Life extension studies - The ABB Group

Life extension studies - The ABB Group

Life extension studies - The ABB Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

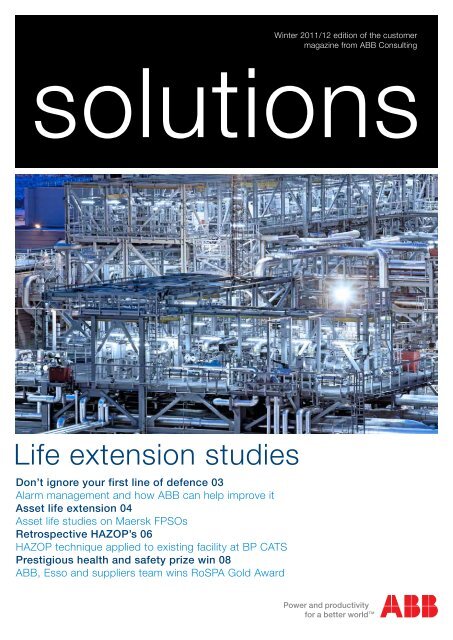

Winter 2011/12 edition of the customer<br />

magazine from <strong>ABB</strong> Consulting<br />

solutions<br />

<strong>Life</strong> <strong>extension</strong> <strong>studies</strong><br />

Don’t ignore your first line of defence 03<br />

Alarm management and how <strong>ABB</strong> can help improve it<br />

Asset life <strong>extension</strong> 04<br />

Asset life <strong>studies</strong> on Maersk FPSOs<br />

Retrospective HAZOP’s 06<br />

HAZOP technique applied to existing facility at BP CATS<br />

Prestigious health and safety prize win 08<br />

<strong>ABB</strong>, Esso and suppliers team wins RoSPA Gold Award

Editorial<br />

Peter Hunt<br />

Business Development Director<br />

<strong>ABB</strong> Consulting<br />

Looking ahead...<br />

Welcome to the second edition of the new format<br />

Solutions newsletter.<br />

© Maersk<br />

Maersk Curlew FPSO 04. BP CATS Terminal 06.<br />

© BP<br />

This edition includes articles from pharmaceutical,<br />

chemical and oil & gas companies with process safety,<br />

asset ageing and integrity being key themes. Two of our<br />

articles, PTT and Springfield Fuels, focus on technical<br />

training and competency where <strong>ABB</strong> Consulting<br />

continues to see a high demand from our customers.<br />

Shasun Pharma Solutions 08.<br />

© Shasun<br />

During 2011 well over 2000 delegates attended <strong>ABB</strong>’s<br />

lunchtime talks, seminars, training courses, conferences<br />

and webinars. We also provided an increased amount of<br />

bespoke training at customer sites / offices.<br />

We continue to develop this offer with lunchtime<br />

talks now running in Yorkshire in addition to those in<br />

Humberside, the North East, the North West, Aberdeen<br />

and Grangemouth.<br />

We have also increased the number of our IChemE<br />

approved courses and our Pressure Relief training<br />

course is now running in Singapore and Australia.<br />

Best wishes for 2012 to all of our readers.<br />

‘Hot topic’ update<br />

3 Don’t ignore your first line of defence<br />

Feature articles<br />

4 Asset life <strong>extension</strong><br />

Asset life <strong>studies</strong> on Maersk FPSOs<br />

6 Retrospective HAZOPs<br />

HAZOP technique applied to existing facility at BP CATS<br />

Pressure systems training<br />

<strong>ABB</strong> deliver training for Springfield Fuels Ltd<br />

8 Prestigious health and safety prize win<br />

Project team wins RoSPA Gold Award<br />

Ageing plant assessment<br />

Management of ageing assets at Shasun<br />

12 Continued support to PTT<br />

Continued Technical Due Diligence training for PTT<br />

Conferences and events<br />

9 Conferences<br />

Recent conferences <strong>ABB</strong> have sponsored, exhibited at<br />

or attended<br />

10 Events / training<br />

Recent events or training courses <strong>ABB</strong> have attended<br />

<strong>ABB</strong> solutions winter 2011 • Customer magazine from <strong>ABB</strong> Consulting • Copyright 2011 • If you have any comments or feedback please contact<br />

Graeme Collings - graeme.collings@gb.abb.com • <strong>ABB</strong> Consulting, Daresbury Park, Daresbury, Warrington, Cheshire, WA4 4BT, United Kingdom •<br />

Tel: +44 (0)1925 741111 • E-mail: contact@gb.abb.com • Follow us on twitter: www.twitter.com/<strong>ABB</strong>CONSULTINGUK<br />

