relationshipthrived for close to 40 years. By 2002,the number of Matsuura customersin the United States was increasingsteadily, the need for technical supportgrowing accordingly. To ensure the mostimmediate and highest quality customersupport stateside, Matsuura formed a newtechnical and service support subsidiary,Matsuura Machinery Technical Services(MMTS), located at the Methods facilityin Sudbury, Mass. Those services will becontinued and expanded in the new SaintPaul facility.TODAYMatsuura Machinery Corporationis third generation family-owned,approximately 500 employees worldwide,with an ongoing commitment toexcellence. Both their VMCs andHMCs have won design awards, and thecompany itself has been recognized asone of “The Best 300 Small and Medium<strong>Manufacturing</strong> Enterprises” in Japan.When asked to define the Matsuuraniche in the marketplace, Schwartzwas emphatic. “Beyond our experienceproviding the very highest quality ofequipment, it’s really our out of the boxautomation capability that sets us apartand gives us the sizzle. We can put animpressive number of tools and palletstogether as a standard offering that givesthe customer untended operating capability,unlike anyone else in the business. This issomething nobody else can do.”PMB KYLE is the vice president of businessdevelopment at the Saint Paul Port Authorityin Saint Paul, Minn. She can be reached atblk@sppa.com.14 | PRECISION MANUFACTURING May | June <strong>2013</strong>

NOMINATIONS NOW OPEN!TUESDAY, SEPTEMBER 24CategoriesBold New StrategyAwarded to companies in operation for 25+years that have made major modificationto their original business plan.Emerging PlayeRAwarded to companies that have been establishedin <strong>Minnesota</strong> within the past 5 years.Community OutreachAwarded to companies who have made effortsto open its doors to the community andboost the image of manufacturing work.Executive of the YearAwarded to an executive of a <strong>Minnesota</strong>basedmanufacturing company who hasdemonstrated personal excellence inindustry advocacy, educational efforts,philanthropy, and employee culture.SustainabilityAwarded to companies who have demonstrateda commitment to green technology.Workforce DevelopmentAwarded to companies who are makinga significant impact on engaging andtraining a skilled workforce for the futureof the manufacturing industry.Minority-OwnedAwarded to companies owned or co-ownedby a member of a minority group.Manufacturer of the YeaRSmall (Revenue under $25 million), Midsize($25-$75 million), and Large ($75 million+):Awarded to companies in three distinct sizebrackets for best overall achievement.For more information visit minnesotabusiness.com#mnbizmanufacturingPRESENTING SPONSORSASSOCIATION PARTNER

MADE IN MINNESOTAGerdauA CAPITOL (SAINT PAUL) STEEL MILLby Bill RemesDid you know that Saint Paul is hometo a production facility for one of thelargest steel manufacturers in the world?This Saint Paul location, acquired in 2004by Gerdau, soon will be the recipientof a major corporate investment inmodernization of its operations.Gerdau will invest $50 million toreplace the continuous caster at itsSaint Paul, Minn., mill. The investmentwill increase special bar quality (SBQ)capacity by 100,000 tons and allowthe mill to produce up to 550,000tons of steel per year. Replacementof the current continuous caster willenable the mill to supply the ever-moredemanding customer base and to focuson new products. The new caster alsowill improve quality levels and addaluminum grain refined capabilitiesthat are limited by the current castingequipment and practices.Breaking GroundWe can be thankful not just for thisexpansion, but also for the fact thatthis Saint Paul steel plant has survived.During a difficult period in the steelindustry, in the early and mid-2000s,approximately 40 steel plants in theUnited States went bankrupt.The company broke ground on thenew caster project in May and anticipatesproject completion by early 2014, subjectto federal, state and local regulatory andother approvals.“This investment demonstrates ourcompany’s commitment to the Saint Paularea and helps us remain our customers’supplier-of-choice for years to come,” saidGuilherme Gerdau Johannpeter, presidentof Gerdau Long Steel North America.Community InvestmentAs part of this investment in theSaint Paul facility, Gerdau and USWLocal 7263 have agreed to extend theirlabor agreement out to 2015. Thecompany also received strong supportfrom the <strong>Minnesota</strong> Chamber ofLeft: Ceremonial ground breaking on Gerdau’s new caster installation at the Saint Paul mill.Right: Saint Paul facility, Red Rock TerminalCommerce throughout the evaluationprocess, and was offered state and localincentives from the State of <strong>Minnesota</strong>,the City of Saint Paul, and the Saint PaulPort Authority.Gerdau also has entered into anagreement with Xcel Energy thatwill help to enable the operationsto remain competitive in the future.The agreement was reviewed by the<strong>Minnesota</strong> Department of Commerceand approved by the <strong>Minnesota</strong> PublicUtilities Commission.During my visit, Mr. RogerioTuratti, plant manager at Gerdau, spokeof the products made here and themarkets served. Gerdau has an annualmanufacturing capacity of approximately12 million tons of finished steel productsin North America. Products producedat Gerdau include many specialty gradessuch as SBQ products, structural steel(A36), grinding ball bar stock (used inmining operations), rebar, and otherspecialty products.Markets ServedGlobally, the company has morethan 45,000 employees and industrialoperations in 14 countries with locationsin the Americas, Europe and Asia, whichtogether represent an installed capacityof more than 27 million tons of steelper year. Gerdau is the largest recyclerin Latin America and around the worldtransforms millions of metric tons ofscrap into steel each year. The companyis listed on the stock exchanges of SaoPaulo, New York, and Madrid, and hasapproximately 140,000 shareholders.Solid PresenceMr. Turatti has been with Gerdau sincehe graduated from college with a bachelor’sdegree in metallurgy in Brazil, and hasworked for Gerdau in such places as hisnative Brazil, Japan, Germany and Canada.Given his breadth of experience, it wasso interesting to hear him speak in suchcomplimentary terms of his new homehere in Saint Paul, his staff and plant, andour culture and environment. He is mostproud to say that this is one of the bestlocations in the United States. He creditsour fantastic educational system, which hisdaughter now enjoys, with providing himwith a very highly educated workforce.<strong>Minnesota</strong> can enjoy the presencehere of Gerdau in Saint Paul—providing good paying jobs as well asmanufacturing products that can be soldand exported around the state, the nation,and even around the world.PMBILL REMES is director ofsales, membership andadvertising for MPMA. Hecan be reached atbill@mpma.com.16 | PRECISION MANUFACTURING May | June <strong>2013</strong>sponsored by HEGMAN MACHINERY

