Untitled - COMEVAL

Untitled - COMEVAL

Untitled - COMEVAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Unival® BUTTERFLY VALVES<br />

Index<br />

Data Sheets Manual<br />

Engineering Data 4-9<br />

General Design Considerations 10-11<br />

Flow Data 12-13<br />

Seats - Application Guide 14<br />

Valve Coding 15<br />

Attributes of Design - Wafer Series 700 16<br />

Parts and materials - Wafer Series 700 17<br />

Dimensions - Wafer Series 700 DN32-600 18<br />

Dimensions - Wafer Series 700 DN700-1200 19<br />

Attributes of Design - Wafer Series 701 20<br />

Parts and materials - Wafer Series 701 21<br />

Dimensions - Wafer Series 701 DN40-300 22<br />

Dimensions - Wafer Series 701 DN350-600 23<br />

Attributes of Design - Lug Series 750 24<br />

Parts and materials - Lug Series 750 25<br />

Dimensions - Lug Series 750 26<br />

Assembling Set 27<br />

Attributes of Design - U Type Series 7U 28<br />

Parts and Materials - U Type Series 7U 29<br />

Dimensions - U Type Series 7U 30<br />

Attributes of Design - Double Flange Series 790 31<br />

Parts and Materials - Double Flange Series 790 32<br />

Dimensions - Double Flange Series 790 33<br />

Grooved Ends Butterfl y Valves 34<br />

Attributes of Design - Grooved Ends Series 760 35<br />

Parts and Materials - Grooved Ends Series 760 36<br />

Dimensions - Grooved Ends Series 760 37<br />

Attributes of Design - Double Eccentric Series 791 38<br />

Parts and Materials - Double Eccentric Series 791 39<br />

Dimensions - Double Eccentric Series 791 40<br />

Triple Eccentric Butterfl y Valves (Under construction)<br />

Actuation and Accessories 41-44<br />

Torque Values for Actuators Sizing 45<br />

Pneumatic Actuators 46-54<br />

Parts and Materials - With Pneumatic Actuator - Wafer Series 700 55<br />

Dimensions - With Pneumatic Actuator - Wafer Series 700 56<br />

Parts and Materials - With Pneumatic Actuator - Lug Series 750 57<br />

Parts and Materials - With Pneumatic Actuator - Lug Series 750 58<br />

Dimensions - With Pneumatic Actuator - Lug Series 750 59<br />

Electric Actuators 60-68<br />

Parts and Materials - With Electric Actuator - Wafer Series 700 69<br />

Dimensions - With Electric Actuator - Wafer Series 700 DN32-600 70<br />

Parts and Materials - With Electric Actuator - Lug Series 750 71<br />

Dimensions - With Electric Actuator - Lug Series 750 72<br />

Installation, Start-Up and Maintenance 73-76<br />

Material Selection Guidance 77-83<br />

Data subject to change without prior notice<br />

3

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Data Sheets Manual<br />

Equivalent DIN / ANSI Material Designation for Cast Valve Material<br />

DIN Nº Material AISI / ASTM<br />

GG20 - EN JL 1030 - EN GJL 200 0.5020 A48 30B<br />

GG25 - EN JL 1040 - EN GJL 250 0.5020 A48 40B<br />

GGG40 - EN JS 1030 - EN GJS 400-15 0.7040 60-40-18<br />

GGG40.3 - EN JS 1020 - EN GJS 400-18 0.7043 -<br />

GGG50 - EN JS 1050 - EN GJS 500-7 0.7050 65-45-12<br />

Specifications of Carbon Steel, Stainless and Exotic Materials acc. ASTM Standards<br />

Material<br />

Specification<br />

FORGED CARBON STEEL ASTM 105<br />

CAST CARBON STEEL<br />

ASTM A216WCB<br />

LOW TEMPERATURE CARBON STEEL(ALLOY) ASTM A352 LCB ASTM A352 LCC<br />

CARBON STEEL(ALLOY) CrMo<br />

ASTM A217 WC6<br />

LOW ALLOY CARBON STEEL<br />

ASTM A487 Gr4N ASTM A487 Gr4C<br />

STAINLESS STEEL. 410<br />

ASTM A217 CA15<br />

STAINLESS STEEL. 9%Cr<br />

ASTM A217 CA12<br />

STAINLESS STEEL. 13%Cr<br />

ASTM A352 CAGNM<br />

HASTELLOY® C276<br />

ASTM A494 CWRMN<br />

MONEL ASTM A494 M35-2<br />

BRONZE ALUMINIUM-NIKEL<br />

ASTM B148 GrWC9<br />

STAINLESS STEEL 316<br />

ASTM A 182 F 316 A 351 CF8M<br />

STAINLESS STEEL 316<br />

ASTM A 182 F 316L A 351 CF3M<br />

STAINLESS STEEL 347 (HIGH TEMPERATURE)<br />

ASTM A 351 CF8C<br />

STAINLESS STEEL 304<br />

ASTM A 351 CF8<br />

STAINLESS STEEL 304 L<br />

ASTM A 351 CF3<br />

STAINLESS STEEL 317<br />

ASTM A 351 CG8M<br />

ALLOY 625<br />

ASTM A 494 CW6MC<br />

AVESTA 254 5Mo®<br />

ASTM A351 CK3M CaN<br />

TITANIUM<br />

ASTM B367 C2<br />

Data subject to change without prior notice<br />

4

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Data Sheets Manual<br />

New Harmonized European Face to Face Length Standards / Standardized Face to Face Lengths<br />

The following tables provide the equivalent length specification standard in accordance with the European Harmonization which<br />

came into effect from May 2002 (PED).<br />

New European Material Standardization (DIN VALVES)<br />

Material EN (New Harmonization) DIN (Old)<br />

Cast iron<br />

Ductile<br />

Ductile<br />

Cast steel<br />

Stainless steel<br />

EN-GJL-250 DIN EN 1561<br />

EN-GJS-400-15 DIN EN 1563<br />

EN-GJL-400-18 DIN EN 1563<br />

1.0619+N DIN EN 10213-10-2<br />

1.4408 DIN EN 10213-4<br />

GG25 DIN 1619<br />

GGG40 DIN 1693<br />

GGG40.3 DIN 1693<br />

GSC25N DIN17245<br />

1.4408 DIN 17445<br />

New standards will be of obligatory application from may 2002 when the New European<br />

Directives for pressure vessels come into effect.<br />

These standards also affect other parameters habitualy used in this catalogue like construction lengths:<br />

FACE TO FACE<br />

EN DIN REF: For Valves<br />

CONSTRUCTION DIN EN 558-1 LINE1 DIN 3202 F1 GLOBE,DIAPHRAGM, REGULATING<br />

LENGTH DIN EN 558-1 LINE14 DIN 3202 F4/F5 BALL GATE<br />

(*) WAFER BUILT UNPUBLISHED IN THIS VOLUME (ASK FOR EQUIVALENTS FROM OUR TECHNICAL STAFF)<br />

Flanged Valve Constructions Lengths<br />

Size DIN 3202 F1 DIN 3202 F4 DIN 3202 F5 ANSI / BS 5156<br />

DN15 130 115 --- 108<br />

DN20 150 120 --- 117<br />

DN25 160 125 --- 127<br />

DN32 180 130 --- 146<br />

DN40 200 140 --- 159<br />

DN50 230 150 --- 190<br />

DN65 290 170 --- 216<br />

DN80 310 180 --- 254<br />

DN100 350 190 --- 305<br />

DN125 400 --- 325 356<br />

DN150 480 --- 350 406<br />

DN200 600 --- 400 521<br />

DN250 730 --- --- 635<br />

DN300 850 --- --- 749<br />

Wafer Valve Constructions Lengths<br />

Size DIN 3202 k3 DIN 3202 k4 DIN 3202 k5 API 6D<br />

PN16 PN25 PN40<br />

DN15 --- --- --- 17 25 ---<br />

DN20 --- --- --- 20 --- ---<br />

DN25 --- --- --- 23 35,5 ---<br />

DN32 --- --- --- 28 --- ---<br />

DN40 --- --- --- 31,5 45 ---<br />

DN50 43 43 43 40 56 20<br />

DN65 46 46 46 46 63 20<br />

DN80 64 64 64 51 71 20<br />

DN100 64 64 64 61 80 20<br />

DN125 70 70 70 --- --- 21<br />

DN150 76 76 76 --- --- 22<br />

DN200 89 89 89 --- --- 29<br />

DN250 114 114 114 --- --- 34<br />

Data subject to change without prior notice<br />

5

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Data Sheets Manual<br />

Pressure / Temperature Chart according to EN 1092-1/2<br />

The following graphs represent the Temperature / Pressure relation for all metal seated valves, strainers and other flow control<br />

products made out in the following pressure retaining shell materials:<br />

-Cast Iron EN-GJL-250<br />

-Ductile Iron EN-GJL-400<br />

-Carbon Steel 1.0619+N<br />

-Stainless Steel 1.4408<br />

-And for Design Pressures up to PN 40.<br />

All products with resilient seat or other components are subject to temperature restrictions governed by these resilient materials.<br />

PN 25 / PN 40<br />

PN 16 / PN 25<br />

PN 6 / PN 16<br />

bar<br />

40<br />

35<br />

30<br />

25<br />

20<br />

16<br />

15<br />

10<br />

6<br />

5<br />

GS-C25 N<br />

up to 400ºC<br />

GGG-40.3<br />

up to 350ºC<br />

GG-25<br />

up to 300ºC<br />

40<br />

6<br />

21<br />

16<br />

(1)Graphic section. Valve metal/metal sealing, construction DIN for pressure ratings<br />