2 <strong>ABB</strong> solutions magazine winter 2011/12 www.abb.com/consulting

‘Hot topic’ updates<br />

Typical alarms system.<br />

Don’t ignore your first line of<br />

defence<br />

In principle, modern alarm systems<br />

provide process operators with an<br />

essential tool in managing plant<br />

operations and minimising unplanned<br />

abnormal events, such as plant outage<br />

or equipment damage. In the multiple<br />

lines of defence of any process plant,<br />

they provide an invaluable layer of<br />

protection, combining the flexibility and<br />

adaptability of the plant operator with<br />

the power of technology.<br />

However in practice, poor initial design<br />

and lack of effective alarm management<br />

have resulted in alarm systems that are<br />

not “fit for purpose”. In many cases the<br />

system ceases to be a decision support<br />

tool and becomes a noisy distraction<br />

to be ignored, or in the worst case,<br />

may distract or confuse the operator<br />

and compromise his response to an<br />

abnormal situation.<br />

Over the years, the most extreme cases<br />

of this have led to a number of incidents<br />

in which poor alarm management has<br />

been seen as a key contributing factor<br />

e.g. Texaco Milford Haven, BP Texas<br />

City and Three Mile Island.<br />

Good alarm management not only<br />

reduces the risk of a major plant<br />

incident by enabling good decision<br />

making in complex and stressful<br />

situations, but also brings a host of<br />

other benefits:<br />

−−<br />

Increased production and equipment<br />

availability<br />

−−<br />

Reduced equipment maintenance<br />

costs<br />

−−<br />

Smoother run ups / run downs<br />

−−<br />

Reduced outage for maintenance<br />

−−<br />

Reduced equipment damage<br />

−−<br />

Reduced demand on protective<br />

systems<br />

−−<br />

Lower risk of incidents with serious<br />

safety, environmental or financial<br />

consequences<br />

Realising that you have a problem with<br />

your alarm system may be the first<br />

step to achieving these benefits. An<br />

alarm review will establish compliance<br />

with recognised good practice such<br />

as the EEMUA 191 guideline and ISA<br />

18.02 standard. It provides a ‘where<br />

are we now’ analysis and represents<br />

the benchmark phase of a total alarm<br />

management initiative.<br />

Although it is effective as a standalone<br />

exercise it can also serve as the<br />

first step in a larger alarm improvement<br />

programme, which should comprise the<br />

following elements:<br />

−−<br />

Integration of alarm management<br />

principles into new projects and plant<br />

modifications<br />

−−<br />

Improvement project to remediate<br />

alarm issues on existing systems<br />

−−<br />

Establishing a framework for ongoing<br />

alarm management<br />

−−<br />

Building a team with clear<br />

responsibility and motivation to<br />

deliver and maintain an effective<br />

alarm management system and the<br />

associated benefits<br />

Companies that treat their alarm system<br />

as a key production asset; seeing<br />

the need for ongoing management<br />

to identify any problems and working<br />

to continuously improve their system<br />

are on the journey to improve. <strong>ABB</strong><br />

Consulting has significant history of<br />

successful alarm improvement projects<br />

based on our experience and a broad<br />

range of professional skills.<br />

www.abb.com/consulting <strong>ABB</strong> solutions magazine winter 2011/12<br />

