Robert Adams Thermal Magnetic Motor - The Hydrogen Shop

Robert Adams Thermal Magnetic Motor - The Hydrogen Shop

Robert Adams Thermal Magnetic Motor - The Hydrogen Shop

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Robert</strong> <strong>Adams</strong> <strong><strong>The</strong>rmal</strong> <strong>Magnetic</strong> <strong>Motor</strong><br />

<strong>The</strong>rmo <strong>Magnetic</strong> <strong>Motor</strong><br />

I have unpublished details for a thermo magnetic motor from New<br />

Zealand. It is a later <strong>Robert</strong> <strong>Adams</strong> magnetic motor design that was<br />

reported to produce infinite energy when calibrated properly and Dr<br />

<strong>Adams</strong> was not allowed to manufacture the device on the open market.<br />

Unlike most magnetic motors, this one is not a toy. This is unlike any<br />

magnetic motor most of you have ever heard of and may be a design<br />

which can be utilized by us for free electricity and hot water.<br />

<strong>The</strong>re are some missing details, but I think I have enough details that we<br />

can replicate this machine, since we have some smart guys in the forum<br />

who will probably be more than happy to help on this project.<br />

Missing Information<br />

Missing Information:<br />

1) Wiring Schematics<br />

2) Optimum timing of the motor.<br />

3) Method used for timing the motor.<br />

4) Photos of a working setup.<br />

According to an engineer friend of mine in Australia we have enough

information to duplicate this motor. <strong>The</strong> most important details I think<br />

we have.<br />

USB Rotary Encoder<br />

Phidgets USB Rotary Encoder Robot<strong>Shop</strong><br />

This new technology can be used to calibrate and run our motor. It is a<br />

fantastic system.<br />

Teaser<br />

Secret Alloy Discussed:<br />

Supposedly there is a very secret aspect to the rotor that if not utilized<br />

will prevent the proper function of the thermo aspect of the motor. As I<br />

said earlier, the rotor has holes for the magnets on the side of the rotor<br />

and not on the end of the rotor like his earlier versions. <strong>The</strong>re are eight<br />

equidistant holes drilled through the side of the rotor next to the outer<br />

edge of the rotor. <strong>The</strong> magnets are placed in every other hole and the<br />

remaining holes are plugged with an alloy plug. It is important that this<br />

alloy is made of a particular substance. Anyway, the alloy to be used is<br />

not bismouth and we will leave it a secret for another day.<br />

Rotor Specs

Rotor Specs:<br />

Rotor should be made from non conductive and non magnetic material.<br />

(Aluminum displays strange magnetic properties that are not desirable.)<br />

6 inch diameter rotor.<br />

Rotor must be 1" in thickness.<br />

Rotor must be water proof since there are likely to be water leaks from<br />

time to time.<br />

Drill 8 holes equidistant through the side of your rotor.<br />

Holes are 7/8" holes.<br />

PCD of 4.75"<br />

Sweet Spot / Energy Output Optimum RPM<br />

Sweet Spot:<br />

<strong>The</strong>se motors can be made to run at very high rates of speed and it was<br />

originally thought that the higher speeds were beneficial. According to<br />

my source, the higher speeds are not desirable and he recommended a<br />

sweet spot for this motor of 1820 rpm for optimum energy output.<br />

Golden Ratio

You've probably heard it said that the original <strong>Adams</strong> <strong>Motor</strong> was a<br />

golden ratio motor. Well, the golden ratio does not apply to this motor.<br />

Heat Protection<br />

Quote:<br />

Originally Posted by sucahyo<br />

I would love to read any of Dr <strong>Robert</strong> <strong>Adams</strong> work .<br />

Maybe a hint of what sacred geometric structure, how he can transfer<br />

heat from transistor and coil, how his motor do not heat up while<br />

generating many heat.<br />

Hi Sucahyo,<br />

<strong>The</strong> thermo motor was plagued by the heat problem like everyone<br />

else, so he found a simple way to overcome it. According to my<br />

source, they used the largest heat sinks they could find and stacked<br />

them. <strong>The</strong>y used as many of them as necessary to protect his<br />

sensitive electronics such as but not limited to mosfets and such.<br />

When people were shown a working unit, great care was taken to<br />

conceal some important details. Wiring was always disconnected and<br />

the alloy plugs removed.<br />

More Voltage

Quote:<br />

Originally Posted by sucahyo<br />

From what I recall, he mention that while the generator produce heat, the<br />

rotor is cool?<br />

In term of efficiency, I also read somewhere that more input voltage give<br />

more efficiency.