PN6-40.Cast iron construction material GG25, spheroidal casting GGG40.3, carbon<br />

steel GSC25N and stainless steel casting 1.4408.<br />

35<br />

20<br />

ºC<br />

-10 120 250 350<br />

0 100 200 300 400<br />

22<br />

13<br />

32<br />

28<br />

5 5<br />

17<br />

16 13<br />

24<br />

15<br />

16<br />

10<br />

40<br />

35<br />

30<br />

25<br />

20<br />

21<br />

15<br />

10<br />

5<br />

40<br />

PN 40<br />

PN 25<br />

PN 16<br />

bar<br />

35<br />

40<br />

Stainless steel G-X6 Cr Ni Mo 1810<br />

Temp. range. -60ºC up to +400ºC<br />

40<br />

35<br />

30<br />

32,5<br />

30<br />

25<br />

20<br />

16<br />

15<br />

10<br />

6<br />

5<br />

25<br />

16<br />

-60 -40 -20 0 20 50 150<br />

100 200<br />

20<br />

13<br />

28,5<br />

17,5<br />

Data subject to change without prior notice<br />

12<br />

25<br />

15,5<br />

10<br />

23<br />

14,5<br />

9,5<br />

250<br />

25<br />

20<br />

21<br />

15<br />

13 10<br />

8,5<br />

5<br />

ºC<br />

300<br />

400<br />

(1) For valves with elastic closing plugs or PTFE<br />

Notes: Check maximum recommended temperatures for elastomers as defi ned by each product’s specifi cation (see fi le).<br />

(2) In those cases where there might occur some minor deviation or discrepency between the specifi c chart curves represented in each data sheet and the ones<br />

seen herein, generally, the product version should take precedence.<br />

6

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Data Sheets Manual<br />

Dimensional Table for DIN Standard Flanges<br />

PN10<br />

PN16<br />

DIN Inchs ØD Øk Ød n ØD Øk Ød n<br />

10 3/8” 90 60 14 4 90 60 14 4<br />

15 1/2” 95 65 14 4 95 65 14 4<br />

20 3/4” 105 75 14 4 105 75 14 4<br />

25 1” 115 85 14 4 115 85 14 4<br />

32 1 1/4” 140 100 18 4 140 100 18 4<br />

40 1 1/2” 150 110 18 4 150 110 18 4<br />

50 2” 165 125 18 4 165 125 18 4<br />

65 2 1/2” 185 145 18 4 185 145 18 4<br />

80 3” 200 160 18 4 200 160 18 4<br />

100 4” 220 180 18 8 220 180 18 8<br />

125 5” 250 210 18 8 250 210 18 8<br />

150 6” 285 240 22 8 285 240 22 8<br />

200 8” 340 295 22 8 340 295 22 12<br />

250 10” 395 350 22 12 405 355 26 12<br />

300 12” 445 400 22 12 460 410 26 12<br />

350 14” 505 460 22 12 520 470 26 12<br />

400 16” 565 515 26 16 580 525 30 16<br />

500 20” 670 620 26 20 715 620 33 20<br />

PN25<br />

PN40<br />

DIN Inchs ØD Øk Ød n ØD Øk Ød n<br />

10 3/8” 90 60 14 4 90 60 14 4<br />

15 1/2” 95 65 14 4 95 65 14 4<br />

20 3/4” 105 75 14 4 105 75 14 4<br />

25 1” 115 85 14 4 115 85 14 4<br />

32 1 1/4” 140 100 18 4 140 100 18 4<br />

40 1 1/2” 150 110 18 4 150 110 18 4<br />

50 2” 165 125 18 4 165 125 18 4<br />

65 2 1/2” 185 145 18 4 185 145 18 4<br />

80 3” 200 160 18 4 200 160 18 4<br />

100 4” 220 180 18 8 235 190 22 8<br />

125 5” 250 210 18 8 270 220 26 8<br />

150 6” 285 240 22 8 300 250 26 8<br />

200 8” 360 310 26 12 375 320 30 12<br />

250 10” 425 370 30 12 450 385 33 12<br />

300 12” 485 430 30 16 515 450 33 12<br />

350 14” 555 490 33 16 580 510 33 16<br />

400 16” 620 550 36 16 660 585 36 16<br />

500 20” 730 660 36 20 755 670 39 20<br />

Data subject to change without prior notice<br />

7

Data Sheets Manual<br />

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Dimensional Table for ANSI Standard Flanges<br />

ANSI 150 ANSI 300<br />

DIN Inchs ØD Øg Øk Ød n ØD Øg Øk Ød n<br />

15 1/2” 89 35 60 16 4 95 35 67 16 4<br />

20 3/4” 99 43 70 16 4 117 43 82,5 19 4<br />

25 1” 108 51 79 16 4 124 51 89 19 4<br />

32 1 1/4” 118 64 89 16 4 133 64 99 19 4<br />

40 1 1/2” 127 73 98 16 4 156 73 114 22 4<br />

50 2” 153 92 121 19 4 165 92 127 19 8<br />

65 2 1/2” 178 105 140 19 4 191 105 149 22 8<br />

80 3” 191 127 152 19 4 210 127 168 22 8<br />

100 4” 229 157 191 19 8 254 157 200 22 8<br />

125 5” 254 186 216 22 8 279 186 235 22 8<br />

150 6” 279 216 241 22 8 318 216 270 22 12<br />

200 8” 343 270 298 22 8 381 270 330 25 12<br />

250 10” 406 324 362 25 12 445 324 387 29 16<br />

300 12” 483 381 432 25 12 521 381 451 32 16<br />

350 14” 533 413 476 29 12 584 413 514 32 20<br />

400 16” 597 470 540 29 16 648 470 572 35 20<br />

500 20” 699 584 635 32 20 775 584 686 35 24<br />

Data subject to change without prior notice<br />

8

Data Sheets Manual<br />

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Dimensional Table for BS T. E, F, J, K Standard Flanges<br />

BS / E<br />

BS / F<br />

DIN Inchs ØD Øk Ød n ØD Øk Ød n<br />

15 1/2” 95 67 14 4 95 67 14 4<br />

20 3/4” 102 73 14 4 102 73 14 4<br />

25 1” 114 83 14 4 121 87 18 4<br />

32 1 1/4” 121 87 14 4 133 98 18 4<br />

40 1 1/2” 133 98 14 4 140 105 18 4<br />

50 2” 152 114 14 4 165 127 18 8<br />

65 2 1/2” 165 127 18 4 184 146 18 8<br />

80 3” 184 146 18 4 203 165 18 8<br />

100 4” 216 178 18 8 229 191 18 8<br />

125 5” 254 210 18 8 279 235 22 8<br />

150 6” 279 235 22 8 305 260 22 12<br />

200 8” 337 292 22 8 368 324 22 12<br />

BS / J<br />

BS / K<br />

DIN Inchs ØD Øk Ød n ØD Øk Ød n<br />

15 1/2” 114 83 18 4 114 83 18 4<br />

20 3/4” 114 83 18 4 114 83 18 4<br />

25 1” 121 87 18 4 127 95 18 4<br />

32 1 1/4” 133 98 18 4 133 98 18 4<br />

40 1 1/2” 140 105 18 4 152 114 22 4<br />

50 2” 165 127 22 4 165 127 18 8<br />

65 2 1/2” 184 146 22 8 184 146 22 8<br />

80 3” 203 165 22 8 203 165 22 8<br />

100 4” 229 191 22 8 241 197 25 8<br />

125 5” 279 235 25 8 279 235 25 12<br />

150 6” 305 260 25 12 305 260 25 12<br />

200 8” 368 324 25 12 368 318 29 12<br />

Data subject to change without prior notice<br />

9

Unival® BUTTERFLY VALVES<br />

General Design Considerations<br />

Data Sheets Manual<br />

A butterfl y valve is a type of fl ow control device, typically used to regulate a<br />

fl uid fl owing through a section of pipe. A fl at circular plate (disc) is positioned<br />

in the centre of the pipe. The plate has a rod (shaft) through it connected<br />

to an actuator on the outside of the valve. Rotating the actuator turns<br />

the plate either parallel or perpendicular to the fl ow. Unlike a ball valve, the<br />

plate is always present within the fl ow, therefore a pressure drop is always<br />

induced in the fl ow regardless of valve position.<br />

A butterfl y valve is from a family of valves called quarter turn valves. The<br />

“butterfl y” is a metal disc mounted on a rod. When the valve is closed, the<br />

disc is turned so that it completely blocks off the passageway. When the<br />

valve is fully open, the disc is rotated a quarter turn so that it allows unrestricted<br />

passage. The valve may also be opened incrementally to regulate<br />

fl ow thanks to the gradual interlocking notch.<br />

Butterfl y valves are of simple design, of light weight and volume and very<br />

effective on isolating lines for its quick and safe operation. Most of butterfly<br />

valves design are fl angeless for installation between counter fl anges what<br />

saves space, costs and maintenance.<br />

There are two kind of fl angeless butterfl y valves:<br />

Wafer Style Butterfl y Valves: Wafer style is the more common one and is<br />

lest expensive one. The wafer style butterfl y valve is just about the standard.<br />

It is so common that no one even bothers to use the word “wafer”<br />

when ordering a butterfl y valve. They take it for granted that if they order<br />

a butterfl y valve, they will get a wafer style one. Wafer butterfl y valves are<br />

installed between two fl anges using bolts or studs and nuts. This type of<br />

installation, of course, makes it impossible to disconnect just one side of<br />

the piping system from the valve. That is where the lug style valve comes<br />

in.<br />

Lug Style Butterfl y Valves: Lug style valves are provided with tapered holes<br />

to fi x threaded bolts in. This allows them to be installed into a system using<br />

two sets of bolts and no nuts. The valve is installed between two flanges<br />

using a separate set of bolts for each fl ange. This set-up permits either side<br />

of the piping system to be disconnected without distributing the other side.<br />

