Newsletter - Aachener Verfahrenstechnik - RWTH Aachen University

Newsletter - Aachener Verfahrenstechnik - RWTH Aachen University

Newsletter - Aachener Verfahrenstechnik - RWTH Aachen University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

For the Chemical Process Engineering Department<br />

2011 was a year with a balanced mixture of<br />

new experiences and well known events. At the<br />

Christmasparty 2010, which in combination with<br />

an alumni reunion was a trip into the institute history,<br />

Thomas Melin passed the Chair officially<br />

on to Matthias Wessling. Already in January a<br />

new tradition was started by organizing a membrane<br />

winterschool. In spring the new labs in the<br />

chemistry building in Melaten were ready to use,<br />

the completion of the new mini-plant space was<br />

in October. The move had become necessary,<br />

because our well loved “Halle 2” was demolished<br />

in order to have enough space for a new central<br />

lecture hall building.<br />

Fig.3: A “Thank you” for Professor Melin<br />

In the style of the well know hat ceremony after<br />

each PhD examination on the 8th of July 2011<br />

in the already almost empty “Halle 2”, a honorary<br />

hat ceremony for Professor Melin took place,<br />

after he had passed his exam in the form of a<br />

lecture with slides unknown to him.<br />

Despite - or maybe because of - all this changes,<br />

intense research activities realised. In the following<br />

two exemplary projects will be presented.<br />

Chemical Process Engineering<br />

Membrane-based biogas upgrading<br />

Biogas is a renewable and alternative energy<br />

source. In contrast to solar and wind power, biogas<br />

is generated continuously. Biogas consists<br />

mainly of methane and carbon dioxide. It can be<br />

used by either removing carbon dioxide and inject<br />

the upgraded biogas into the natural gas grid<br />

or by combusting the untreated gas in conventional<br />

heat and power engines. The latter alternative<br />

is inefficient since the heat generated during<br />

combustion can often not be used.<br />

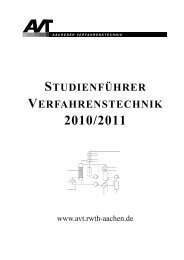

CH 4, CO 2<br />

1.1 bar 16 bar<br />

Fermenter<br />

CO 2<br />

1 bar<br />

Membrane<br />

CH 4<br />

16 bar<br />

Fig.4: Process scheme for membrane based<br />

biogas upgrading<br />

In order to use biogas as natural gas substitute,<br />

carbon dioxide has to be removed from the methane.<br />

Conventional processes to separate carbon<br />

dioxide from methane are amine and water<br />

scrubbing as well as pressure swing adsorption.<br />

However, gas permeation membranes are an<br />

alternative separation method. Typically polymeric<br />

membrane materials can be used to separate<br />

methane and carbon dioxide as carbon dioxide<br />

molecules permeate faster through the membrane<br />

than methane molecules. Gas permeation<br />

technology is an interesting alternative compared<br />

to conventional separation equipment since<br />

the product gas which is supplied to the natural<br />

gas grid is already compressed and further<br />

compression is not required. Thus, biogas upgrading<br />

and gas compression are combined in<br />

one step. In addition, gas permeation technology<br />

operates without any chemicals, which is advantageous<br />

when the biogas plant is installed onfarm.<br />

However, significant methane losses cannot<br />

be avoided when operating gas permeation<br />

modules.<br />

9 Chemical Process Engineering The AVT <strong>Newsletter</strong><br />

Natural gas pipeline