3

Feature articles<br />

Asset life<br />

<strong>extension</strong><br />

Maersk FPSOs develop, build, install and<br />

operate Floating Production, Storage and<br />

Offloading units (FPSOs) tailored for oil<br />

production in demanding environments.<br />

<strong>The</strong>se vessels are among the<br />

most technically complex<br />

vessels in the world, and<br />

Maersk FPSO is a supplier<br />

to some of world’s leading energy<br />

companies. Maersk FPSO recently<br />

commissioned <strong>ABB</strong> Consulting to<br />

undertake three separate projects in<br />

relation to ageing and life <strong>extension</strong>.<br />

<strong>The</strong> first project was for the Curlew<br />

Field, which is developed via subsea<br />

facilities feeding into an FPSO owned<br />

by Maersk FPSO. <strong>The</strong> field partners<br />

are Shell (50%) and Esso (50%), with<br />

Shell as the operator. As part of an<br />

internal Curlew Status Review project,<br />

<strong>ABB</strong> were asked to undertake a study<br />

to identify the major issues and areas<br />

of capital expenditure required in order<br />

to extend the life of the FPSO through<br />

to 2019. <strong>The</strong> study was focused on the<br />

topsides pressure systems, rotating<br />

equipment and fire protection safety<br />

systems. <strong>The</strong> study involved an initial<br />

workshop with key operations and<br />

maintenance personnel to identify the<br />

scope of the study and understand<br />

existing life limiting issues.<br />

This was followed by a structured<br />

review of the original design data for<br />

the systems as well as the operational<br />

history, inspection reports and<br />

maintenance records. This allowed the<br />

multidiscipline <strong>ABB</strong> team to identify the<br />

life limiting issues, quantify the risk in<br />

terms of health, safety, environment,<br />

reputation and production as well as<br />

develop pragmatic recommendations to<br />

eliminate the issues or reduce the risks.<br />

<strong>The</strong> cost for individual recommendations<br />

was then estimated, together with<br />

proposed implementation dates. This<br />

facilitated the development of an<br />

expenditure profile for the asset through<br />

to the revised cessation of production<br />

date.<br />

<strong>The</strong> second project was also for the<br />

Curlew Field and involved undertaking<br />

an audit of the integrity management<br />

systems associated with ageing and<br />

life <strong>extension</strong> ahead of a forthcoming<br />

Key Programme 4 (KP4) audit by the<br />

Health & Safety Executive. This audit<br />

involved on site structured discussions<br />

with the main operations staff and main<br />

engineering disciplines together with a<br />

review of sample documentation across<br />

the five principal elements of the KP4<br />

audit programme.<br />

<strong>The</strong> third project was for the North<br />

Sea Producer FPSO which is currently<br />

Maersk Curlew FPSO.<br />

located on the MacCulloch Field<br />

and is operated by ConocoPhillips.<br />

This project involved the design and<br />

facilitation of a one day workshop to<br />

identify potential ‘gaps’ in the integrity<br />

management systems associated with<br />

ageing and life <strong>extension</strong> ahead of a<br />

forthcoming KP4 audit by the Health &<br />

Safety Executive. <strong>The</strong> output from this<br />

workshop was then used to develop an<br />

‘improvement roadmap’.<br />

All three projects were completed<br />

in a short time frame to the overall<br />

satisfaction of the client.<br />

4 <strong>ABB</strong> solutions magazine winter 2011/12 www.abb.com/consulting

Feature articles<br />

© Maersk FPSOs<br />

“<strong>ABB</strong>’s Asset Integrity Management team carried out an<br />

Asset <strong>Life</strong> Strategy Review and a KP4 gap analysis audit for<br />

our unit Maersk Curlew. Both <strong>studies</strong> were carried out on<br />

time and to the approved budget and we were satisfied with<br />

the reports produced as the final outcome of the <strong>studies</strong>.”<br />

Niels Poulsen, Mechanical Engineer, Maersk FPSOs.<br />

Iain Wright<br />

Principal Consultant<br />

<strong>ABB</strong> Consulting<br />

Maersk FPSOs contributes to global energy supply by delivering safe and reliable floating<br />

oil and gas production services. Maersk FPSOs develop, build, install and operate FPSOs<br />

(Floating Production, Storage and Offloading units) tailored for oil production in demanding<br />

environments. FPSOs are among the most technically complex vessels in the world, and<br />

Maersk FPSOs is a proud supplier to some of world’s leading energy companies.<br />

www.abb.com/consulting <strong>ABB</strong> solutions magazine winter 2011/12<br />

5

Feature articles<br />

BP CATS Terminal, Teesside, UK.<br />

© BP<br />

Retrospective HAZOPs<br />

<strong>The</strong> HAZOP technique has been in use for many years and has<br />