Lug Style Butterfl y Valves are used in dead end service and generally have<br />

a reduced pressure rating.<br />

Valves can also be of dual fl anged design; provided with integral flanges<br />

that are ready to be installed between fl anges of the same standard. These<br />

are more bulky valves and usually required for large sizes and other styles<br />

of performance by the position of the shaft. (see next paragraph).<br />

Other kind of valves by its nature of shaft design are as follows:<br />

Concentric Design: This is the most common and simple design. The valve<br />

shaft is concentric to the disc. It is normally a resilient seated valve. Rotating<br />

the handle turns the plate either parallel or perpendicular to the flow of<br />

water, shutting off the fl ow<br />

Double Centric Design: This design features a slight offset in the way the<br />

disc is positioned, which increases the valve’s sealing ability and decreases<br />

its tendency to wear. It is normally used for throttling functions, larger sizes<br />

and / or metal seated valves.<br />

Triple Offset Design: This design is the one offering a highest degree of<br />

performance. The shaft is totally off set from the central axis thus increasing<br />

the ability of the valve disc to close tightly at even high pressure. These<br />

valves are usually metal seated thus being used for high temperature too.<br />

These valves are usually operated by worm gear to achieve a slow closing.<br />

Data subject to change without prior notice<br />

10

Unival® BUTTERFLY VALVES<br />

General Design Considerations<br />

Data Sheets Manual<br />

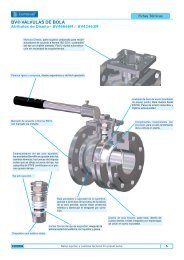

There are some common parts innate to butterfly valves regardless<br />

of its design, brand or materials of construction as follows:<br />

A Body; this is the main framework of the valve which houses the<br />

moving components of the same. It is made of metal and can be of<br />

diverse styles as mentioned above.<br />

B Liner; it is a rubber or plastic circular seat inserted into the body<br />

inner part and can be either vulcanised or made of an insert. The<br />

vulcanised type cannot be removed once assembled whilst the insert<br />

can be replaced at any time. The liner provides the required<br />

tightness to the valve.<br />

C Shaft; it is the rod that drives the disc by rotation. It can be made<br />

of two piece rod (without pin) or a single piece rod (with pin) depending<br />

the way to assemble and disassemble it.<br />

D Disc; It is the plate which is guided by the shaft and blocks or<br />

allows the fluid to pass. It is the closing element of the valve.<br />

E Packing; set of soft goods that provides the atmospheric integrity<br />

to the valve. Usually are provided with a shaft packing in the upper<br />

part and the bottom bush in the lower part.<br />

F Notch plate; it is the metal position indicator and gear locking<br />

fi x on top of the valve neck where the actuator is supported. The<br />

function is locking the actuator in intermediate positions if needed.<br />

G Actuation; it is the component which actions the valve, it may be<br />

a hand lever; usually used for quick action and standard sizes; a<br />

worm gear box; used for slower action and large valve sizes; pneumatic,<br />

electric pr hydraulic actuators; for remote and continuous<br />

operations.<br />

H Name Plate; not innate to the valve design but of equal importance<br />

as it is providing the user all design and working parameters of<br />

the valve. It is normally affixed onto the valve front neck by riveted<br />

aluminium plate.<br />

B<br />

F<br />

H<br />

C<br />

G<br />

E<br />

A<br />

D<br />

Basic Operating and Maintenance Guidelines.<br />

Butterfl y Valves are bidirectional and can also be installed in whatever position being along the horizontal or vertical pipe work<br />

axis. It is recommended to fl ush the pipe work system out with valves fully open before start up. Valves thermal insulation can be<br />

easily carried out thanks to the extended neck design as standard, this makes easier the task to insulate the valves by means<br />

of the aluminium rigid material.<br />

Replaceable seat Butterfl y valves are relatively easy to maintain. The resilient seat is held in place by mechanical means, and<br />

neither bonding nor cementing is necessary, Because the seat is replaceable, the valve seat does not require lapping, grinding,<br />

or machine work. The job can be done at the plant operator by having the adequate tools to carry out this service.<br />

If, otherwise, valves are of vulcanised seat, these have no possibility to be serviced although the low cost of the valve would not<br />

suggest to do it.<br />

The actuation is quickly dismounted and replaced if needed. All valve top works are normally designed to comply with ISO 5211<br />

standard that guides the dimensions to be followed in order to adapt actuators with full versatility.<br />

This engineering manual illustrates all the UNIVAL® range of butterfl y valves, one of the largest portfolios of butterfl y valves presently available<br />

for isolating and regulating duties. It is comprehensive of diverse styles and materials of construction and offers an in-deep study to the superb<br />

design and performance availed by the more than a million units installed all over the world.<br />

Data subject to change without prior notice<br />

11

Unival® BUTTERFLY VALVES<br />

Flow Data<br />

Data Sheets Manual<br />

A valve fl ow coeffi cient represents the standard flow rate which flows through the<br />

valve at a given opening, referred to pre-established conditions:<br />

* Kv value is the volume of water at 20ºC, in cubic meters per hour (m3/h), that will<br />

flow through the valve at a static pressure drop of 1 bar across the valve<br />

* Cv value is the volume of water at 60ºF, in gallons per minute (gpm), that will flow<br />

through the valve at a static pressure drop of 1 psi across the valve<br />

Conversion from Kv to Cv can be roughly calculated by means of the following expression:<br />

Cv = Kv x 1,17<br />

Flow rate through the valve with other liquids can be calculated with the following<br />

expressions (for gases please consult us)<br />

Kv = q (SG / dp)1/2<br />

where<br />

q = water fl ow (m3/h)<br />

SG = specifi c gravity (1 for water)<br />

dp = pressure drop (bar)<br />

Cv = q (SG / dp)1/2<br />

where<br />

q = water fl ow (US gallons per minute)<br />

SG = specifi c gravity (1 for water)<br />

dp = pressure drop (psi)<br />

It is common practice to size the valves on the basis of pipe DN for on off application.<br />

Nevertheless, Butterfl y Valves used for control purpose should be calculated on the<br />

basis of operating conditions.<br />

First step is to calculate the Kv values for the different working conditions and then<br />

choose the DN with such Kv values in the region of 20º to 70º valve opening angle.<br />

As a general guideline, fl ow velocities should under certain limits, so as to avoid<br />

valve excessive noise, vibration and cavitation:<br />

Liquids: < 4,5 m/s; Gases: < 100 m/s<br />

<strong>COMEVAL</strong> Technical Department is at your disposal to help you sizing your system.<br />

Data subject to change without prior notice<br />

12

Unival® BUTTERFLY VALVES<br />

Flow Data<br />

Data Sheets Manual<br />

Size<br />

Opening Angle of the Valve<br />

DN 10º 20º 30º 40º 50º 60º 70º 80º 90º<br />

25 - - 1,5 5 8,3 14 22 33 36<br />

32 - 0,8 1,7 5,3 9,5 16 25 37 41<br />

40 - 1,5 3,5 8 14 23 37 55 61<br />

50 - 2,5 7 14 24 40 64 95 105<br />

65 - 5 11 23 40 67 107 159 176<br />

80 - 9 20 35 61 101 161 240 265<br />

100 - 16 38 78 137 226 360 538 594<br />

125 0,5 26 69 129 219 361 576 860 950<br />

150 0,8 44 105 205 373 617 983 1468 1622<br />

200 1,3 82 205 387 680 1124 1792 2676 2957<br />

250 2,1 138 345 669 1084 1791 2855 4263 4711<br />

300 3,7 210 534 1028 1639 2707 4318 6449 7126<br />

350 5,5 305 750 1326 2347 3878 6184 9236 10205<br />

400 7,4 388 935 1813 3208 5301 8454 12625 13950<br />

450 9,7 550 1212 2370 4193 6929 11049 16500 18232<br />

500 13 658 1595 2981 5275 8716 13900 20758 22937<br />

600 20 962 2246 4431 7919 13083 20864 31158 34429<br />

700 55 1233 2725 5105 9022 14906 23770 35499 39225<br />

800 135 1719 3394 6367 10338 17081 27239 40905 44950<br />

900 180 2475 4731 8631 13691 22620 36072 54165 59525<br />

1000 250 3342 6443 11752 18642 30800 49116 73755 81050<br />

1200 320 4715 8643 15155 24198 39980 63757 95741 105210<br />

Kv<br />

Disc Opening<br />

Data subject to change without prior notice<br />

13

Unival® BUTTERFLY VALVES<br />

Seats - Application Guide<br />

Data Sheets Manual<br />

NBR Butadiene Acrylonitrile (-20ºC) -10ºC ... 75ºC (90ºC)<br />

Lubricating oil, cutting oils, fuel oils, animal and vegetable oils, aviation kerosen, LPG, oily air. Generally resistant to oils and<br />

solvents.<br />

Limited resistance to ozone and wheather.<br />

EPDM Ethylene Propylene Diene (-20ºC) -5ºC ... 120ºC (130ºC)<br />

Salts in water, diluted acids, alkaline solutions, ester, ketones, alcohols, glycols, hot water, intermittent steam, sterilisation<br />

Good resistance to ozone and wheather.<br />

It is attacked by hydrocarbon solutions, chlorinated hydrocarbons and other petroleum based oils.<br />

Viton (FPM) Vinylidenefluoride-hexafluoro-propyleneco-polymer (-20ºC) -10ºC ... 150ºC (180º)<br />