Hi Sucahyo,<br />

Yes, to get high efficiency required fairly high input voltages. For<br />

instance, for a 10 KW unit with a 6" rotor and (4) (7/8"X1")<br />

neodyne magnets 360 volts DC was found to be very efficient<br />

operating voltage while 720 volts DC was found to be better. <strong>The</strong>se<br />

particular voltages were appreciated since they could be chopped<br />

into 240 volts sine wave without the need for a setup transformer in<br />

the conversion to household AC.<br />

Your Question:<br />

From what I recall, he mention that while the generator produce<br />

heat, the rotor is cool?<br />

Response:<br />

On the earlier non thermal motors the complete setups ran cool. On<br />

the later thermo units, there was a lot of heat generated but many of<br />

the prototype rotors were made from wood products so you may be<br />

right about the rotor running cool. I don't have the answer to this<br />

question.<br />

<strong>The</strong> large stacked heat sinks protected the mosfets and other<br />

sensitive electronics, and then there were other tricks too. Water was<br />

pumped through each core which caused the generation of extremely<br />

high heat temperatures and so each stator core coil assembly was<br />

bathed in oil to prevent the coils from overheating. Each coil was<br />

encased in a copper tube assembly full of oil to help prevent<br />

overheating of the coils.<br />

More info to be released shortly. I'm in the process of trying to<br />

summarize some notes.

Tuning Fun<br />

This motor is going to be especially fun to tune properly, since the two<br />

drive stators are also the pickup coils. So, the equipment we choose to<br />

run our setup such as but not limited to usb rotory encoder device will<br />

have to be programmed to send electricity to the stators at a specific time<br />

interval then be ready to receive high voltage from the coils at another<br />

interval. As I said earlier there is a sweet spot of 1820 rpm @ 60 hz run<br />

speed. I forgot to mention the 60 hz before. <strong>The</strong>re are also some other<br />

sweet spots which were kept a secret from us. We have no idea what they<br />

were and/or what they were related to.<br />

So, this motor is not without its complexities and it holds many secrets<br />

which hopefully we will be able to tap into and understand later on<br />

Wire Resistance<br />

When winding coils, it's all about the resistance. On the older four coil<br />

motors 36 ohms/coil was required for a total overall resistance of 144<br />

ohms for all four coils. Well, now we are using two coils instead of four<br />

and the total resistance required has not changed. Soooo?<br />

Many replicators failed to follow this rule of thumb in the past and so<br />

their motors did not produce positive results and they then blamed the

inventor and said he was a fraud.<br />

Due To Lack of Interest<br />

Due to Lack of Interest<br />

<strong>The</strong>re appears to be a serious lack of interest in this thread, so the rest of<br />

the information will not be posted here. Thanks!!<br />

Firing Stator<br />

When firing the stators, it's very important to only fire a stator on one<br />

side of the magnet at a time. What we have in this particular setup is a<br />

rotor with stators on both sides of the magnet. We have two stators, one<br />

on the north pole side and one on the south pole side of the rotor. <strong>The</strong><br />

stators are separated by one another by 180 degrees. This is a very<br />

important aspect also. After experimenting with many different<br />

prototypes and setups, the inventor discovered that two stator/pickup<br />

coils were much more efficient than any other combination. He was also<br />

able to achieve OU to a much higher level and figures from his later<br />

machines were never published because they were so high.<br />

Summary:<br />

1) Fire stators on only one side of the magnet at a time!!<br />

2) Number of stator/pickup coils is two. Stator and pickup coil are the<br />

same coils!!

