Brochure for download - Ammann Group

Brochure for download - Ammann Group

Brochure for download - Ammann Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Road Paver Tracked - WheeledAFT 270 E/G - AFW 270 E/GThe machines of this class have been designed <strong>for</strong> use, primarily, on small andnarrow sites where their compact dimensions, their manoeuvrability and very goodtraction fulfil the typical requirements of a contractor <strong>for</strong> these kinds of jobs. Thetraction on wheels enables a good transfer speed on the road, reducing idling time.The wheeled machine has three axles: in the front, two axles <strong>for</strong> steeringand in the rear, the axle <strong>for</strong> traction. The rear axle is fitted with largepneumatic tyres so that the machine can also be driven on soft ground.The current version is equipped with four-wheel drive traction as standard.The steering system, with a hydraulic pump, provides smooth control whenturning.Traction on tracks is suitable <strong>for</strong> job sites located on difficult ground and itassures a very thorough levelling effect.The tracked machine has rubber pads and an automatic tensioningdevice system with a grease accumulator. The hydrostatic transmissionis implemented by two variable flow-rate pumps that feed two motorswith two displacements directly attached to the planetary gearboxes thatoperate the tracks. An electronic and proportional control mounted oneach pump provides a progressive start and stop and maintains the setspeed constant. The steering-wheel is electronically controlled; the speedremains constant when steering.The hoppers are independently controlled by means of an electro-hydraulicsystem. The front pushing rollers move in sequence with the hoppers.2

Technical specificationsFeeding of materialThe feeding system <strong>for</strong> the material is carried out by twoindependent reverse chain belt conveyors and augerscontrolled by paddle microswitches which regulate the flowof material to the screed in order to maintain the mosteffective distribution of material under any conditions. Theheight of the augers is electro-hydraulically adjustable.Man on board versionMan on board operations from one adjustable seat that canslide to the left or the right. The dashboard is adjustablein accordance with the seat position to facilitate ease ofoperation. There are ground controls with anti-vandalguards <strong>for</strong> the road operator. A foldable canopy with rearsupports ensures good visibility.Screed optionsThe FSV 270 E/G is a vibrating screed equipped with gas orelectric heating, automatic lighting and temperature controland the ISR system (Screed Assist) <strong>for</strong> pressure adjustment.Max paving widths:FSV 270 E/G1400–2730 mmOptional 3330 mmApplicationssquares and courtyardssmall building lotsfootpathscycle tracksclosing trenchesurban centresmunicipal roads and small parking areasEquipmentStandardAutomatic heating controlHydraulically adjustable augers heightFour wheel drive (DT) <strong>for</strong> AFW 270The ISR system (Screed Assist)Folding canopy (Man on board version)OptionalLongitudinal levelling systemSlope control systemReduction plates at 500 mmMechanical extensions at 3330 mmFolding canopy (F version) <strong>for</strong> AFT 270Proportional ultrasonic augers controlOn-Off ultrasonic augers controlElectro-hydraulic camber adjustmentTracked Paver AFT 270 E/G Wheeled Paver AFW 270 E/GWeight kg 5200 / 5000 (F) 5200Diesel engine Deutz D2011L03i / kW 33.2 (45 HP) at 2500 rpm Deutz D2011L03i / kW 33.2 (45 HP) at 2500 rpmPaving width mm 1400 – 2730 1400 – 2730Max paving width mm 3330 3330Production t/h 150 1503