Strong and weak mineral acids, aliphatic hydrocarbons, chlorine gas, oils, aliphatic acids, phosporic acids, ozone, certain<br />

aromatic solvents<br />

Not suitable for hot water, steam and dry heat.<br />

Hypalon (CSM) Chlorosulfonated polyethylene (-20ºC) -10ºC ... 110ºC (130ºC)<br />

Good chlorine and weather resistance. Low resistance to oil and fats<br />

Silicone (-40ºC) -20ºC ... 170ºC (190ºC)<br />

Good wheather resistance. Recommended for hot air applications. Not resistant to mineral oils. Moderate mechanical properties.<br />

PTFE PTFE/EPDM (-20ºC) -5ºC ... 110ºC (120ºC) - PTFE/NBR (-20ºC) -10ºC ... 80ºC (90ºC)<br />

Excellent resistance to chemicals or biopharmaceuticals, strong acids and solvents, alkalies and salts in water. Excellent<br />

resistance to weather.<br />

FEP -20ºC ... 120ºC (130ºC)<br />

Similar properties to PTFE but more translucent and with lower porosity, so most suitable for concentrated mineral acids,<br />

aromatic, aliphatic and chlorinated solvents.<br />

PFA -20ºC ... 180ºC (190ºC)<br />

Similar to FEP but with smoother surface texture and for higher continuos service temperatures.<br />

Breaf Peak Temperature<br />

Working Temperature<br />

Temperature ranges given just for reference.<br />

Body pressure-temperature rating also to be considered for valve selection.<br />

Please consult our Technical Department for a particular application.<br />

Data subject to change without prior notice<br />

14

Unival® BUTTERFLY VALVES<br />

Valve Coding<br />

Data Sheets Manual<br />

V F 7 0 0 P X/Y X/Y X/Y 0 0 0 5 0<br />

VF = UNIVAL<br />

BUTTERFLY VALVE<br />

IDENTIFICATION<br />

050 = Valve size DN50<br />

100 = Valve size DN100<br />

700 = WAFER TYPE CARTRIDGE SEAT<br />

701 = WAFER TYPE WITH EDGE-BOOT SEAT<br />

751 = LUG TYPE WITH EDGE-BOOT SEAT<br />

750 = LUG TYPE WITH BACK SEAT<br />

760 = GROOVE END TYPE<br />

790 = DOUBLE FLANGE TYPE<br />

7U = U-TYPE<br />

791 = DOUBLE ECCENTRIC TYPE<br />

00 Special Requirements<br />

P = WITH LEVER<br />

R = WITH WORM GEAR<br />

B = BARE SHAFT<br />

XXX<br />

G* = DISC IN DUCTILE IRON GGG40<br />

I* = DISC IN ST. STEEL AISI316<br />

B* = DISC IN AL-BZ<br />

F* = DISC COATED FEP<br />

P* = DISC COATED PFA<br />

*E* = SEAT IN EPDM<br />

*N* = SEAT IN NBR<br />

*V* = SEAT IN VITON<br />

*S* = SEAT IN SILICON<br />

*T* = SEAT IN PTFE<br />

*F* = SEAT IN FEP<br />

*P* = SEAT IN PFA<br />

*H* = SEAT IN HYPALON<br />

YYY<br />

G* = BODY IN DI GGG40<br />

A* = BODY IN CS WCB<br />

I* = BODY IN ST.ST. AISI316<br />

*G* = DISC IN DI GGG40 NICKEL PLATED<br />

*I* = DISC IN ST.ST. AISI316<br />

*B* = DISC IN AL-BZ<br />

*F* = DISC COATED FEP<br />

*P* = DISC COATED PFA<br />

*N = SEAT IN NBR *T =SEAT IN PTFE<br />

*V = SEAT IN VITON *F = SEAT IN FEP<br />

*S = SEAT IN SILICON *P = SEAT IN PFA<br />

*H = HYPALON<br />

*0 = BODY IN GG25<br />

Data subject to change without prior notice<br />

15

Unival® BUTTERFLY VALVES<br />

Attributes of Design - Wafer Series VF700<br />

Data Sheets Manual<br />

Notch Plate; with position indicator and gear<br />

locking, lever locking in intermediate position<br />

when needed.<br />

Top Mounting Arrangement; top flange to suit<br />

actuators as per ISO 5211 standard, square<br />

stem with bevelled edges to ease actuator<br />

coupling.<br />

Marking according to EN19, with name plate including<br />

CE marking, valve identifi cation and serial number for full<br />

traceability purpose.<br />

Rugged and light Lever; Ergonomic design,<br />

trigger style with covered spring.<br />

Prepared for padlocking application to avoid<br />

undesired operation.<br />

O-ring safety shaft sealing, with<br />

retaining washer to ensure proper<br />

working under pressure.<br />

Finely Machined Disc Edges with final<br />

polishing, provides tight valve sealing<br />

and ensures minimum operating torque<br />

and longer duration of the rubber liner.<br />

Centring eyelets; series 700 provide<br />

full passing bolts to assemble between<br />

counter fl anges ISO / DIN / EN 1092<br />

PN10/16 and ASA 150.<br />

Extended Valve Neck<br />

enables thermal isolation<br />

in heating plants.<br />

One Piece Shaft; solid, stainless steel<br />

corrosion resistant. One piece<br />

through design ensures dependability<br />

and positive disc positioning.<br />

Precise Shaft Guiding System; the<br />

shaft is carried in four estrategically<br />

placed bushings preventing deflection<br />

under pressure, thus ensuring<br />

optimal guidance, positive location<br />

and long life. PTFE bushing accurate<br />

guidance reduces torque and isolates<br />

the stem from valve body, preventing<br />

stem corrosion.<br />

Precision Machined Body; thus<br />

the liner with shaft location can<br />

be accurately positioned to ensure<br />

minimal operation wear<br />

and extended life span.<br />

Epoxy powder paint protection<br />

Replaceable seat liner with phenolic backed seat,<br />

up to DN400, aluminium backed seat DN450 and<br />

above,non-collapsible, stretch resistant, blow out<br />

proof, allows softer rubber liners, which ensure<br />

longer life span and better tightness.<br />

Liner is profi led to ensure a tight shut off sealing<br />

when installing between flanges (pressure activated<br />

system), thus no need to provide gaskets<br />

between valve and counter flanges.<br />

Shaft-Disc threaded union standard up to<br />

DN300: disc offers clean surface against<br />

the fluid, without union pins source of<br />

corrosion and turbulences in small sizes.<br />

Data subject to change without prior notice<br />

16

Unival® BUTTERFLY VALVES<br />

Parts and Materials - Wafer Series VF700<br />

Data Sheets Manual<br />

Nº Part Material<br />

1 BODY Cast Iron EN-JL1040 (GG25) / Ductile Iron EN-JS1030 (GGG40) / St. Steel A351 CF8M / Carbon Steel A216 WCB<br />

2 DISC Nickel Plated Ductile Iron EN-JS1030 (GGG40) / St. Steel CF8M / Al-Bronze / FEP or PFA Coated / Uranus UB6<br />

3 LINER NBR / EPDM / Viton / Hypalon / Silicon / PTFE / FEP / PFA<br />

4 STEM St. Steel AISI 416<br />

5 O-RING EPDM, NBR<br />

6 BUSHINGS PTFE<br />

7 WASHER Steel<br />

8 CIRCLIP Steel<br />

9 NOTCH PLATE Aluminium<br />

10 HAND LEVER Alumminium / Ductile Iron<br />

11 STUDS Steel<br />

13 WASHERS Steel<br />

14 NUT Steel<br />

15 WORM GEAR Ductile Iron<br />

Data subject to change without prior notice<br />

17

Unival® BUTTERFLY VALVES<br />

Dimensions - Wafer Series VF700 DN32-600<br />

Data Sheets Manual<br />

DN<br />

MAIN DIMENSIONS COUPLING DETAIL LEVER WORM GEAR Weight<br />

A B ØC D E R ØG ØJ ØM T L F S Z ØK (kg)<br />

32 121 57 73 33 32 7x7 65 50 7 74 200 156 42 116 150 2,0<br />

40 130 61 82 33 32 9x9 65 50 7 74 200 156 42 116 150 6,0<br />

50 137 77 95 43 32 9x9 65 50 7 74 200 156 42 116 150 6,5<br />

65 142 88 109 46 32 9x9 65 50 7 74 200 156 42 116 150 7,0<br />

80 158 95 127 46 32 9x9 65 50 7 74 200 156 42 116 150 8,0<br />

100 180 107 152 52 32 11x11 65 50 7 74 200 156 42 116 150 9,0<br />

125 192 122 180 56 42 14x14 90 70 9 79 278 156 42 168 250 10,5<br />

150 215 144 207 56 42 14x14 90 70 9 79 278 156 42 168 250 12,5<br />

200 242 171 260 60 30 17x17 125 102 11 40 355 223 70 195 300 21,5<br />

250 280 205 315 68 32 22x22 150 125 13 40 507 223 70 195 300 37,5<br />

300 310 235 370 78 32 27x27 150 125 13 37 507 223 80 195 300 45,5<br />

350 337 259 418 78 45 27x27 150 125 14 - - 223 80 195 300 54,5<br />

400 358 304 470 102 50 27x27 150 125 14 - - 270 114 208 300 90,0<br />

450 380 365 525 114 50 30x30 210 165 22 - - 270 114 258 300 107,5<br />

500 427 392 575 127 65 30x30 210 165 22 - - 339 125 222 300 156,0<br />

600 617 514 693 154 70 40x40 300 210 22 - - 339 125 222 300 231,5<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 20<br />