3) Have one stator on North pole side and the other on South pole side of<br />

the rotor.<br />

4) Make sure all north poles are on the same side of the rotor.<br />

5) Make sure stators are located 180 degrees apart from one another on<br />

opposite sides of rotor.<br />

<strong>The</strong>rmo <strong>Motor</strong> Housing & Rotor

<strong>The</strong> thermo motor housing is very unique from several aspects. It can be<br />

made out of wood products and this is true with the rotor also. Many of<br />

the prototypes used wood products but if wood products are used care<br />

must be taken to either choose water proof wood products or seal your<br />

wood products so they are not affected adversely by water conditions.<br />

Perspex and other plastics can also be used. It is important to use non<br />

magnetic screws such as stainless steel and/or brass where possible for<br />

best results. Also, the drive shaft and rotor mount bracket should also be<br />

made of non magnetic materials such as but not limited to brass or<br />

stainless. <strong>The</strong> structure of the motor housing is like an open ended box.<br />

It's a complete box type structure with only one side open. <strong>The</strong> rationale<br />

for this design was not imparted to me. Anyway, it's a plain easily made<br />

structure that supposedly works very well. I don't have specific<br />

dimensions of the box, so we'll have to come up with our own size for<br />

that. When building your box, you'll have to keep in mind that your rotor<br />

is 6", (6 inches), in diameter. <strong>The</strong> stator cores are approximately 3.5<br />

inches in length and are mounted through the side of box. You have two<br />

stators, one on each side of the rotor, so this will give you a frame of<br />

reference for the size of your box. You also need to keep in mind that this<br />

is a water motor and will need to be serviced from time to time with<br />

respect to water connections and proactive leak policing, so you must<br />

make the box a size that will allow you easy servicing of your internal<br />

parts. I would suggest a box where the closed end opposite the open end<br />

of the box can be removed fairly easily for servicing. Of course the other<br />

ends of the box will have to be permanently fixed for obvious reasons.<br />

Rotor needs to be made out of 1 inch thick material.<br />

Material used for box must be at least 3/4 inch in thickness. One inch<br />

would be better.<br />

Remember this motor has the capability of running in excess of 5,000

pm, so the housing must be very firm and stable indeed.<br />

Stator Core<br />

<strong>The</strong> stator core is 3/4 inch in diameter and at least 3.5 inches in length. It<br />

needs to be a one piece core made out of pure iron with as little carbon in<br />

it as possible. No alloys should be in it. This is a water core system, so<br />

there will need to be a 3/8 inch hole drilled through the center of the core<br />

from one end to approximately 3/4 of an inch from the other end of the<br />

core. A 9/16 inch hole then needs to be drilled through the side at the<br />

closed end of the core to meet up with the 3/8 inch hole through the<br />

center of the core. Both holes need to be tapped for water fittings. Prior<br />

to drilling the holes, a taper needs to be added to the core on the end that<br />

will mate up with the magnet. <strong>The</strong> end of the core that will correspond<br />

with the magnet needs to be true, flat, and polished. <strong>The</strong> magnet contact<br />

end of the core must be taper leaving the flat end approximately 1/2 the<br />

diameter of the magnet. <strong>The</strong>re is some sort of vortex aetheric force<br />

allowed at the tip of the core by configuring it in this manner. This is a<br />

very important aspect!!<br />

Also, the outside tapped end of the core needs to be threaded for magnet<br />

gap adjustment. If you are going to have the stator sticking through your<br />

housing, you might want to consider adding the thickness of your box to<br />

the overall length of your stator core. Otherwise, you may have a stator<br />

core that is to short. You might also want to place your core in the box<br />

and figure the optimum point for your side hole on your core before<br />

drilling it. You can mark the optimum point for drilling and drill it later.<br />