OKUMAQUALITY.NOWWITHINYOURREACH.ANNOUNCINg AffORdAbLE ExCELLENCE fROMOKUMA ANd HEgMAN MACHINERYIf you thought Okuma machine toolswere beyond your reach, we challengeyou to think again.We believe you’ll find that this group of machines is more affordablethan you previously thought.Ask for a quote today and see for yourself.H gENOS L-serieshorizontal lathesH Lb3000 Exhorizontal latheH gENOS M460vertical machining centerH gENOS M560vertical machining centerH Mb-4000Hhorizontal machining centerH Mb-5000Hhorizontal machining center8718 Monticello Lane NorthMaple Grove, MN 55369(763) 424-5622www.hegmanmachinery.com

Ace Cutter GrindingCUTTING COSTS WITH LUBE-TECHAs a small, family-owned business,Ace Cutter Grinding doesn’t have anoverflow of cash to spend on tools andcoolants, which is why it decided toswitch to Lube-Tech last year.Chuck Anderson started the companyin 2001, working as a one-man shop outof his garage. He planned to do a fewextra side jobs to help fund his retirementsavings; but, through hard work and acommitment to quality, extra orders keptcoming in and the company continuedto grow. Eventually, Anderson outgrewthe garage and built a pole shed next tohis house. Last year the shed becametoo small, so he moved operations into a3,000-square-foot building in Monticello.Today, Ace Cutter Grinding ismaking a name for itself, specializingin CNC milling and precision grindingfor niche industries. It has 10 full-timeemployees, including Anderson’s son,Kyle, the facility manager, and hisdaughter, Kelly Lindberg, the officemanager. Like many small shops, it isfocused on sustaining growth and can’tafford to waste time or money on fluidmanagement.Until recently, Ace Cutter Grindinghad been ordering oils, coolants, andspecialty lubricants from multiple vendorsbased on whoever had the best price.However, it didn’t realize it was payingextra freight costs and top dollar because itwas ordering such small amounts.All that changed when the shopswitched to Lube-Tech.Critical Components“We used to spend a lot of money onspecialty products, but now we’re getting afair price,” said Kyle Anderson. “Also ourcoolants never lasted very long, but theydo now, and our parts are coming off themachines with much more consistency.”Due to the nature of the workperformed at the shop, precision andquality are critical. The company pridesitself on testing and inspecting every singlepart before it leaves the door. It neverFacility Manager Kyle Anderson and Lead Machinist Brett Willhite perform quality controlon parts, which have become much more consistent since changing coolant.considered coolant a major decision orexpense—until tool life was factored in.“At some precision manufacturers, thecost of tools makes up 25 to 30 percentof total costs, which could potentially beeven higher at small job shops” said LukeBame, industrial solutions provider atLube-Tech. “So if you can improve yourtool life up to 10 or more parts per tool,that’s a huge savings. It’s really importantto have the right fluid for the rightmachines so you’re not wasting moneyand potentially reducing quality.”In addition to purchasing less expensivecoolant, Ace Cutter Grinding learned howto maintain existing coolant to save evenmore money. Lube-Tech showed Ace CutterGrinding the proper way to mix coolant, forexample, and demonstrated how to read arefractometer to achieve the proper coolantto-waterratio.“Every machinist and operator shouldunderstand coolant maintenance 101,”Bame said. “They should be able to read arefractometer, understand concentrationlevels, and fix those levels when they gettoo high or low. Little things like that willmake sure you’re not wasting fluid andshortening tool life.”Educating the CustomerAnderson said he learns somethingnew every few weeks when Lube-Techdrops off or picks up fluids. He said theeducation and customer service his smallshop has received is unmatched andunlike any other vendor with whom he’sworked.“They come out to our shop on aregular basis, test our water, and inviteus all to informational seminars thataffect our business and save us money,”Anderson said. “Whenever we havequestions, they get back to us right away.They even pulled our sump pump out andtalked about the best way to clean it. Theorders we place are here the next day. Andthe prices are better than any competitorswe had purchased from previously.”The ability to consolidate andrecycle all of Ace Cutter Grinding’sfluids, including chemicals, cleaners andlubricants, is like icing on the cake. Lube-Tech’s liquid recycling service is availableto customers of all sizes, whether theygenerate one drum or 200,000 gallons ofspent coolant per year.“I think some shops feel like they’retoo small to be customers of Lube-Tech,”18 | PRECISION MANUFACTURING May | June <strong>2013</strong>PAID SUPPLEMENT

SHOP PROFILEFluids are the lifeblood of machines and engines—big or small—because they affect overall machine performance.- Luke Bame, industrial solutions provider, Lube-TechBame said. “Sure, we work with a lot oflarge manufacturing companies, but ourservices are just as relevant and affordablefor smaller shops.”About Lube-TechSince 1925, Lube-Tech and itsfounding companies have been helpingcustomers reduce operating costs, extendthe life of tools and equipment, andmaximize profits. Today, Lube-Tech isone of the Midwest’s largest distributor,blender and packager of lubricants,fuels and chemicals in the country. Thecompany’s customer commitment isanchored by the following three pillars.Broadest Product PortfolioWith more than 5,000 unique productsavailable to customers in the industrialsector alone, Lube-Tech offers the widestselection of lubricants, energy solutions,premier brands and supporting services.Lube-Tech literally can provide a solutionto every fluid related challenge.High-Performance Petroleum InnovationLube-Tech is one of just a few compoundblenders in the United States. Thecompany’s state-of-the-art lab, whichis open for customer tours, is wheretechnicians develop custom blendproducts and solutions for virtually everytype of machine or application. They alsocan analyze what a fluid is doing—or notdoing—to maximize performance andrecommend changes.Strategic Business SupportAs one of the country’s largest ExxonMobildistributors and a leader in the worldwidesmall engine fluid market, Lube-Tech’sknowledge runs deep and wide. It is theleading expert on many types of fluids.“Fluids are the lifeblood of machinesand engines—big or small—because theyaffect overall machine performance,” Bamesaid. “We can analyze fluids for certainparticles or by-products to detect problemswith a machine before they occur. Wecan also take a look at how many partsyou’re getting with your current fluidand determine whether it makes senseto switch to a different fluid to improveperformance or simply enhance it withadditives to prolong its life.”For small shops like Ace CutterGrinding, the ability to leverage theknowledge and purchasing power ofa larger company like Lube-Tech iskey. And if fluids are the lifeblood oftheir machines, they’ll be in a healthyposition for growth.PMFor more information about Lube-Tech, visit www.lubetech.com or contactLuke Bame at 952-250-4280 or lukebam@lubetech.com.Above (left to right): Luke Bame, Kyle Anderson, Kelly Lindberg and Chuck Anderson at Ace Cutter Grinding, a growing,family-owned business that relies on Lube-Tech for cradle to grave fluid management.PAID SUPPLEMENTMay | June <strong>2013</strong> PRECISION MANUFACTURING | 19