Body end connections wafer type to be installed between flanges<br />

DN32-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request<br />

Epoxy painted Blue RAL5002<br />

Operating Parameters:<br />

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

18

Unival® BUTTERFLY VALVES<br />

Dimensions - Wafer Series VF700 DN700-1200<br />

Data Sheets Manual<br />

DN<br />

MAIN DIMENSIONS COUPLING DETAIL PN10 CONNECTION WORM GEAR Weight<br />

A B D E ØR ØG ØJ ØN ØP M nXØd F S Z ØK (kg)<br />

700 629 539 165 80 63,35 300 254 18 840 M27 24xØ30 357 243 382 435 372<br />

800 666 608 190 80 63,35 300 254 18 950 M30 24xØ33 357 243 382 435 655<br />

900 722 667 205 118 75 300 254 18 1050 M30 28xØ33 410 278 476 435 769<br />

1000 800 732 218 142 85 300 254 18 1160 M33 28xØ36 410 278 476 435 943<br />

1200 940 844 276 150 105 300 288 22 1380 M36 32xØ40 - - - - 1472<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 20<br />

Body end connections wafer type to be installed between flanges<br />

DN700-1200: EN 1091-1/2 PN10 or PN16 or ASA150 other connections available on request<br />

Epoxy painted Blue RAL5002<br />

Operating Parameters:<br />

Working pressure: 0...10 bar-g<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

19

Unival® BUTTERFLY VALVES<br />

Attributes of Design - Wafer Series VF701<br />

Data Sheets Manual<br />

Notch Plate; with position indicator and gear<br />

locking, lever locking in intermediate position<br />

when needed.<br />

Top Mounting Arrangement; top flange to suit<br />

actuators as per ISO 5211 standard, square<br />

stem with bevelled edges to ease actuator<br />

coupling.<br />

Marking according to EN19, with name plate including<br />

CE marking, valve identifi cation and serial number for full<br />

traceability purpose.<br />

Rugged and light Lever; Ergonomic design,<br />

trigger style with covered spring.<br />

Prepared for padlocking application to avoid<br />

undesired operation.<br />

One Piece Shaft; solid, stainless steel<br />

corrosion resistant. One piece<br />

through design ensures dependability<br />

and positive disc positioning.<br />

O-ring safety shaft sealing,<br />

with retaining washer to ensure<br />

proper working under<br />

pressure.<br />

Extended Valve Neck<br />

enables thermal isolation<br />

in heating plants.<br />

Finely Machined Disc Edges with fi nal<br />

polishing, provides tight valve sealing<br />

and ensures minimum operating torque<br />

and longer duration of the rubber liner.<br />

Precise Shaft Guiding System; the<br />

shaft is carried in four estrategically<br />

placed bushings preventing deflection<br />

under pressure, thus ensuring<br />

optimal guidance, positive location<br />

and long life. PTFE bushing accurate<br />

guidance reduces torque and isolates<br />

the stem from valve body, preventing<br />

stem corrosion.<br />

Precision Machined Body; thus<br />

the liner with shaft location can<br />

be accurately positioned to ensure<br />

minimal operation wear<br />

and extended life span.<br />

Epoxy powder paint protection<br />

Centring eyelets; series 700 provide<br />

full passing bolts to assemble between<br />

counter fl anges ISO / DIN / EN 1092<br />

PN10/16 and ASA 150.<br />

Replaceable seat liner edge boot seat design,<br />

replaceable lined without need for special tools.<br />

Data subject to change without prior notice<br />

Shaft-Disc threaded union standard up to<br />

DN300: disc offers clean surface against<br />

the fluid, without union pins source of<br />

corrosion and turbulences in small sizes.<br />

20

Unival® BUTTERFLY VALVES<br />

Parts and Materials - Wafer Series VF701<br />

Data Sheets Manual<br />

Nº Part Material<br />

1 BODY Cast Iron EN-JL1040 (GG25) / Ductile Iron EN-JS1030 (GGG40) / St. Steel A351 CF8M / Carbon Steel A216 WCB<br />

2 DISC Nickel Plated Ductile Iron EN-JS1030 (GGG40) / St. Steel CF8M / Al-Bronze / FEP or PFA Coated / Uranus UB6<br />

3 LINER NBR / EPDM / Viton / Hypalon / Silicon / PTFE / FEP / PFA<br />

4 STEM St. Steel AISI 416<br />

5 O-RING EPDM, NBR, Viton<br />

6 BUSHINGS PTFE<br />

7 WASHER Steel<br />

8 CIRCLIP Steel<br />

9 NOTCH PLATE Aluminium<br />

10 HAND LEVER Alumminium / Ductile Iron<br />

11 STUDS Steel<br />

13-14 WASHERS Steel<br />

15 WORM GEAR Ductile Iron<br />

Data subject to change without prior notice<br />

21

Unival® BUTTERFLY VALVES<br />

Dimensions - Wafer Series VF701 DN40-300<br />

Data Sheets Manual<br />

DN<br />

MAIN DIMENSIONS COUPLING DETAIL LEVER WORM GEAR Weight<br />

A B D E R ØG ØJ ØM T L F S Z ØK (kg)<br />

40 143 55 33 32,5 9x9 65 50 8 60 190 155 45 125 150 6,0<br />

50 143 55 43 32,5 9x9 65 50 8 60 190 155 45 125 150 6,5<br />

65 155 64 46 32,5 9x9 65 50 8 60 190 155 45 125 150 7,0<br />

80 162 72 46 32,5 9x9 65 50 8 60 190 155 45 125 150 8,0<br />

100 183,8 90 52 42,5 11x11 90 70 10 70 220 155 45 125 150 9,0<br />

125 197 101 56 42,5 14x14 90 70 10 70 220 155 45 125 150 10,5<br />

150 210 114 56 42,5 14x14 90 70 10 70 220 155 45 125 150 12,5<br />

200 240 145 60 42,,5 17x17 125 102 12 31 360 250 63 205 300 21,5<br />

250 286 178 68 37 22x22 125 102 12 31 360 250 63 205 300 37,5<br />

300 309 204 78 37 22x22 125 102 12 35 498 250 80 204 300 45,5<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Edge boot seat design<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 20<br />

Body end connections wafer type to be installed between flanges<br />

DN40-300: EN 1092-1/2 PN10/16 and ASA150; other connections available on request<br />

Epoxy painted Blue RAL5005<br />

Operating Parameters:<br />

Working pressure: PN16 0...16 bar-g; PN10 0...10 bar-g<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

22

Unival® BUTTERFLY VALVES<br />

Dimensions - Wafer Series VF701 DN350-600<br />

Data Sheets Manual<br />

DN<br />

MAIN DIMENSIONS COUPLING DETAIL WORM GEAR Weight<br />

A B D E R ØG ØJ ØM F S Z ØK (kg)<br />

350 368 267 78 45 22x22 125 102 12 227 80 205 300 55<br />

400 400 299 102 51,2 22x22 175 140 18 278 179 220 300 90<br />

450 422 318 114 51,2 27x27 175 140 18 278 179 220 300 108<br />

500 480 348 127 64,2 27x27 175 140 18 278 179 220 300 156<br />

600 562 444 154 70,2 36x36 210 165 22 304 198 240 300 232<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Edge boot seat design<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 20<br />

Body end connections wafer type to be installed between flanges<br />

DN350-600: EN 1092-1/2 PN10/16 and ASA150; other connections available on request<br />

Epoxy painted Blue RAL5005<br />

Operating Parameters:<br />

Working pressure: PN16 0...16 bar-g; PN10 0...10 bar-g<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