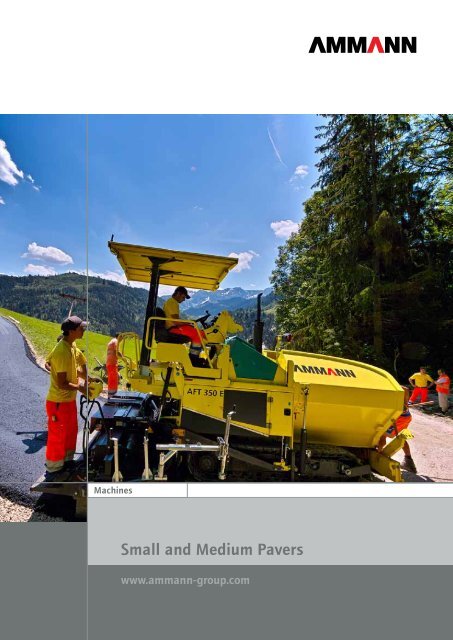

Road Paver Tracked - WheeledAFT 350 E/G - AFW 350 E/GThe machines of this class are ideal <strong>for</strong> small and medium sized job sites wheregood manoeuvrability <strong>for</strong> operating in restricted environments is requisite.Despite their compact dimensions these machines are able to pave in a width ofup to 4.5 m. The tracked version is suitable <strong>for</strong> job sites on difficult ground andensures a very thorough levelling effect.The wheeled machine has three axles: in the front, two axles <strong>for</strong> steeringand in the rear, the axle <strong>for</strong> traction. The rear axle is fitted with largepneumatic tyres so that the machine can also be driven on soft ground.Large full rubber tyres are fitted to the front oscillating axles. The steeringsystem with the hydraulic pump provides smooth control when turning.The tracked machine has rubber pads and an automatic tensioningdevice system with a grease accumulator. The hydrostatic transmissionis implemented by two variable flow-rate pumps that feed two motorswith two displacements directly attached to the planetary gearboxes thatoperate the tracks. An electronic and proportional control mounted oneach pump provides a progressive start and stop and maintains the setspeed constant. The steering-wheel is electronically controlled; the speedremains constant when steering. The hoppers are independently controlledby means of an electro-hydraulic system. The front pushing rollers move insequence with the hoppers. The two adjustable seats, left and right, canslide externally. The dashboard is adjustable in accordance with the seatposition to ensure ease of operation. There are ground controls with antivandalguards <strong>for</strong> the road operator. A hydraulic foldable canopy with rearsupports ensures good visibility.4

Technical specificationsFeeding of materialThe feeding system <strong>for</strong> the material is carried out by twoindependent reverse chain belt conveyors and augerscontrolled by paddle microswitches which regulate the flowof material to the screed in order to maintain the mosteffective distribution of material under any conditions.The height of the augers is electro-hydraulically adjustable.Screed optionsVibrating screed (FSV) or screed with tamper andvibration (FST) equipped with gas or electric heating,automatic lighting and temperature control, the ISR system(Screed Assist) with pressure adjustment.Max paving widths:FSV 355 E/GFST 350 E/G1830–3550 mmOptional 4130 mm1830–3500 mmOptional 4080–4500 mmApplicationslayers of final wearing course, binder,tout-venant on:national and municipal roadslarge squaressport grounds and courtyardsbuilding lots and parking areasEquipmentStandardAutomatic heating controlHydraulically adjustable auger heightThe ISR system (Screed Assist)Hydraulic folding canopyOptionalFour wheel drive (DT) <strong>for</strong> AFWLongitudinal levelling systemSlope control systemReduction plates at 800 mmMechanical extensions 2x290 mmMechanical extensions 2x500 mm <strong>for</strong> FSTProportional ultrasonic augers controlElectro-hydraulic camber adjustmentTracked Paver AFT 350 E/GWheeled Paver AFW 350 E/GWeight kg 7500 7500Diesel engine Deutz TD2011L04i / kW 52 (70 HP) at 2300 rpm Deutz TD2011L04i / kW 52 (70 HP) at 2300 rpmPaving width mm 1830 – 3500 (FST) 1830 – 3500 (FST)Max paving width mm 4500 (FST) 4500 (FST)Production t/h 230 2305

Screed versions and specificationsFSV 150 G<strong>Ammann</strong> Pavers Screed FSV 150 FSV 270 FSV 355 FSV 350 FST 350 FST 500 FSV 500Paver AFW 150 AFW/T 270 AFW 350 AFW/T 350 AFW/T 350 AFW/T 500 AFW/T 500Basic width m 0.80 1.40 1.83 1.83 1.83 2.55 2.55Open width m 1.30 2.73 3.55 3.50 3.50 4.90 4.90Min paving width m 0.25 0.50 0.80 0.80 0.80 1.50 1.50Max paving width m 1.65 3.33 4.13 4.08/4.50 4.08/4.50 6.50 6.50Tamper yes/no no no no no yes yes noRPM tamper rpm no no no no 0/1650 0/1700 noVibrator yes/no opt. yes yes yes yes yes yesRPM vibrator rpm 3000 3250 0/3200 0/3200 0/3200 0/3200 0/3200Heating G/E G G/E G/E G/E G/E G/E G/EHeating tamper Electric no no no no no no noNr. burners Nr. 3 4 4 4 4 8 8Mechanical extensions mm 2x175 2x300 2x290 2x290 2x500 2x290 2x500 2x800 2x800Crowning % ±2.0 ±4.5 +4.0 - 2.5 +4.0 - 2.5 +4.0 - 2.5 +4.0 - 2.5 +4.0 - 2.5Hydr. crowning yes/no no opt. opt. opt. opt. opt. opt.Weight kg 130 700 1265 1226 1326 3144 2900Mech. extensions weight kg 2x52 2x52 2x52 2x60(290)2x82(290)2x118(500)2x4882x425Rotating side plates yes/no no no no no no opt. opt.Foldable plat<strong>for</strong>m yes/no yes yes yes yes yes yes yesSpecifications are subject to changes due to technical improvementsFSV 270 E/G7

