1. é¡æ表é¢ã®åå¦çæ§è³ªã¨åæ£å®å®æ§è©ä¾¡

1. é¡æ表é¢ã®åå¦çæ§è³ªã¨åæ£å®å®æ§è©ä¾¡

1. é¡æ表é¢ã®åå¦çæ§è³ªã¨åæ£å®å®æ§è©ä¾¡

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

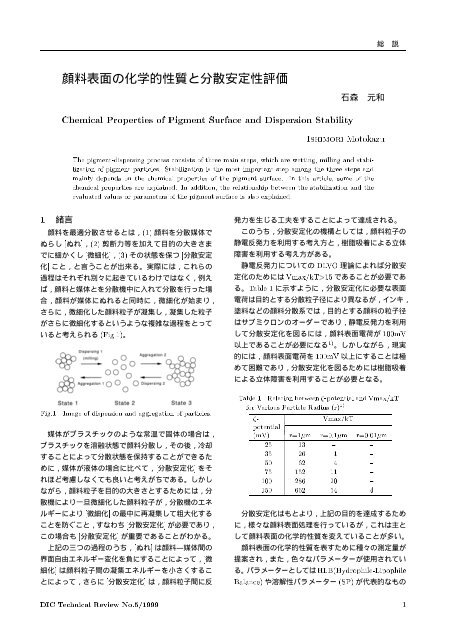

Chemical Properties of Pigment Surface and Dispersion Stability<br />

<br />

Ishimori Motokazu<br />

The pigment-dispersing process consists of three main steps, which are wetting, milling and stabilization<br />

of pigment particles. Stabilization is the most important step among the three steps and<br />

mainly depends on the chemical properties of the pigment surface. In this article, some of the<br />

chemical properties are explained. In addition, the relationship between the stabilization and the<br />