23

Unival® BUTTERFLY VALVES<br />

Attributes of Design - Lug Series VF750<br />

Data Sheets Manual<br />

Notch Plate; with position indicator and gear<br />

locking, lever locking in intermediate position<br />

when needed.<br />

Top Mounting Arrangement; top flange to suit<br />

actuators as per ISO 5211 standard, square<br />

stem with bevelled edges to ease actuator<br />

coupling.<br />

Marking according to EN19, with name plate including<br />

CE marking, valve identifi cation and serial number for full<br />

traceability purpose.<br />

Rugged and light Lever; Ergonomic design,<br />

trigger style with covered spring.<br />

Prepared for padlocking application to avoid<br />

undesired operation.<br />

O-ring safety shaft sealing, with<br />

retaining washer to ensure proper<br />

working under pressure.<br />

Finely Machined Disc Edges with final<br />

polishing, provides tight valve sealing<br />

and ensures minimum operating torque<br />

and longer duration of the rubber liner.<br />

Threaded eyelets; the choice for pipe<br />

ends. Available for several DIN / ASA<br />

counterfl anges.<br />

Extended Valve Neck<br />

enables thermal isolation<br />

in heating plants.<br />

One Piece Shaft; solid, stainless steel<br />

corrosion resistant. One piece<br />

through design ensures dependability<br />

and positive disc positioning.<br />

Precise Shaft Guiding System; the<br />

shaft is carried in four estrategically<br />

placed bushings preventing defl ection<br />

under pressure, thus ensuring<br />

optimal guidance, positive location<br />

and long life. PTFE bushing accurate<br />

guidance reduces torque and<br />

isolates the stem from valve body,<br />

preventing stem corrosion.<br />

Precision Machined Body; thus<br />

the liner with shaft location can<br />

be accurately positioned to ensure<br />

minimal operation wear<br />

and extended life span.<br />

Epoxy powder paint protection<br />

Replaceable seat liner with phenolic backed seat,<br />

non-collapsible, stretch resistant, blow out proof,<br />

allows softer rubber liners, which ensure longer<br />

life span and better tightness.<br />

Liner is profi led to ensure a tight shut off sealing<br />

when installing between fl anges (pressure activated<br />

system), thus no need to provide gaskets between<br />

valve and counter fl anges.<br />

Shaft-Disc threaded union standard up to<br />

DN300: disc offers clean surface against<br />

the fluid, without union pins source of<br />

corrosion and turbulences in small sizes.<br />

Data subject to change without prior notice<br />

24

Unival® BUTTERFLY VALVES<br />

Parts and Materials - Lug eries VF750<br />

Data Sheets Manual<br />

Nº Part Material<br />

1 BODY Cast Iron EN-JL1040 (GG25) / Ductile Iron EN-JS1030 (GGG40) / St. Steel A351 CF8M / Carbon Steel A216 WCB<br />

2 DISC Nickel Plated Ductile Iron EN-JS1030 (GGG40) / St. Steel CF8M / Al-Bronze / FEP or PFA Coated / Uranus UB6<br />

3 LINER NBR / EPDM / Viton / Hypalon / Silicon / PTFE / FEP / PFA<br />

4 STEM St. Steel AISI 416<br />

5 O-RING EPDM, NBR<br />

6 BUSHINGS PTFE<br />

7 WASHER Steel<br />

8 CIRCLIP Steel<br />

9 NOTCH PLATE Aluminium<br />

10 HAND LEVER Alumminium / Ductile Iron<br />

11 STUDS Steel<br />

13 WASHERS Steel<br />

14 NUT Steel<br />

15 WORM GEAR Ductile Iron<br />

Data subject to change without prior notice<br />

25

Unival® BUTTERFLY VALVES<br />

Dimensions - Lug Series VF750<br />

Data Sheets Manual<br />

LUG CONNECTION<br />

DN<br />

MAIN DIMENSIONS<br />

COUPLING DETAIL<br />

LEVER & WORM GEAR<br />

Weight<br />

PN10<br />

PN16<br />

(kg)<br />

A B ØC D E R ØG ØJ ØM ØP nxØd ØP nxØd T L F S Z ØK<br />

25 121 53 65 33 32 7x7 65 50 7 85 4xM12 85 4xM12 74 200 156 42 116 150 2,5<br />

32 121 57 73 33 32 7x7 65 50 7 100 4xM16 100 4xM16 74 200 156 42 116 150 2,5<br />

40 130 61 82 33 32 9x9 65 50 7 110 4xM16 110 4xM16 74 200 156 42 116 150 7,0<br />

50 136,5 77 95 43 32 9x9 65 50 7 125 4xM16 125 4xM16 74 200 156 42 116 150 7,5<br />

65 142 87,5 109 46 32 9x9 65 50 7 145 4xM16 145 4xM16 74 200 156 42 116 150 8,5<br />

80 158 95 127 46 32 9x9 65 50 7 160 8xM16 160 8xM16 74 200 156 42 116 150 9,5<br />

100 180 107 152 52 32 11x11 65 50 7 180 8xM16 180 8xM16 47 200 156 42 116 150 11,0<br />

125 192 121,5 180 56 42 14x14 90 70 9 210 8xM16 210 8xM16 79 278 156 42 168 250 13,5<br />

150 215 144 207 56 42 14x14 90 70 9 240 8xM20 240 8xM20 79 278 156 42 168 250 15,5<br />

200 241,5 171 260 60 30 17x17 125 102 11 295 8xM20 295 12xM20 40 355 223 70 195 300 25,0<br />

250 280 205 315 68 32 22x22 150 125 13 350 12xM20 355 12xM24 40 507 223 70 195 300 45,0<br />

300 310 235 370 78 32 27x27 150 125 13 400 12xM20 410 12xM24 37 507 223 80 195 300 57,0<br />

350 337 258,5 418 78 45 27x27 150 125 14 460 16xM20 470 16xM24 - - 223 80 195 300 79,5<br />

400 357,3 303,3 470 102 50 27x27 150 125 14 515 16xM24 525 16xM27 - - 270 114 208 300 123,0<br />

450 380 365 525 114 50 30x30 210 165 22 565 20xM24 585 20xM27 - - 270 114 258 300 155,0<br />

500 426,3 392 575 127 65 30x30 210 165 22 620 20xM24 650 20xM30 - - 339 125 222 300 228,5<br />

600 616,5 513,5 693 154 70 40x40 300 210 22 725 20xM27 770 20xM33 - - 339 125 222 300 309,0<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 20<br />

Body end connections lug type to be installed between flanges<br />

EN1092-1/2 PN16 DN25-300, PN10 DN350-600. Other connections available on request<br />

Epoxy painted Blue RAL5002<br />

Operating Parameters:<br />

Working pressure: 0...16 bar-g DN25-300; 0...10 bar-g DN350-600<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