proven to be an excellent tool to help identify process hazards,<br />

allow companies to control major accident risks and prevent<br />

operability issues.<br />

6 <strong>ABB</strong> solutions magazine winter 2011/12 www.abb.com/consulting

Feature articles<br />

<strong>The</strong> technique has traditionally<br />

been applied during projects and<br />

modifications. However, an increasing<br />

use of the HAZOP technique is to apply<br />

it in a ‘retrospective’ manner to existing<br />

facilities and not only on new projects or<br />

for modifications. BP require HAZOPs to<br />

be conducted on their existing assets in<br />

order to ensure that they are operated<br />

to the highest safety standards.<br />

<strong>ABB</strong> Consulting were approached by<br />

personnel at the BP CATS gas terminal<br />

to conduct a retrospective HAZOP.<br />

This involved utilising an experienced<br />

HAZOP leader and scribe from <strong>ABB</strong>,<br />

BP process and mechanical engineers,<br />

senior operators and other specialist<br />

disciplines. <strong>The</strong> study was conducted<br />

over a number of months utilising a<br />

highly structured approach to HAZOPs.<br />

BP have set new, higher standards<br />

for conducting HAZOPs. HAZOP is a<br />

rigorous, searching technique and when<br />

applied utilising a multi-disciplined team<br />

can help identify many issues that the<br />

original designers may have overlooked.<br />

Similarly, personnel who have operated<br />

and maintained such processes can<br />

highlight problems they have faced<br />

during day to day operations.<br />

Many recommendations are generated<br />

from such an in depth, critical<br />

review of production facilities. <strong>The</strong><br />

recommendations are aimed at<br />

continually reducing risks to as low as<br />

reasonably practicable levels such that<br />

incidents are prevented and companies<br />

continue to operate successfully.<br />

<strong>The</strong> partnership between <strong>ABB</strong><br />

skilled HAZOP resources and BP’s<br />

experienced operations personnel can<br />

yield significant business benefits for<br />

successful continued operation.<br />

A retrospective HAZOP provides BP<br />

with a new ‘baseline’ study which can<br />

further be used and kept ‘evergreen’,<br />

as future process improvements are<br />

identified and subjected to the HAZOP<br />

methodology. <strong>The</strong> HAZOP report<br />

thereby becomes a living document<br />

that reflects current understanding of<br />

hazards and risks.<br />

<strong>ABB</strong> is now supporting BP CATS in<br />

the close out of the actions. This is a<br />

prioritised programme of work to ensure<br />

that the risk reduction benefits of the<br />

HAZOPs are fully realised in a timely<br />

manner.<br />

BP is one of the world’s leading international<br />

oil and gas companies, providing its customers<br />

with fuel for transportation, energy for heat<br />

and light, retail services and petrochemicals<br />

products for everyday items.<br />

CATS is the Central Area Transmission System,<br />

which delivers 20% of the UKs gas through<br />

a 404 kilometre (223 mile) pipeline from the<br />

Central North Sea to the CATS processing<br />

Terminal in Teesside on the North East coast<br />

of England, UK.<br />

Pressure systems training<br />

Springfields Fuels Ltd (SFL) manage<br />

the integrity of their process plant using<br />

a risk based approach. This requires<br />

a consistent and appropriate level of<br />

technical competence relating to design<br />

features, legislative compliance, modes<br />

of deterioration, fitness for service<br />

and other key aspects of equipment<br />

integrity.<br />

In setting up a Skills Development<br />

Programme, SFL recognised that the<br />

technical and professional development<br />

of their professional engineers is<br />

particularly important to the success<br />

of the business. <strong>The</strong> company<br />

identified a need to develop their<br />

‘Responsible Engineers’ at their site<br />

near Preston with a wider and deeper<br />

knowledge on legislative compliance<br />

relevant to SFL areas of operation,<br />

particularly in relation to National and<br />

International codes in such areas as<br />

pressure systems, piping integrity and<br />

management of deterioration.<br />

SFL required a focussed technical<br />

training programme to be delivered<br />

by experts in the necessary technical<br />

areas. <strong>The</strong>y recognised <strong>ABB</strong>’s technical<br />

expertise and long-standing experience<br />

of developing and delivering technical<br />

training. SFL commissioned a series of<br />

three two-day training courses covering<br />

pressure equipment integrity.<br />

This tailored training programme will<br />

be followed by appropriate hands-on<br />

experience, coaching and mentoring<br />

to support and embed the learning.<br />

This training will also form the basis of<br />

development of new engineers.<br />

“By working with the consultants at <strong>ABB</strong> we were<br />

able to tailor the course content to meet the specific<br />

needs of our business. I have received many positive<br />

comments from the engineers who attended the three<br />

two day courses, and as an engineering community<br />

we have benefited greatly from the training.”<br />

Mark Britt, Inspection <strong>Group</strong> Manager, SFL<br />

Springfield Fuels Ltd Preston site.<br />

Springfields, near Preston, has provided nuclear fuel fabrication services since the mid-<br />

1940s – in fact it was the first plant in the world to produce fuel for a commercial power<br />

station. On 1 April 2010 Westinghouse entered into an agreement with the Nuclear<br />

Decommissioning Authority (NDA) for a long-term lease of the Springfields site, which<br />

transferred responsibility for the commercial fuel manufacturing business and Springfields<br />

Fuels Limited to Westinghouse.<br />

© SFL<br />

www.abb.com/consulting <strong>ABB</strong> solutions magazine winter 2011/12<br />

7

Feature articles<br />

Prestigious health and safety prize win<br />

<strong>ABB</strong> Consulting’s demolition and<br />

remediation team have won a top safety<br />

certificate awarded by the country’s<br />

Royal Society for the Prevention of<br />

Accidents (RoSPA) for the rigorous<br />

safety management standards applied<br />

in 2010 to one of many projects<br />

undertaken by the group. <strong>The</strong> joint<br />

<strong>ABB</strong> / Esso demolition and remediation<br />

project team have been awarded the<br />

RoSPA Gold for the fourth year running<br />

and the 7th RoSPA award in total. This<br />

is recognised as a fantastic achievement<br />

by the project team who are setting the<br />

industry standard for safe demolition<br />

and remediation projects, through their<br />

leadership, dedication and commitment<br />

to delivering health and safety<br />

excellence.<br />

<strong>The</strong> work associated with the award<br />

winning project is predominantly<br />

located within complex city centre<br />

environments, where reducing petrol<br />

retail margins and rising land prices<br />

have made the sale of land financially<br />

attractive. To enable the land to be sold,<br />

it needs to be remediated to eliminate<br />

<strong>The</strong> ‘Team’ members of the <strong>ABB</strong>, Esso and suppliers senior managers.<br />