Otherwise you may have located the hole such that it may not line up<br />

properly with where you wanted it to connect with your copper water

tubing.<br />

Coil<br />

<strong>The</strong> coils need to be wound with a 3/4 inch open center to accommodate<br />

the stator core later. <strong>The</strong> approximate size of the coil is 2 inches X 2.25<br />

inches. One of the coils needs to be wound clockwise while the other<br />

needs to be wound counter clockwise since one is on the South pole of the<br />

magnet and the other is on the North pole. Bear in mind that we don't<br />

know if this is a repulsion situation or an attraction situation. This was<br />

another secret kept from us. So, experimentation must be done with both<br />

and utilize the method that produces the best results. It is thought by<br />

someone that repulsion was his method of choice and that may well be<br />

the case. <strong>The</strong> type of wire needed is .5 and that is probably a metric<br />

designation since it is a designation from New Zealand. Also, when<br />

winding your coils remember that it's not the number of winds but the<br />

resistance that counts. So, check for resistance on your coil while winding<br />

it.<br />

Bobbins<br />

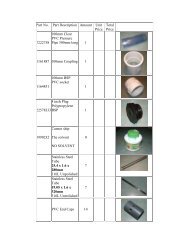

<strong>The</strong> bobbins are very easy to make from pvc pipe and use 1/4" ABS<br />

plastic sheet for your sideboards. I use the thinnest pvc pipe available<br />

and then cut the ABS side boards out of my flat sheet with a adjustable<br />

hole saw. I cut them about 1/4" wider than I want them to be and turn<br />

them down to the right specifications later on a lathe. I then drill the<br />

holes in the side board disks to the right size with a compound bit. <strong>The</strong><br />

pvc pipe fits snugly into the hole in the disk. I also use super glue to<br />

permanently affix the sideboards to the pvc pipe.

Anyway I forgot to mention that the inside diameter of the pvc pipe is 3/4<br />

inch, so it fits right over the outside of the stator core perfectly nice.<br />

Balanced<br />

<strong>The</strong> rotor needs to be perfectly balanced and also the drive shaft needs to<br />

be perfectly true as well because the stator cores are going to be almost<br />

right on the rotor. <strong>The</strong>refore if the shaft is bent and/or the rotor is not<br />

balanced perfectly the stator and rotor will hit each other. Also, this<br />

motor has the potential of turning at some serious speeds in excess of<br />

5,000 rpm, so if it's out of balance it would be very problematic to say the<br />

least. So, pick your drive shaft wisely and make sure it's true; Drill your<br />

rotor perfectly through dead center and make sure it's balanced<br />

perfectly. You need to make sure that you drill your eight holes in exactly<br />

the proper place also or the rotor will be off balance. <strong>The</strong>re is absolutely<br />

no room for any wobble on this rotor!! You need to make sure the depth<br />

of your magnets and alloy inserts are proper too so that nothing is<br />

sticking out to snag a stator. Also, you need to be very careful when<br />

machining your alloy inserts to make sure each of them is true and the<br />

same weight or you'll have an offbalance condition just from that. Some<br />

guy reported his machine was turning at 10,000 rpm and that leaves no<br />

margin for error.<br />

Interconnected Stators<br />

<strong>The</strong> stators are interconnected to one another via copper tubing. <strong>The</strong>re is<br />

a water reservoir and water is continuously circulated through each of<br />

the two stators via a water pump and the attached copper tubing. Each<br />

of the two stators have a water inlet hole at the back and a water outlet

hole 3/4 of an inch from the magnet contact point on the front side of the<br />

stator.<br />

Magnet Size<br />

Very good results were achieved with 3/4" X 1" magnets. Some of the<br />

later motors used 7/8" X 1".<br />

When using 3/4" magnets, the stator should be 1/2 the diameter of the<br />

magnet.<br />

When using magnets exceeding 3/4" in diameter the stator should be<br />

tapered to 3/4 of the diameter of the magnet.<br />

Purpose of Water Use?<br />

Water Serves 2 Purposes:<br />

#1) Water takes the massive aetheric heat buildup away from the the<br />

cores and<br />

coils.<br />

#2) Water takes on a massive electrical charge itself and acts as the<br />

magnetic conductor between the north and south poles of the magnets.<br />

My Gut<br />

Quote:

