Untitled - COMEVAL

Untitled - COMEVAL

Untitled - COMEVAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

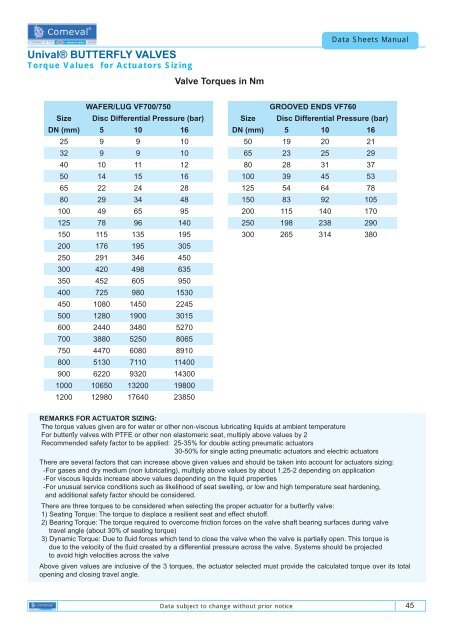

Unival® BUTTERFLY VALVES<br />

Torque Values for Actuators Sizing<br />

Valve Torques in Nm<br />

Data Sheets Manual<br />

WAFER/LUG VF700/750<br />

Size Disc Differential Pressure (bar)<br />

DN (mm) 5 10 16<br />

25 9 9 10<br />

32 9 9 10<br />

40 10 11 12<br />

50 14 15 16<br />

65 22 24 28<br />

80 29 34 48<br />

100 49 65 95<br />

125 78 96 140<br />

150 115 135 195<br />

200 176 195 305<br />

250 291 346 450<br />

300 420 498 635<br />

350 452 605 950<br />

400 725 980 1530<br />

450 1080 1450 2245<br />

500 1280 1900 3015<br />

600 2440 3480 5270<br />

700 3880 5250 8065<br />

750 4470 6080 8910<br />

800 5130 7110 11400<br />

900 6220 9320 14300<br />

1000 10650 13200 19800<br />

1200 12980 17640 23850<br />

GROOVED ENDS VF760<br />

Size Disc Differential Pressure (bar)<br />

DN (mm) 5 10 16<br />

50 19 20 21<br />

65 23 25 29<br />

80 28 31 37<br />

100 39 45 53<br />

125 54 64 78<br />

150 83 92 105<br />

200 115 140 170<br />

250 198 238 290<br />

300 265 314 380<br />

REMARKS FOR ACTUATOR SIZING:<br />

The torque values given are for water or other non-viscous lubricating liquids at ambient temperature<br />

For butterfl y valves with PTFE or other non elastomeric seat, multiply above values by 2<br />

Recommended safety factor to be applied: 25-35% for double acting pneumatic actuators<br />

30-50% for single acting pneumatic actuators and electric actuators<br />

There are several factors that can increase above given values and should be taken into account for actuators sizing:<br />

-For gases and dry medium (non lubricating), multiply above values by about 1,25-2 depending on application<br />

-For viscous liquids increase above values depending on the liquid properties<br />

-For unusual service conditions such as likelihood of seat swelling, or low and high temperature seat hardening,<br />

and additional safety factor should be considered.<br />

There are three torques to be considered when selecting the proper actuator for a butterfly valve:<br />

1) Seating Torque: The torque to displace a resilient seat and effect shutoff.<br />

2) Bearing Torque: The torque required to overcome friction forces on the valve shaft bearing surfaces during valve<br />

travel angle (about 30% of seating torque)<br />

3) Dynamic Torque: Due to fl uid forces which tend to close the valve when the valve is partially open. This torque is<br />

due to the velocity of the fl uid created by a differential pressure across the valve. Systems should be projected<br />

to avoid high velocities across the valve<br />

Above given values are inclusive of the 3 torques, the actuator selected must provide the calculated torque over its total<br />

opening and closing travel angle.<br />

Data subject to change without prior notice<br />

45