WHO’S WHODr. Kevin Kopischke, Alexandria Technical &Community CollegeAN AGENT FOR POSITIVE CHANGEby Stephani SimonDr. Kevin Kopischke with wife Donnaand five grandchildren.Exciting times are led by excitingpeople. One such vibrant leader you willget to know today is Dr. Kevin Kopischke,president of Alexandria Technicaland Community College. Kopischke’sprofessional career has been dedicated tothe next generation of <strong>Minnesota</strong>’s workers.He is known as an agent of positive changein this region, preparing students for thejobs of the future. How does he do this? Heis an innovative thinker, has a proven trackrecord with program development, and along, mutually respectful relationship withthe region’s business community.In 2004, Dr. Kopischke was appointed tobe only the fourth president of AlexandriaTechnical College by the <strong>Minnesota</strong> StateColleges and Universities Board of Trustees.Though the search process was conductednationally, Kopischke was the clear choice.He had served as vice president for thecollege since 1991, responsible for thecollege’s customized and contract training,marketing and management programs,new program development, and externalrelations. And he has the breadth ofexperience and success working with<strong>Minnesota</strong> employers that has proven tobe invaluable.After almost 10 years as president ofAlexandria Technical and CommunityCollege, Kopischke credits the school’sfaculty and staff for continuous focuson staying current in addressing theworkforce skills shortage in <strong>Minnesota</strong>.The staff has developed and implementedinnovative new techniques and programsto link industry, the college, and studentsin order to better serve the surroundingcommunity workforce needs.Beyond the work, Kopischke is homegrown <strong>Minnesota</strong>n. He grew up inMorgan, <strong>Minnesota</strong>, learned about hardwork and caring for customers whilehelping out at his dad’s 3-2 café, Jim’s PoolHall. He started young, filling whateverroles were needed.Indeed, hospitality became such a partof his character that, as he considered posthighschool education, he gravitated towardsthe hospitality industry. Kopischke’s firstdegree, a 2-year technical degree from theUniversity of <strong>Minnesota</strong>-Crookston, is infood service and hospitality for hotel andrestaurant management.By the time Kopischke was 22, hehad married Donna, his high schoolsweetheart, and was back in school. AtSt. Cloud State University he earnedboth a bachelor’s degree in marketingeducation as well as a master’s degreein educational administration andleadership. He ultimately went on tocomplete his doctorate in education fromthe University of <strong>Minnesota</strong>-Twin Cities.Changing CourseSomewhere in there Kopischkechanged courses. How is it that hetransitioned from a future in hospitalityto one of customized training andincumbent worker programs?It was his senior year at St. CloudState that changed the course of hislife. Kopischke had the opportunity tostudent teach at Alexandria Technicaland Community College, an institutionknown for its expertise in marketing ofthe college and its programs. Duringthat time, he was invited to speak abouthospitality; he had found his calling—teaching and training. A position openedup at Alex Tech and Kopischke taught atthe school for the next 10 years.Kopischke moved into his firstadministrative job in 1986, when hetook a position as the vice presidentfor Brainerd Technical College (nowCentral Lakes College). While in theposition, Kopischke was responsible forstudent services that included customizedtraining for corporations’ incumbentworkers. Those skills helped preparehim for his next advancement back toAlexandria Technical College in 1991,where he served as the vice presidentresponsible for the college’s customizedand contract training, marketing andmanagement programs, new programdevelopment, and external relations. Heheld that job for the next 13 years.During this period, Kopischke servedas chief of staff, occasionally assumingleadership responsibilities for thepresident who also served as a general inthe <strong>Minnesota</strong> National Guard. The workultimately prepared him to take over asthe college’s president.Celebrating FamilyDuring his years as a faculty memberat Alexandria Technical and CommunityCollege, Kopischke and his wife raisedtheir three kids. Kristi now lives in SiouxFalls, S.D.; Jay resides in Minnetonkawith his wife and two boys; and Lindsaylives in Alexandria with her husband, twodaughters and son. Kopischke and his wife,who just recently celebrated 40 years ofmarriage, often gather with their childrenand grandkids in their spare time. Witha home on Lake Carlos in Alexandria,the family enjoys spending time together.Today, Kopischke spends much of hisfree time serving on boards, includingthe Douglas County Hospital, theAlexandria Area Economic DevelopmentCommission, and the <strong>Minnesota</strong> LakesMaritime Museum.Kopischke anticipates that he still hasa long career ahead of him in Alexandria,working on new design models forP-14 learning systems. The state’smanufacturing community—and ourfuture workforce—are the benefactors ofhis continued service towards a strongerPMmanufacturing future.STEPHANI SIMON isthe president of Inprela(formerly OrangeCommunications) inMinneapolis, <strong>Minnesota</strong>.She can be reached atstephani@inprela.com.20 | PRECISION MANUFACTURING May | June <strong>2013</strong>

WHEN NUMBERS MATTER:6 NEW JOBS.2 MONTHS TO FULFILL.1 a51nx HMC.Making the parts that really matter takesa horizontal machining center that deliverswhat matters most: faster cycle times,greater reliability and higher-qualityresults. Which is why a Makino HMC is theonly real choice for the production partsthat matter most.It’s the speed you need to handle the jobsthat matter. The Makino a51nx and a61nx.makino.comWHEN YOU MAKE WHAT MATTERSYour local distributorfor MN, NE, IA, SD,ND and western WI is:Productivity Inc.15150 25th Avenue NorthPlymouth, MN 55447763.476.8600www.productivity.com