“RoSPA firmly believes that organisations that have<br />

demonstrated their commitment to continuous<br />

improvement in accident and ill health prevention<br />

deserve recognition. <strong>ABB</strong> / Esso demolition and<br />

remediation projects has shown that it is committed to<br />

striving for such continuous improvement and we are<br />

delighted to honour it through the presentation of an<br />

award.”<br />

David Rawlins, RoSPA Awards Manager<br />

any potential historical legacy issues. In<br />

delivering the project, <strong>ABB</strong> has overall<br />

responsibility for decommissioning,<br />

CDM coordination, land remediation<br />

and project management. <strong>ABB</strong> applied<br />

their five stage demolition methodology<br />

to the project to offer Esso a safe, cost<br />

effective and complete solution.<br />

Ageing plant assessment<br />

<strong>The</strong> integrity management of ageing<br />

plant has become a key issue for much<br />

of the process industry in the UK, as<br />

an increasing number of assets are<br />

operated beyond their original design<br />

life.<br />

<strong>The</strong> leadership team at Shasun<br />

Pharma Solutions’ Cramlington site<br />

are developing and implementing a<br />

proactive and consistent approach to<br />

the management of ageing assets. In<br />

support of this initiative, <strong>ABB</strong> Consulting<br />

were engaged to carry out an ageing<br />

plant ‘health check’ for the site.<br />

<strong>The</strong> health check consisted of an audit<br />

and a criticality analysis. <strong>The</strong> audit<br />

included a review of the current asset<br />

integrity management systems and an<br />

assessment of the vulnerability of the<br />

site’s assets to ageing. <strong>The</strong> criticality<br />

analysis took into consideration both the<br />

findings from the audit and the Health,<br />

Safety, Environmental and production<br />

consequences of equipment failure.<br />

<strong>The</strong> study highlighted that the site<br />

management team already have in place<br />

a number of effective systems and<br />

policies for the management of ageing<br />

plant. Opportunities for improvement<br />

were also identified. <strong>The</strong>se opportunities<br />

were prioritised by means of the<br />

criticality assessment and corrective<br />

actions recommended.<br />

Shasun Pharma Solutions found the<br />

health check to be a value adding<br />

process and plan to use the output<br />

of the study to optimise their integrity<br />

management programs.<br />

Shasun Pharma Solutions’ Cramlington site.<br />

© Shasun<br />

Shasun Pharma Solutions is the vertically<br />

integrated chemistry partner for the<br />

pharmaceutical industry. Its services include<br />

innovative process research and development,<br />

rapid response small scale manufacture for<br />

clinical trial supply and full scale commercial<br />

manufacture of advanced intermediates and<br />

API’s, all with seamless technology transfer and<br />

under cGMP.<br />

8 <strong>ABB</strong> solutions magazine winter 2011/12 www.abb.com/consulting

Pressure relief<br />

conference<br />

Edinburgh<br />

Conference delegates - Asif Raza, <strong>ABB</strong>; Andy<br />

Plant, Lucite; Malcolm Pass, <strong>ABB</strong>; Zac Meadows,<br />

FujiFilm Imaging; Bill Brown, Syngenta; Liz<br />

Thomas, <strong>ABB</strong>; Phyllida Sumner, FujiFilm<br />

Diosynths; Roger Bours, Fike; Neil Roberts, Dow<br />

Corning; Colin Deddes, BP; Gaynor Woodford<br />

and John Walkington, <strong>ABB</strong>.<br />

HazardEx<br />

conference 2011<br />

North Yorkshire<br />