evaluated values or parameters of the pigment surface is also explained.<br />

1 <br />

(1) <br />

[](2) <br />

[](3) [<br />

] <br />

<br />

<br />

<br />

<br />

<br />

(Fig.1)<br />

Fig.1 Image of dispersion and aggregation of particles.<br />

<br />

<br />

<br />

[] <br />

<br />

<br />

<br />

[] <br />

[] <br />

[] <br />

[] <br />

[<br />

] <br />

[] <br />

<br />

<br />

<br />

<br />

DLVO <br />

Vmax/kT>15 <br />

Table 1 <br />

<br />

<br />

<br />

100mV<br />

1) <br />

100mV <br />

<br />

<br />

Table 1 Relation between -potential and Vmax/kT<br />

for Various Particle Radius (r) 1)<br />

- Vmax/kT<br />

potential<br />

(mV) r=1m r=0.1m r=0.01m<br />

25 13 { {<br />

35 26 1 {<br />

50 62 4 {<br />

75 152 11 {<br />

100 286 20 {<br />

150 662 54 4<br />

<br />

<br />

<br />

<br />

<br />

HLB(Hydrophile-Lipophile<br />

Balance) (SP) <br />

DIC Technical Review No.5/1999 1

SP ( d ) ( p )<br />

( h )<br />

2) <br />

3) <br />

<br />

<br />

<br />

<br />

Table 2 <br />

<br />

<br />

Table 2 Relation between Chemical Properties and<br />

Measured Values or Parameters of Pigment Surface<br />

Chemical Property<br />

Measured Value<br />

Parameter Hydrophilic Acidic<br />

/Hydrophobic /Basic<br />

HLB <br />

SP <br />

Amounts of resin adsorption <br />

Titration value of acid or base <br />

Amounts of acid or base adsorption <br />

Isoelectric point <br />

Heat of acid or base adsorption <br />

Ka, Kb <br />

relate partly relate not relate<br />

2 <br />

2.1 HLB<br />

HLB <br />

(1) HLB<br />

20 <br />

HLB = (Wp=Ws) 1 20 (1)<br />

Wp Ws<br />

Ws = 1000Wp = 600 HLB = 12<br />

Pascal 4) HLB <br />

HLB<br />

HLB<br />

(Table 3)<br />

<br />

HLB <br />

<br />

<br />

2.2 (SP)<br />

SP <br />

<br />

<br />

SP <br />

<br />

(1E) <br />

(Vm) <br />

SP <br />

SP Hansen <br />

2;5) SP <br />

( d ) ( p ) ( h ) 3 <br />

70 <br />

(Table 4)<br />

33 <br />

<br />

(Table 5)<br />

53 <br />

SP (Table 6)<br />

<br />

<br />

1 SP <br />

<br />

2 SP SP SP<br />

<br />

SP 42 <br />

<br />

SP <br />

6) SP 31 <br />

<br />

<br />

SP 7) Shareef <br />

SP 8) <br />

15 <br />

3) <br />

SP 3 ( d p h ) <br />

<br />

3 <br />

2.1 HLB <br />

HLB SP <br />

<br />

<br />

SP <br />

<br />

SP SP <br />

<br />

2 DIC Technical Review No.5/1999

Table 3 Required HLB Values - Pigment Colors 4)<br />

Pigments<br />

Required HLB<br />

{Organics{<br />

BON red dark 6 - 8<br />

Toluidine red medium 8 - 10<br />

Toluidine yellow 9 - 11<br />

Phthalocyanine green (yellow shade) 12 - 14<br />

Phthalocyanine green (blue shade) 10 - 12<br />

Phthalocyanine blue (red shade) 11 - 13<br />

Phthalocyanine blue (intermediate shade) 14 - 16<br />

Phthalocyanine blue (intermediate shade) 14 - 16<br />

Phthalocyanine blue (green shade) 14 - 16<br />

\Green-Gold" 11 - 13<br />

Quinacridone violet 11 - 13<br />

Quinacridone red 12 - 14<br />

High strength azo yellow 13 - 15<br />

{Inorganics{<br />

Lampblack 10 - 12<br />

Red iron oxide 13 - 15<br />

Molybdate orange 16 - 18<br />

Rutile titanium dioxide 17 - 20<br />

Chrome yellow medium 18 - 20<br />

Yellow iron oxide 20+<br />

Table 4 Components of the Solubility Parameter<br />

for Solvents 2) Solvents d p h<br />

15 m-Cresol 8.82 3.0 6.1<br />

22A Methylcellosolve 7.9 4.5 7.9<br />

29 Acetone 7.58 5.7 2.0<br />

35 Ethyl acetate 7.44 4.6 2.5<br />

45 Dimethyl formamide 8.52 6.7 5.5<br />

58 Toluene 8.67 <strong>1.</strong>0 2.0<br />

Table 5 Characteristic Parameters for Polymers<br />

and Resins 5)<br />

Polymers o do po ho ao R Ao<br />

B 1<strong>1.</strong>3 9.2 5.0 4.2 6.5 4.0<br />

C 1<strong>1.</strong>5 8.5 5.5 5.5 7.8 4.7<br />

D 9.4 8.5 2.5 3.0 3.9 5.3<br />

E 1<strong>1.</strong>2 9.4 3.2 5.1 6.0 5.0<br />

G 9.8 8.6 3.0 2.0 3.6 3.5<br />

J 10.8 7.0 7.0 4.3 8.2 5.5<br />

[Polymer]<br />

BPoly(methy methacrylate)<br />

CEpikote 1001-epoxy<br />

DPlexal P65-66% oil length alkyd<br />

EPentalyn 830-alcohol soluble rosin resin<br />

GPolystyrene LG<br />

J 1/2 Sec. Nitrocellulose-H 23<br />

SP <br />

9) <br />

<br />

SP<br />

<br />

Table 6 Characteristic Parameters for Various<br />

Pigments 5)<br />

Pigments o do po ho ao R Ao<br />

1 16.8 1<strong>1.</strong>8 7.3 9.5 12.0 8.4<br />

3 10.0 8.7 3.5 3.5 5.0 2.5<br />

7 10.5 9.6 3.0 3.2 4.4 3.9<br />