Leadership Insights:Communication - Getting the Messageby B Kyle, with contributions from Ellen Green“The best salespeople are great listeners – that’s how you find out what the buyer wants.”- Larry Wilson and Spencer Johnson, The One-Minute SalespersonPeople Interviewed for this Section Include:Mike Schuffenhauer, president, MultiSource <strong>Manufacturing</strong> LLCDoug Plunkett, director of sales and marketing, rmsRed Heitkamp, retired, RTI Remmele EngineeringBill Kuban, president, Kurt <strong>Manufacturing</strong> (1931-2012)Do you remember the party game—Telephone?Participants quickly pass a whispered message around acircle to see what might come out at the end. An amusingdemonstration of failed communication, the game rarelyends with anything close to the original message—with no illeffect, of course. And yet, what a classic example of the typicaloutcome of poor communication skills.In business, the consequences of poor communication canbe devastating. The good news is that communication done wellcontributes significantly to the sustainability of a company andits healthy bottom line. But how to do it well?Communication comes from the Latin word communis,meaning to share. It requires a sender, a message, a medium,and a recipient. The classic definition of communication is “theexchange of information.” So it goes both ways.All communication conveys a point, though it maynot always have the expected results. So it would be fairto say that successful communication takes place when thereceiver understands the intended message. Such successfulcommunication is the building block upon which all goodrelationships are made.Messages can be transmitted in many ways. Indeed, yousend and receive thousands, perhaps millions, of them daily.Just think for a moment, of the people you speak with, the newsyou watch or read, snail mail and email, even the advertisementscoming at you visually throughout the day. It is tiring justthinking about this volume. You also communicate when youmight not intend to, through all the nonverbal cues of bodylanguage, posture, dress, the car you drive, etc. And then, ofcourse, you communicate by how you conduct yourself—whatvalues do you convey in a handshake, the integrity of your workethic, the timely completion of a job, the hard-but-necessaryconversations you’d rather avoid?As it applies specifically to business, good communicationis crucial to your success both inside and outside theorganization. We’ll look at both sides of the communicationfence as it applies to four priority areas: competitors,customers, employees, and colleaguesHear What you Need to HearIt’s a rare person who wants to hear what he doesn’t wantto hear.- Dick CavettCourage is what it takes to stand up and speak; courage isalso what it takes to sit down and listen.- Winston ChurchillInterestingly enough, the leaders interviewed for this articlehad the most to say about the art of listening as their mostbeneficial form of communication. Listening is one of the “softskills”; yet, it certainly is as important as technical skills in termsof business success.22 | PRECISION MANUFACTURING May | June <strong>2013</strong>LEADERSHIP INSIGHTS SERIES

Listening sounds easy; but is it? Calvin Coolidge once said,“No man ever listened himself out of a job.” But we forget suchwisdom all too easily in the rush to teach, assert, perhaps eveninstruct, that which we already know.Of all the skills of leadership, listening is the most valuable —andone of the least understood. Most captains of industry listen onlysometimes, and they remain ordinary leaders. But a few, the greatones, never stop listening. That’s how they get word before anyoneelse of unseen problems and opportunities.”- Peter Nulty, National Business Hall of Fame, Fortune MagazineNot surprisingly, this wise perspective is shared by othergreat leaders. The communications skills most critical to therelationships you want to build is at the receiving, not the sendingend. Indeed, it is in the listening that learning happens. Successfulprecision manufacturers consider active listening indispensableto the health of their businesses and the industry. They bring it upoften because it’s a part of everything that good leaders do. Andthey’re willing to share. So how do you listen to the audiencesimportant messages to making your business thrive?Listening to CompetitorsEvery person I work with knows something better than me.My job is to listen long enough to find it and use it.- Jack NicholsLearn to listen. Opportunity could be knocking at yourdoor very softly.- Frank TygerListening to competitors is key to finding and maintainingyour market niche. Red Heitkamp of Remmele says thatcommunication “is about being there, being focused, andlistening.” Thus, the Remmele presence at the annual MedicalDesign and <strong>Manufacturing</strong> conference for example, is to exhibitand to learn about what other implant and surgical-instrumentmakers are doing. By attending medical conferences, Remmelegains customer perspective on competitors and their products.“You need to be ‘even more out there’ if you’re competingin the global market,” Heitkamp says. Beyond using the libraryto research competitors, you can look online for their websites,which will tell you a lot about their companies and thus abouthow you want to be different. Beyond that, he says, nothing canreplace a good network to help you know the market trends.Doug Plunkett of rms suggests watching your strongestcompetitor—or any company you admire—for what seems towork for them: “Before you ever go to the machine, look at thebest practices of the best manufacturer of a similar product.” Helikes to watch for what doesn’t work for others, too. There’s noneed to reinvent every wheel.Listening to CustomersSeek first to understand, then to be understood.- Steven R. Covey, 7 Habits of Highly Effective PeopleThe leaders interviewed all have strong opinions about theneed to listen to customers—mostly about the importance oflistening after a sale, especially when product developmentis involved. <strong>Precision</strong> manufacturers are innovators; theircustomers depend on this. As such, communication, is a hardskill in this business community.Red Heitkamp says, “People become part of a developmentteam so that they can build on the strengths of everyone in it. Ifyou’re only there to take, it’s evident right way. You have to bringsomething—technical, finance, project management, or someother expertise—to the party. But whatever you bring, you needto listen. You have to be honest and open all the time, especiallywhen you’re sharing risk.”The late Bill Kuban of Kurt <strong>Manufacturing</strong> Company Inc.notes the importance of listening and responding to both formaland informal customer messages in kind: “The customer drivesit, but you’ve got to initiate the conversation, too. Listen, listen,listen. We wouldn’t have the quality we do without listening tothe demands of our customers.”Heitkamp suggests that many problems are the result ofmisunderstanding, so listening well can help you to preventthem. When there are problems, listening is critical to theirsolution. And, while you may be the expert on making widgetnumber one, you might miss out on making widget numbertwo if you can’t hear what your customer is saying.Mike Schuffenhauer, of MultiSource <strong>Manufacturing</strong> LLC,regularly checks in with his customers to gauge their satisfactionwith his company’s performance. “I hope I’m the customers’sounding board: ‘Get me between the eyes. I want to know. Iwant to be there.’“I like to ask, ‘Is our stock going up or down?’ The metricsmay say we’re delivering 99.9 percent, but the customers won’tsend me stuff if they don’t have confidence in me— regardlessof the numbers. I use that analogy because your stock doesn’talways have to do with proven success but with how people feelabout your company. If it’s not good, they’re not going to sendyou that next opportunity.”Schuffenhauer avoids taking customers to football orhockey games: “I’d rather spend quality time, have lunch withthem maybe, but just chat about business and get to know them,listen and not talk over them (which is hard to do). Listen, listen,listen, and respond when it’s time. They’ll tell you how you’redoing . . . You have to get a feel for the customer business.”He reminds employees dealing with customers that, giventhe slow economy of recent years, people everywhere areLEADERSHIP INSIGHTS SERIESMay | June <strong>2013</strong> PRECISION MANUFACTURING | 23