Alan King, <strong>ABB</strong>, presented a paper<br />

entitled ‘SIL determination in the<br />

hazardous area’ at the HazardEx<br />

conference 2011 in Harrogate, UK.<br />

Conferences and events<br />

IQPC offshore<br />

safety summit<br />

Aberdeen<br />

<strong>ABB</strong> exhibited at the IQPC offshore<br />

safety summit in Aberdeen. Rob Turner,<br />

<strong>ABB</strong>, gave a presentation entitled ‘Alarm<br />

management: A key element of Process<br />

Safety Management (PSM)’. <strong>The</strong>re were<br />

delegates from ConocoPhillips, Hess,<br />

National Grid and GDF Suez.<br />

<strong>ABB</strong> hosted its second conference<br />

and exhibition on ‘Pressure relief’ in<br />

Edinburgh. <strong>The</strong>re were 80 delegates<br />

with guest speakers from Lucite,<br />

FujiFilm, Syngenta, Fike, SABIC, Dow<br />

Corning and BP. Malcolm Pass, <strong>ABB</strong>,<br />

also held a PEL Software introduction<br />

session. <strong>The</strong> event was very well<br />

received and preparation for the 2012<br />

conference is under way. Please contact<br />

Debby Law - deborah.law@gb.abb.com<br />

if you would be interested in presenting<br />

at the 2012 conference.<br />

Asset integrity<br />

management<br />

Aberdeen seminar<br />

Andy Hollins, <strong>ABB</strong>, presented at the<br />

asset integrity management seminar<br />

in Aberdeen. His presentation, entitled<br />

‘<strong>Life</strong> <strong>extension</strong> of upstream assets -<br />

managing integrity and process safety’<br />

was very well received by over 60<br />

delegates from companies such as BP,<br />

Total, Centrica Storage Ltd, Marathon<br />

Oil and Maersk Oil.<br />

Andy Hollins, <strong>ABB</strong>, presenting at the asset<br />

integrity management seminar.<br />

Alan King, <strong>ABB</strong>, presenting at the HazardEx<br />

conference 2011.<br />

Launch of 2012<br />

Improving Business<br />

Performance<br />

Annual conference<br />

This one-day conference, run in<br />

association with the Chemical Industries<br />

Association (CIA) will be held on 29th<br />

February 2012 at the Thorpe Park Hotel<br />

in Leeds. This conference will explore<br />

the key attributes of resource efficiency<br />

and promote sharing of the lessons<br />

learned by those that have started<br />

on the continuous improvement path.<br />

Delegates will learn from organisations<br />

that have taken varying approachs to<br />

business improvement. To find out more<br />

please contact Debby Law -<br />

deborah.law@gb.abb.com or visit:<br />

http://bit.ly/ibpc2012<br />

Improving Business<br />

Performance conference flyer.<br />

Rob Turner, <strong>ABB</strong>, presenting at the IQPC<br />

offshore safety summit.<br />

Hazards Asia Pacific<br />

Symposium<br />

Kuala Lumpur<br />

<strong>The</strong> <strong>ABB</strong> exhibition stand at the conference. From<br />

left: John Walkington, Ken Bell, Peter Hunt and<br />

Jon Cook of <strong>ABB</strong>.<br />

<strong>ABB</strong> Consulting were the headline<br />

sponsor of the first HAZARDS AP<br />

symposium in Kuala Lumpur. It was<br />

jointly organised by the Chemical<br />

Industries Council of Malaysia (CICM)<br />

and the IChemE. During the event, <strong>ABB</strong><br />

presented four technical papers by Ken<br />

Bell, Allen Ormond and Jon Cook. With<br />

over 230 attendees, the symposium was<br />

very well attended with delegates from<br />

companies such as Petronas, Syngenta,<br />

Shell, BASF, DuPont, Talisman,<br />

Huntsman, ConocoPhillips and Orica.<br />

www.abb.com/consulting <strong>ABB</strong> solutions magazine winter 2011/12<br />