26

Unival® BUTTERFLY VALVES<br />

Assembling Set<br />

Data Sheets Manual<br />

UNI VF700 (wafer) PN10<br />

DN<br />

Bolts with nuts Stay bolts with nuts Flanges PN10*<br />

Quantity Size Quantity Size Quantity<br />

40 4 M16x85 - - 2<br />

50 4 M16x100 - - 2<br />

65 4 M16x110 - - 2<br />

80 8 M16x110 - - 2<br />

100 8 M16x110 - - 2<br />

125 8 M16x120 - - 2<br />

150 8 M20x125 - - 2<br />

200 8 M20x140 - - 2<br />

250 12 M20x150 - - 2<br />

300 12 M20x160 - - 2<br />

350 16 M20x160 - - 2<br />

400 16 M24x200 - - 2<br />

450 20 M24x220 - - 2<br />

500 20 M24x230 - - 2<br />

600 20 M27x270 - - 2<br />

700 8 M27x70 20/40 M27x310 2<br />

800 8 M30x80 20/40 M30x340 2<br />

900 8 M30x80 24/48 M30x360 2<br />

1000 8 M33x80 24/48 M33x380 2<br />

*Welding neck flanges EN1092-1 11 PN10 (DIN2632)<br />

UNI VF700 (wafer) PN16<br />

DN<br />

Bolts with nuts Stay bolts with nuts Flanges PN16*<br />

Quantity Size Quantity Size Quantity<br />

40 4 M16x90 - - 2<br />

50 4 M16x100 - - 2<br />

65 4 M16x110 - - 2<br />

80 8 M16x110 - - 2<br />

100 8 M16x120 - - 2<br />

125 8 M16x130 - - 2<br />

150 8 M20x140 - - 2<br />

200 12 M20x140 - - 2<br />

250 12 M24x160 - - 2<br />

300 12 M24x180 - - 2<br />

350 16 M24x180 - - 2<br />

400 16 M27x220 - - 2<br />

450 20 M27x230 - - 2<br />

500 20 M30x250 - - 2<br />

600 20 M33x300 - - 2<br />

700 8 M33x90 20/40 M33x340 2<br />

800 8 M36x90 20/40 M36x370 2<br />

900 8 M36x90 24/48 M36x390 2<br />

1000 8 M39x100 24/48 M39x420 2<br />

*Welding neck fl anges EN1092-1 11 PN16 (DIN2633)<br />

UNI VF750 (lug) PN10<br />

DN<br />

Bolts<br />

Flanges PN10*<br />

Quantity Size Quantity<br />

25 8 M12x30 2<br />

32 8 M16x30 2<br />

40 8 M16x30 2<br />

50 8 M16x35 2<br />

65 8 M16x40 2<br />

80 16 M16x40 2<br />

100 16 M16x40 2<br />

125 16 M16x45 2<br />

150 16 M20x45 2<br />

200 16 M20x50 2<br />

250 24 M20x55 2<br />

300 24 M20x60 2<br />

350 32 M20x60 2<br />

400 32 M24x70 2<br />

450 40 M24x70 2<br />

500 40 M24x80 2<br />

600 40 M27x80 2<br />

*Welding neck flanges EN1092-1 11 PN10 (DIN2632)<br />

UNI VF750 (lug) PN16<br />

DN<br />

Bolts<br />

Flanges PN16*<br />

Quantity Size Quantity<br />

25 8 M12x30 2<br />

32 8 M16x30 2<br />

40 8 M16x30 2<br />

50 8 M16x35 2<br />

65 16 M16x40 2<br />

80 16 M16x40 2<br />

100 16 M16x40 2<br />

125 16 M16x45 2<br />

150 16 M20x45 2<br />

200 24 M20x50 2<br />

250 24 M24x55 2<br />

300 24 M24x60 2<br />

350 32 M24x60 2<br />

400 32 M27x75 2<br />

450 40 M27x80 2<br />

500 40 M30x90 2<br />

600 40 M33x90 2<br />

*Welding neck fl anges EN1092-1 11 PN16 (DIN2633)<br />

Data subject to change without prior notice<br />

27

Unival® BUTTERFLY VALVES<br />

Attributes of Design - U Type Series VF7U<br />

Data Sheets Manual<br />

Notch Plate; with position indicator and gear<br />

locking, lever locking in intermediate position<br />

when needed.<br />

Top Mounting Arrangement; top flange to suit<br />

actuators as per ISO 5211 standard, square<br />

stem with bevelled edges to ease actuator<br />

coupling.<br />

Marking according to EN19, with name plate including<br />

CE marking, valve identifi cation and serial number for full<br />

traceability purpose.<br />

Rugged and light Lever; Ergonomic design,<br />

trigger style with covered spring.<br />

Prepared for padlocking application to avoid<br />

undesired operation.<br />

O-ring safety shaft sealing, with<br />

retaining washer to ensure proper<br />

working under pressure.<br />

Finely Machined Disc Edges with final<br />

polishing, provides tight valve sealing<br />

and ensures minimum operating torque<br />

and longer duration of the rubber liner.<br />

Flanged ends with U-Shape body.<br />

Short pattern allows interchangeability<br />

with Wafer and Lug Butterfly valves.<br />

Extended Valve Neck<br />

enables thermal isolation<br />

in heating plants.<br />

One Piece Shaft; solid, stainless steel<br />

corrosion resistant. One piece<br />

through design ensures dependability<br />

and positive disc positioning.<br />

Precise Shaft Guiding System; the<br />

shaft is carried in four estrategically<br />

placed bushings preventing defl ection<br />

under pressure, thus ensuring<br />

optimal guidance, positive location<br />

and long life. PTFE bushing accurate<br />

guidance reduces torque and<br />

isolates the stem from valve body,<br />

preventing stem corrosion.<br />

Precision Machined Body; thus<br />

the liner with shaft location can<br />

be accurately positioned to ensure<br />

minimal operation wear<br />

and extended life span.<br />

Epoxy powder paint protection<br />

Replaceable seat liner with phenolic backed seat,<br />

non-collapsible, stretch resistant, blow out proof,<br />

allows softer rubber liners, which ensure longer<br />

life span and better tightness.<br />

Liner is profi led to ensure a tight shut off sealing<br />

when installing between fl anges (pressure activated<br />

system), thus no need to provide gaskets between<br />

valve and counter fl anges.<br />

Shaft-Disc threaded union standard up to<br />

DN300: disc offers clean surface against<br />

the fluid, without union pins source of<br />

corrosion and turbulences in small sizes.<br />

Data subject to change without prior notice<br />

28

Unival® BUTTERFLY VALVES<br />

Parts and Materials - U Type Series VF7U<br />

Data Sheets Manual<br />

Nº Part Material<br />

1 BODY Cast Iron EN-JL1040 (GG25) / Ductile Iron EN-JS1030 (GGG40) / St. Steel A351 CF8M / Carbon Steel A216 WCB<br />

2 DISC Nickel Plated Ductile Iron EN-JS1030 (GGG40) / St. Steel CF8M / Al-Bronze / FEP or PFA Coated / Uranus UB6<br />

3 LINER NBR / EPDM / Viton / Hypalon / Silicon / PTFE / FEP / PFA<br />

4 STEM St. Steel AISI 416<br />

5 O-RING EPDM, NBR<br />

6 BUSHINGS PTFE<br />

7 WASHER Steel<br />

8 CIRCLIP Steel<br />

9 NOTCH PLATE Aluminium<br />

10 HAND LEVER Alumminium / Ductile Iron<br />

11 STUDS Steel<br />

13 WASHERS Steel<br />

14 NUT Steel<br />

15 WORM GEAR Ductile Iron<br />

Data subject to change without prior notice<br />

29

Data Sheets Manual<br />

Unival® BUTTERFLY VALVES<br />

Dimensions - U Type Series VF7U<br />

DN MAIN DIMENSIONES COUPLING DETAIL VALVE CONNECTION<br />

PN10<br />

PN16<br />

LEVER & WORM GEAR<br />

A B D E □R ØG ØJ ØN ØP nxØd M ØP nxØd M T L F S Z ØK<br />

150 215 144 56 42 14x14 90 70 9 240 8xØ18 - 240 8xØ22 - 79 278 156 42 168 250<br />

200 241,5 171 60 30 17x17 125 102 11 295 8xØ18 - 295 12xØ22 - 40 355 223 70 195 300<br />

250 280 205 68 32 22x22 150 125 13 350 12xØ22 - 355 12xØ26 - 40 507 223 70 195 300<br />

300 300 240 78 32 27x27 150 125 13 400 12xØ28 - 410 12xØ26 - 37 507 223 80 195 300<br />

350 340 260 78 45 27x27 150 125 14 460 16xØ28 - 470 16xØ26 - - - 223 80 195 300<br />

400 360 302 102 50 27x27 150 125 14 515 16xØ28 - 525 16xØ30 - - - 270 114 208 300<br />

450 390 346 114 50 30x30 210 165 22 565 20xØ28 24 585 20xØ30 27 - - 270 114 258 300<br />

500 420 370 127 65 30x30 210 165 22 620 20xØ28 24 650 20xØ33 30 - - 339 125 222 300<br />

600 495 465 154 70 40x40 210 165 22 725 20xØ31 27 770 20xØ36 33 - - 339 125 222 300<br />

700 624 520 163 80 Ø63,35 300 254 18 840 24xØ31 27 840 24xØ36 33 - - 339 125 222 300<br />

800 672 591 188 80 Ø63,35 300 254 18 950 24xØ34 30 950 24xØ39 36 - - 339 125 222 300<br />

900 720 656 203 118 Ø75 300 254 18 1050 28xØ34 30 1050 28xØ39 36 - - 339 125 222 300<br />

1000 800 721 216 142 Ø85 300 254 18 1160 28xØ37 33 1170 28xØ42 39 - - 339 125 222 300<br />

1200 940,7 844,1 276 150 Ø105 350 298 22 1380 32xØ40 36 1390 32xØ49 45 - - 339 125 222 300<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 20<br />

Flanged end connections to EN1092-1/2 PN16 DN150-300, PN10 DN350-1200. Other connections available on request.<br />

Epoxy painted Blue RAL5002<br />

Operating Parameters:<br />

Working pressure: 0...16 bar-g DN150-300; 0...10 bar-g DN350-1200<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