anxious. Listening matters that much more: “It may be a bigdeal to them when we make a mistake. They’re afraid they’regoing to lose their jobs.”This is what Red Heitkamp calls listening with emotionalintelligence. At its root, actively listening with emotionalintelligence is not only hearing the actual words someone says, butalso understanding the perspectives and motivations behind thewords. A good listener sets aside assumptions and expectations.Hearing from EmployeesThe ear of the leader must ring with the voices of the people.- Woodrow WilsonHeitkamp says he had an “aha moment” when he learnedabout the 16 types of the Myers Briggs Personality Indicator(MBPI). This theory/test of personality type and cognitivestyle recognizes and values that people learn things in differentways. It provides one way of recognizing each team member’scontribution, and helping leaders capitalize on individualstrengths and tendencies.The bigger the company, Heitkamp continues, the moreeffort it takes to recognize the uniqueness of employees at alllevels and to hear from them. “You can’t talk in person withevery person every day, so you learn to listen through othermethods. But be creative. Depending on the kind of informationyou’re looking for, you might try a survey, a suggestion box, afocus group, an employee question column in the companynewsletter, or an open-door policy for a couple of hours a week.”Heitkamp recommends taking advantage of all the toolsand technologies available for reaching out to and listeningto employees. Younger workers may respond more readily toTwitter and tweets, for example. It can be worth the effort tomove out of your comfort zone and experiment a little. Youmight ask your employees directly about how they would preferto stay in touch with you. That said, don’t ask if you don’t wantto hear the answer! And, despite the current rage over all thingstechnocentric, do make sure you see your team members inperson once in a while, too. Nothing can replace the personaltouch of connection.Electronic technologies may be useful in expanding onthe face-to-face interactions of employees and departments,especially for those working at different locations, even more soif they are cities or countries apart. And don’t forget intershiftcommunication. Scheduling a few minutes of overlap timebetween shifts is a great statement about the importance ofemployee interaction, and contributes to overall esprit de corps.You may not need overlap for every shift change, but scheduleit regularly. If you are a dynamic company, things are changingall the time and your workers need to keep up, too. A littleemployee training on how to listen won’t hurt, either.Learning from Colleagues and NetworksI only wish I could find an institute that teaches people howto listen. Business people need to listen at least as much asthey need to talk. Too many people fail to realize that realcommunication goes in both directions.- Lee Iacocca, former CEO, Chrysler CorporationNetworking is about relationship-building. The two mostimportant networking skills you can develop are listening andasking questions. Why? Because listening validates the otherperson and shows respect. Asking questions shows an activeinterest in another’s opinions and thoughts. Simple, right?A champion of networks of all kinds, Heitkamp says thatnetworking is about knowing. “If you pull the shades, you can’tlook out, and you see and hear nothing but yourself.” You need tolift the shades, open the windows, look out and connect to others.For starters, Heitkamp suggests attending seminars, servingon boards, and becoming active in trade associations relevant toboth you and your customers. Enable networks both in and outof your company for employees as well. Their channels will bedifferent from yours, and you may need their perspective, too.And when you participate in networking relationships, you’vegot to share part of yourself, too. Heitkamp says, “You can’t bepart of a viable partnership—inside or outside your company—without it. You owe it to the relationship to participate.”“Our industry is full of ‘I’ve got a secret,’” says Heitkamp.“We need to realize that it’s hard to develop anything if you’rethe only one who knows something. If that’s where you are,you won’t listen to and learn from others very well, and youwon’t take full advantage of the latest technologies that areavailable through sharing. Look at Apple—once it published itsstandards, it developed twice as fast.”Mike Schuffenhauer agrees: “There are a lot of ideas outthere I haven’t thought of, and it’s nice to hear from somebodyelse. Industry groups can provide a safe environment for talkingabout your company. You don’t have to be super-specific aboutdetails and customers. You can learn things from other energeticpeople who have worked hard, too.”And Then, Do What you Need to DoWe listened to what our customers wanted and acted on whatthey said. Good things happen when you pay attention.- John F. Smith, former CEO and president, General MotorsThe point of all this listening, of course, is to obtain theinformation you need—through hard fact or gut knowledge—to ensure the vitality of your business. Here’s a brief example ofhow it can work:24 | PRECISION MANUFACTURING May | June <strong>2013</strong>LEADERSHIP INSIGHTS SERIES

