Untitled - COMEVAL

Untitled - COMEVAL

Untitled - COMEVAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Unival® BUTTERFLY VALVES<br />

Installation, Start-Up and Maintenance<br />

Data Sheets Manual<br />

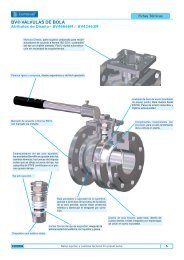

A butterfl y valve is a type of fl ow control device, typically used to regulate a<br />

fl uid fl owing through a section of pipe. A fl at circular plate (disc) is positioned<br />

in the centre of the pipe. The plate has a rod (shaft) through it connected<br />

to an actuator on the outside of the valve. Rotating the actuator turns<br />

the plate either parallel or perpendicular to the fl ow. Unlike a ball valve, the<br />

plate is always present within the fl ow, therefore a pressure drop is always<br />

induced in the fl ow regardless of valve position.<br />

A butterfl y valve is from a family of valves called quarter turn valves. The<br />

“butterfl y” is a metal disc mounted on a rod. When the valve is closed, the<br />

disc is turned so that it completely blocks off the passageway. When the<br />

valve is fully open, the disc is rotated a quarter turn so that it allows unrestricted<br />

passage. The valve may also be opened incrementally to regulate<br />

fl ow thanks to the gradual interlocking notch.<br />

Butterfl y valves are of simple design, of light weight and volume and very<br />

effective on isolating lines for its quick and safe operation. Most of butterfly<br />

valves design are fl angeless for installation between counter fl anges what<br />

saves space, costs and maintenance.<br />

UNIVAL® Butterfly Valves are devised to stop the flow of liquids<br />

and neutral gases. The valves close by turning the disc 90º clockwise.<br />

The valves can also be used as throttling design by fixing the<br />

lever in intermediate positions by means of the gradual lock gear.<br />

The valves are engineered to match standard operational duties, in<br />

the event of special duties such as aggressive or abrasive media, it<br />

is the plant engineer and / or purchaser responsibility to check that<br />

the selected valve be suitable to the application as well as the dimensional,<br />

pressure, temperature and material compatibility parameters.<br />

UNIVAL® butterfly valves are designed, manufactured and tested in conformity<br />

to the most strict quality standards that the DIN EN ISO 9001 standard dictates.<br />

All valves are subject to individual hydro and leakage tests at our QC Dept in conformity<br />

with EN 10.204 / 2.2. The testing medium is water at room temperature.<br />

Each manufacturing lot is strictly controlled by our Quality Section at the plant<br />

before dispatch. Extensive reports as per EN-10.204/3.1B are fi lled out and<br />

are submitted to the Purchase if required. Moreover, witness testing carried out<br />

by Notify Bodies are arranged upon request at our modern Testing Facilities.<br />

All valves are provided with a Declaration of Conformity<br />

in conformity with PED 97/23/CE (to European destinations).<br />

Please consult our Data Sheets for specifi c information about the valve performance<br />

details. Factory reserves the right to alter or implement new product<br />

modifi cations at any time. Our Data Sheets can be freely down loaded via<br />

Internet www.comeval.es or calling our sales department +34 96 147 90 11.<br />

Data subject to change without prior notice<br />

73