9

Conferences and events<br />

PEL goes back to school!<br />

A new initiative has been undertaken to<br />

provide undergraduates access to PEL for<br />

their final year projects. <strong>The</strong> universities of<br />

Cambridge, Heriot Watt, Newcastle have so<br />

far joined the scheme.<br />

PEL training<br />

In response to the overwhelming requests<br />

from users, two physical properties<br />

masterclasses and two ‘Open’ PEL training<br />

courses have been presented in <strong>ABB</strong>’s<br />

offices at Belasis and Daresbury. Users from<br />

INEOS Chlor, Mexichem, Lucite, Sabic,<br />

Fujifilm, Urenco, Worley Parsons, Teijin Films,<br />

Huntsman Tioxide, Invista, Johnson Matthey,<br />

and <strong>ABB</strong> attended. Such was the excellent<br />

feedback that these courses have now been<br />

scheduled for 2012.<br />

www.tinyurl.com/es-seminars<br />

ProvueDB.net grows in popularity<br />

This new product extends the successful<br />

desktop system for creating and controlling<br />

datasheets with the ability to access them<br />

from anywhere in the world - through your<br />

normal browser. Create your datasheets in<br />

China, check them in the UK, and approve<br />

them in Houston! <strong>The</strong>re is nothing to<br />

download or install, and you get the latest<br />

updates automatically. Add to this the ability<br />

to transfer your existing databases from<br />

the desktop, instant access to all previous<br />

revisions, and an audit trail for each field on<br />

each datasheet and the package becomes<br />

pretty irresistible.<br />

CAPRE<br />

This is a new development designed to help<br />

engineers with pressure relief calculations. It is<br />

a suite of important, commonly-used pressure<br />

relief calculations for flexible use within Excel.<br />

CAPRE (pronounced CAPR-i) stands for<br />

CAlculations for Pressure Relief in Excel. It<br />

will deliver a set of validated, documented,<br />

and secure calculations all with the same<br />

user interface making them easy-to-use and<br />

readily accessible. Initially CAPRE will be<br />

accessed from Microsoft Excel. In the longer<br />

term CAPRE would also be accessible from<br />

PEL Relief and possibly the internet and other<br />

systems such as MathCAD and Python.<br />

This is a short term development project and<br />

we plan to release CAPRE at the next PEL<br />

Roadshow targeted for early 2012. If you<br />

would like to get involved in the development<br />

for this exciting new product please do not<br />

hesitate to contact us.<br />

“We couldn’t have designed this project in<br />

France so effectively without ProvueDB.net”<br />

Carolyn Potter, Senior Process Engineer,<br />

Croda, UK<br />

5th annual global<br />

refining summit<br />

Rotterdam<br />

<strong>ABB</strong> Consulting sponsored and had a<br />

joint exhibition stand with <strong>ABB</strong> Process<br />

Automation at the 5th annual global<br />

refining summit in Rotterdam. Gerry<br />

Brennan, <strong>ABB</strong>, gave a presentation on<br />

‘Process Safety Management and the<br />

potential shortcomings in your layers of<br />

protection’ which was very well received.<br />

<strong>The</strong> conference was well attended from<br />

companies such as Total, Saudi Aramco,<br />

Shell and BP.<br />

Gerry Brennan, <strong>ABB</strong>, giving his presentation.<br />

PSPIs for Power &<br />

Steam Generation<br />

Conference<br />

<strong>ABB</strong> were sole sponsors of the<br />

‘Practical application for Process Safety<br />

Performance Indicators (PSPIs) for<br />

power and steam generation’ conference<br />

held at the Energy Institute in London.<br />

Graeme Ellis, <strong>ABB</strong>, gave a presentation<br />

entitled ‘Using the learning from recent<br />

incidents to inform selection of PSPIs to<br />

improve process safety awareness’ as<br />

well as hosting a workshop on ‘How can<br />

we get PSPI alignment between sites<br />

in the same company?’ Both were very<br />

well received by delegates, including<br />

representatives from E.ON, Centrica,<br />

EDF Energy, Scottish Power, International<br />

Power, Drax & SSE.<br />

Discover Energy<br />

Efficiency<br />

Yorkshire, UK<br />

<strong>ABB</strong> sponsored the Yorkshire Chemical<br />

Focus event entitled ‘Discover Energy<br />

Efficiency’ held in Huddersfield. Colin<br />

Board, <strong>ABB</strong>, gave a presentation on<br />

‘Creating the energy aware organisation’<br />

to delegates from Unilever, Heineken and<br />

Croda amongst others.<br />

CIA awards<br />

Birmingham, UK<br />

Peter Hunt, <strong>ABB</strong>, (left) and Steve Elliott, CIA (right)<br />

with award winner Ian Williamson, Syngenta.<br />

<strong>ABB</strong> were the Chemical Industry<br />

Association (CIA) awards headline<br />

sponsor and also sponsored the<br />

prestigious Manufacturing and Resource<br />

Efficiency Award. This years winner was<br />

Syngenta, based in Grangemouth.<br />

IChemE registered<br />

safety professionals<br />

<strong>ABB</strong> are pleased to announce that<br />

Graeme Laughland has recently<br />

been appointed as a registered<br />

safety professional by the IChemE.<br />

Demonstrating competence in the field<br />

of process safety is a topic that many<br />

of our customers are interested in. For<br />

more information on how to become a<br />

safety professional contact the IChemE.<br />

Website: www.ichem.org<br />

For further information about PEL please visit:<br />

www.pelsoftware.com<br />

PEL Support Services<br />

+44 (0)1925 741126<br />

Graeme Ellis, <strong>ABB</strong>, with the other presenters at<br />

the conference.<br />

Graeme Laughland,<br />

<strong>ABB</strong>, with his<br />

certificate.<br />

10 <strong>ABB</strong> solutions magazine winter 2011/12 www.abb.com/consulting

Conferences and events<br />

Forthcoming events for 2012<br />

Conferences<br />

29 th February Improving Business Performance Leeds<br />

30 th May Integrity Management Manchester<br />

27 th June Pressure Relief Manchester<br />

27 th November Process Safety Management London<br />

11 th - 12 th December Shutdowns and Turnarounds Manchester<br />

Seminars<br />

21 st February Delivering Projects in a Live Operating Plant Teesside<br />

28 th February Learning from Buncefield Manchester<br />

7 th March Hot Topics for Power Generation Edinburgh<br />

8 th March Asset Closure Edinburgh<br />

15 th March Alarm Management in Practice Bristol<br />

Lunchtime forums<br />

12 th January Alarm Management - ISA 18.2 vs EEMUA 191 Grangemouth<br />

13 th January Human Factors in Maintenance Teesside<br />

19 th January Risk Based Inspection - Quantitative or Qualitative Aberdeen<br />

20 th January Living with Corrosion Grimsby<br />

27 th January Automation Legacy Migration - How to Start Daresbury<br />

2 nd February After the Energy Audit - Where Next? Grangemouth<br />

3 rd February HAZOPs Only Reduce Risks When the Actions are Done! Teesside<br />

17 th February Inspection is More than PSSR Hull<br />

23 rd February Assessing Your Human Factors Huddersfield<br />

24 th February SMART Decommissioning Daresbury<br />

Webinars<br />

18 th January Growing Old Gracefully! - Challenge of Ageing Assets Internet<br />

