Kiswire - Steel wire rope

Kiswire - Steel wire rope

Kiswire - Steel wire rope

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GENERAL INFOMATION ON WIRE ROPE<br />

for SELECTION & USAGE<br />

1.DIAMETER<br />

The diameter of <strong>rope</strong> is the diameter of its circumference, circumscribed to its normal section. This diameter is given in<br />

millimeters.<br />

1) PRACTICAL DIAMETER OF WIRE ROPE<br />

The practical diameter of a <strong>rope</strong> is measured by following an established method, its value must be equal to the value<br />

of the nominal diameter (the dimension by which a <strong>rope</strong> is identified) except for certain allowed tolerances.<br />

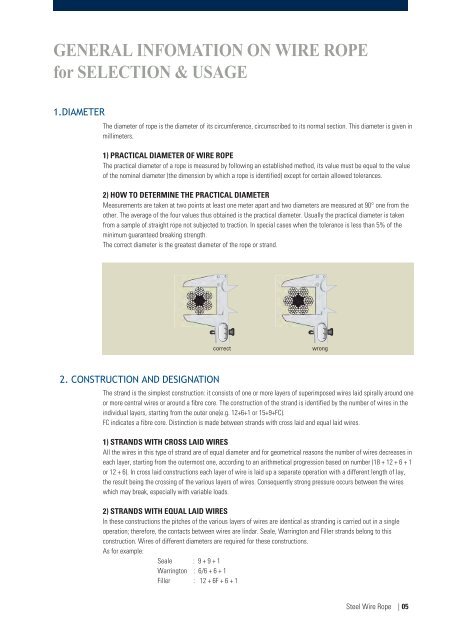

2) HOW TO DETERMINE THE PRACTICAL DIAMETER<br />

Measurements are taken at two points at least one meter apart and two diameters are measured at 90° one from the<br />

other. The average of the four values thus obtained is the practical diameter. Usually the practical diameter is taken<br />

from a sample of straight <strong>rope</strong> not subjected to traction. In special cases when the tolerance is less than 5% of the<br />

minimum guaranteed breaking strength.<br />

The correct diameter is the greatest diameter of the <strong>rope</strong> or strand.<br />

correct<br />

wrong<br />

2. CONSTRUCTION AND DESIGNATION<br />

The strand is the simplest construction: it consists of one or more layers of superimposed <strong>wire</strong>s laid spirally around one<br />

or more central <strong>wire</strong>s or around a fibre core. The construction of the strand is identified by the number of <strong>wire</strong>s in the<br />

individual layers, starting from the outer one(e.g. 12+6+1 or 15+9+FC).<br />

FC indicates a fibre core. Distinction is made between strands with cross laid and equal laid <strong>wire</strong>s.<br />

1) STRANDS WITH CROSS LAID WIRES<br />

All the <strong>wire</strong>s in this type of strand are of equal diameter and for geometrical reasons the number of <strong>wire</strong>s decreases in<br />

each layer, starting from the outermost one, according to an arithmetical progression based on number (18 + 12 + 6 + 1<br />

or 12 + 6). In cross laid constructions each layer of <strong>wire</strong> is laid up a separate operation with a different length of lay,<br />

the result being the crossing of the various layers of <strong>wire</strong>s. Consequently strong pressure occurs between the <strong>wire</strong>s<br />

which may break, especially with variable loads.<br />

2) STRANDS WITH EQUAL LAID WIRES<br />

In these constructions the pitches of the various layers of <strong>wire</strong>s are identical as stranding is carried out in a single<br />

operation; therefore, the contacts between <strong>wire</strong>s are lindar. Seale, Warrington and Filler strands belong to this<br />

construction. Wires of different diameters are required for these constructions.<br />

As for example:<br />

Seale : 9 + 9 + 1<br />

Warrington : 6/6 + 6 + 1<br />

Filler : 12 + 6F + 6 + 1<br />

<strong>Steel</strong> Wire Rope | 05