Kiswire - Steel wire rope

Kiswire - Steel wire rope

Kiswire - Steel wire rope

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SINGLE STRAND ROPES are commonly called strands.<br />

ROUND STRANDED ROPES consist of a number of strands either laid around a fibre core or metallic strand or an<br />

independent <strong>wire</strong> <strong>rope</strong> core. They can be identified by the number to each strand.<br />

A <strong>rope</strong> with 6 strands, each having 9+9+1<strong>wire</strong>s laid around a central fibre core is designated as; 6 x (9 + 9 + 1) + FC<br />

or more concisely 6 x 19 Seale + FC. If this same <strong>rope</strong> has an independent <strong>wire</strong> <strong>rope</strong> core, the designation will be:<br />

6 x (9 + 9 + 1) + IWRC.<br />

The IWRC is a metallic <strong>rope</strong> having for example a construction designated by 7 x (6 + 1) or 7 x 7. Should the strands<br />

also contain a fibre core then the <strong>rope</strong> will be known for example as 6 x (12 + FC) + FC or 6 x 12 + 7FC.<br />

Lastly if the <strong>rope</strong> is formed of two or more layers of strands superimposed around a FC, then it will be known as:<br />

12 x (6 + 1) + 6 x (6 + 1) + FC or 18 x 7 + FC.<br />

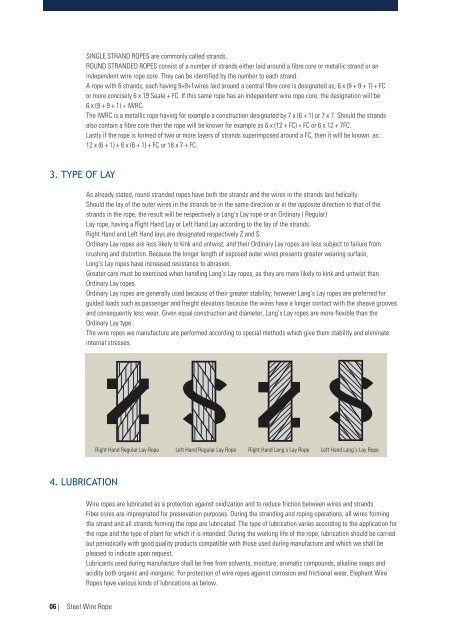

3. TYPE OF LAY<br />

As already stated, round stranded <strong>rope</strong>s have both the strands and the <strong>wire</strong>s in the strands laid helically.<br />

Should the lay of the outer <strong>wire</strong>s in the strands be in the same direction or in the opposite direction to that of the<br />

strands in the <strong>rope</strong>, the result will be respectively a Lang’s Lay <strong>rope</strong> or an Ordinary ( Regular)<br />

Lay <strong>rope</strong>, having a Right Hand Lay or Left Hand Lay according to the lay of the strands.<br />

Right Hand and Left Hand lays are designated respectively Z and S.<br />

Ordinary Lay <strong>rope</strong>s are less likely to kink and untwist, and their Ordinary Lay <strong>rope</strong>s are less subject to failure from<br />

crushing and distortion. Because the longer length of exposed outer <strong>wire</strong>s presents greater wearing surface,<br />

Long’s Lay <strong>rope</strong>s have increased resistance to abrasion.<br />

Greater care must be exercised when handling Lang’s Lay <strong>rope</strong>s, as they are more likely to kink and untwist than<br />

Ordinary Lay <strong>rope</strong>s.<br />

Ordinary Lay <strong>rope</strong>s are generally used because of their greater stability; however Lang’s Lay <strong>rope</strong>s are preferred for<br />

guided loads such as passenger and freight elevators because the <strong>wire</strong>s have a longer contact with the sheave grooves<br />

and consequently less wear. Given equal construction and diameter, Lang’s Lay <strong>rope</strong>s are more flexible than the<br />

Ordinary Lay type.<br />

The <strong>wire</strong> <strong>rope</strong>s we manufacture are performed according to special methods which give them stability and eliminate<br />

internal stresses.<br />

Right Hand Regular Lay Rope Left Hand Regular Lay Rope Right Hand Lang’s Lay Rope Left Hand Lang’s Lay Rope<br />

4. LUBRICATION<br />

Wire <strong>rope</strong>s are lubricated as a protection against oxidization and to reduce friction between <strong>wire</strong>s and strands.<br />

Fiber cores are impregnated for preservation purposes. During the stranding and roping operations, all <strong>wire</strong>s forming<br />

the strand and all strands forming the <strong>rope</strong> are lubricated. The type of lubrication varies according to the application for<br />

the <strong>rope</strong> and the type of plant for which it is intended. During the working life of the <strong>rope</strong>, lubrication should be carried<br />

out periodically with good quality products compatible with those used during manufacture and which we shall be<br />

pleased to indicate upon request.<br />

Lubricants used during manufacture shall be free from solvents, moisture, aromatic compounds, alkaline soaps and<br />

acidity both organic and inorganic. For protection of <strong>wire</strong> <strong>rope</strong>s against corrosion and frictional wear, Elephant Wire<br />

Ropes have various kinds of lubrications as below.<br />

06 | <strong>Steel</strong> Wire Rope