Originally Posted by Slovenia<br />

Very good results were achieved with 3/4" X 1" magnets. Some of the<br />

later motors used 7/8" X 1".<br />

When using 3/4" magnets, the stator should be 1/2 the diameter of the<br />

magnet.<br />

When using magnets exceeding 3/4" in diameter the stator should be<br />

tapered to 3/4 of the diameter of the magnet.<br />

My gut tells me to go with 1/2 the magnet face diameter for the<br />

tapered tip of the stator core. I feel this is very important.<br />

Magnet Suggestion<br />

For my money, I would suggest that the 3/4" X 1" neodyne magnets<br />

should be more than adequate. Great results were achieved with this<br />

particular size of magnet. <strong>The</strong> inventor was very happy with this<br />

particular size of magnet.<br />

Strange Phenomena<br />

Some of the later motors exhibited some other strange characteristics.<br />

<strong>The</strong>y displayed the characteristic of becoming weightless. Yes, on several<br />

occasions the motors became weightless and went airborne. On at least<br />

one occasion it was reported that the motor went all the way to the<br />

ceiling at which point it disconnected from its power source and fell to<br />

the floor. I had never heard this reported before with reference to these<br />

types of motors.

Easy Drive Shaft Configuration<br />

I used a 1/2 inch threaded 304L stainless steel rod for my drive shaft. I<br />

studied the option of mounting a hub onto the side of my rotor, but was<br />

unable to find the right type available for my needs and didn't want to<br />

have to machine one from scratch. So, I was looking for expedient<br />

options and found one which is not ideal but will work well for a<br />

prototype. <strong>The</strong> 1/2 inch threaded rod is what I finally arrived at for a<br />

prototype motor. It is a much easier and cheaper method. You still need<br />

two large stainless washers so that you can have a washer on each side of<br />

the rotor. You then need four stainless steel nuts, so that you can force<br />

the washers tightly in place to the side of the rotor. <strong>The</strong> second nut on<br />

each side will enable you to lock the nuts in place. I would also use<br />

Locktite to ensure your nuts don't loosen when the rotor is spinning at a<br />

high rpm. I utilized a brass spacer sleeve on each end of the machine<br />

where the threaded rod came in contact with the roller bearings. <strong>The</strong><br />

sleeve travels a lot more smoothly against the rollers than did the<br />

threaded rod. For roller bearings I'd choose fairly large round ball<br />

bearings and not needle bearings. <strong>The</strong> needle variety are terrible for this<br />

application. Anyway, the bronze sleeve needs to be locked in place with a<br />

nut on the inside of the motor housing on both ends. You want to use a<br />

locking sleeve stop on the outside of the motor housing on both ends of<br />

the threaded rod. <strong>The</strong>n tighten your inner two nuts against the bronze<br />

sleeve forcing it against the outer locking sleeve. This works very well.<br />

As far as the usb rotary encoder, I have no idea how to apply it to my<br />

needs yet. I'm waiting for further feedback from my engineering friend.

I'll share more when I have it.<br />

Secret Alloy<br />

Material Fishing Sinkers Are Made Of. You want the pure stuff, (i.e.: no<br />

alloys added to it)!!<br />

You'll need four plugs made from this material and they need to be the<br />

exact size of your magnets and perfectly balanced so as not to throw off<br />

the balance of your rotor. <strong>The</strong>y need to be the exact length of one another<br />

and the exact width of one another.<br />

Energy Storage<br />

<strong>The</strong> inventor preferred high voltage industrial type capacitors. <strong>The</strong>y<br />

worked exceptionally well for him. <strong>The</strong>se of course are very expensive<br />

and potentially very dangerous.<br />

Other folks using his setups are using battery banks to capture the<br />

energy and store it. <strong>The</strong>se work very well also and are somewhat<br />