22 nd February Making Change Work Internet<br />

21 st March Is Your Electrical System Discriminating? Internet<br />

18 th April HAZOPs Only Reduce Risks When the Actions are Done! Internet<br />

16 th May Human Factors in Maintenance Internet<br />

Training courses<br />

11 th January An Engineers Guide to DSEAR Manchester<br />

19 th January Human Factors Incident Investigation Manchester<br />

31 st January Hazard Study Awareness* Manchester<br />

8 th February Electrostatics Ignition Hazards* Grimsby<br />

8 th February Mechanical Legislation Awareness Edinburgh<br />

16 th February SIL Awareness for Control / Electrical Technicians Cardiff<br />

21 st - 22 nd February Essentials of Pressure Systems* York<br />

7 th - 8 th March IEC 61508 / 61511 SIL Determination* Frodsham<br />

13 th - 14 th March Achieved SIL Manchester<br />

13 th - 14 th March Maintenance and Reliability Improvement Aberdeen<br />

13 th - 15 th March Pressure Relief* Bristol<br />

20 th - 21 st March Risk Based Inspection Manchester<br />

21 st - 22 nd March Project Management in the Process Industries Teesside<br />

21 st - 23 rd March Pressure Relief* Australia<br />

26 th - 28 th March Pressure Relief* Singapore<br />

27 th - 29 th March Human Factors in the Workplace Manchester<br />

Conferences<br />

Conferences are major industry<br />

forums focusing on key topic areas.<br />

Please contact us if you would be<br />

interested in presenting at any of<br />

our 2012 conferences.<br />

Seminars<br />

Seminars are focused on industry<br />

‘hot topics’ and include inputs from<br />

external speakers.<br />

Lunchtime forums<br />

Lunchtime forums provide an<br />

update on key industry topics and<br />

share best practice.<br />

Webinars<br />

Webinars are focused on industry<br />

‘hot topics’ and are accessed over<br />

the web.<br />

A full list of all the above events is<br />

available at:<br />

www.tinyurl.com/es-seminars<br />

Technical training<br />

Training courses provide in-depth<br />

knowledge on key subjects as<br />

part of an engineer’s professional<br />

development.<br />

A full list of training courses is<br />

available at:<br />

www.tinyurl.com/es-courses<br />

All of these events are organised and<br />

delivered by <strong>ABB</strong> Consulting.<br />

For more information on:<br />

Seminars please contact -<br />

Deborah Law<br />

Tel: +44 (0)1642 372029<br />

E-Mail: deborah.law@gb.abb.com<br />

Training courses please contact -<br />

Jackie Kendall<br />

Tel: +44 (0)1642 372121<br />

E-Mail: jackie.kendall@gb.abb.com<br />

* IChemE approved training course<br />

www.abb.com/consulting <strong>ABB</strong> solutions magazine winter 2011/12<br />

11

Further news<br />

Continued support to PTT <strong>Group</strong><br />

<strong>ABB</strong> Consulting continue to support the<br />

PTT <strong>Group</strong> with consultancy services<br />

through our Thailand office. PTT have<br />

recently developed a growth plan which<br />

may include acquisitions and mergers<br />

both in Thailand and overseas.<br />

the senior engineers were provided with<br />

more technical training on the topic.<br />

<strong>The</strong> events were a combination of<br />

formal training, practical examples<br />

and specific workshops created for<br />

the PTTCH business. In total, over 60<br />

people attended the events over 5 days.<br />

<strong>ABB</strong> were engaged as a technical<br />

advisor to PTT for a potential target<br />

in the United States. Our process<br />

technology and asset integrity expertise<br />

combined with significant experience in<br />

Technical Due Diligence (TDD) were the<br />

major factors associated with the award<br />

of the contract.<br />

ES/Sol/Win11-12/SNL010a<br />

PTT Chemical (PTTCH) also has a<br />

growth strategy and wish to be able to<br />

act with more independence in future<br />

TDD activities. PTTCH commissioned<br />

<strong>ABB</strong> to create a bespoke training event<br />

for TDD for the PTTCH organisation.<br />

<strong>The</strong>re were two separate events for<br />

different levels of the organisation.<br />

Vice presidents and senior managers<br />

attended an awareness event which<br />

highlighted the corporate issues whilst<br />

Ken Bell and Brian Hudson, <strong>ABB</strong>, (centre) with delegates from the TDD awareness training.<br />

PTT Public Company Limited (PTT PCL) or just (PTT), is a Thai state-owned SET-listed oil<br />

and gas company. Formerly known as the Petroleum Authority of Thailand (PTT), it owns<br />

extensive submarine gas pipelines in the Gulf of Thailand, a network of LPG terminals<br />

throughout the Kingdom, and is involved in electricity generation, petrochemical products,<br />

oil and gas exploration and production, and gasoline retailing businesses.<br />

Technical Consultancy.<br />

<strong>ABB</strong> Consulting provides technical consulting and engineering services to improve performance<br />

in the areas of compliance, operations and engineering to customers in the chemical,<br />

petrochemical, oil & gas, power, pharmaceuticals, metals and consumer industries worldwide.<br />

We offer expertise in the following areas:<br />

−−<br />

−−<br />

−−<br />

−−<br />

−−<br />

Environmental services<br />

Functional engineering<br />

Industrial energy efficiency<br />

Inspection<br />

Integrity management<br />

−−<br />

Operations improvement<br />

−−<br />

Process safety<br />

−−<br />

Project services<br />

−−<br />

Technical software<br />

−−<br />

Technical training<br />

www.abb.com/consulting<br />

<strong>ABB</strong> Consulting<br />

Tel: +44 (0)1925 741111<br />

E-Mail: contact@gb.abb.com