Medical device manufacturing is one of RemmeleEngineering’s target sectors. Heitkamp learned long ago thatphysicians rarely meet with medical device sales reps. He beganlooking for other ways to get their attention. With the launch ofRemmele’s next surgical tool, a prospective ad agency proposeda 20-page brochure for a single new surgical tool. They clearlywere not listening or asking the right questions. Heitkamprejected the expensive proposal in favor of a single-pageproduct depiction. “Just enough for a busy surgeon to digest in30 seconds—on the way to the restroom and back,” Heitkampsays with a smile.Heitkamp saved money and time on the briefer, moreeffective sales aid. The surgeons got the information theyneeded, with time left over for feedback. And sales went up.Listening can pay off in ways you can’t imagine. Do a littlebrainstorming. Experiment until you find the best method ofcommunication for your particular audience and purpose.Think about what you want your audience to do once theyhave heard your message. And know that getting your messageacross will be easier and more fruitful if you’ve listen enough toknow who they are.To the leaders of today and tomorrow—we salute you.- B KyleB KYLE is the vice president of business development at the Saint PaulPort Authority in Saint Paul, Minn. She can be reached at blk@sppa.com.Too Much NoiseCommunications experts give the name noise to anything that gets in the way of an intended message. Here are someexamples of noise to watch for and eliminate or work around where you can. Each can affect the sender as well as receiver.• Physical: Remote locations or uncomfortable surroundings such as background noise, poor light, excessive heat or cold.• Environmental: Faulty or outdated equipment, staff shortages.• Flawed System Design: Unclear organizational structure, dysfunctial information systems, lack of supervision ortraining.• Physiological: Personal discomfort caused by ill health or disabilities, including impaired sight or hearing.• Attitudinal: Poor management, lack of consultation with employees, personality conflicts, lack of motivation, bias,preconceived ideas, resistance to change.• Language: Differences in native language, accents, use of legalese, jargon or ambiguous words.• Cultural: Differences in cultural understandings and practices.• Poor Presentation: Without consideration of audience, unorganized, too simple, or too complex.• Message Overload: Too many messages at the same time, not necessarily from the same sender.For further reading:Argyris, Chris. Harvard Business Review on Effective Communication. Boston: Cambridge, MA: Harvard Business School Press, 1999(Harvard Business Review Paperback Series).Thank you to the following donors who made this series possible:Agrimson Tool Company, Inc.Dave FiedlerKurt <strong>Manufacturing</strong> Company Inc.Production Engineering Corp.Tom DaggettAmerican Engineering TestingDeborah KalinaCliftonLarsonAllen LLPProductivity IncTooling Science, Inc.American Machine &Gundrillling Co., Inc.Anderson Automatics, Inc.Benny Machine CompanyBrian RobinsonCarlson Advisors, LLPColumbia <strong>Precision</strong> Machine Corp.Concept Machine Tool Sales, Inc.Dakota ElectricDynamic GroupEllison Machinery CompanyHaberman Machine, Inc.Hales Machine Tool, Inc.Hegman Machine Tool, Inc.Huot <strong>Manufacturing</strong> CompanyInternational <strong>Precision</strong> Machining, Inc.John HuotJosh RalphLiesch Associates, IncLubrication Technologies, Inc.Lynn MolineMike ReuterMRG Tool and Die Corp.MultiSource <strong>Manufacturing</strong> LLCNesstech Concrete MoldsNTM, Inc.On Time Delivery Service, Inc.rmsRobert Carlson JRRod GramseScott TaylorSaint Paul Port AuthorityState of <strong>Minnesota</strong>Superior Tool & MachiningTed Roberts JrTim SwansonToolkraft, Inc.Ultra MachiningUniversity National BankWells Fargo BankWilson Tool International, Inc.Wyoming Machine, Inc.Xcel EnergyYeager MachineLEADERSHIP INSIGHTS SERIESMay | June <strong>2013</strong> PRECISION MANUFACTURING | 25

BEST PRACTICESImplementing QualityNUMBERS IN QUESTIONby Bruce Brigham and Keith SummersQuality can be defined, as excerptedfrom Wikipedia:As the systematic activitiesimplemented in a quality systemso that quality requirements for aproduct or service will be fulfilled.It is the systematic measurement,comparison with a standard,monitoring of processes and anassociated feedback loop thatconfers error prevention.In practical application, words aresoon overwhelmed by numbers. Today’smanufacturing and measurementprocesses have the ability to generatenumbers at a rate that far outpacestheir ability to make parts. Whilemanufacturing produces parts, qualityproduces numbers, and lots of them!So, what do we do with these numberswe call data? Hopefully, we can convertthem into useful information that allowsus to pass a part on to the next step inthe process, prove that the final productconforms to its specifications, and improveprocess performance. Unfortunately,managing these numbers often becomesa “can’t see the forest for the trees” typeof problem. We get lots of numbers, frommany different sources, and finding waysto ignore the less than useful ones, findthe most helpful ones, and combine othersinto a more useful whole is sometimes aschallenging as making the part.A Single DatabaseOne of the best ways to meet thesechallenges is to get all the numbersinto a single relational database likeMicrosoft SQL Server or Oracle RDBMS.From this single repository of data wecan query out relationships and presentthem in tables, charts, and reports.These products have been used for yearsto manage enterprise-wide data fororganizations and now have been scaledand simplified to fit the needs of almostanyone trying to manage quality data forreporting and process improvement.Data from gages with digital output,CNC machines with sensors, in-line gagingsystems, CMMs, vision systems, automaticfixture gaging, and many other shop floorsystems generate their own unique resultsand data formats. Front end data collectionsoftware provides the flexibility to acceptdata from these different sources, provideuniform and critical real time processfeedback, and send the data along to asingle database for storage security andfurther analysis and reporting.Linking Blocks of DataThe key to the database is establishingtrace fields that link blocks of data from oneprocess source to another. Lot numbers,serial numbers, machine IDs, date ranges,and other trace information provide themeans for creating a web of relationshipsthat we can use to filter data out or torecombine into a more useful whole.The shop floor (or quality lab)generated data must be converted intoeasy-to-understand information asquickly as possible. Obtaining shop floorfeedback as soon as possible yields theReal-Time SPC. The timing of longtermtrends and other quality analysisis not as time sensitive as the shop floordata. When you consider most shopsgenerate thousands of features acrossall parts, it becomes a daunting task tokeep your eye on everything. You needsoftware that runs period checks acrossall combinations of features and filters,thereby focusing your energy. Printingand viewing 5,000 control charts is justnot practical.Time-oriented charts help the shopfloor best. Seeing what just happenedand comparing it to what happened inthe past helps operators quickly identifypotential problems.Reporting RequirementsReporting requirements often reflectthe “smaller, tighter, faster” demandsof today’s manufacturing. The needto assemble large quantities of data,documenting multiple inspectionprocesses from multiple stages inthe manufacturing process, with fulltraceability on the part, process andoperator, can be a clerical nightmare—one wants to combine paper reports, datafiles, and spreadsheets into a coherentwhole. With all of the required data ina single location, this reporting can beautomated and reported through customreport templates or sent to other softwarelike Excel or MiniTab®.Process Improvement EffortProcess improvement efforts now canlook at all of the data that indicates howwell a process can meet requirements.Rather than look at a single bore sizeand position for a single part number, adatabase approach enables us to look atevery similar bore and position done bythat process and compare it to similarbores and sizes at other processes.Thisenables process improvement and givesnew insight on the capability of oneprocess versus another.Beyond shop floor feedback, customerreports and process improvement projects,an automated collection and analysis systemalso enables simple desktop “dashboards” ofkey process variables. It reflects Real-Timeanalysis of what is happening on the shopfloor to manufacturing management.Not too long ago, the avalanche ofthe “number problem” was made simplerby the fact that numbers took a littlemore effort to get to: Someone wouldhave to make a measurement, write itdown, save it, or pass it on as needed. Theproliferation of digital data on the shopfloor enables us to save the time we usedto use for many of those manual tasks. Awell planned database enables us to usethe trees to see the forest.PMBRUCE BRIGHAM is vice-president at ProLinkSoftware. He can be reached at bbrigham@prolinksoftware.com. Keith Summers is presidentof Productivity Quality Inc. He can be reached atkeith.summers@pqi.net.26 | PRECISION MANUFACTURING May | June <strong>2013</strong>sponsored by | PRODUCTIVITY QUALITY INC