expensive too if you buy good ones. It's my understanding that only one<br />

bank of batteries is necessary for this type motor.<br />

<strong>The</strong>re are many differing rules of thumb out there.<br />

Anyway, when you are using a battery bank there is a proper protocol to<br />

use to ensure the most efficient use of the storage system and it was never

made clear to me. This is a very important aspect to get right also. So,<br />

maybe some of the experts will shed some more light in this area.<br />

Also, with this particular system we are generating very hot water and if<br />

we don't cool it before recirculating it through the system, we can easily<br />

make steam which can also be utilized for running a steam generator or<br />

something else. We can always use the hot water for taking a shower.<br />

This is a very good unique system.<br />

Self Runner<br />

This machine was reported to be a self runner. It took the mains to get it<br />

started of course, but once it was going it generated a lot more energy<br />

than was needed to run it.<br />

Armor Board<br />

Armor board is used by some to build this particular motor. Armor<br />

board is a very expensive particle board type board. It has some very<br />

interesting characteristics, but the only characteristic we are interested<br />

in is the fact that it is waterproof. Armor board is relatively hard to<br />

machine but when machined properly makes a very good rotor. It also is<br />

a great material to use for the frame of the motor. Marine plywood<br />

would of course also be okay for use on the frame but not for the rotor.<br />

Plywood is not a good option for the rotor since in many cases there are<br />

voids within the plywood that make it almost impossible to balance<br />

properly. So, armor board is a very good choice for the rotor. Particle<br />

board will work nicely until you spring a leak with this water motor

system and that is very likely indeed. So, remember to use only<br />

waterproof materials when fabricating your motor housing and rotor.<br />

Also remember not to use any metals within the framework and/or rotor<br />

other than brass or stainless steel. Don't use any aluminum since it does<br />

exhibit some very strange magnetic phenomenon that are undesirable.<br />

<strong>The</strong> undesirable phenomenon were not shared with me.<br />

Metric Wire Sizes Given<br />

Quote:<br />

Originally Posted by Slovenia<br />

I do know that <strong>Adams</strong> recommended .5 wire size for the 1050 KW motors<br />

and .35 for anything less than that.<br />

<strong>The</strong> wire sizes given were in mm, so .5mm for 10 KW 50 KW<br />

motors and .35mm for anything less than 10 KW. One chap uses .<br />

4mm and says he's not getting good results.<br />

I imagine that the wire size is not the problem in this case. <strong>The</strong>re is<br />

little margin for error in the tuning of this device!! If tuned<br />

improperly you just won't see good results.<br />

Piggybacked Rotor Systems

It's my understanding that these separate rotor systems can be<br />

piggybacked into multiple rotor systems for much more power output,<br />

something like the Harold Aspden systems but not the same really. No<br />

particular detail was given in this area. Anyway, if you look at Harold<br />

Aspden's multirotor systems it might give you some ideas about how<br />

these rotors could be assembled into a multiple high output<br />

arrangement.<br />

Recap on Core Material<br />

Use pure iron if possible for your core material.<br />

<strong>The</strong> lead plugs referred to are something entirely different. <strong>The</strong> lead<br />

inserts go between the magnets in the rotor. <strong>The</strong>re are (8) holes in the<br />

rotor and every other hole is for a magnet. the remaining holes in the<br />

rotor are for the lead plugs. <strong>The</strong> lead plugs are the exact same size as the<br />

magnets and must be perfectly balanced or they will throw the balance of<br />

the rotor off. <strong>The</strong> balance of the rotor is a critical factor because the air<br />

gap between the magnets and the cores is only .040. <strong>The</strong>re is no<br />

allowance for rotor wobble here.<br />

Recap on Coil Location<br />

<strong>The</strong> north and south poles of all the magnets are utilized in this motor.<br />

<strong>The</strong>re is a core coil assembly on the north pole side of the rotor and (1)<br />

core coil assembly on the south pole of the magnet. Both of the

electromagnet assemblies are separated by 180 degrees. This is also<br />

critical.<br />

<strong>The</strong> north poles of the magnets are all on the same side of the rotor. All<br />

the south poles of the magnets are on the other side of the rotor.<br />

<strong>The</strong>re were some misunderstandings, so that is why I'm recapping!!<br />

24 AWG Wire<br />

Quote:<br />

Originally Posted by eternalightwithin<br />

10kW50kW<br />

24AWG<br />

Thanks!!<br />

Yes, 24 awg wire is the right wire to use for the 1050 KW machines<br />

& 27 awg for machines less than that.<br />

.5mm 10KW and higher machines<br />

.35mm Less than 10KW machines<br />

Conversion Site:<br />

AWG to Metric Conversion Chart

Recap on <strong>Motor</strong> Housing & Rotor<br />

Use only nonconductive material for housing and/or rotor.<br />

Remember the water proof aspect!!<br />

Drive shaft and hub need to be either brass or non magnetic stainless.<br />

Don't use any aluminum either on the rotor or in the motor housing!!<br />

Someone needed clarification.<br />

Magnets<br />

Remember we are using both sides of the magnets with this motor. This<br />

particular aspect is what allows this motor to be extraordinary. <strong>The</strong><br />

water conduit between the north and south poles of the magnets is also of<br />

great importance.<br />

Remember that the stators have to be separated from one another by 180<br />

degrees and also that they are on opposite sides of the rotor!! Also, you<br />

only have (2) stators with this machine and those (2) stators also act as<br />

the generator coils too.