HeatingGas Electric VibrationCompactionTamper andVibrationAFW 150 x - x -800 –16501400 –AFW / T 270 x x x -33301830 –AFW / T 350 x x x x45002550 –AFW / T 500 x x x x65008FSV / FST

1300 mmAFW 150mm2730 mmAFW / T 270mm3500 mmAFW / T 350mm4900 mmAFW / T 500mm500 E/G9

Road Paver Tracked - WheeledAFT 500 E/G - AFW 500 E/GThe machines of this class are ideal <strong>for</strong> medium-to-large size job sites wheregood manoeuvrability, together with high per<strong>for</strong>mance, are requisite. Due to theirexcellent weight distribution, both the wheeled traction models (4x6 and 6x6) andthe tracked version are very easy to handle and are able to pave in a width of up to6.5 m <strong>for</strong> a wide range of applications.The wheeled machine has three axles: in the front, two axles <strong>for</strong> steeringand in the rear, the axle <strong>for</strong> traction. The rear axle is fitted with largepneumatic tyres so that the machine can also be driven on soft ground.Large full rubber tyres are fitted to the front oscillating axles. The steeringsystem with the hydraulic pump provides smooth control when turning.The tracked machine has rubber pads and an automatic tensioningdevice system with a grease accumulator. The hydrostatic transmissionis implemented by two variable flow-rate pumps that feed two motorswith two displacements directly attached to the planetary gearboxes thatoperate the tracks. An electronic and proportional control mounted oneach pump provides a progressive start and stop and maintains the setspeed constant. The steering-wheel is electronically controlled; the speedremains constant when steering. The hoppers are independently controlledby means of an electro-hydraulic system. The front pushing rollers areadjustable and oscillating.The two adjustable seats, left and right, can slide externally. The dashboardis adjustable in accordance with the seat position to ensure ease ofoperation. There are ground controls with anti-vandal guards <strong>for</strong> the roadoperator. A hydraulic foldable canopy with rear supports ensures good visibility.12

Technical SpecificationsFeeding of materialThe feeding system <strong>for</strong> the material is carried out by twoindependent reverse chain belt conveyors, controlled bypaddle microswitches, and the augers equipped with twoproportional ultrasonic controls which regulate the flowof material to the screed in order to maintain the mosteffective distribution of material under any conditions. Theheight of the augers is electro-hydraulically adjustable.Screed optionsVibrating screed (FSV) or screed with tamper andvibration (FST) equipped with gas or electric heating,automatic lighting and temperature control, the ISR system(Screed Assist) with pressure adjustment.Max paving widths:FSV 500 E/G; FST 500 E/G2550–4900 mmOptional 6500 mmApplicationslayers of final wearing course, binder,tout-venant as well as draining asphaltand cold mix on:freeways and national roadslarge squarescivil and industrial building lots, largeparking areasEquipmentStandardAutomatic heating controlHydraulically adjustable augers heightProportional ultrasonic augers controlThe ISR system (Screed Assist)Hydraulic folding canopyOptionalFour wheel drive (DT) <strong>for</strong> AFW6 wheel drive (DTI) <strong>for</strong> AFWLongitudinal levelling systemSlope control systemReduction plates at 1500 mmMechanical extensions 2x800 mmElectro-hydraulic camber adjustmentRotating screed side-end platesHeated screed side-end platesTracked Paver AFT 500 E/GWheeled Paver AFW 500 E/GWeight kg 15000 15000Diesel engine Cummins QSB4.5 / kW 119 (160 HP) at 2200 rpm Cummins QSB4.5 / kW 119 (160 HP) at 2200 rpmPaving width mm 2550 – 4900 2550 – 4900Max paving width mm 6500 6500Production t/h 500 50013