Lunch & LearnManaging Measurement DataWednesday, June 26, 10:00 - 1:00Take QC-CALC to the Next LevelPlease join us on June 26 for a free “Lunch & Learn”presentation with Gene VanPatten from ProLink Software.Gene will present how using a single database for all ofyour QA data can automate reporting, give new insightinto process control, increase data security and enhanceimmediate feedback to process operators.Anish Shah from PQI will follow with a discussion onmanaging data to comply with FDA 21 CFR Part 11requirements. A“free lunch” will be followed up by a tourand demonstration of how we use these tools in ourinspection lab. After lunch, for interested current ProLinkQC-CALC software users, Gene will give an update onnew software releases and present tips and tricks forgetting the most out of QC-CALC.Visual Factory DashboardsAgenda10:00 Welcome10:05 Gene VanPatten, ProLink CorporationBuilding a comprehensive datamanagement solution for QA data:> Operator feedback> Customer reporting> Process improvement> Data storage and security11:00 Anish Shah, PQIControlling data to meet FDA21 CFR Part 11 requirements11:45 LunchFollowing lunch, a tour and demonstrationof how our inspection lab manages its datawill be available for anyone interested1:00 - 3:00 Pro Link User Group MeetingOptional: For interestedQC CALC software usersSPC Office Buddy& Minitab IntegrationPlant/CorporateLevel ReportingPRODUCTIVITY QUALITY INC15150 25th Avenue North, STE 200Plymouth, MN 55447763-249-8130800-772-0620To Registeremail: training@pqi.netonline: www.gagesite.com/events.phpcall: Lebron Fix at 763-249-8130

QUALITYAPPROVEDby Melissa DeBilzanThe ABCs ofEmployee Certificationand CredentialsPart 2: Employee ApprenticeshipsYou wouldn’t visit a doctor without seeing MD or DO after his or her name. You wouldn’t hire a tax accountant without a CPA designation. And you might not want amechanic who isn’t ASE-certified to work on your car. So why would you allow employees to perform certain machining, welding or quality processes without similardesignations? That’s the argument many professional societies are making to manufacturers.The cover story of the March/April <strong>2013</strong> issue provided anoverview of the main credentialsor certifications available to manufacturingemployees, why they’re on the rise, andhow they can benefit employers. If youmissed it, here’s a quick review:The most common credentials inthe manufacturing industry have beendeveloped by three organizations: theNational Institute for Metalworking Skills(NIMS), the American Welding Society(AWS), and the American Society forQuality (ASQ).Some of these programs aredesigned for entry-level workers andothers are geared for experiencedtechnicians and engineers. Regardlessof the level of certification achieved,more manufacturers seem to agree thatcertification allows everyone to “speak thesame language” when it comes to hiringand training skilled workers as well asproving certain capabilities to customers.That has led to a significant increase inthe number of certifications issued byNIMS, AWS and ASQ in recent years.The number of certifications issued byNIMS alone has increased by 20 percenteach year for the past 5 years, with CNCprogrammers and CNC operators amongthe most popular programs.Many manufacturers say certificationsare not only good for their employees, butalso good for business.At Kurt <strong>Manufacturing</strong>, where atleast eight employees are ASQ-certifiedin the machining division alone,certification helps boost the bottom line.“Customers know that our quality peopleare certified,” said Jeff McIntosh, qualitymanager, “and they are reassured thatthey’ll get good products. This has helpedwin new business as well.”Though the requirements for eachcredential are different, most involvea certain level of training, testing andhands-on demonstration before thatcredential is earned. In an effort tostreamline the process for employees,some manufacturers have begun offeringstate-run apprenticeship programs thatlead to these certifications … and theprocess is easier than they thought.Apprenticeships as aPath to CertificationFor some employers, the wordapprenticeship conjures up images ofendless paperwork, impossible standards,and lengthy visits by state administrators.However, Rich Davy, field representativewith the <strong>Minnesota</strong> Department of Labor,says today’s apprenticeships aren’t like thatat all. In fact, they look vastly differentfrom those developed even 5 years ago.“The focus is no longer only meetinga certain number of hours,” Davy said.“The focus is on achieving certaincompetencies. Companies can decideif they want a time-based program, acompetency-based program or a hybridprogram which combines both typesof programs. What the state offers is asystem for manufacturers to credentialtheir employees for on-the-job trainingcombined with related technicaleducation. And we’ve tried to make thatsystem as user-friendly as possible.”To offer a state-registered andapproved apprenticeship program, acompany simply needs to identify theskills to be learned, the training to bereceived, and the wages to be received.In many cases, those skills can lead tocertain certifications or credentials. Theagreement can be terminated or changedat any time. Most apprenticeships arecompleted in 3 to 4 years.Of course, some companies offerinformal apprenticeships that don’tinvolve the state, but they miss out onreceiving free technical assistance fromstate experts. More importantly, theiremployees won’t receive a state-issuedjourneyperson’s certificate, which isnationally recognized.“A lot of companies use the termapprenticeship to describe a trainingprogram at their company becauseit’s a great way to attract and retainemployees,” Davy said. “But it’s not atrue apprenticeship program unless it’sregistered with the state. As a matter offact, in Wisconsin, apprenticeship is atrademarked name. A state-registeredapprenticeship is a real asset for employersand a great benefit for employees.”Essentially, any manufacturer—largeor small—can offer a state-registeredapprenticeship program for its employeesas long as it includes four components.The first is on-the-job training. Thisis a list of skills or competencies theapprentice will learn. A machiningapprenticeship, for example, mightinclude bench work and certain tasksinvolving milling, drilling, and latheoperations. If the skills and competenciesare aligned with NIMS standards, theapprenticeship would result in a NIMScertifiedmachinist.The second component of a stateregisteredapprenticeship is 144 hours ofrelated technical education, which canbe taken at a local technical college or28 | PRECISION MANUFACTURING May | June <strong>2013</strong>