Coil Winding Direction<br />

This is also very important!! One of the coils is left wound while the<br />

other is right wound. I was told which goes with north and which goes<br />

with south pole magnets, but I am unable to find those particular notes.<br />

Anyway, it is thought that <strong>Adams</strong> used repulsion in these particular<br />

motors, so we want to repel the magnets with our stators and not attract<br />

them. Anyway, I'll continue to look for those notes because it is<br />

paramount that we wind the coils the proper direction or the exercise is<br />

futile.<br />

<strong>The</strong> north pole magnet side coil is wound one direction while the south<br />

pole magnet side coil is wound the opposite direction.<br />

I'll try to find the proper particulars and get back to you.<br />

Coil Winding Direction (Clockwise & Counterclockwise)<br />

Quote:<br />

Originally Posted by Slovenia<br />

This is also very important!! One of the coils is left wound while the other<br />

is right wound. I was told which goes with north and which goes with<br />

south pole magnets, but I am unable to find those particular notes.<br />

Anyway, it is thought that <strong>Adams</strong> used repulsion in these particular<br />

motors, so we want to repel the magnets with our stators and not attract<br />

them. Anyway, I'll continue to look for those notes because it is<br />

paramount that we wind the coils the proper direction or the exercise is<br />

futile.

<strong>The</strong> north pole magnet side coil is wound one direction while the south<br />

pole magnet side coil is wound the opposite direction.<br />

I'll try to find the proper particulars and get back to you.<br />

I'm unable to find the notes referring to which coils are wound<br />

which way, but I woke up the other night after much thought and<br />

I'm pretty sure I was told to wind the coil on the stator facing the<br />

north pole magnet clockwise and to wind the coil on the stator facing<br />

the south pole magnet counter clockwise. This may or may not be<br />

right, but I feel it is right.<br />

Water Lines<br />

Water lines inside motor housing that conduct water from the outlets of<br />

both stators need to be located on the outside front of each stator for easy<br />

maintenance. If you spring a water leak you don't want to yank the back<br />

of your housing off. You want to be able to get in there fast and correct<br />

your problem with minimum effort and minimum frustration.<br />

Anyway, as stated earlier in the thread, the motor housing is a box with<br />

the front end of the box open. This is a square box, so the bottom, top,<br />

back, and sides of the box are the same exact dimensions. For now I'll let<br />

you choose your own dimensions. You should have a pretty good idea<br />

from the diagrams how it must be done.<br />

<strong>The</strong> water lines come out the side of the stators approximately 3/4" from<br />

the end of the stator core facing the magnet. You can make the back of

the stator core a long as you need. Allow for gap adjustment. Remember<br />

that the coil is 2.25" X 2".<br />

Water Pump Scenario:<br />

You need to have a water reservoir and a pump to circulate water from<br />

the reservoir to the cores and then back to the reservoir for recirculation.<br />

You can pull off any hot water you want to use from the reservoir for<br />

other needs if you like. If you are not going to utilize the hot water for<br />

anything, you need to find a way to cool it down before recirculating it<br />

back through the stators.<br />

Drive Shaft Diameter<br />

It's a good idea to make the drive shaft 3/4" diameter but if you choose to<br />

make it less you probably shouldn't make it less than 1/2" diameter. <strong>The</strong><br />

length of the shaft is up to you. Depending on your timing mechanism,<br />

you may want it longer or shorter than I might prescribe. So, I'll leave<br />

that up to you.<br />

Shaft Collars:<br />

Use shaft collars on the outside of both bearings on the outside of the<br />

motor housing, to keep the shaft from having any side movement. This<br />

will prevent your stator cores and magnets from getting together at 3,000<br />

rpm.