Untitled - COMEVAL

Untitled - COMEVAL

Untitled - COMEVAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

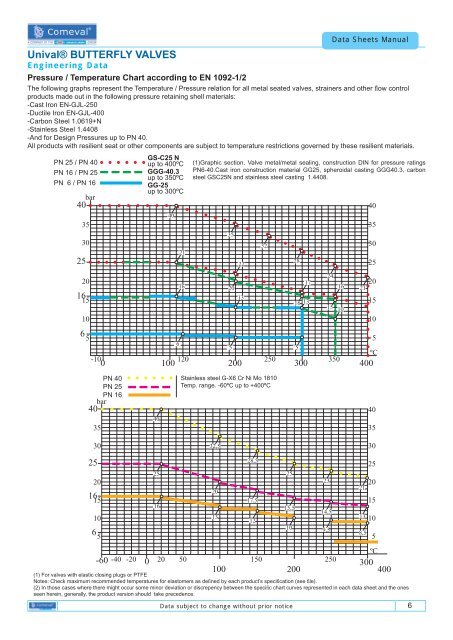

Unival® BUTTERFLY VALVES<br />

Engineering Data<br />

Data Sheets Manual<br />

Pressure / Temperature Chart according to EN 1092-1/2<br />

The following graphs represent the Temperature / Pressure relation for all metal seated valves, strainers and other flow control<br />

products made out in the following pressure retaining shell materials:<br />

-Cast Iron EN-GJL-250<br />

-Ductile Iron EN-GJL-400<br />

-Carbon Steel 1.0619+N<br />

-Stainless Steel 1.4408<br />

-And for Design Pressures up to PN 40.<br />

All products with resilient seat or other components are subject to temperature restrictions governed by these resilient materials.<br />

PN 25 / PN 40<br />

PN 16 / PN 25<br />

PN 6 / PN 16<br />

bar<br />

40<br />

35<br />

30<br />

25<br />

20<br />

16<br />

15<br />

10<br />

6<br />

5<br />

GS-C25 N<br />

up to 400ºC<br />

GGG-40.3<br />

up to 350ºC<br />

GG-25<br />

up to 300ºC<br />

40<br />

6<br />

21<br />

16<br />

(1)Graphic section. Valve metal/metal sealing, construction DIN for pressure ratings<br />

PN6-40.Cast iron construction material GG25, spheroidal casting GGG40.3, carbon<br />

steel GSC25N and stainless steel casting 1.4408.<br />

35<br />

20<br />

ºC<br />

-10 120 250 350<br />

0 100 200 300 400<br />

22<br />

13<br />

32<br />

28<br />

5 5<br />

17<br />

16 13<br />

24<br />

15<br />

16<br />

10<br />

40<br />

35<br />

30<br />

25<br />

20<br />

21<br />

15<br />

10<br />

5<br />

40<br />

PN 40<br />

PN 25<br />

PN 16<br />

bar<br />

35<br />

40<br />

Stainless steel G-X6 Cr Ni Mo 1810<br />

Temp. range. -60ºC up to +400ºC<br />

40<br />

35<br />

30<br />

32,5<br />

30<br />

25<br />

20<br />

16<br />

15<br />

10<br />

6<br />

5<br />

25<br />

16<br />

-60 -40 -20 0 20 50 150<br />

100 200<br />

20<br />

13<br />

28,5<br />

17,5<br />

Data subject to change without prior notice<br />

12<br />

25<br />

15,5<br />

10<br />

23<br />

14,5<br />

9,5<br />

250<br />

25<br />

20<br />

21<br />

15<br />

13 10<br />

8,5<br />

5<br />

ºC<br />

300<br />

400<br />

(1) For valves with elastic closing plugs or PTFE<br />

Notes: Check maximum recommended temperatures for elastomers as defi ned by each product’s specifi cation (see fi le).<br />

(2) In those cases where there might occur some minor deviation or discrepency between the specifi c chart curves represented in each data sheet and the ones<br />

seen herein, generally, the product version should take precedence.<br />

6