Road Paver Tracked AFT 500 E/G - Ammann Group

Road Paver Tracked AFT 500 E/G - Ammann Group

Road Paver Tracked AFT 500 E/G - Ammann Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

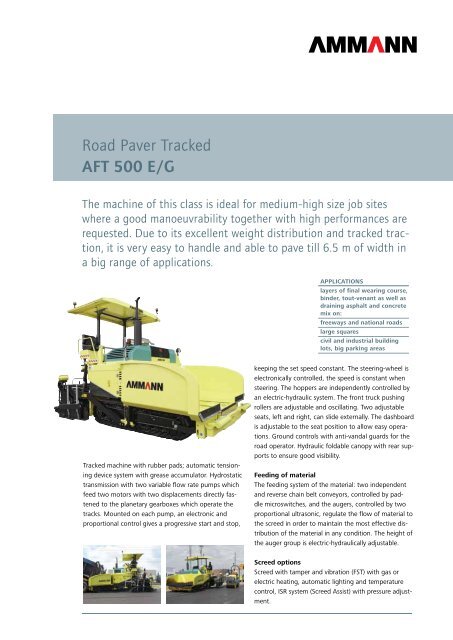

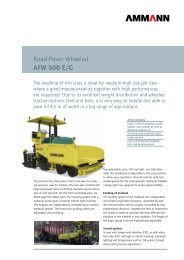

<strong>Road</strong> <strong>Paver</strong> <strong>Tracked</strong><br />

<strong>AFT</strong> <strong>500</strong> E/G<br />

The machine of this class is ideal for medium-high size job sites<br />

where a good manoeuvrability together with high performances are<br />

requested. Due to its excellent weight distribution and tracked traction,<br />

it is very easy to handle and able to pave till 6.5 m of width in<br />

a big range of applications.<br />

Applications<br />

layers of final wearing course,<br />

binder, tout-venant as well as<br />

draining asphalt and concrete<br />

mix on:<br />

freeways and national roads<br />

large squares<br />

civil and industrial building<br />

lots, big parking areas<br />

<strong>Tracked</strong> machine with rubber pads; automatic tensioning<br />

device system with grease accumulator. Hydrostatic<br />

transmission with two variable flow rate pumps which<br />

feed two motors with two displacements directly fastened<br />

to the planetary gearboxes which operate the<br />

tracks. Mounted on each pump, an electronic and<br />

proportional control gives a progressive start and stop,<br />

keeping the set speed constant. The steering-wheel is<br />

electronically controlled, the speed is constant when<br />

steering. The hoppers are independently controlled by<br />

an electric-hydraulic system. The front truck pushing<br />

rollers are adjustable and oscillating. Two adjustable<br />

seats, left and right, can slide externally. The dashboard<br />

is adjustable to the seat position to allow easy operations.<br />

Ground controls with anti-vandal guards for the<br />

road operator. Hydraulic foldable canopy with rear supports<br />

to ensure good visibility.<br />

Feeding of material<br />

The feeding system of the material: two independent<br />

and reverse chain belt conveyors, controlled by paddle<br />

microswitches, and the augers, controlled by two<br />

proportional ultrasonic, regulate the flow of material to<br />

the screed in order to maintain the most effective distribution<br />

of the material in any condition. The height of<br />

the auger group is electric-hydraulically adjustable.<br />

Screed options<br />

Screed with tamper and vibration (FST) with gas or<br />

electric heating, automatic lighting and temperature<br />

control, ISR system (Screed Assist) with pressure adjustment.

This drawing is neither a lowed to be copied, replicated, shown or open up to<br />

third parties or used by third parties for self-construction or production.<br />

N<br />

tolerance<br />

M<br />

F<br />

H<br />

/<br />

Drawing Nr.<br />

R<br />

G<br />

Version<br />

<strong>Ammann</strong> Schweiz AG<br />

Eisenbahnstrasse 25<br />

CH-4901 Langenthal<br />

Tel +41 62 916 63 56<br />

Fax +41 62 916 64 03<br />

info.aag@ammann-group.com<br />

www.ammann-group.com<br />

Technical specification<br />

1 2<br />

3 4 5 6 7<br />

8<br />

A<br />

A<br />

B<br />

C<br />

αA<br />

1 2<br />

Dimensions:<br />

L<br />

I<br />

B<br />

A<br />

αP<br />

A B C D E F G H I L<br />

shaping processes ISO 2768 - cL<br />

weldment constructions EN ISO 13920 - BF<br />

machining processes ISO 2768 -mK<br />

final change<br />

first used for:<br />

6100 5860 2076 2550 3240 3520 1630 3000 2580 2000<br />

1:30<br />

Drawn 13/02/2012 Garramone<br />

Checked<br />

Page 1 1 Doc.Type: IDW<br />

CH - Langenthal<br />

<strong>AFT</strong><strong>500</strong><br />

3 4 5 6 7 8<br />

M N R aA aP<br />

3100 <strong>500</strong> 600 15° 16°<br />

Screed Options: FST <strong>500</strong> E/G<br />

Max paving widths:<br />

2550–4900 mm<br />

Optional 6<strong>500</strong> mm<br />

Equipment<br />

Standard<br />

Automatic heating control<br />

Augers height hydraulically adjustable<br />

Proportional ultrasonic augers control<br />

ISR system (Screed Assist)<br />

Hydraulic folding canopy<br />

Optional<br />

Longitudinal levelling system<br />

Slope control system<br />

Reduction plates at 1<strong>500</strong> mm<br />

Mechanical extensions 2 x 800 mm<br />

Electric-hydraulic camber adjustment<br />

Rotating screed side end plates<br />

C<br />

D<br />

E<br />

A3<br />

B<br />

C<br />

D<br />

E<br />

F<br />

<strong>Tracked</strong> <strong>Paver</strong> <strong>AFT</strong> <strong>500</strong> E/G<br />

Length (transport) mm 5860<br />

Dimensions<br />

(see ill.)<br />

Engine<br />

Manufacturer<br />

Cummins QSB4.5<br />

Type<br />

Diesel, Turbo-Intercooler,<br />

electronic control<br />

No. of cylinders 4<br />

Power (DIN/ISO 3046/1) at 2200 rpm kW 119 (160 HP)<br />

Max torque<br />

Nm 457 at 1<strong>500</strong> rpm<br />

Generator<br />

24V–70 A<br />

Brakes<br />

Service brake<br />

Hydrostatic<br />

Parking brake/Emergency<br />

Multiple disks negative brake<br />

on reduction gears<br />

Traction - Steering<br />

Transmission type<br />

Hydrostatic<br />

Steering type<br />

Electronic<br />

Internal turning radius m 1.00<br />

Performances<br />

Production t/h <strong>500</strong><br />

Layer thickness mm 5–300<br />

Hopper capacity t 12<br />

Max Speed (transfer) km/h 4.5<br />

Max Speed (work) m/min. 37<br />

Tank capacity<br />

Fuel tank l 200<br />

Hydraulic oil l 170<br />

Ecological liquid l 30<br />

Weights (CECE)<br />

<strong>Paver</strong> with screed kg 1<strong>500</strong>0<br />

03/2013 Sizes, specifications and photos are not binding and can change without any notice.<br />

Productivity Partnership for a Lifetime