This drawing is neither a lowed to be copied, replicated, shown or open up tothird parties or used by third parties <strong>for</strong> self-construction or production.Diese Zeichnung darf ohne unsere schriftliche Bewi ligung weder kopiert, nachgebildet, Dri tpersonen gezeigtDiese Zeichnung darf ohne unsere schriftliche Bewi ligung weder kopiert, nachgebildet, Dri tpersonen gezeigtDiese Zeichnung darf ohne unsere schriftliche Bewi ligung weder kopiert, nachgebildet, Dri tpersonen gezeigtNNNMtoleranceMMMToleranzαFToleranzToleranzHFHGHHFRGRRGGDimensions1 23 4 5 6 78AAFW 150ABLBA B C D E F G H I L M2735 2550 640 800 870 1500 1130 410 1290 1850 70CCa20°D1 2I3 4 5 6 7C8ABADEEABAFT 270 F1 2LCshaping processes ISO 2768 - cLweldment constructions EN ISO 13920 - BF1:15machining processes ISO 2768 -mKDrawn 18/02/2013 Garramonefinal changeCheckedfirst used <strong>for</strong>:Page 1 / 1 Doc.Type: IDWDrawing Nr.VersionCH - Langenthal Paver AFW150AFW1503 4 5 6 7 8A3FBCA C D E G H I L M N4360 1180 1650 2900 1300 1800 1525 1350 2000 480R aA aP560 15° 15°DABoder zugänglich gemacht, noch zur Selbstausführung oder zur Herste lung durch Dri te benutzt werdenαA1 21 2AFT 270IAαP3 4 5 6 7Um<strong>for</strong>mende Verfahren ISO 2768 - cLASchweisskonstruktion EN ISO 13920 - BFA3 1:25Spanende Verfahren ISO 2768 - mKGez 15/02/2012 Garramone FLetzte ÄnderungGepr1.Verwendung:Blatt 1 / 1 Dok.Art: IDWDok.Nr.VersionCH-LangenthalAFT270 F -3 4 5 6 7 8CDE8BEA B C D E F G H I L4250 4100 1180 1650 2900 3100 1300 2250 1525 1350CLCM N R aA aP2800 480 560 15° 15°Doder zugänglich gemacht, noch zur Selbstausführung oder zur Herste lung durch Dri te benutzt werden1 2A1 2BαAAFW 270IαPBDAE3 4 5 6 78Um<strong>for</strong>mende Verfahren ISO 2768 - cLSchweisskonstruktion EN ISO 13920 - BFSpanende Verfahren ISO 2768 - mKGez 15/02/2012 GarramoneLetzte ÄnderungGepr1.Verwendung:Blatt 1 / 1 Dok.Art: IDWDok.Nr.VersionCH-LangenthalAFT270 -3 4 5 6 7 8CA31:25EAFBA B C D E F G H I L4250 4100 1180 1650 2900 3100 1300 2250 1380 1350M N R aA aP2800 480 560 24° 14°CLCD14oder zugänglich gemacht, noch zur Selbstausführung oder zur Herste lung durch Dri te benutzt werdenαA1 2IαPBDAEUm<strong>for</strong>mende Verfahren ISO 2768 - cLSchweisskonstruktion EN ISO 13920 - BFSpanende Verfahren ISO 2768 - mKGez 15/02/2012 GarramoneLetzte ÄnderungGepr1.Verwendung:Blatt 1 / 1 Dok.Art: IDWDok.Nr.VersionCH-LangenthalAFW270 -3 4 5 6 7 8CA31:25EF