10 12.0 10.8 3.5 4.0 5.3 5.2<br />

11 12.0 10.0 4.8 4.5 6.6 4.8<br />

14 1<strong>1.</strong>5 9.6 5.2 3.6 6.3 4.4<br />

25 9.1 9.0 2.7 2.3 3.6 2.5<br />

[Pigment]<br />

1TiO2 3C.I.pigment red 48 (Mn)<br />

7C.I.pigment red 57 (Ca) 10C.I.pigment blue 15<br />

11C.I.pigment green 7 14C.I.pigment violet 23<br />

25C.I.pigment yellow 12<br />

<br />

10) <br />

3 <br />

<br />

<br />

Arrhenius <br />

Broensted-Lowry Lewis <br />

<br />

(D N ) <br />

(A N ) 11) Drago <br />

(E A E B ) (C A C B )<br />

12) <br />

DIC Technical Review No.5/1999 3

3.1 <br />

<br />

Sorensen <br />

13) Sorensen Lewis <br />

<br />

<br />

<br />

Lewis <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

(Table 7)<br />

<br />

<br />

3.2 <br />

<br />

<br />

<br />

<br />

<br />

<br />

3.2.1 <br />

<br />

Fowkes (2) Drago <br />

E A E B C A C B <br />

<br />

12) <br />

PMMA PMMA <br />

<br />

(E B = 3:56C B = 1:99)PMMA <br />

<br />

50 <br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

01H AB E A E B C A C B (2)<br />

3.2.2 <br />

<br />

<br />

<br />

<br />

<br />

14) <br />

<br />

Table 7 Evaluation of Binders 13)<br />

Type Commercial Name Basic Acid Amphoteric Neutral<br />

CELLULOSICS<br />

Cellulose esters CAB *<br />

ACRYLICS<br />

MMA Elvacite 2013 *<br />

EMA Elvacite 2043 *<br />

Polyacrylate Parloid B72 *<br />

Synedol 2263 XB *<br />

POLYAMIDES<br />

Alcohol soluble Versamid 758 ***<br />

POLYURETHANES<br />

Estane 5707 IF *<br />

Polyisocyanate Desmodur N *<br />

Polyisocyanate Desmodur L *<br />

4 DIC Technical Review No.5/1999

15) <br />

3.2.3 <br />

<br />

<br />

28 <br />

n-<br />

<br />

<br />

16) <br />

3.2.4 <br />

<br />

<br />

<br />

<br />

<br />

<br />

17) <br />

<br />

IEP<br />

<br />

<br />

pH <br />

<br />

(Fig.2) 18) <br />

Fig.2 Zeta-potentials of some pigments in various<br />

pH values. 18)<br />

T-1:non treated T-2:acid treated T-4:base treated<br />

pH <br />

<br />

pH <br />

(T-1) <br />

(T-2) <br />

(T-4) <br />

<br />

<br />

TI <br />

<br />

<br />

<br />

<br />

(Fig.3)TI 1 <br />

<br />

IEP TI 1<br />

<br />

IEP <br />

IEP <br />

<br />

Labib (D N ) 9 <br />

11 <br />

D N <br />

(Table 8) 11) <br />

3.2.5 <br />

<br />

<br />

<br />

n-<br />

<br />

<br />

<br />

<br />

<br />

18) <br />

<br />

TI <br />

<br />

<br />

<br />

<br />

3.2.6 (KaKb)<br />

Schreiber Inverse Gas Chromatography(IGC) <br />

(Ka<br />

Kb) <br />

19) <br />

DIC Technical Review No.5/1999 5

Fig.3 Relation of isoelectric points of phthalocyanine pigments and TI values in acidic, basic and amphoteric<br />

resins. 18)<br />

acidic resin basic resin amphoteric resin<br />

<br />

<br />

<br />

(Ka)<br />

(Kb) 20) (3) <br />

(Isp) (0.5

5101) 5g 100ml <br />

pH <br />

10 %<br />

pH DIN/ISO787 <br />

Schroeder <br />

<br />

<br />

<br />

22) <br />

<br />

<br />

<br />

<br />

<br />

() 1999<br />

2 <br />

<br />

<br />

1) : \ 7 ", p. 31, <br />

(1982).<br />

2) C. M. Hansen, J. Paint Technol., 39, (505),104<br />

(1967).<br />

3) , : , 55,459(1982).<br />

4) R. H. Pascal, F. L. Reig, Ocial Digest, 36,839<br />

(1964).<br />

5) C. M. Hansen, J. Paint Technol., 39, (511),505<br />

(1967).<br />

6) , , , , , <br />

: , 47,412(1974).<br />

7) , , : , 67,489(1994).<br />

8) K. M. A. Shareef, M. Yaseen, M. Mahmood. Ali,<br />

P. J. Reddy, J. Coatings Technol., 58, (733),35<br />

(1986).<br />

9) , , : , 62,524(1989).<br />

10) , , : , 63,744(1990).<br />

11) M. E. Labib, R. Williams, J. Colloid Interface Sci.,<br />

97, (2),356(1984).<br />

12) F. M. Fowkes, M. A. Mostafa, Ind. Eng. Chem.<br />

Prod. Res. Dev., 17, (1),3(1978).<br />

13) P. Sorensen, J. Paint Technol., 47(602),31(1975).<br />

14) , , : , 61,692(1988).<br />

15) , : , 67,547(1994).<br />

16) , , : , 52,306(1979).<br />

17) F. M. Fowkes, Dis.Faraday Soc., 42,246(1966).<br />

18) , , : , 65,155(1992).<br />

19) H. P. Schreiber,70th Anniversary Conference on<br />

Colour Materials, Oct.22-24, Tokyo,2C-2V, (1997).<br />

20) U. Panzer, H. P. Schreiber, Macromolecules, 25,<br />

(14),3633(1992).<br />

21) , , : 1994 <br />

, ,10B-07(1994).<br />

22) J. Schroeder, Prog.Org.Coatings, 19,227(1991).<br />

<br />

<br />

<br />

<br />

Ishimori Motokazu<br />

DIC Technical Review No.5/1999 7

8 DIC Technical Review No.5/1999