FEATURE STORYeven online through Tooling University(www.toolingu.com).The third component is 50 hoursof safety training. Much of this canbe achieved through ordinary shopfloor activities, such as a safety reviewbefore the start of a new shift, or abrief discussion on the importance ofergonomics by a guest speaker froman insurance company. Training also isavailable online.The final component is a wageschedule. In the construction industry,wages are based on prevailing rates (ratesthat are set by each county). However,manufacturers are free to pay whateverrates they want to apprentices as longas they’re at least minimum wage andcomply with labor laws.“The whole objective of apprenticeshipis for people to be fully skilled,” Davy said.“We can help employers identify the skillsand training they need for a successfulprogram. We also encourage them todesign their own programs in order toinclude company-specific skills, trainingand job-related instruction.”Growing Their OwnSkilled WorkersCurrently, 23 manufacturers in<strong>Minnesota</strong> have active apprenticeshipprograms, including Haberman Machine,Inc., in Oakdale, E.J. Ajax in Fridley, EatonCorporation’s plant in Eden Prairie, MRGTool and Die Corp. in Faribault, Truth<strong>Manufacturing</strong> in Owatonna, and UnitedSteel Products in Montgomery.The biggest benefit of anapprenticeship program, they say, is theability to produce employees who arefully trained to meet the exact needs oftheir company. In a way, apprenticeshipsallow them to develop their very ownpipeline of skilled workers.When Eaton Corporation’s plant inEden Prairie, which employs 250 people,couldn’t find the machinists and tool anddie makers it needed several years ago,the company decided to begin trainingand promoting from within. It did this bydeveloping an apprenticeship programfor select entry-level employees that ledto NIMS certification.“NIMS works well for us becauseit forces our employees to prove bothknowledge and skills,” said Ron Krueger,training coordinator at Eaton. “Mostpeople can do some type of classroomtraining and pass a written test. But at theend of the day, they may or may not beable to run a piece of equipment.”In 2007 and 2008, Eaton becamethe first company in the country tohave employees complete NIMS-basedapprenticeships in machine maintenanceand repair and Level 3 machining. TheEden Prairie plant hasn’t looked back since.“Our employees finished the programin 18 to 24 months and gained the sameskill sets and knowledge as a personwho would’ve spent 4 years in a similarprogram,” Krueger said. “That’s becausewe can move them on if they prove theyhave certain skill sets.”Since then at least six more employeeshave completed their apprenticeshipand earned NIMS credentials. All wereentry-level employees who showedpromise. They began by gaining a betterunderstanding of math, bench work,layout, and safety skills. By the timethey were done they were operating andprogramming CNC machines. As theyprogressed, they received pay raises.The program has been so successfulthat Eaton has a waiting list of employeeshoping to become the next apprentices.Following an application and interviewprocess, the company selects twoemployees for the program and never hasmore than two at a time. This year Eatonis adding apprenticeship programs ingrinding and CNC milling and turning,which also will lead to NIMS certification.Apprenticeship programs at smallermanufacturers can be just as successful.E.J. Ajax, which employs 50 people, offersapprenticeship programs for Class Apunch press operators, production sheetmetal workers, Class A machine operatorsand tool and die makers. Like Eaton, all ofthem lead to a journeyperson’s certificateand NIMS certification.“I think a lot of smaller companiesworry that apprenticeships will be tooexpensive or time-consuming,” said RobDuvall, production supervisor and directorof training. “There’s no cost involved otherthan the time it takes to do the paperwork.And I can get that done in matter ofminutes, so the time commitment isminimal. The state has made it very easyfor smaller companies like ours and doesn’trequire anything to be written in stone,including the wages proposed.”Changes to the wage schedule orany other major component of theapprenticeship program need to bereceived and approved by the state toensure they comply with current laborlaws and apprenticeship rules.Since 2006, at least 26 employeesat E.J. Ajax have completed anapprenticeship program and earnedNIMS credentials. Most of them are stillwith the company and have gone ontohigher paying positions. One employeeearned his journeyperson’s card in threedifferent fields.“The bottom line is that we have welltrainedindividuals doing complex work,”Duvall said. “That has played a role ingetting new business because customershave the confidence that we can meettheir needs. And on a personal note, ithas improved employee morale.“Many employees want more thana paycheck; they want a career. Theaverage journeyperson will make morethan the average 4-year college graduateand will never find himself flippingburgers. Employees want the benefit ofan apprenticeship program because thatgives them a clear path to advancement.”He went on to say that E.J. Ajax hasbeen sought out by students in severallocal technical colleges and high schoolsbecause of its apprenticeship program.The company will be adding moreprograms in the near future.Haberman Machine, Inc., is anothersmall shop that offers state-registeredapprenticeship programs leading to NIMScertification. However, the company isnewer to the apprenticeship game, havingdeveloped programs for CNC operatorsand CNC machinists in 2012.“We started looking at how manyskilled machinists we’ll need in the futureand knew we needed to start growingour own so we wouldn’t be scrambling tofind them later,” said Kimberly Arrigoni,controller at Haberman.After hiring 25 entry-level employeeslast year, Haberman began the processof grooming them for long-termemployment and career advancement. Allof them were new to the industry, but areworking toward becoming NIMS-certifiedoperators. At the same time, several[ continued ]May | June <strong>2013</strong> PRECISION MANUFACTURING | 29