This drawing is neither a lowed to be copied, replicated, shown or open up tothird parties or used by third parties <strong>for</strong> self-construction or production.This drawing is neither a lowed to be copied, replicated, shown or open up tothird parties or used by third parties <strong>for</strong> self-construction or production.This drawing is neither a lowed to be copied, replicated, shown or open up tothird parties or used by third parties <strong>for</strong> self-construction or production.This drawing is neither a lowed to be copied, replicated, shown or open up tothird parties or used by third parties <strong>for</strong> self-construction or production.NNNNMMtolerancetolerancetolerancetoleranceFMMFFFHHHHRRRGRGGG1 23 4 5 6 78AAAFT 350BBA B C D E F G H I L5030 4900 1320 1850 3100 3480 1380 2500 2033 1660M N R aA aPCC2800 480 580 15° 16°LDAαA1 2I3 4 5 6 7CαPBDAE8EABAFW 3501 2shaping processes ISO 2768 - cLweldment constructions EN ISO 13920 - BF1:28machining processes ISO 2768 -mKDrawn 23/02/2013 Garramone Ffinal changeCheckedfirst used <strong>for</strong>: AFT350 Page 1 / 1 Doc.Type: IDWDrawing Nr.VersionBCH - Langenthal AFT350AFT3503 4 5 6 7 8A3A B C D E F G H I L5030 4900 1320 1850 3100 3480 1380 2500 1735 1660M N R aA aP2800 480 580 23° 16°CLCDαA1 2IBC3 4 5 6 D 7αP8EAAEAA B C D E F G H I L6100 5860 2076 2550 3240 3520 1630 3000 2580 2000M N R aA aPBC1 2AFT 500Lshaping processes ISO 2768 - cLweldment constructions EN ISO 13920 - BF1:28machining processes ISO 2768 -mKDrawn 23/02/2013 Garramonefinal changeCheckedfirst used <strong>for</strong>: AFW350 Page 1 / 1 Doc.Type: IDWDrawing Nr.VersionCH - Langenthal AFW350AFW3503 4 5 6 7 8A3FBC3100 500 600 15° 16°DαAIBαPCDE1 2AE3 4 5 6 78A1 2shaping processes ISO 2768 - cLweldment constructions EN ISO 13920 - BF1:30machining processes ISO 2768 -mKDrawn 13/02/2012 Garramonefinal changeCheckedfirst used <strong>for</strong>:Page 1 / 1 Doc.Type: IDWDrawing Nr.VersionCH - LangenthalAFT5003 4 5 6 7 8A3AFA B C D E F G H I L6100 5860 2076 2550 3240 3520 1630 3000 1922 2000BAFW 500BM N R aA aP3100 500 600 15° 15°CLCDαAIBAαPCDEE1 2shaping processes ISO 2768 - cLweldment constructions EN ISO 13920 - BF1:30machining processes ISO 2768 -mKDrawn 13/02/2012 Garramonefinal changeCheckedfirst used <strong>for</strong>:Page 1 / 1 Doc.Type: IDWDrawing Nr.VersionCH - LangenthalAFW5003 4 5 6 7 8A3F15

<strong>Ammann</strong> distribution companiesGermany<strong>Ammann</strong> Verdichtung GmbHD-53773 HennefTel +49 22 42 880 20Fax +49 22 42 88 02 59info.avd@ammann-group.comFrance<strong>Ammann</strong> France SASF-94046 Créteil/CedexTel +33 1 45 17 08 88Fax +33 1 45 17 08 90info.afr@ammann-group.comUnited Kingdom<strong>Ammann</strong> Equipment Ltd.Bearley Strat<strong>for</strong>d upon AvonGB-Warwickshire, CV37 8XYTel +44 1789 414 525Fax +44 1789 414 495info.ael@ammann-group.comUSA<strong>Ammann</strong> America Inc.Ponte Vedra, Florida 32082, USATel +1 904 543 1691Fax +1 888 266 1210info@ammann-america.comRussia<strong>Ammann</strong> Russland o.o.o.RU-129343 MoscowTel +7 495 933 35 61Fax +7 495 933 35 67info.aru@ammann-group.comBrasil<strong>Ammann</strong> do BrasilGravataí -RS- Brasil 94180 – 452Tel +55 51 9315 3099info.abr@ammann-group.comSouth Africa<strong>Ammann</strong> Construction MachinerySouth Africa229 Hull Road, Rynfiel, BenoniTel +27 11 849 3939Fax +27 11 849 8889United Arab Emirates<strong>Ammann</strong> NME / DubaiDubaiTel +971 4 299 14 49 | 7Fax +971 4 299 14 49info.nme@ammann-group.com<strong>Ammann</strong> manufacturing companiesSwitzerland<strong>Ammann</strong> Schweiz AGCH-4901 LangenthalTel +41 62 916 61 61Fax +41 62 916 64 03info.aag@ammann-group.comGermany<strong>Ammann</strong> Verdichtung GmbHD-53773 HennefTel +49 22 42 880 20Fax +49 22 42 88 02 59info.avd@ammann-group.comCzech Republic<strong>Ammann</strong> Czech Republic a.s.CZ-54901 Nové Město nad MetujíTel +420 491 476 111Fax +420 491 470 405info.acz@ammann-group.com<strong>Ammann</strong> Spare PartsTel +41 62 916 66 66Fax +41 62 916 6804spareparts.machines@ammann-group.comSizes, specifications and photos are not binding and may be changed without any notice being givenInternational Distribution Partners: www.ammann-group.com03 / 2013