30

Unival® BUTTERFLY VALVES<br />

Attributes of Design - Double Flange Series VF790<br />

Data Sheets Manual<br />

Notch Plate; with position indicator and gear<br />

locking, lever locking in intermediate position<br />

when needed.<br />

Top Mounting Arrangement; top flange to suit<br />

actuators as per ISO 5211 standard, square<br />

stem with bevelled edges to ease actuator<br />

coupling.<br />

Marking according to EN19, with name plate including<br />

CE marking, valve identifi cation and serial number for full<br />

traceability purpose.<br />

Rugged and light Lever; Ergonomic design,<br />

trigger style with covered spring.<br />

Prepared for padlocking application to avoid<br />

undesired operation.<br />

O-ring safety shaft sealing, with<br />

retaining washer to ensure proper<br />

working under pressure.<br />

Finely Machined Disc Edges with final<br />

polishing, provides tight valve sealing<br />

and ensures minimum operating torque<br />

and longer duration of the rubber liner.<br />

Extended Valve Neck<br />

enables thermal isolation<br />

in heating plants.<br />

One Piece Shaft; solid, stainless steel<br />

corrosion resistant. One piece<br />

through design ensures dependability<br />

and positive disc positioning.<br />

Precise Shaft Guiding System; the<br />

shaft is carried in four estrategically<br />

placed bushings preventing defl ection<br />

under pressure, thus ensuring<br />

optimal guidance, positive location<br />

and long life. PTFE bushing accurate<br />

guidance reduces torque and<br />

isolates the stem from valve body,<br />

preventing stem corrosion.<br />

Precision Machined Body; thus<br />

the liner with shaft location can<br />

be accurately positioned to ensure<br />

minimal operation wear<br />

and extended life span.<br />

Double Flange Design; Available for<br />

several DIN / ASA counterfl anges.<br />

Epoxy powder paint protection<br />

Replaceable seat liner with phenolic backed seat,<br />

non-collapsible, stretch resistant, blow out proof,<br />

allows softer rubber liners, which ensure longer<br />

life span and better tightness.<br />

Liner is profi led to ensure a tight shut off sealing<br />

when installing between fl anges (pressure activated<br />

system), thus no need to provide gaskets between<br />

valve and counter fl anges.<br />

Shaft-Disc threaded union standard up to<br />

DN300: disc offers clean surface against<br />

the fluid, without union pins source of<br />

corrosion and turbulences in small sizes.<br />

Data subject to change without prior notice<br />

31

Unival® BUTTERFLY VALVES<br />

Parts and Materials - Double Flange Series VF790<br />

Data Sheets Manual<br />

Nº Part Material<br />

1 BODY Cast Iron EN-JL1040 (GG25) / Ductile Iron EN-JS1030 (GGG40) / St. Steel A351 CF8M / Carbon Steel A216 WCB<br />

2 DISC Nickel Plated Ductile Iron EN-JS1030 (GGG40) / St. Steel CF8M / Al-Bronze / FEP or PFA Coated<br />

3 LINER NBR / EPDM / Viton / Hypalon / Silicon / PTFE / FEP / PFA<br />

4 STEM St. Steel AISI 416<br />

5 O-RING EPDM, NBR<br />

6 BUSHINGS PTFE<br />

7 WASHER Steel<br />

8 CIRCLIP Steel<br />

9 NOTCH PLATE Aluminium<br />

10 HAND LEVER Alumminium / Ductile Iron<br />

11 STUDS Steel<br />

13 WASHERS Steel<br />

14 NUT Steel<br />

15 WORM GEAR Ductile Iron<br />

Data subject to change without prior notice<br />

32

Data Sheets Manual<br />

Unival® BUTTERFLY VALVES<br />

Dimensions - Double Flange Series VF790<br />

MAIN<br />

VALVE CONNECTION<br />

COUPLING DETAIL<br />

DN DIMENSIONS<br />

PN10<br />

PN16<br />

LEVER & WORM GEAR<br />

D E □R ØG ØJ ØN ØP nxØd ØP nxØd T L F S Z ØK<br />

50 108 32 9x9 65 50 7 125 4xØ18 125 4xØ18 74 200 156 42 116 150<br />

65 112 32 9x9 65 50 7 145 4xØ18 145 4xØ18 74 200 156 42 116 150<br />

80 114 32 9x9 65 50 7 160 8xØ18 160 8xØ18 74 200 156 42 116 150<br />

100 127 32 11x11 65 50 7 180 8xØ18 180 8xØ18 74 200 156 42 116 150<br />

125 140 42 14x14 90 70 9 210 8xØ18 210 8xØ18 79 278 156 42 168 250<br />

150 140 42 14x14 90 70 9 240 8xØ18 240 8xØ22 79 278 156 42 168 250<br />

200 152 30 17x17 125 102 11 295 8xØ18 295 12xØ22 40 355 223 70 195 300<br />

250 165 32 22x22 150 125 13 350 12xØ22 355 12xØ26 - - 223 70 195 300<br />

300 178 32 27x27 150 125 13 400 12xØ28 410 12xØ26 - - 223 80 195 300<br />

350 190 45 27x27 150 125 14 460 16xØ28 470 16xØ26 - - 223 80 195 300<br />

400 216 50 27x27 150 125 14 515 16xØ28 525 16xØ30 - - 270 114 208 300<br />

450 222 50 30x30 210 165 22 565 20xØ28 585 20xØ30 - - 270 114 258 300<br />

500 229 65 30x30 210 165 22 620 20xØ28 650 20xØ33 - - 339 125 222 300<br />

600 267 70 40x40 210 165 22 725 20xØ31 770 20xØ36 - - 339 125 222 300<br />

700 292 80 Ø63,35 300 254 18 840 24xØ31 840 24xØ36 - - 339 125 222 300<br />

800 318 80 Ø63,35 300 254 18 950 24xØ34 950 24xØ39 - - 339 125 222 300<br />

900 330 118 Ø75 300 254 18 1050 28xØ34 1050 28xØ39 - - 339 125 222 300<br />

1000 410 142 Ø85 300 254 18 1160 28xØ37 1170 28xØ42 - - 339 125 222 300<br />

1200 470 150 Ø105 350 298 22 1380 32xØ40 1390 32xØ49 - - 339 125 222 300<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Face to face dimensions according to EN558-1 Series 13<br />

Flanged end connections to EN1092 PN16 DN50-300, PN10 DN350-1200. Other connections available on request<br />

Epoxy painted Blue RAL5002<br />

Operating Parameters:<br />

Working pressure: 0...16 bar-g DN50-300; 0...10 bar-g DN350-1200<br />

Working temperature: according to sealing material<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, compressed air, low pressure steam, etc.<br />

Data subject to change without prior notice<br />

33

Unival® BUTTERFLY VALVES<br />

Grooved Ends Butterfly Valves<br />

Data Sheets Manual<br />

UNIVAL® Grooved ends butterfl y valves are concentric<br />

valves which offer reliable service in all water works<br />

duties. Valves are bi-directional and can be installed in<br />

whatever position. The grooved ends design allows the<br />

contractor to tie the valves onto the pipe work with grooved<br />

couplings thus saving signifi cant costs in fl ange and<br />

bolting kits. Grooved couplings are very common on the<br />

water sector what requires from valve manufacturers to<br />

design ends to accommodate this fl ourishing demand.<br />

UNIVAL® butterfl y valves are at the forefront of this requirement<br />

with the newly launched type VF-760. Other<br />

equipment is being added up to the grooved end design<br />

such as strainers, gate valves and check valves.<br />

These valves have an excellent fl ow control with low<br />

pressure drop. The valve design is simple, of light weight<br />

and volume and very effective on isolating lines for its<br />

quick and safe operation. The gradual lock hand lever<br />

design allows to lock the valve at intermediate positions<br />

thus making it possible to control de amount of fl ow.<br />

Salient attributes of the UNIVAL® Grooved ends butterfly<br />

Valves:<br />

1.- Body; long neck to allow isolation in HVAC duties,<br />

precisely cast, cleaned and machined grooves to allow<br />

perfect coupling of groove clamps. Body is externally and<br />

internally EPOXI coated to offer better environmental resistance.<br />

Seat less design; no slot to accommodate the<br />

disc.<br />

2.- Shaft; Two piece shaft (without pin), easy dismantling.<br />

Made of polished stainless steel 420.<br />

3.- Disc: Fully encapsulated rubber disc. Engulfs the<br />

shaft and tights the valve. Can be of EPDM for water<br />

service or NBR for other fl uids.<br />

4.- Packing; EPDM or NBR set of O-Rings placed at the<br />

upper and lower parts of the shaft providing good atmospheric<br />

integrity to the valve.<br />

5.- Notch plate; Cast Aluminium position indicator and<br />

gear locking fi x on top of the valve neck. Locks the lever<br />

in intermediate positions if needed.<br />

6.- Actuation; Hand lever is the standard up to DN 300<br />

whereas worm gear box is used for larger sizes.<br />

Data subject to change without prior notice<br />

34

Unival® BUTTERFLY VALVES<br />

Attributes of Design - Grooved Ends Butterfly Valves Series VF760<br />

Data Sheets Manual<br />

Top Mounting Arrangement; top flange to<br />

suit actuators as per ISO 5211 standard,<br />

square stem with bevelled edges to ease<br />

actuator coupling.<br />

Marking according to EN19, with name<br />

plate including CE marking, valve<br />

identification and serial number for full<br />

traceability purpose.<br />

Rugged and light Lever; ergonomic design,<br />

trigger style with covered spring.<br />

Prepared for padlocking application to avoid<br />

undesired operation.<br />

Notch Plate; with position<br />

indicator and gear locking,<br />

lever locking in intermediate<br />

position when needed.<br />

Double PTFE bushing units; to ensure the atmospheric tighness<br />

Shaft; two piece shaft (without pin), easy dismantling.<br />

Body; externally and internally EPOXI<br />

coated to offer better environmental<br />

resistance. Seat less design; no slot to<br />

accommodate the disc.<br />

Disc; Fully encapsulated rubber disc.<br />

Grooved ends; available in different standards<br />

of construction.<br />

O-ring safety shaft sealing, with retaining<br />

washer to ensure proper working under<br />

pressure.<br />

Data subject to change without prior notice<br />

35

Unival® BUTTERFLY VALVES<br />

Parts and Materials - Grooved Ends Series VF760<br />

Data Sheets Manual<br />

Nº Part Material<br />

1 BODY Ductile Iron EN-JS1050 (GGG50)<br />

2 DISC Ductile Iron - NBR - EPDM - Viton Coated<br />

3 TOP STEM SS420<br />

4 BOTTOM STEM SS420<br />

5 O-RING EPDM - NBR - Viton<br />

6 BUSHINGS PTFE<br />

7 WASHERS SS420<br />

8 PLUG Carbon Steel Zinc Coated<br />

9 NOTCH PLATE Aluminium<br />

10 HAND LEVER Aluminium<br />

11 BOLTS Steel<br />

12 NUTS Steel<br />

13 WASHERS Steel<br />

Data subject to change without prior notice<br />

36

Unival® BUTTERFLY VALVES<br />

Dimensions - Grooved Ends Series VF760<br />

Data Sheets Manual<br />

DN<br />

MAIN DIMENSIONS COUPLING DETAIL LEVER & WORM GEAR Weight<br />

A B Pipe OD D Ød E R ØG ØJ ØM T L F C Z ØK (kg)<br />

50 101,6 70 60,3 86 48,5 32,5 9x9 65 50 8 60 190 155 45 125 150 7,0<br />

65 106,2 75 76,1 97 61,2 32,5 9x9 65 50 8 60 190 155 45 125 150 8,0<br />

80 112,5 82 88,9 97 74,5 32,5 9x9 65 50 8 60 190 155 45 125 150 8,0<br />

100 135,4 100 114,3 116 96,8 42,5 11x11 90 70 10 70 220 155 45 125 150 9,5<br />

125 147,8 100 139,7 133 124,4 42,5 14x14 90 70 10 70 220 155 45 125 150 11,5<br />

150 178,1 115 168,3 134 149 42,5 14x14 90 70 10 70 220 155 45 125 150 12,5<br />

200 204 150 219,1 148 200 40 17x17 125 102 12 31 360 250 63 205 300 22,0<br />

250 250 233 273,3 159 250 40 22x22 125 102 12 31 360 250 63 205 300 31,0<br />

300 275 258 324,1 163 299,5 40 22x22 125 102 12 35 498 230 80 204 300 43,0<br />

Dimensions are expressed in mm, and subjected to manufacturing tolerances. Data can be altered without notice by our Design Department for the product benefi t.<br />

Manufacture Design Standards:<br />

Harmonised Standard EN 593<br />

QA certifi ed to ISO 9001:2000<br />

According to Pressure Equipment Directive PED 97/23/EC by a recognised Notify body<br />

Testing standards EN12266-1 / API 598<br />

Marking according to EN 19<br />

Grooved end connections according to AWWAC606 or Metric<br />

Epoxy painted Blue RAL5005<br />

Operating Parameters:<br />

Working pressure: 0...16 bar-g<br />

Working temperature: NBR coated -10...80ºC / EPDM coated -10...110ºC / Viton coated -10...150ºC<br />

See Engineering Data for complete overview of operating parameters<br />

Main Applications:Water, oil, etc.<br />

Data subject to change without prior notice<br />

37

Unival® BUTTERFLY VALVES<br />

Attributes of Design - Double Eccentric Series VF791<br />

Data Sheets Manual<br />

Top fl ange as per ISO5211<br />

standard can suit for all kinds<br />

of actuators such as handles,<br />

gear box, electric actuator and<br />

pneumatic actuators<br />

Bushes: The bushings strategically placed<br />

reduces the bending of the shaft and ensure<br />

bi-directional tightness under maximum<br />

working pressure.<br />

Disc: Double Eccentric design<br />

disc reduces friction of the sealing<br />

ring and provide the valve<br />

a long service life.<br />

With low torque for economy in<br />

actuator selection<br />

Seat: Overall weld<br />

body sealing<br />

Connection between disc and shaft:<br />

Two pieces stem design, taper pin connection<br />

between disc and shaft which<br />

ensures positive vibration proof.<br />

Disc Ring: rubber and graphite<br />

compounds disc ring can meet<br />